How Hydrophilic Coatings Improve the Performance of Nitinol Tubing in Medical Devices

Hydrophilic coatings on nitinol tubing can change your experience with medical procedures. These coatings lower friction a lot. This means catheters move more smoothly through blood vessels. Clinical studies show nitinol tubing with hydrophilic coating gives doctors better control. It also helps doctors move catheters more easily. You get better catheter lubricity. Procedures are safer and faster for you. The table below shows how these coatings lower clot and fibrin buildup. This helps patients have better results:

Material Type | Thrombus Deposition (mg/cm²) | Fibrin Deposition (µg/cm²) |

|---|---|---|

Untreated Thin Film Nitinol | 4.5 ± 2.3 | 45.6 ± 7.4 |

Superhydrophilic Thin Film Nitinol | 2.9 ± 0.4 | 194 ± 25 |

Hydrophilic coatings make medical procedures work better and feel more comfortable for you.

Key Takeaways

Hydrophilic coatings make nitinol tubing very smooth and slick. This helps catheters slide easily through blood vessels. It causes less pain and lowers risk for patients. These coatings cut down friction by up to 98%. This gives doctors better control. It also makes medical procedures safer and faster for people. Hydrophilic coatings lower the chance of blood clots. They also help stop tissue damage. This helps devices work better and stay safe in your body. The coatings stick well to nitinol tubing and last a long time. This makes sure the device works well during and after procedures. Using devices with hydrophilic coatings helps people heal faster. It causes less discomfort. It also gives better results in hard medical treatments.

How Hydrophilic Coatings Work

Surface Properties

Hydrophilic coatings help medical devices work better. These coatings pull in water and keep it on the surface. When you touch a coated device, it feels smooth and slippery. The coating uses special polymers to make a thin, soft layer. This layer acts like a cushion between the device and your body. You feel less pain and more comfort during procedures.

Hydrophilic coatings use hydrogen bonds and ionic forces to make the surface slippery. This helps catheters move easily through blood vessels.

You can see how these coatings work in the table below:

Aspect | Explanation |

|---|---|

Polymer Composition | Made from polymers like PEG, polyacrylamide, or polyvinyl alcohol that absorb water. |

Water Interaction | Polymers bind water molecules, forming a hydrogel-like hydration layer. |

Lubricity Mechanism | The hydration layer reduces friction, improving catheter lubricity and device performance. |

Antifouling Properties | Coatings resist protein and cell buildup, lowering the risk of clots and infection. |

Medical Application | Devices move smoothly, reducing tissue damage and improving outcomes in medical procedures. |

Application to Nitinol Tubing

Adding hydrophilic coatings to nitinol tubing changes how the surface acts. The coating is put on using special steps like chemical etching or hydrogel layering. These steps help the surface grab more water. For example, the water contact angle drops from about 86° to as low as 22° after coating. This means the surface is much more hydrophilic.

Nitinol tubing with hydrophilic coating lets catheters move more smoothly. The coating also makes the tubing safer for your body. This helps lower problems during medical procedures. Researchers found these coatings make a strong, even layer. This layer helps devices work better and keeps you safe. You get good results and a better experience every time you use a device with this coating.

Benefits of Nitinol Tubing with Hydrophilic Coating

Friction Reduction

When nitinol tubing has hydrophilic coating, catheters move much easier. The coating makes the surface smooth and slippery. This helps lower friction between the device and your tissue. Catheters can glide through blood vessels with less force. You feel less pain and less discomfort during procedures.

Studies show hydrophilic coatings can cut friction by up to 98%. Pull forces can go as low as 3 grams. The coefficient of friction can be just 0.01. These numbers mean doctors have better control. It is safer to move catheters in tight or twisty vessels. There are fewer blood clots and less damage to vessel walls. This means better results for you.

Hydrophilic coatings on nitinol tubing help make medical procedures easier and safer. They lower friction and protect sensitive tissues.

Improved Lubricity and Maneuverability

Catheter lubricity is important for good medical procedures. Hydrophilic coatings soak up water and body fluids. This forms a slick layer on the nitinol tubing. The layer helps catheters move smoothly and turn easily. Even in tricky parts of the body, you get better movement. Insertion is easier and there is less tissue irritation.

Hydrophilic coatings can work with other surface treatments. These include polishing or nanotechnology-based coatings. These changes fill tiny gaps and make the surface extra smooth. Catheters need less effort to move. There is less risk of tissue damage. New ways of crosslinking hydrophilic polymers help coatings last longer. You get smooth catheter movement for the whole procedure.

Hydrophilic coatings on nitinol guidewires help them move through delicate neurovascular pathways.

Surface changes improve grip and control. You get better movement during surgery.

Nanoparticle coatings add antimicrobial properties and make devices stronger. This makes them safer and more effective.

Enhanced Biocompatibility

Nitinol tubing with hydrophilic coating works better and is safer for your body. Clinical trials show these coatings lower nickel ion release. They also help stop swelling and blood clots. You get a safer device that works well with your body for a long time.

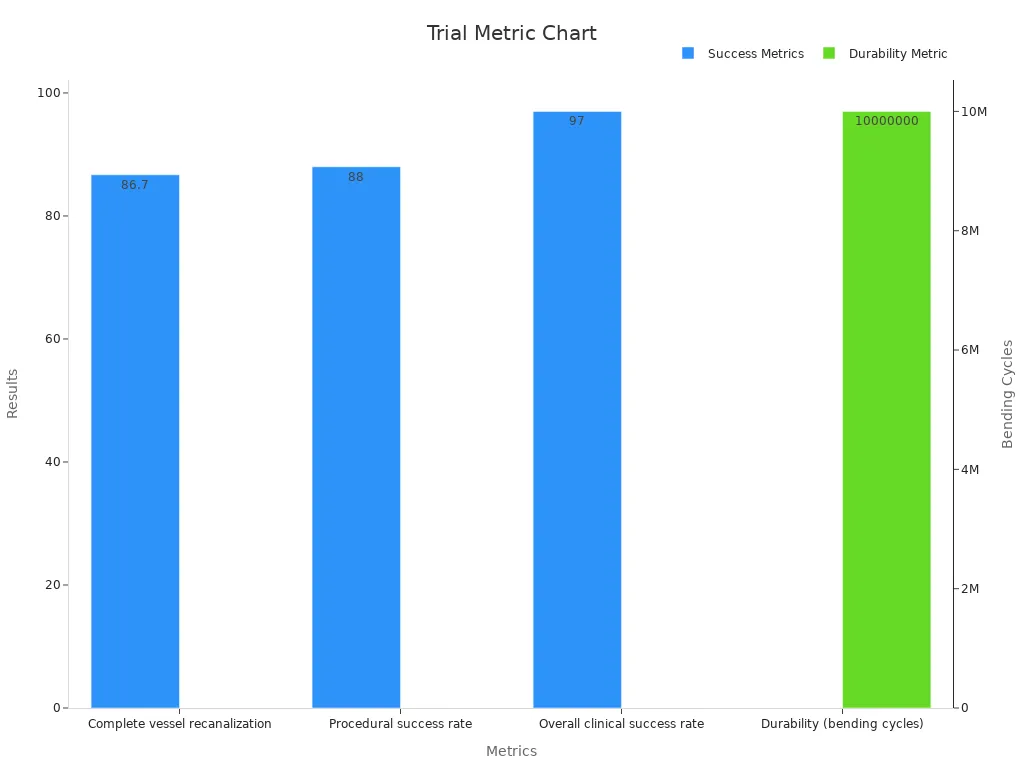

The table below shows important clinical results for nitinol tubing with hydrophilic and biocompatible coatings:

Performance Metric | Quantified Result |

|---|---|

Complete vessel recanalization | 86.7% |

Procedural success rate | 88% |

Durability (bending cycles) | 10 million |

Overall clinical success rate | 97% |

These results mean you can expect high success and long-lasting performance. Clinical trials like DAWN and PARTNER 3 show nitinol devices with hydrophilic coatings lower implant rejection by about 30%. This is compared to regular metals. There is less vessel wall damage. There are fewer cases of vessels getting blocked again after treatment.

Surface changes, like biocompatible passive films, help stop corrosion and improve how the body reacts. Studies show nitinol alloys with hydrophilic coatings help healthy cells grow. They also lower nickel release, making them safer for long-term use.

With nitinol tubing with hydrophilic coating, you get a device that works better and keeps you safer during and after medical procedures.

Clinical Impact and Applications

Hydrophilic Coated Guidewire Uses

Hydrophilic coated guidewires help in many medical procedures. These guidewires let doctors do hard tasks, like fixing blocked blood vessels. They are used in coronary angioplasty and recanalization. Reports from Demax say hydrophilic coatings lower friction. Less friction means less tissue damage and fewer injuries. Doctors can move catheters more easily, even in tough spots.

In a study, doctors said hydrophilic coated guidewires were easier to move and see.

Devices like the Glidewire worked better and gave better results for patients.

Hydrophilic coated guidewires work well in vascular procedures, like pulmonary angiography and treating chronic blockages.

These changes lead to more success, shorter procedures, and fewer problems like vessel tears or misplaced catheters.

Patient Comfort and Safety

Hydrophilic coatings on nitinol tubing help you feel better and safer. You have less pain and heal faster after your procedure. The table below shows important clinical data:

Clinical Metric | Improvement with Hydrophilic Coated Nitinol Tubing | Clinical Impact |

|---|---|---|

Recovery Improvement | ~20% faster recovery | Quicker return to normal activities, shorter hospital stay |

Pain Reduction | Lower pain levels post-procedure | Enhanced comfort during and after surgery |

Complication Rates | Reduced risk of vessel trauma and inflammation | Increased safety, fewer adverse events |

Ureteral Trauma | Less mechanical trauma, lower mucosal irritation | Less tissue damage, better healing outcomes |

Operative Time | Shorter procedures (avg. 58 min with thin scopes) | Greater efficiency, less anesthesia exposure |

Postoperative Stenting | Often unnecessary | Less invasive recovery, improved comfort |

Device Performance | 97% functional reliability in hospital use | Reliable, safe surgeries |

Hydrophilic coatings are tested to make sure they are even and strong. These coatings lower friction and help catheters move smoothly. This means less chance of hurting tissue. Rules make sure these devices stay safe and comfortable for you.

Device Flexibility in Complex Anatomy

Catheters and guidewires need to bend and twist inside your body. Hydrophilic coatings help with this. Makers use flexible nitinol cores and slippery coatings. This mix lets devices move easily through curvy vessels.

Studies and doctor stories show these guidewires help doctors do better and avoid problems. The Solo™ Hydro Hybrid Guidewire uses a hydrophilic coated tip and flexible parts. This helps doctors reach hard spots safely. You get safer and faster procedures with better results. Slippery catheters and less friction help doctors finish tough jobs with confidence.

When you pick devices with hydrophilic coatings, you get new technology that makes medical procedures safer, quicker, and more comfortable.

Durability and Safety

Coating Adhesion

You want your medical devices to last and work well. Hydrophilic coatings must stick tightly to nitinol tubing. This helps them do their job. Makers use special ways to bond these coatings. They use chemical steps to make a strong link to the metal. This strong bond keeps the coating from coming off or peeling.

When you use catheters with hydrophilic coatings, you can tell the difference. The coating stays on, even when the device bends or moves in tight places. This gives you smooth movement and good results every time. If the coating does not stick well, it can come off. This can cause more friction and less safety. Good coatings stay on and help you avoid these problems.

Tip: Always check if your device uses a trusted hydrophilic coating process. A strong bond means your device is safer and lasts longer.

Long-Term Performance

You need devices that keep working well for a long time. Hydrophilic coatings on nitinol tubing have shown great results in labs and real life. In one study, researchers put nitinol stents with hydrophilic coating in rabbits. They checked the stents after 30 and 180 days. Both coated and uncoated stents stayed open and worked as they should.

The study showed no extra swelling or thick vessel lining with coated stents. The hydrophilic coating was very thin and stuck well. It did not change how the stent worked. You can trust these coatings do not cause problems in your body, even after many months. This means you get safe and steady results the whole time the device is in place.

Hydrophilic coatings help your devices last longer and stay smooth.

You get fewer problems and better results during medical procedures.

Feature | Benefit for You |

|---|---|

Strong adhesion | No peeling or flaking |

Stable over months | Reliable device function |

No extra inflammation | Safer for long-term use |

When you pick nitinol tubing with hydrophilic coating, you choose safety, strength, and great performance.

Hydrophilic coatings help make nitinol tubing safer for you. They also make your care more comfortable. Catheters work better and cause less tissue damage. You can heal faster after your procedure. These coatings help new medical devices work well and be easy to use.

New studies look at special coatings that can give medicine, help bones grow, and stop infections.

In the future, hydrophilic coatings may give you even more good things, like:

Knit coatings that get bigger to touch bone better.

Hydrogel layers that can give helpful things to your body.

Drug or peptide coatings that help stop germs.

FAQ

What makes hydrophilic coatings important for nitinol tubing?

Hydrophilic coatings help devices slide easily in your body. You feel less rubbing and more comfort. These coatings make procedures safer for you. They also help stop tissue damage and blood clots.

How long do hydrophilic coatings last on medical devices?

Hydrophilic coatings last for your whole procedure. Makers test them to make sure they stick well and last long. Most coatings work for months, even if the device bends a lot.

Are hydrophilic coatings safe for your body?

Yes, these coatings are safe for you. They stop rust and lower nickel from coming out. Studies show they help stop swelling and allergic reactions. Your body can use these devices more easily.

Can hydrophilic coatings improve device performance in complex anatomy?

Yes, they help in tricky parts of your body. Devices bend and move better in tight or twisty places. Hydrophilic coatings help doctors reach hard spots with less risk.

See Also

How Nitinol Tubing Supports Progress In Medical Technology

A Deep Dive Into Nitinol Tubing Uses In Healthcare

Ways Nitinol Tubing Is Transforming Modern Medical Devices

The Process Behind Manufacturing Nitinol Tubing For Medicine