Nitinol tubing vs stainless steel tubing comparison: 5 key differences for better choices

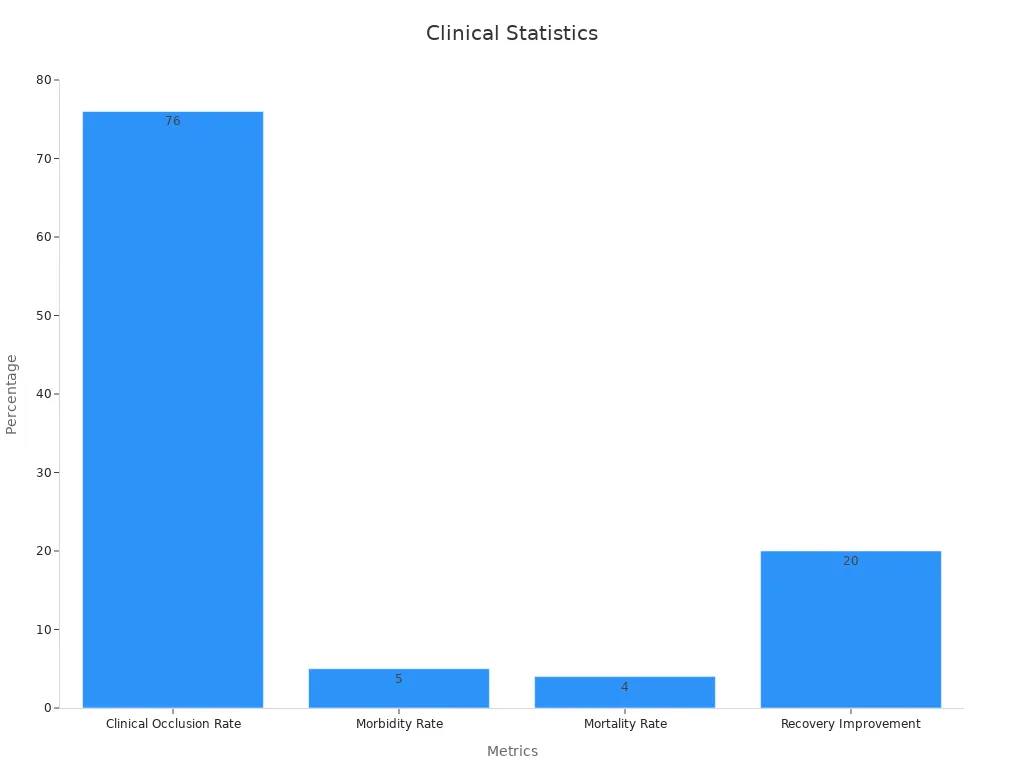

Clinicians and engineers often face the choice between nitinol tubing vs stainless steel tubing comparison when selecting materials for medical devices that require flexibility, durability, and safety. Nitinol tubing stands out due to its superelasticity, high fatigue resistance, and superior biocompatibility. Devices such as implants and minimally invasive tools benefit from nitinol's unique ability to endure millions of bends and return to its original shape after deformation. On the other hand, stainless steel tubing offers higher tensile strength and cost savings, making it a strong candidate for more robust medical applications. The following clinical statistics highlight the advantages of nitinol in medical devices:

Key Takeaways

Nitinol tubing offers exceptional flexibility and shape memory, making it ideal for devices that need to bend and return to their original shape.

Stainless steel tubing provides higher strength and rigidity, best suited for devices that must keep a fixed shape and resist strong forces.

Nitinol excels in fatigue resistance and biocompatibility, supporting long-term use in dynamic medical devices like stents and guidewires.

Stainless steel tubing is easier to manufacture, more affordable, and widely available, making it a cost-effective choice for many medical applications.

Choosing the right tubing depends on device needs and budget: pick nitinol for flexibility and advanced performance, and stainless steel for strength and cost savings.

Flexibility & Shape Memory

Nitinol Tubing Superelasticity

Nitinol tubing stands out in medical applications because of its superelasticity and shape memory effect. This material can recover from deformation strains up to 13%, which means it bends and returns to its original shape even after significant stress. Superelasticity and shape memory allow nitinol tubing to adapt to the body’s movements, making it ideal for dynamic medical applications. Scientific studies show that nitinol tubing can undergo several times larger reversible deformation than stainless steel tubing. The tubing’s microstructure, including grain orientation, supports this unique behavior. Mechanical and fatigue testing, such as tensile and torsion tests, confirm that nitinol tubing maintains its flexibility and durability under repeated use. Cardiovascular stents, guidewires, and orthopedic implants benefit from nitinol’s superelasticity and shape memory effect. These devices require both flexibility and the ability to return to a preset shape, which nitinol tubing provides reliably.

Parameter | Value/Description |

|---|---|

Deformation Strain Recovery | Up to 13% |

Flexibility Increase | 32% to 40% over thicker needles |

Positional Accuracy | ±2.5 microns |

Wall Thickness Tolerance | ±0.005 mm |

Stainless Steel Tubing Rigidity

Stainless steel tubing offers a different profile in flexibility comparison. Stainless steel provides high rigidity, which supports devices that need to maintain a fixed shape during use. Medical devices such as hypodermic needles, catheters, and instrument shafts rely on stainless steel tubing for its mechanical strength and dimensional precision. Stainless steel grades 304 and 316 are common in these applications because they combine strength, corrosion resistance, and biocompatibility. Stainless steel tubing is precision-engineered with tight tolerances, often as small as ±0.0005 inches, ensuring consistent rigidity and performance. While stainless steel tubing can be bent or shaped, it does not offer the superelasticity and shape memory effect found in nitinol tubing. This rigidity makes stainless steel tubing suitable for devices that require stability rather than flexibility.

Stainless steel tubing supports complex articulating instruments for minimally invasive procedures.

Advances in tubing technology allow for smaller diameters and thinner walls, balancing rigidity with some flexibility.

Stainless steel tubing remains a top choice for applications where device shape must not change during use.

Best Devices for Each Material

Medical devices benefit from the unique properties of each tubing material. Nitinol tubing is best for dynamic medical applications that demand high flexibility, superelasticity, and shape memory. These include:

Cardiovascular stents and vascular grafts, where superelasticity and shape memory effect allow for compression and expansion.

Orthopedic implants, which adapt to body movement and mechanical stress.

Endoscopic instruments, which require navigation through tight anatomical structures.

Stainless steel tubing excels in applications where rigidity and strength are critical:

Hypodermic needles and catheters, which need precise, stable shapes.

Instrument shafts for reusable and disposable medical devices.

Devices for minimally invasive surgery that require consistent performance and dimensional accuracy.

Tip: Choose nitinol tubing for devices that need to flex and recover shape, and stainless steel tubing for devices that must stay rigid during use.

Strength & Durability

Tensile Strength

Tensile strength measures how much force a material can handle before breaking. Stainless steel tubing usually offers higher tensile strength than nitinol tubing. This property makes stainless steel a strong choice for medical devices that need to resist stretching or pulling forces. The following table compares the tensile strength and durability features of both materials:

Material | Tensile Strength Range (MPa) | Key Durability Characteristics |

|---|---|---|

Nitinol Tubing | 500–900 | Superelasticity, shape memory effect, excellent fatigue resistance, corrosion resistance enhanced by surface finish |

Stainless Steel | 600–1100+ | Higher tensile strength, rigidity, corrosion resistance dependent on chromium content and surface maintenance |

Stainless steel tubing can reach tensile strength values of 600 MPa or higher, while nitinol tubing typically ranges from 500 to 900 MPa. This difference means stainless steel tubing often supports devices that require high mechanical strength and rigidity.

Fatigue Resistance

Fatigue resistance describes how well a material performs under repeated bending or stress. Nitinol tubing stands out for its excellent fatigue resistance, which comes from its superelasticity and shape memory. Studies show nitinol can endure many cycles of bending without breaking, making it ideal for medical applications that demand repeated movement. For example, nitinol tubing in stents and guidewires maintains performance even after millions of cycles. Stainless steel tubing, while strong, does not match nitinol’s fatigue resistance. It works best in devices that do not need to flex often.

Nitinol tubing shows strong fatigue resistance, especially in dynamic environments.

Stainless steel tubing performs well under static loads but may fail sooner under repeated stress.

Long-Term Use in Medical Devices

Medical devices must last through years of use. Nitinol’s superelasticity and fatigue resistance give it an edge in long-term performance for dynamic applications. Devices like stents, orthopedic implants, and flexible surgical tools benefit from nitinol tubing’s ability to recover shape and resist fatigue. Stainless steel tubing remains a top choice for devices that need high tensile strength and rigidity, such as hypodermic needles and instrument shafts. Both materials offer good corrosion resistance, but nitinol’s surface finish can further enhance its durability in harsh environments.

Tip: Select nitinol tubing for devices that require repeated flexing and long-term durability. Choose stainless steel tubing for applications where strength and rigidity matter most.

Biocompatibility & Safety

Corrosion Resistance

Nitinol tubing and stainless steel tubing both play vital roles in medical applications, but their corrosion resistance levels differ. Nitinol shows excellent corrosion resistance, especially after surface treatments like electropolishing. Scientific measurements such as breakdown potential (Eb) using ASTM F2129, scanning electron microscopy, and nickel leach testing help evaluate corrosion resistance in nitinol tubing. These tests confirm that nitinol forms a stable oxide layer, which protects against corrosion in harsh medical environments. Stainless steel tubing relies on its chromium content for corrosion resistance. However, stainless steel can still experience pitting corrosion, especially if the surface becomes damaged. Stainless steel tubing offers good corrosion resistance, but nitinol tubing often outperforms it in demanding medical applications.

Scientific Measurement | Description | Relevance to Corrosion Resistance |

|---|---|---|

Breakdown Potential (Eb) | Measures voltage for pitting corrosion | Key for nitinol tubing |

SEM | Analyzes surface and oxide layer | Influences corrosion resistance |

EDS | Determines oxide layer composition | Affects corrosion behavior |

Nickel Leach Testing | Measures nickel ion release | Assesses biocompatibility and corrosion |

Biocompatibility Testing (ISO 10993) | Evaluates safety and toxicity | Ensures medical device durability |

Patient Safety

Patient safety remains a top priority in all medical devices. Nitinol tubing provides excellent biocompatibility and corrosion resistance, which reduces the risk of inflammation and rejection in implants. Clinical studies show that nitinol implants, such as stents and guidewires, help lower complication rates and speed up recovery. Surface treatments on nitinol tubing, like electropolishing, create a nickel-free oxide layer that further improves safety. Stainless steel tubing also offers good biocompatibility and corrosion resistance, making it a reliable choice for many medical applications. However, nitinol tubing often leads to faster recovery and fewer complications in minimally invasive procedures. Stainless steel tubing remains trusted for its strength and reliability in implants and surgical tools.

Note: Both nitinol tubing and stainless steel tubing meet strict medical standards for patient safety, but nitinol tubing often provides added benefits in advanced applications.

Biocompatibility in Medical Devices

Biocompatibility ensures that materials used in medical devices do not harm the body. Nitinol tubing achieves high biocompatibility through surface treatments like electropolishing and chemical passivation. These processes create a smooth, oxide-rich surface that reduces nickel ion release and improves corrosion resistance. Empirical tests show that nitinol tubing reduces platelet adhesion and coagulation, making it safer for blood-contacting implants. Compliance with standards such as ASTM F2063 and ISO 10993 confirms the biocompatibility of nitinol tubing in medical devices. Clinical trials, including DAWN and PARTNER 3, support the safety and effectiveness of nitinol implants. Stainless steel tubing also meets biocompatibility requirements, but nitinol tubing often excels in challenging medical applications. Both materials support a wide range of devices and implants, but nitinol tubing stands out for its superior biocompatibility and corrosion resistance.

Manufacturability & Customization

Fabrication Challenges

Nitinol tubing fabrication presents unique challenges in medical device engineering. Manufacturers must use high-purity nickel and titanium, alloyed under vacuum to avoid contamination. The process includes forging, rolling, and tube forming, followed by grinding and drawing to achieve precise diameters and wall thicknesses. Heat treatment and aging set the shape memory and superelasticity that define nitinol’s flexibility and performance. Laser cutting allows for complex geometries, but machining nitinol remains difficult due to its ductility and reactivity. Additive manufacturing can create advanced structures, but it increases cost and demands strict control of powder quality and laser settings. In contrast, stainless steel tubing uses more conventional methods. Stainless steel is easier to machine and form, does not require such strict compositional control, and offers higher fatigue resistance. Stainless steel tubing fabrication does not need the same level of surface finishing or heat treatment as nitinol tubing.

Nitinol requires strict compositional control for transformation temperatures and tensile strength.

Stainless steel tubing is less sensitive to impurities and easier to process.

Design Flexibility

Medical device engineering often demands high flexibility and customization. Nitinol tubing enables innovative designs because of its superelasticity and shape memory. Devices can feature intricate shapes and thin walls, supporting advanced minimally invasive procedures. However, customization with nitinol requires tight control over transformation temperatures and fatigue resistance. Stainless steel tubing provides design flexibility through easy machining and forming. Stainless steel supports a wide range of devices, from rigid shafts to flexible catheters, but does not match nitinol’s ability to recover shape after deformation. Both materials allow for precise tolerances, but nitinol’s unique properties enable devices with superior flexibility and performance.

Tip: Choose nitinol for devices needing complex shapes and high flexibility. Select stainless steel for applications requiring strength, rigidity, and easier fabrication.

Joining Materials in Devices

Joining nitinol and stainless steel in medical devices introduces further complexity. Mechanical joining, such as crimping or swaging, works for some applications but can increase device diameter and stiffness. Adhesive bonding, using cyanoacrylate or epoxy, is common for joining nitinol tubing to stainless steel tubing. This method accommodates differences in thermal expansion and maintains flexibility, but requires careful surface preparation and longer cure times. Welding methods, including laser and plasma welding, demand precise heat control to preserve nitinol’s superelasticity and tensile strength. Soldering is possible but less preferred due to biocompatibility and automation concerns. Medical device engineering teams often design devices from single blocks of material to avoid joining challenges and maintain performance.

Joining Method | Nitinol Tubing | Stainless Steel Tubing | Notes |

|---|---|---|---|

Mechanical (Crimp) | Limited | Common | May increase stiffness |

Adhesive Bonding | Preferred | Common | Maintains flexibility, needs prep |

Welding | Challenging | Easier | Heat control critical for nitinol |

Soldering | Possible | Common | Biocompatibility concerns for nitinol |

Medical device engineering benefits from understanding these fabrication and joining challenges. Nitinol enables advanced device performance and flexibility but requires specialized processes. Stainless steel tubing offers easier manufacturing and high tensile strength, supporting a broad range of medical devices.

Cost & Availability

Material Costs

Stainless steel tubing remains the most cost-effective choice for many medical devices. Manufacturers prefer stainless steel because it offers excellent tensile strength, corrosion resistance, and reliable performance at a moderate price. Stainless steel tubing is widely available, which helps keep costs low for both large and small medical projects. In contrast, nitinol tubing carries a premium price. The higher cost comes from expensive raw materials like titanium and nickel, as well as complex manufacturing steps. Tubing forms of nitinol require more processing than wire or sheet, which increases the final price. For example, nitinol shape memory wire can cost between $30 and $100 for just five feet, while stainless steel tubing costs much less for the same length. Medical device teams must weigh these price differences when selecting materials.

Supply Chain

The supply chain for stainless steel tubing is robust and dependable. Most suppliers keep standard sizes in stock, which allows for fast delivery and fewer production delays. Stainless steel tubing benefits from global sourcing and modern manufacturing, making it easy to find and order. Suppliers with certifications like ISO 13485 and ASTM F2063 ensure quality and compliance for medical devices. Nitinol tubing faces more supply chain challenges. Fewer suppliers produce high-quality nitinol tubing, and lead times can be longer. Supply chain disruptions or raw material shortages may affect nitinol tubing availability. However, suppliers who invest in research and development offer advanced tubing solutions and better support for specialized medical devices.

Timely delivery and inventory of standard sizes help avoid delays.

Certified suppliers reduce risk in critical medical applications.

Ongoing support and innovation improve supply chain resilience.

Value for Medical Projects

Stainless steel tubing delivers strong value for most medical projects. Its moderate upfront cost, high tensile strength, and durability make it suitable for a wide range of devices. Modern processing methods lower manufacturing and maintenance costs, which adds to its long-term value. Stainless steel supports both simple and complex medical devices, from hypodermic needles to surgical instruments. Nitinol tubing, while more expensive, offers unique performance benefits for advanced medical devices. Its superelasticity and shape memory justify the higher price in applications where flexibility and fatigue resistance are critical. Medical teams should balance performance needs with budget limits. For cost-sensitive projects, stainless steel tubing provides reliable performance and availability. For devices that demand advanced properties, nitinol tubing offers long-term value despite the higher initial investment.

Tip: Match the tubing material to the device’s performance requirements and project budget to achieve the best results in medical applications.

Nitinol Tubing vs Stainless Steel Tubing Comparison for Devices

Minimally Invasive Medical Devices

In the nitinol tubing vs stainless steel tubing comparison, nitinol stands out for minimally invasive medical applications. Nitinol provides shape memory and superelasticity, which allow catheters, guidewires, and self-expanding stents to navigate complex anatomy. These devices require flexibility and precise size recovery. Nitinol enables stents and implants to expand smoothly and return to their original form after deployment. Catheters and guidewires made from nitinol tubing resist kinking and maintain trackability, which improves procedural safety. Nitinol’s elasticity supports neurovascular therapies and interventional cardiology, where device movement and vessel conformity are critical. Stainless steel tubing offers high tensile strength and dimensional precision, but it lacks the elasticity needed for advanced navigation. For minimally invasive medical devices, nitinol tubing delivers superior performance in applications demanding flexibility, fatigue resistance, and reliable deployment.

Cost-Sensitive Devices

Cost-sensitive applications often favor stainless steel in the nitinol tubing vs stainless steel tubing comparison. Stainless steel tubing provides high tensile strength, corrosion resistance, and consistent quality at a lower price. Medical devices such as hypodermic needles, basic catheters, and reusable instrument shafts benefit from stainless steel’s affordability and availability. These devices do not require the shape memory or superelasticity of nitinol. Stainless steel supports implants and stents where rigidity and strength matter more than flexibility. Manufacturers choose stainless steel for guidewires and catheters in routine procedures, where cost control is essential. Stainless steel tubing meets regulatory standards and offers reliable performance for a wide range of medical applications.

Summary Table of Best Uses

The following table summarizes the nitinol tubing vs stainless steel tubing comparison for common medical device scenarios:

Device/Application | Preferred Material | Key Reason(s) |

|---|---|---|

Neurovascular catheters | Nitinol | Shape memory, kink resistance, flexibility |

Interventional guidewires | Nitinol | Superelasticity, trackability, fatigue life |

Self-expanding stents | Nitinol | Size recovery, vessel conformity |

Cardiovascular stents | Stainless Steel | High tensile strength, cost efficiency |

Orthopedic implants | Stainless Steel | Rigidity, tensile strength, durability |

Basic catheters | Stainless Steel | Cost, dimensional precision |

Complex implants | Nitinol | Fatigue resistance, shape memory |

Routine guidewires | Stainless Steel | Strength, affordability |

High-radiopacity stents | Nitinol-Pt/W | Visibility, compression force |

Tip: For material selection for implantable devices, match the tubing’s properties to the device’s performance needs and budget. Nitinol excels in flexible, fatigue-resistant applications, while stainless steel leads in cost-sensitive, high-strength scenarios.

Selecting the right tubing for medical devices depends on five key differences. Nitinol offers unmatched flexibility, fatigue resistance, and biocompatibility for advanced medical applications. Stainless steel provides strength and cost efficiency for many medical devices. Each device has unique requirements. Medical teams should evaluate nitinol and stainless steel by prototyping or consulting with experts. Testing both materials helps ensure the best fit for each medical device project.

FAQ

What is the main advantage of nitinol tubing in devices?

Nitinol tubing offers superelasticity and shape memory. These features help devices bend and return to their original shape. Many engineers choose nitinol for flexible and dynamic device designs.

When should stainless steel tubing be used instead of nitinol?

Stainless steel tubing works best for devices that need high strength and rigidity. It supports applications where the device must keep its shape and resist bending during use.

Can nitinol and stainless steel tubing be joined in one device?

Engineers can join nitinol and stainless steel tubing using adhesive bonding or mechanical methods. Careful surface preparation ensures a strong connection. This approach helps combine the strengths of both materials.

Is nitinol tubing safe for long-term implants?

Nitinol tubing shows excellent biocompatibility and corrosion resistance. Many clinical studies confirm its safety for long-term use in medical implants.

How does cost affect material selection for medical devices?

Cost plays a key role in material selection. Stainless steel tubing offers a lower price and wide availability. Nitinol tubing costs more but provides unique performance for advanced medical applications.

See Also

Choosing The Ideal Nitinol Tubing Supplier For You

Evaluating Tensile Strength Between Nitinol And Stainless Steel Tubing

A Detailed Guide To Selecting Proper Nitinol Tubing

Finding The Most Cost-Effective 2mm OD Nitinol Tubing Supplier