Why Nitinol Is the Top Choice for Stent Design in 2025

Nitinol Tubing vs. stainless steel stents shows clear advantages for nitinol in 2025. Nitinol is flexible, strong, and has shape memory, making it superior for stents. Doctors achieve better outcomes with nitinol compared to stainless steel stents. In real-world use, nitinol stents stay open longer and move less. For instance, patients with nitinol stents in critical blood vessels experience improved mobility and better heart health after six and twelve months. When comparing Nitinol Tubing vs. stainless steel stents, nitinol conforms to the body more effectively, making it an excellent choice for cardiovascular care.

Key Takeaways

Nitinol stents can bend and go back to their shape. This makes them better for blood vessels that move than stainless steel stents. Nitinol stents open by themselves inside the body. This lets doctors use smaller tools. It also helps them reach hard spots more easily. Nitinol stents last longer and do not rust or wear out fast. This means people need fewer replacements. It also saves money over time. Nitinol stents are safer for patients. They cause fewer blood clots and allergies because of special surface treatments. New nitinol stents have smart things like sensors and drug delivery. These help patients and change how stents work in the future.

Nitinol Tubing vs. Stainless Steel Stents

Mechanical Properties

When you look at nitinol tubing vs. stainless steel stents, how they work matters a lot. Nitinol is very flexible and can bend without breaking. It also does not get tired or rust easily. The table below shows how they are different:

Property | Nitinol Tubing | Stainless Steel Tubing |

|---|---|---|

Flexibility | High flexibility due to superelasticity and shape memory; can undergo >7% strain and recover shape | More rigid, about twice as stiff as Nitinol; lacks superelasticity and shape memory |

Fatigue Resistance | Excellent; survives millions to billions of bending cycles; fatigue strength decreases slightly at high speeds | Good but lower than Nitinol under repeated bending; steady fatigue strength but fails sooner under high strain |

Corrosion Resistance | Superior due to stable oxide layer; resists rust and pitting especially in chloride-rich body fluids | Good due to chromium content but more prone to pitting corrosion and rust, especially if surface damaged |

Nitinol tubing stays strong and bends well for a long time. It does not kink or wear out fast, so stents last longer in the body. Stainless steel tubing is strong but can get weaker after welding or lots of use. It does not have shape memory like nitinol. This means nitinol tubing vs. stainless steel stents gives better bending and fits better in moving blood vessels.

Clinical Performance

How stents work in the body is very important. Nitinol tubing vs. stainless steel stents act differently when doctors put them in and after.

Tip: Nitinol stents open up by themselves, but stainless steel stents need a balloon to open.

Feature | Self-Expanding Nitinol Stents | Balloon-Expandable Stainless Steel Stents |

|---|---|---|

Deployment Mechanism | Expand spontaneously due to shape-memory effect at body temp | Expanded by inflating a balloon at the target site |

Delivery Device Size | Smaller delivery devices (no balloon needed) | Larger delivery devices (balloon required) |

Radial Strength | High elasticity, regains shape after compression | Higher radial stiffness, does not regain shape after compression |

Repositioning Ability | Cannot be resheathed or repositioned after deployment | Allows more accurate placement, less foreshortening |

Suitability | Preferred in tortuous vessels due to flexibility | Favored in rigid, straight lesions for precise placement |

Radiopacity | Requires radiopaque markers for visualization | Generally higher radiopacity facilitating accurate deployment |

Nitinol stents open up on their own when they get warm in the body. This lets doctors use smaller tools and reach tricky spots. Stainless steel stents need a balloon to open, so bigger tools are needed. This can make it hard to use them in small or twisty blood vessels. Nitinol tubing vs. stainless steel stents also changes how well the stent moves with the vessel. Nitinol can bounce back to its shape after being squeezed. Stainless steel stents can bend and not go back to their old shape.

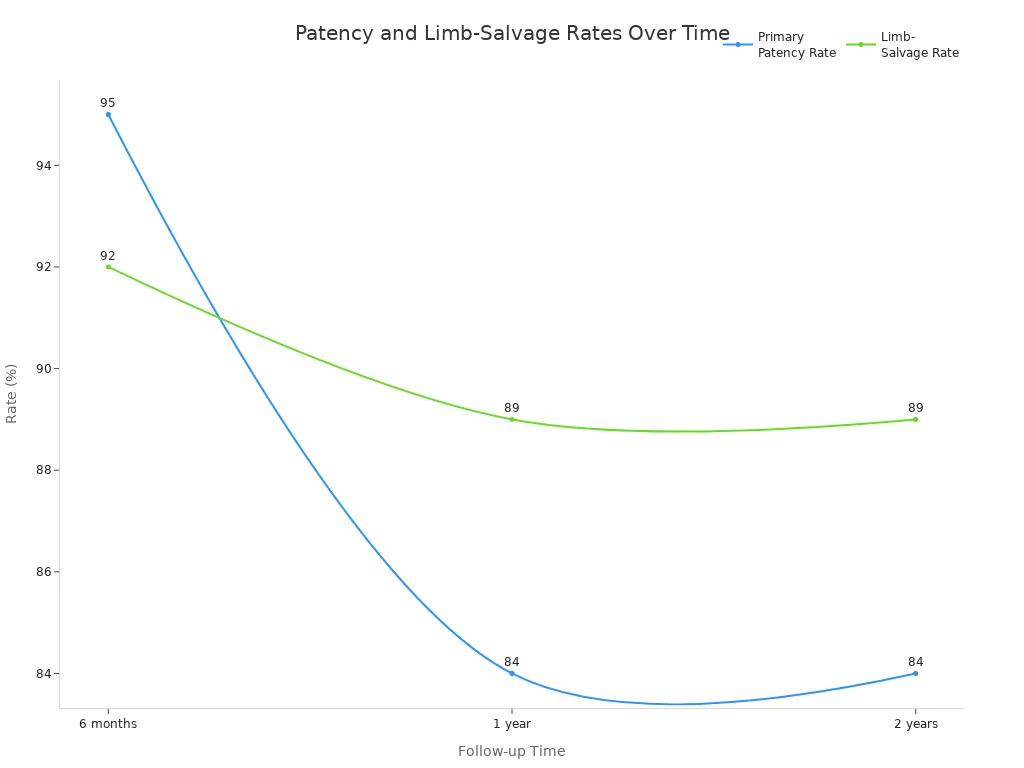

Studies show nitinol stents block up less and keep blood flowing better, especially in certain arteries. New nitinol stents break less and bend more easily. Some studies found stainless steel stents did not work better than balloon treatment alone. In animal tests, stainless steel stents caused more blood clots and hurt the vessel more than nitinol stents.

Cost is also important when picking nitinol tubing vs. stainless steel stents. Nitinol stents cost more at first, but they last longer and need fewer replacements. This saves money over time. Stainless steel stents are cheaper at first but may need to be replaced more often, which can cost more later.

Nitinol tubing vs. stainless steel stents is still a big question in blood vessel care. Nitinol’s flexibility, strength, and rust resistance make it the top pick for many stents in 2025.

Superelasticity and Shape Memory

Stent Deployment

Super elastic nitinol tube technology helps doctors put stents in blood vessels. Superelasticity lets nitinol stents get very small. Doctors use tiny catheters to move them. When the stent gets to the right spot, it opens by itself. This happens because of a special change inside the super elastic nitinol tube. The stent can bend and flex but always goes back to its shape. This helps the stent stay open and not break.

Super elastic nitinol tube stents use shape memory to reach the right size after opening. The stent pushes against the artery wall and keeps it open. The stent stays in place, so it does not move or leak. Doctors see fewer problems like vessel damage or the stent moving. The stent can expand with steady force, so it fits even if the vessel changes size. This makes results better for patients.

Note: Steps like heat treatment and careful mixing make sure each super elastic nitinol tube stent works the same every time.

Adaptability in Vascular Anatomy

Super elastic nitinol tube stents can fit many kinds of blood vessels. These stents twist and bend to match each patient’s blood vessels. The stents fit well in curved or branching arteries. Special surface treatments on the super elastic nitinol tube help the body accept the stent and lower bad reactions.

Doctors use these stents in hard cases, like twisted or narrow arteries. The stents are flexible and strong, so they last longer and do not break easily. Studies show super elastic nitinol tube stents have fewer problems and better long-term results than other materials. Patients get better faster and leave the hospital sooner. The stents work with MRI scans, so follow-up care is easier.

Super elastic nitinol tube stents help doctors do less invasive procedures. Doctors fix blocked arteries without big cuts. Patients walk more and feel better after these treatments. The stents keep blood moving and lower the chance of the artery closing again. These benefits make nitinol the best choice for vascular stents in 2025.

Durability and Biocompatibility

Fatigue and Corrosion Resistance

Nitinol stents last a long time in the body. They do not break or wear out easily, even after many bends. Stainless steel stents can get weaker if their surface is scratched or used a lot. Nitinol stents are safe for MRI scans because they are not magnetic. Both nitinol and stainless steel stents resist rust, but nitinol’s special coating helps it do better in tough body fluids.

Property | Nitinol Stents | Stainless Steel Stents |

|---|---|---|

Fatigue Resistance | Exceptional fatigue resistance in tension-tension and rotary bending tests; superior under cyclic loading | Lower fatigue resistance; improved by surface treatments but still less than nitinol |

Corrosion Resistance | High corrosion resistance with proper surface treatment; tested by ASTM F2129-2008 | Good resistance, but can be inferior to nitinol depending on surface finish |

Clinical Relevance | MRI compatible; mechanical behavior suits self-expanding stents | Less MRI compatible; used in balloon-expandable stents with high radial strength |

Patient Safety

Biocompatibility means the stent works well with the body. Nitinol stents are very safe, especially when the surface is treated well. These treatments help stop nickel from leaking out and lower swelling in the body. Animal tests show nitinol stents with smooth surfaces cause less reaction and keep nickel levels steady.

Nitinol stents have 36% less fibrin(ogen) sticking and 63% less platelets sticking than stainless steel stents.

Less clotting happens on nitinol, so there is a lower chance of blood clots.

Polishing the surface makes nitinol stents even safer by stopping nickel from coming out.

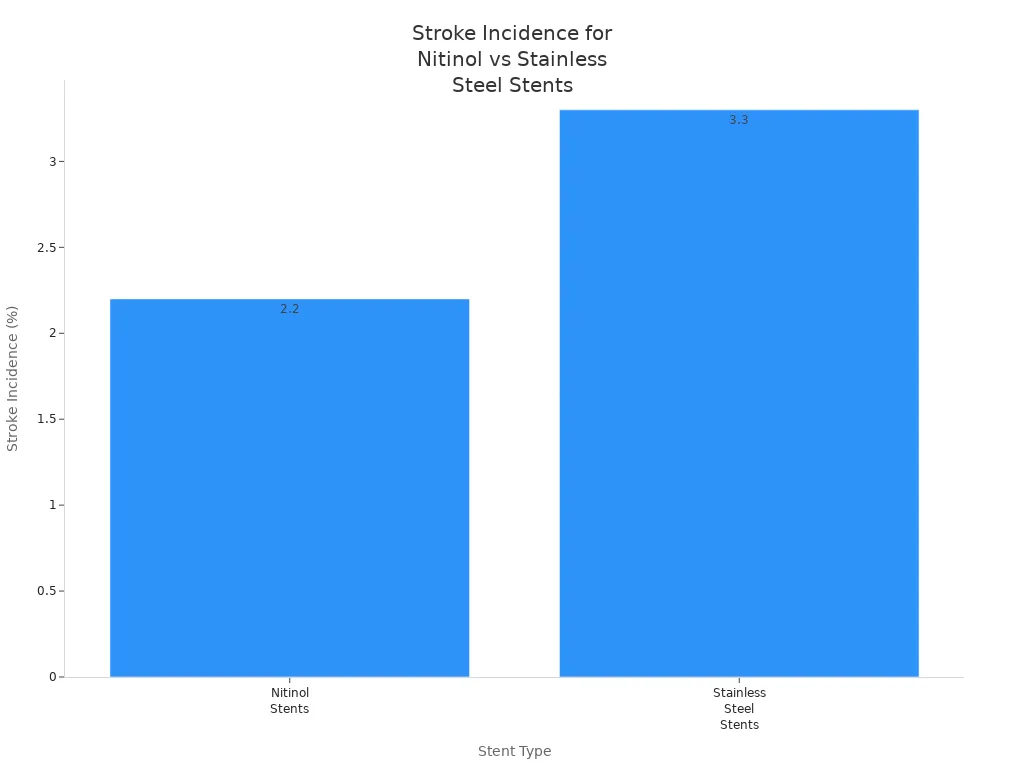

Studies show both types of stents are safe for patients. Stroke and brain problems are about the same, but nitinol stents have a little fewer problems. Groups like the FDA and CE mark say nitinol stents are safe to use. With good surface treatment, nitinol stents are strong and safe, so they are a great choice for blood vessel care in 2025.

Nitinol Used in Stents: Innovation

Advanced Applications

Nitinol used in stents has changed how doctors fix blood vessel problems. Today, many uses for nitinol make stents safer and smarter. Some new stents have tiny sensors inside them. These sensors can check blood pressure and send data to doctors. This lets doctors watch patients right away and help fast if needed.

Other uses help with drug delivery. Some nitinol stents have special coatings that slowly let out medicine. For example, the Eluvia stent uses paclitaxel to stop the vessel from closing again. This stent keeps blood moving and lowers the chance of another surgery. Studies show patients with these stents have fewer problems and better results after one year.

Many uses also include new ways to make stents. Additive manufacturing and laser welding help build thin, bendy stents that fit better. Some stents use bio-friendly materials that break down over time. These uses help patients heal faster and lower long-term risks.

Doctors think nitinol used in stents is a big step forward for more uses in vascular and non-vascular stents.

Future of Vascular Stents

The future will bring even more cool uses for nitinol. Experts think artificial intelligence will help design stents for each patient. AI can look at scans and pick the best stent size and shape. This makes treatments safer and more personal.

Other uses will make stents even smaller and more bendy. New surface treatments help nitinol stents last longer and lower nickel release. Companies now use eco-friendly ways to make stents, which helps the planet.

Patents show that many uses focus on better drug delivery and new ways to place stents. Some stents use nanoparticles to carry medicine right where it is needed. These uses try to stop vessels from closing and keep patients healthy.

Nitinol used in stents will keep growing as new uses appear. Doctors and engineers work together to find better ways to help patients. The future of stents will have more smart features, better drug delivery, and safer materials. Nitinol will stay important for these changes.

Nitinol is a top pick for stent design because it is safe and lasts a long time. It works well in the body and helps patients get better results. Studies show nitinol stents keep arteries open and stop problems from happening.

Parameter | Result |

|---|---|

Procedural success rate | Up to 98% |

Clinical success before elective surgery | Up to 94% |

Patients with complications during follow-up | 0% |

Experts say nitinol will change how doctors treat blood vessels. New technology will make stents even safer and work better for patients.

FAQ

What makes nitinol different from stainless steel in stents?

Nitinol bends and returns to its shape. Stainless steel stays rigid. Nitinol resists breaking and rusting better. Doctors use nitinol for stents that need to move with the body.

Are nitinol stents safe for people with metal allergies?

Nitinol stents have special coatings. These coatings keep nickel from leaking out. Most patients do not have allergic reactions. Doctors check for allergies before using nitinol stents.

Can doctors use nitinol stents in all blood vessels?

Doctors use nitinol stents in many blood vessels. Nitinol works well in curved or moving arteries. Some very small or hard arteries may need other types of stents.

How long do nitinol stents last inside the body?

Nitinol stents last for many years. They resist breaking and rusting. Most patients do not need another stent after the first one.

Do nitinol stents work with MRI scans?

Nitinol stents are MRI compatible. Patients can safely have MRI scans after getting a nitinol stent.

See Also

Nitinol Tubes Shaping The Future Of Medical Devices

How Nitinol Tubing Drives Progress In Medical Technology

Nitinol Tubing Transforming The Medical Device Industry

The Importance Of Nitinol Tubing In Medical Innovations

Discovering Nitinol Tubing Uses In Modern Healthcare Devices