Nitinol Tubing Surface Treatment Tips Most People Ignore

You may not realize how crucial Nitinol Tubing surface treatment is. It significantly impacts the safety and durability of a device. Many overlook that even small improvements in Nitinol Tubing surface treatment can make a big difference. These enhancements help nitinol tubing perform better within the body. For example, electropolishing as a Nitinol Tubing surface treatment reduces nickel ion release, making the shape memory alloy safer for patients. Plasma treatments, another form of Nitinol Tubing surface treatment, increase superelasticity and improve the interaction between cells, proteins, and the device. These surface treatment steps promote faster healing and reduce risks for patients relying on nitinol in critical medical devices.

Key Takeaways

Clean nitinol tubing very well before any surface treatment. This removes oils, glue, and heat scale. It helps make the finish even and work better.

Pick electropolishing instead of mechanical polishing. This makes a smooth surface. It helps stop corrosion and lowers nickel release.

Watch heat treatment closely. This forms a thin, even oxide layer. The layer protects the tubing and keeps it safe. It also stops cracks from forming.

Use passivation after polishing. This builds a strong titanium dioxide layer. The layer blocks nickel ions. It also helps stop corrosion.

Do strict quality checks. Test for nickel release. Check if the surface is smooth. This keeps nitinol tubing safe and reliable.

Biocompatibility and Nitinol Tubing

Why Biocompatibility Matters

It is important to think about biocompatibility with nitinol tubing. This means nitinol devices should not hurt the body or cause bad reactions. Many medical devices use nitinol because it can change shape and stretch easily. But nitinol has a lot of nickel, and that can be a problem if not handled right.

Nitinol has 40% to 50% nickel. This can let nickel ions out, which might cause allergies or cell damage.

If the surface is rough or damaged, corrosion can happen. This lets more nickel out and makes biocompatibility worse.

Surface treatments like electropolishing and passivation help stop corrosion and nickel release.

Clean work areas and strong quality checks are needed. You should follow rules like ISO 13485 and FDA QSR.

Checking the surface often during making keeps devices safe and working well.

Stopping contamination while making nitinol tubing is very important for blood and tissue safety.

Rules are also important. ASTM F2063 is the main rule for nitinol tubing in medical devices. It says you must test for cell damage, allergies, irritation, and other safety things. You need to show proof you followed these rules before your device can be used by patients.

Surface Chemistry Impact

Surface chemistry and finishing change how safe nitinol tubing is. Changing the surface can control how much nickel gets into the body. Studies show polished nitinol lets out less nickel and does not corrode as much as untreated nitinol. For example, electropolished or mechanically polished nitinol has a smoother oxide layer. This layer blocks nickel ions and lowers the chance of swelling or pain.

Tip: Pick surface treatments that make the oxide layer better. This helps stop allergies and keeps devices working.

Smaller and fewer surface spots on nitinol tubing help stop corrosion. Oxide layers made by heat, especially on laser-cut stents, give more protection. By caring about surface chemistry, you help nitinol devices stay safe and work well in the body.

Nitinol Tubing Surface Treatment Methods

Pre-Treatment Cleaning

You must clean nitinol tubing well before any surface treatment. Cleaning gets rid of oils, glue, and scales that can cause problems later. If you do not clean it right, the finish will not be even. This can make the device work poorly. Here are the best cleaning steps:

Take off glue and coatings that vapor degreasing cannot remove. If glue is left, electropolishing will not be even.

Clean welded spots to get rid of burnt oils and grease. Burnt oils are hard to remove and can hurt the surface.

Remove tough scale from heat treating. Scale acts like a shield and causes uneven polishing.

Make sure the surface is even after blasting. Use the same pressure so there are no bright or dull spots after electropolishing.

Doing these steps gives you a clean base for more treatments. This helps stop corrosion and lowers nickel ion release.

Mechanical and Electropolishing

Mechanical polishing uses rough materials to smooth the tubing. But it leaves lines and flaws. These flaws can trap dirt and let out more nickel. Electropolishing takes off a thin layer and makes the surface very smooth. This helps stop corrosion and makes the tubing safer for people.

Surface Treatment Method | Surface Roughness (Ra) | Corrosion Resistance | Nickel Ion Release | Fatigue Life & Other Notes |

|---|---|---|---|---|

Mechanical Polishing | Rougher surface with grooves and flaws remaining | Lower corrosion resistance; more corrosion sites | Higher nickel ion release | Flaws remain; weaker fatigue resistance |

Electropolishing | Very smooth surface; Ra below 0.5 μm; reduces roughness by up to 75% | High breakdown voltage (~1000 mV); fewer corrosion sites; about 75% better corrosion resistance | Reduced nickel ion release; safer for implants | Removes surface flaws and cracks; improves fatigue life and biocompatibility |

Electropolished tubing is special because it makes the surface very smooth, below Ra 0.1 µm. This smoothness lowers tissue irritation and nickel ion release. That keeps people safer. Animal tests show electropolished tubing lets out less nickel and causes fewer problems. The process also makes a titanium dioxide layer that helps with safety. You should always check for nickel release to follow the rules.

Tip: Pick electropolishing instead of mechanical polishing. It gives better corrosion resistance and safer nitinol tubing.

Heat and Oxidation

Heat treatment is needed to give nitinol its shape memory and superelasticity. But it also changes the oxide layer on the tubing. Heating nitinol at about 500°C in low-pressure air makes a thin, TiO2-rich oxide layer. This layer helps stop corrosion and lowers nickel ion release. If you use more heat or oxygen, the oxide layer gets thicker and has more nickel. This lets out more nickel and makes corrosion worse.

Heat Treatment Condition | Oxide Layer Composition | Oxide Thickness (nm) | Nickel Content | Corrosion Resistance / Ni Release |

|---|---|---|---|---|

Shape setting at ~500°C (short-time heating) | TiO2-enriched, Ni-depleted | 15 - 50 | Depleted in Ni | Critical for corrosion resistance and biocompatibility |

500°C in low-pressure air | TiO2-enriched, Ni-depleted | ~15 | Low Ni release | Best corrosion resistance, lowest Ni release |

Higher temperature or oxygen activity | TiO2-enriched, Ni-depleted | >15 (up to 50) | Increased Ni release | Corrosion resistance decreases as Ni release accelerates |

Too much oxidation makes thick, brittle layers. These can crack and weaken the tubing. This leads to more nickel ion release and less safety. Always control the heat treatment to avoid these problems.

Passivation

Passivation is a chemical step that makes the surface stronger against corrosion. Nitric acid is used to take away nickel and nickel oxide. This leaves a strong titanium dioxide layer. The layer blocks nickel ion release and helps with safety.

Passivation in nitric acid takes away nickel and nickel oxide. This makes more titanium dioxide and better corrosion resistance.

Adding silver, niobium, or tantalum to nitinol helps passivation and lowers nickel ion release.

Smoother surfaces from passivation help stop biofilm, which lowers infection risk.

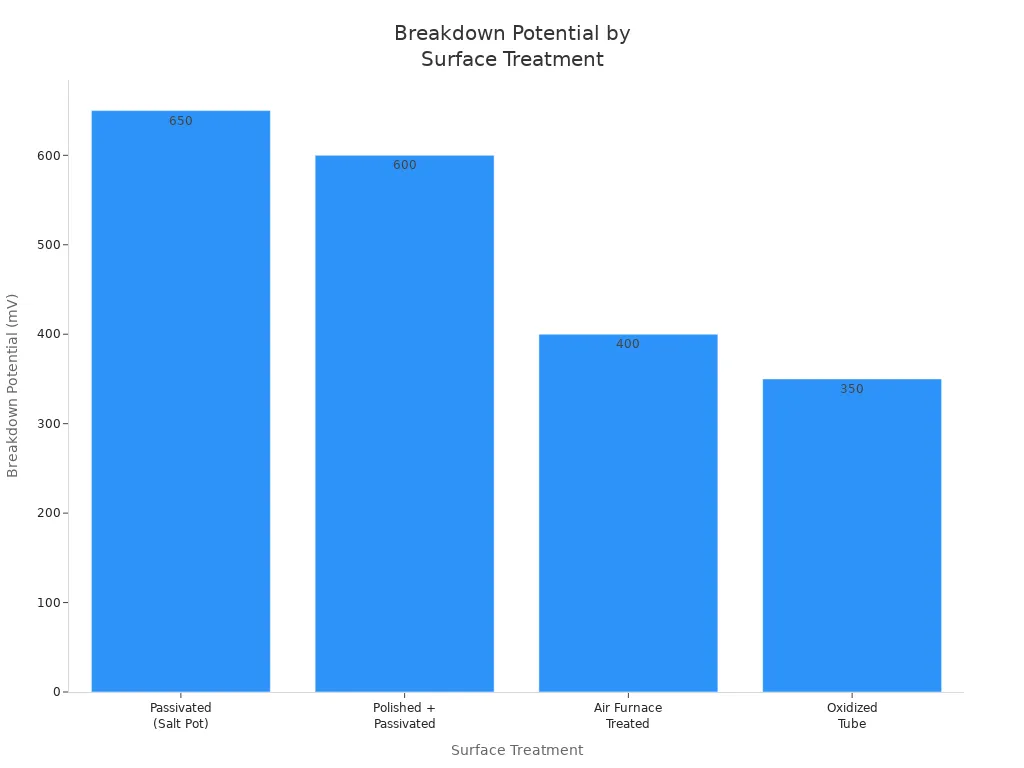

Surface Treatment | Breakdown Potential (mV) | Corrosion Resistance | Biological Response |

|---|---|---|---|

Passivated (Salt Pot) | ~650 | High | Low inflammation |

Polished + Passivated | ~600 | Good | Low restenosis |

Air Furnace Treated | ~400 | Moderate | Moderate inflammation |

Oxidized Tube | ~350 | Low | Higher tissue response |

You should use passivation with polishing for the best results. This gives high corrosion resistance and low nickel ion release. That is important for safety in medical use.

Parylene and PVD Coatings

Parylene and PVD coatings are new ways to protect nitinol tubing. Parylene makes a thin, even layer that covers the whole surface. It works even on tricky shapes. This coating stops water, chemicals, and body fluids from getting in. That makes it good for medical devices.

Parylene gives strong electrical insulation.

The coating is thin and does not make tubing stiff.

Parylene causes little reaction in tissue and lowers friction. This helps in stents and catheters.

The coating lowers the chance of blood clots.

Parylene-coated nitinol tubing is used in many devices, like brain implants and drug delivery systems.

PVD coatings also help stop corrosion and can be used with parylene for more protection. Both coatings keep nitinol’s shape memory and flexibility. They also lower nickel ion release.

Sodium Hypochlorite and Chemical Treatments

Sodium hypochlorite (NaOCl) is a chemical used to clean nitinol tubing. It removes dirt and kills germs. Short dips, like 5 to 20 minutes, clean the surface without much corrosion. If you leave tubing in NaOCl too long, it can cause more corrosion and surface problems, especially after heat treatment.

Sodium hypochlorite is good for quick cleaning and killing germs.

Keep exposure short to protect the surface.

Other chemicals can be used, but always check if they are safe for nitinol and meet the rules.

Plasma and Laser Treatments

Plasma and laser treatments are new ways to change the surface of nitinol tubing. Plasma oxidation makes a thin, even titanium oxide layer, usually 50 to 100 nm thick. This layer makes the tubing stronger, stops corrosion, and lowers nickel ion release.

Plasma oxidation makes a TiO2 layer with no nickel-rich parts. This helps superelasticity.

The surface gets tiny bumps that help stop corrosion and support safety.

Microwave plasma oxidation makes thick, even coatings that lower nickel on the surface.

Plasma treatments raise open circuit potential, so tubing resists corrosion better.

Do not make the oxide layer too thick, or it may crack and lose superelasticity.

Laser treatments also change the surface to stop corrosion and lower the risk of blood clots. Plasma-treated nitinol tubing works well and lets out little nickel, even after a long time in animal tests. These new treatments help you meet tough safety rules and make devices last longer.

Note: Plasma and laser treatments are part of anodization and coatings. They let you control the surface exactly how you want.

Optimizing Nitinol Tubing Biocompatibility

Oxide Layer Control

You can make nitinol tubing safer by managing the oxide layer. A thin and even oxide layer helps stop nickel ions from getting out. It also protects the tubing from rust. If the oxide layer is too thick, it can crack when the tubing bends. Cracks let more nickel ions escape and make the tubing less safe. Use electropolishing or mechanical polishing to keep the oxide layer thin and stable. The table below shows how different ways of treating the tubing change the oxide layer and how well it works:

Processing Method | Oxide Layer Thickness | Corrosion Resistance | Nickel Ion Release |

|---|---|---|---|

Oxidized Tube | Thickest | Uniform, low pitting | Higher |

Mechanical Polish | Thin | High | Low |

Electropolish | Thin | High | Low |

Tip: Always check the oxide layer thickness during production. Thin and even layers help make nitinol tubing safer for people.

Reducing Nickel Release

Nickel ion release is a big worry for nitinol in medical devices. You can lower nickel ion release by using special surface treatments. These include electropolishing, passivation, and chemical cleaning. These steps take away flaws and make a strong barrier. Less nickel ion release means fewer allergies and better healing. This makes the tubing safer for the body. Companies test for nickel ion release and follow rules like ISO 10993 and ASTM F2063 to keep patients safe.

Use electropolishing to smooth the surface and lower nickel ion release.

Apply passivation to build a stable oxide layer.

Test for nickel ion release after every treatment step.

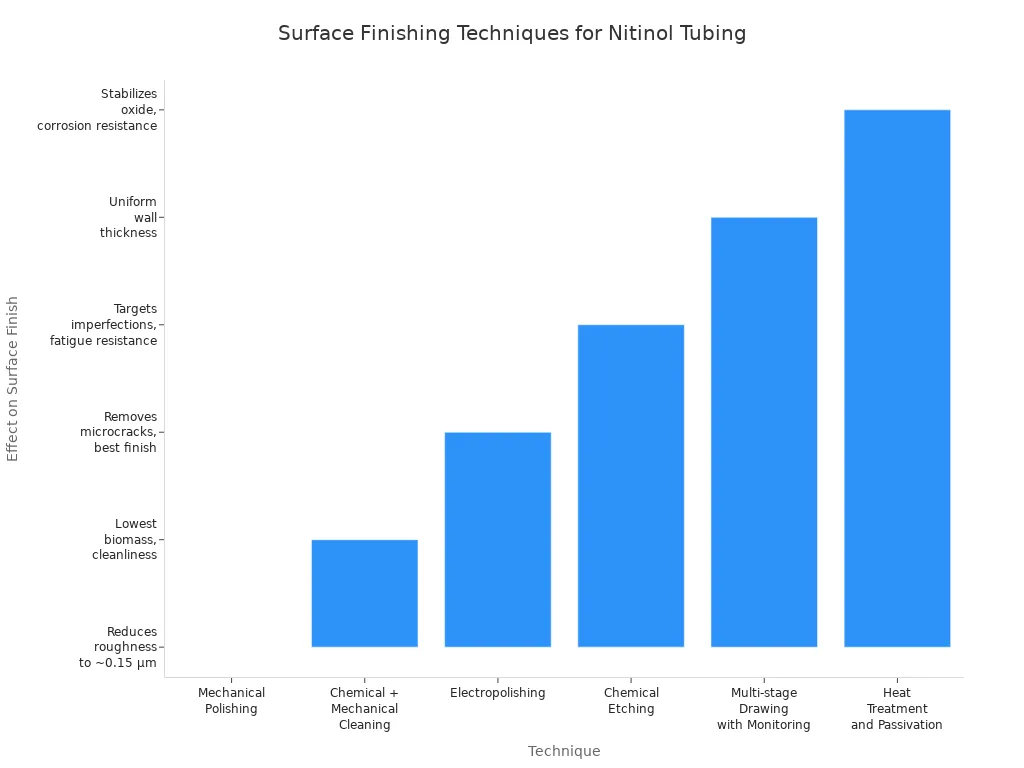

Achieving Uniform Surface Finish

A smooth and even surface helps nitinol tubing last longer. Smooth tubing lowers the chance of blood clots and helps cells grow. You can use mechanical polishing, chemical etching, or electropolishing to get a smooth finish. These methods remove tiny cracks and flaws. This makes the tubing stronger and safer for the body. The chart below shows how different finishing methods change nitinol tubing:

You should also check wall thickness and surface smoothness with special tools. Laser micrometers and surface profilometers help you do this. This makes sure your nitinol tubing meets strict medical rules and works well in the body.

Implementation Checklist

Step-by-Step Process

You can use easy steps to treat nitinol tubing. This helps make safe and strong medical devices. Here is a simple checklist you can follow:

Inspect the nitinol tubing

Look for dirt, glue, or damage. Make sure the tubing is clean before starting.Clean the surface

Use safe cleaning products. Take off all oils and scales. This gets the nitinol ready for more treatments.Apply mechanical or electropolishing

Pick the best method for your device. Electropolishing makes the surface smoother and lowers nickel release.Heat treat the nitinol

Set the shape and make a thin oxide layer. Watch the heat and time so the layer does not get too thick or break easily.Passivate the surface

Use nitric acid or other chemicals. Build a strong titanium dioxide layer. This step helps stop corrosion.Add coatings if needed

Use parylene or PVD coatings for extra safety. These coatings block nickel ions and keep the tubing bendy.Rinse and dry the tubing

Wash away any leftover chemicals. Dry the nitinol tubing in a clean place.

Tip: Write down each step. Take pictures and note the chemicals and times you use.

Quality Control

You need good quality checks to make sure your nitinol tubing treatment works. Use these steps to check your work:

Test for nickel ion release after every treatment.

Measure oxide layer thickness with a profilometer.

Look at the surface for cracks or rough spots.

Check wall thickness and how bendy the tubing is.

Keep records of all your tests and results.

Follow rules like ISO 13485 and ASTM F2063.

Quality Control Step | Tool/Method | What to Look For |

|---|---|---|

Nickel Ion Release Test | Chemical analysis | Low nickel levels |

Oxide Layer Thickness | Profilometer | Thin, even layer |

Surface Inspection | Microscope | No cracks or flaws |

Wall Thickness | Laser micrometer | Consistent measurements |

Note: Good records help you show your nitinol tubing is safe and meets medical rules.

Common Mistakes

Incomplete Cleaning

Some people think a quick rinse is enough. But this leaves oils, glue, and heat scale behind. These things can stop later treatments from working well. They also make the surface uneven. If you do not clean well, the tubing can rust more easily. It can also let out more nickel. Always take off all dirt before any surface treatment. Use safe cleaners and check the tubing with a microscope to find hidden spots.

Tip: Clean every nitinol tubing piece very well. Even a little dirt can make the device less safe.

Improper Oxide Layer Formation

If you do not watch the heat and oxygen, problems happen. The oxide layer can get too thick or not even. This layer might crack when the tubing bends. Cracks let nickel ions get out. Bad oxide layers also make the tubing weaker and easier to rust. Always check the heat treatment closely. Use the right heat and time to make a thin, even oxide layer. This helps keep biocompatibility high.

Inadequate Passivation

Some people skip or rush passivation. Without good passivation, the surface keeps more nickel and nickel oxide. This can hurt patients. Bad passivation also makes the tubing rust more. Use nitric acid or another safe way to make a strong titanium dioxide layer. Always test the tubing after passivation to make sure it is safe and stable.

Poor Rinsing and Storage

If you do not rinse well, chemicals stay on the nitinol. These chemicals can mix with body fluids and cause problems. Storing tubing in dirty or wet places can also cause rust and surface damage. Always rinse tubing with clean water and dry it in a dust-free place. Store finished tubing in sealed, dry containers.

Not checking if chemicals are safe for nitinol

Not following rules like ASTM F2063

Picking tubing just because it is cheap

Not finishing and treating the surface right

Letting heat from bad cutting or welding hurt the tubing

How to avoid these pitfalls:

Cut slowly and use sharp tools to lower heat and flaws.

Do not bend tubing too much to stop cracks.

Use the right heat treatment and cool it fast.

Use electropolishing or chemical etching to fix small cracks.

Test tubing for coating strength, rust resistance, and nickel release.

Buy from certified suppliers who follow all safety rules.

Remember: Being careful at every step keeps nitinol tubing safe and strong for medical use.

You can make nitinol tubing safer by cleaning it well. Controlling the oxide layer and using good passivation also help. These steps lower nickel release and make the tubing work better in the body.

Check your process to see if you missed any steps.

Add electropolishing or plasma treatments if you have not tried them.

Tip: Try a new surface treatment this month. You will notice better results and safer devices for patients.

FAQ

What is the best way to reduce nickel release from nitinol tubing?

You should use electropolishing and passivation. These treatments make the surface smooth and add a strong oxide layer. This helps stop nickel ions from getting out.

How do I know if my nitinol tubing is clean enough before treatment?

Check the tubing under a microscope. Look for any dirt, glue, or heat scale. If you see any, clean it again. Clean tubing helps all other treatments work better.

Can I skip passivation if I already electropolished the tubing?

No, you should not skip passivation. Electropolishing smooths the surface, but passivation adds extra protection. Both steps together give you the best corrosion resistance and safety.

Why does oxide layer thickness matter for nitinol tubing?

A thin, even oxide layer protects the tubing from rust and nickel release. If the layer is too thick, it can crack and make the tubing less safe.

What should I do if I see rust spots after treatment?

You should clean the tubing again and repeat passivation. Rust spots mean the surface is not protected well. Always check for rust before using the tubing in a device.

See Also

Comprehensive Overview of Nitinol Parts and Production Methods

The Process Behind Manufacturing Nitinol Tubing for Medicine

Detailed Instructions for Choosing Appropriate Nitinol Tubing

The Importance of Nitinol Tubing in Minimally Invasive Surgery