Why Medical Applications Rely on Surface-Treated Nitinol Tubing

Nitinol tubing surface treatment is very important in medicine. If nitinol tubing is not treated, it can let out nickel ions. These nickel ions can cause allergies, swelling, or even be poisonous. Studies show that after using nitinol devices, nickel in the blood goes up. Not every patient feels sick from this. Cracks and rust in nitinol can make the device break or cause big problems. Surface treatments make nitinol safer for the body. They help stop these issues and make nitinol tubing better and safer for medical devices.

Key Takeaways

Surface treatment on nitinol tubing stops bad nickel ions from leaking out. This makes medical devices safer for people. It also helps lower allergic reactions.

Treated nitinol tubing does not rust, crack, or wear out as fast. This means devices last longer and work better.

Electropolishing and heat treatment make a strong, smooth oxide layer. This layer protects the tubing. It also helps the body accept the tubing more easily.

Surface-treated nitinol tubing lowers the chance of blood clots and swelling. This helps patients heal faster and have fewer problems.

Cleaning and sterilizing treated nitinol tubing keeps devices safe and germ-free. This helps patients get better results.

Nitinol in Medical Applications

Unique Properties

Nitinol is special in medicine because of its amazing traits. It is a shape memory alloy. This means it can go back to its old shape after bending or stretching when it gets warm. This helps many medical devices that need to change shape inside the body.

Nitinol can bend and flex a lot without breaking.

It is strong and lasts a long time.

Nitinol acts like human tissue, so devices move with the body.

It is easy to shape into thin, bendy tubing for tricky devices.

The alloy does not rust and is safe for the body.

Nitinol works well at body temperature.

These things make nitinol great for less invasive surgeries. Doctors use nitinol devices to reach hard spots with less harm to patients.

Common Uses

Nitinol tubing is used in many medical tools. Its bendiness and strength help lots of devices. The most common uses are:

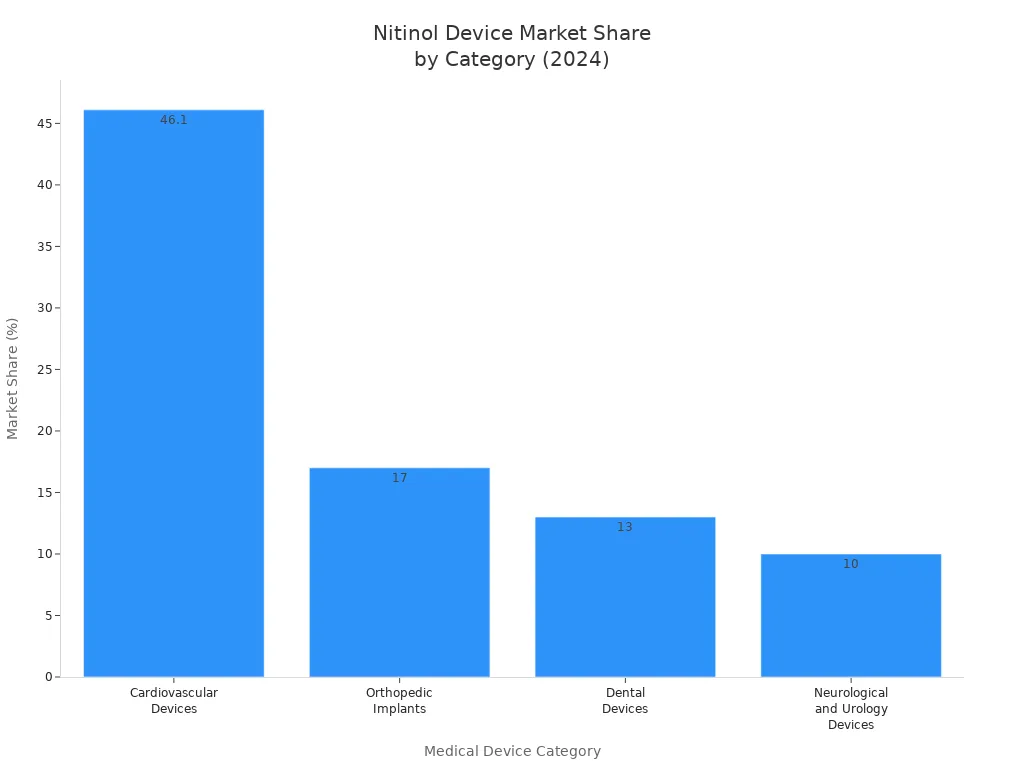

Medical Device Category | Common Usage in Nitinol Tubing Devices | Market Share / Revenue (2024) |

|---|---|---|

Cardiovascular Devices | Stents, guidewires, catheters, embolic protection devices, self-expanding stent-electrodes | Largest segment; stents hold 46.1% revenue share |

Cardiovascular segment revenue: USD 2.2 billion | ||

Orthopedic Implants | Use of nitinol tubing in fixation devices | Smaller share compared to cardiovascular |

Dental Devices | Dental archwires and related devices | Smaller share compared to cardiovascular |

Neurological and Urology Devices | Emerging applications with nitinol tubing | Smaller share compared to cardiovascular |

Cardiovascular devices use the most nitinol tubing. Stents and guidewires are the main ones. Hospitals use these for less invasive heart and blood vessel treatments. Orthopedic, dental, and brain tools also use nitinol, but not as much. More doctors want nitinol because it helps make treatments safer and better.

Untreated Nitinol Issues

Nickel Release

Untreated nitinol tubing can let nickel ions into the body. This happens because the surface has more nickel without a good oxide layer. If the oxide layer is thick but not stable, more nickel can get out in the body. The TiO2 oxide layer needs to be strong to keep nickel inside. If it is weak, nickel moves into the body more easily. Some people can get allergies or health problems from this.

Researchers saw that untreated nitinol breaks down faster. It has lower pitting potentials, so it lets out more nickel. This can happen quickly or over time. Treated nitinol makes a strong oxide layer. This keeps nickel inside and makes the tubing safer for medical use.

Note: If untreated nitinol releases a lot of nickel, it can be risky for patients who are sensitive to nickel.

Corrosion and Wear

Nitinol tubing without surface treatment gets more corrosion and wear. Corrosion is when metal reacts with body fluids. Untreated nitinol corrodes faster because it is not protected. Many studies show untreated nitinol has higher corrosion rates in fake body fluids. Clarke and Shabalovskaya found that surface treatments make the oxide layer thicker. This helps stop corrosion and lowers nickel release.

Untreated nitinol can also crack under stress. This makes the tubing less safe. Treated nitinol has a strong oxide layer. It resists cracking and corrosion. This helps medical devices last longer and work better.

Untreated nitinol: more corrosion, more nickel release, less safety.

Treated nitinol: better corrosion resistance, less nickel release, more reliability.

Nitinol Tubing Surface Treatment Methods

Surface treatment methods help make nitinol tubing safe for medical use. These methods stop too much nickel from coming out. They also help the tubing last longer and work well in the body. Each method fixes different problems like nickel release, rust, and how the tubing works with the body. The right surface treatment makes sure the tubing meets tough medical rules.

Chemical Techniques

Chemical techniques are common ways to treat nitinol tubing. They help take off bad layers and make a strong, safe finish.

Pickling: Takes off the oxide layer and some metal. This leaves a rough surface.

Etching: Takes off the oxide layer but keeps the surface smooth.

Etched and Mechanically Polished: Uses both chemical and mechanical steps. The tubing looks like stainless steel, but tiny scratches may still be there.

Chemical treatments lower how much nickel comes out of the tubing. Studies show that chemical passivation, like using hydrogen peroxide, helps stop nickel from leaking. This makes the tubing less harmful to cells. These treatments also help stop rust, so the tubing is safer. Research found that polished nitinol stents let out less nickel and resist rust better than untreated ones. In animal tests, polished stents had less nickel nearby and caused less reaction in tissue. This means they work better with the body.

Note: Good chemical polishing lowers nickel release and helps stop bad effects in the body. This step is important for making safe nitinol tubing for medical devices.

Mechanical and Electrochemical

Mechanical and electrochemical methods make the tubing surface even better. Mechanical polishing can fix surface problems, but it might leave small marks. These marks can make rust and nickel release worse. Electrochemical treatments, like electropolishing and anodization, give more even results.

Electropolishing makes the surface smooth and takes away tiny flaws. This creates a strong titanium dioxide layer. The layer helps stop rust and makes the tubing safer for the body. A smoother surface also helps cells stick to implants. Electropolishing works better than regular passivation because it makes a stronger protective layer. That is why it is used for top medical devices.

Electrochemical anodization puts special oxide layers on the tubing. These layers, like Ni2O3-doped TiO2 nanotubes, help the tubing work better in the body and stop rust. Tests show that chemical and electrochemical treatments protect the tubing better than just mechanical polishing. These methods help nitinol tubing meet strict medical standards.

Heat and Oxide Layer Formation

Heat treatment is another way to treat nitinol tubing. It helps set the tubing’s shape and makes protective oxide layers. When heated, nickel can move to the surface and form nickel oxides. Later, passivation steps remove these and add more titanium dioxide. This helps stop rust and nickel release.

Aspect | Evidence Summary |

|---|---|

Role of heat treatment | Makes a strong TiO2 layer that blocks nickel from getting out |

Oxide layer thickness | Best thickness is 50-80 nm to stop peeling and keep tubing flexible |

Composition changes | Heat treatment lowers nickel oxides and adds more titanium dioxide |

Mechanical stability | Good heat treatment makes the oxide layer stay strong when bent |

Corrosion resistance | TiO2 layer from heat treatment helps stop rust and works well in the body |

Surface modification methods | Plasma oxidation and careful heating make the oxide layer better and more even |

The thickness and type of oxide layer from heat treatment matter a lot. A thin, even titanium dioxide layer stops nickel from getting out and keeps the tubing from rusting. If the layer is too thick, it can trap nickel and let more out if the tubing bends. Surface treatments like electropolishing after heating make the oxide layer thinner and more even. This helps stop nickel release and rust.

Careful control of heat treatment, wall thickness, and surface finish keeps nitinol tubing safe for medical use. By watching these things, makers can make tubing that works well in the body and lasts a long time.

Surface Treatment Benefits

Biocompatibility

Biocompatibility is very important for medical devices with nitinol tubing. Surface treatments like electropolishing make the tubing smooth and flat. This smooth finish helps stop platelets and proteins from sticking. It lowers the chance of blood clots. Electropolished nitinol tubing lets out fewer nickel ions. This makes it safer for people and lowers allergic or toxic reactions.

Electropolished tubing does not start the blood’s clotting system as much.

Platelets stick less to treated tubing, so clots are less likely.

Endothelial cells grow better on electropolished tubing.

Treated tubing forms a thin layer of titanium oxynitride or titanium oxide. This helps the body accept the device.

Blood tests show electropolished stents keep blood cell counts steady. Untreated ones do not.

Inflammatory markers stay lower on treated tubing, so there is less irritation.

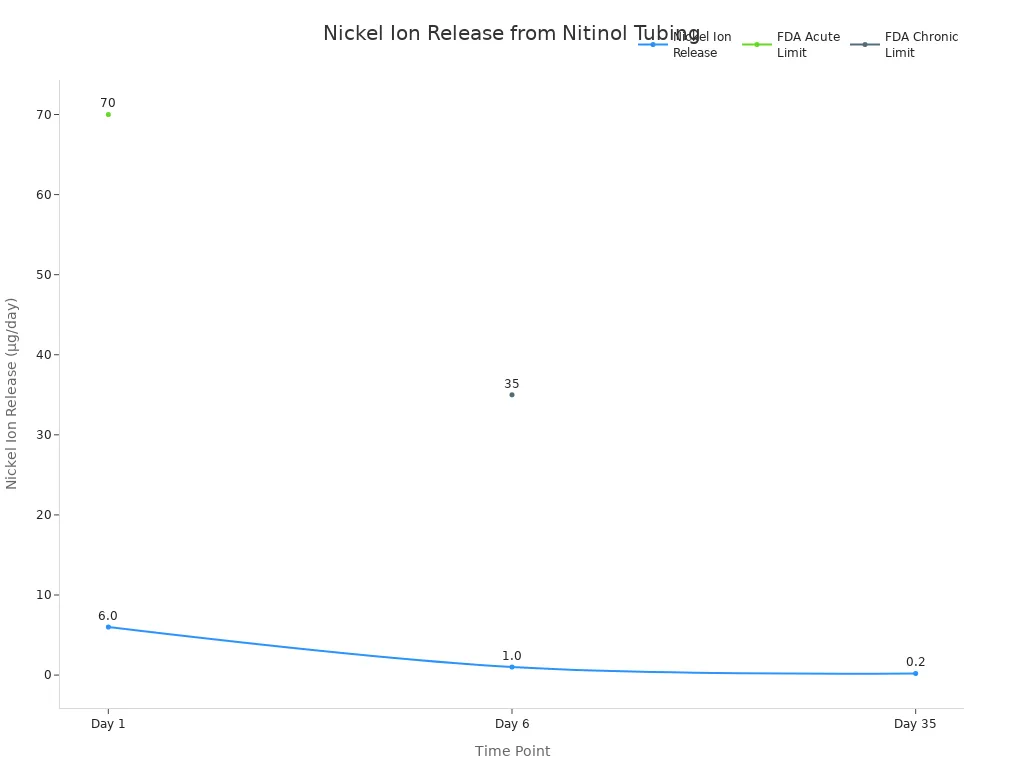

These changes mean nitinol tubing with surface treatment causes fewer problems. Patients have better results. Medical uses with treated nitinol tubing have less risk of clots and swelling. Groups like the FDA set strict rules for nickel ion release to keep people safe. The table below shows how treated tubing meets these rules:

Parameter | Measured Values | Regulatory Limits |

|---|---|---|

Nickel Ion Release Day 1 | ~6.0 µg/day (max 7.6 µg/day) | FDA acute limit: 70 µg/day |

Nickel Ion Release Day 6 | ~1 µg/day | FDA chronic limit: 35 µg/day |

Nickel Ion Release Day 35 | ~0.2 µg/day | - |

Surface-treated nitinol tubing not only meets but often beats these safety rules. This high biocompatibility helps nitinol work well in sensitive medical uses.

Regulatory groups want clear labels for nickel sensitivity. They also want regular checks to keep devices safe.

Durability and Fatigue Resistance

Durability and fatigue resistance matter for implants that stay in the body. Small cracks or rough spots can make nitinol tubing weak. These flaws can cause the tubing to break after many uses. Surface treatments like electropolishing take away these flaws. This makes the tubing smooth and stops rust.

Smooth tubing lowers crack risk and helps it last longer.

Hydrophilic and polymer coatings make tubing slippery. This helps when putting it in and lowers wear.

The titanium dioxide layer from treatment stops rust and keeps tubing safe for the body.

Careful finishing and coatings stop nickel from wearing off. This is important for safety.

Medical nitinol tubing must meet tough rules for surface quality. Smoother tubing also stops bacteria from sticking. This lowers infection risk. Surface treatments help nitinol tubing last through millions of bends without breaking. This makes it good for long-term medical devices.

Studies show these treatments help nitinol devices last longer and work better. The better oxide layer lowers nickel ion release. It also makes tubing stronger and safer for the body.

Tissue Integration

Tissue integration means the body accepts and grows around the implant. Surface treatments change the oxide layer on nitinol tubing. This adds more titanium oxide and lowers nickel release. These changes help cells stick and grow on the tubing. This is important for healing.

Treated tubing helps bone cells grow and bond with tissue.

The right roughness and pore size help tissue grow into the implant.

Special coatings, like phosphate ions, lower clot risk and help blood vessel cells cover the tubing.

Tests show surface-treated nitinol tubing causes less clotting and better healing. Treated implants have less swelling and more stable tissue growth. These benefits make treated nitinol tubing a good choice for implants that need to work with the body.

Cleaning and Sterility

Keeping nitinol tubing clean and sterile is very important for safety. Surface-treated tubing needs special cleaning and sterilizing steps. The right cleaning agents must not hurt the tubing or any metal coating. Tubing must be fully dry before sterilizing to avoid problems.

Ethylene oxide sterilizing works well for nitinol but may hurt some coatings.

Autoclaving is good for metal-coated parts but may not fit all nitinol tubing.

Each device needs careful review of cleaning and sterilizing steps to keep it safe.

Some surface treatments, like alumina or hydroxyapatite coatings, help stop bacteria and improve safety. These coatings can block nickel and lower infection risk after surgery.

Surface Treatment Type | Key Properties and Effects | Relation to Microbial Contamination Resistance |

|---|---|---|

Alumina (Al2O3) coating via MAO | Stops rust and wear; safe for the body; porous surface helps cells grow | Blocks nickel release; stops bacteria; makes implant safer |

Hydroxyapatite coating | Put on without electricity; blocks nickel release | Stops bacteria |

Iodine coating | Kills bacteria | Stops bacteria |

Nano-silver coating | Kills bacteria | Stops bacteria |

Composite thermal insulation coating | Lowers heat damage during use; stops nickel release | May lower bacteria risk during surgery |

Careful cleaning and sterilizing checks make sure nitinol tubing stays safe and works well for patients.

Surface-treated nitinol tubing helps patients do better, have fewer problems, and meet strict rules. These benefits help medical devices last longer and work better, making nitinol a trusted choice in healthcare.

Surface treatment is very important for using nitinol tubing safely in medicine. Experts say that special finishing steps like electropolishing help the tubing work better with the body and last longer. Companies use these treatments to follow tough rules and keep patients safe. As more nitinol tubing is used around the world, doctors should always think about surface treatment when picking materials for new devices.

FAQ

What is the main reason for treating the surface of nitinol tubing?

Surface treatment helps stop nickel from coming out. It also keeps the tubing from rusting. This makes nitinol tubing safer for people. Medical devices last longer and work better when treated.

How does surface-treated nitinol tubing help prevent allergic reactions?

A strong oxide layer forms on the tubing during treatment. This layer keeps nickel ions from getting into the body. People who are sensitive to nickel have less chance of allergies.

Can surface-treated nitinol tubing be used in all types of medical devices?

Most heart, bone, and dental devices use treated nitinol tubing. Makers pick the best treatment for each device. Not every device needs the same kind of treatment.

Does surface treatment affect the strength of nitinol tubing?

Surface treatment can make tubing stronger by fixing small cracks. A smooth surface helps stop breaking and wearing out. Devices become tougher and last longer.

How do manufacturers ensure nitinol tubing stays clean and sterile?

Manufacturers use special ways to clean and sterilize tubing. They pick cleaners that do not hurt the tubing or its coating. Careful drying and checking keep tubing safe for patients.

See Also

Discovering How Nitinol Tubing Enhances Healthcare Equipment

The Importance Of Nitinol Tubing In Modern Medical Uses

Nitinol Tubing's Impact On Progressing Medical Innovations