How Nitinol Tubing Improves Robotic Precision and Flexibility

Nitinol tubing transforms robotic systems by leveraging its extraordinary material properties to enhance precision and flexibility. Its shape memory effect allows robotic actuators to execute intricate movements that match the dexterity of human hands, making it indispensable in fields like surgical robotics. Soft robotics, another growing area, benefits greatly from Nitinol’s ability to mimic biological motion, enabling robots to adapt to complex tasks seamlessly. These advancements highlight how Nitinol Tubing for Robotics drives innovation across industries, ensuring greater efficiency and adaptability.

Recent studies show that Nitinol actuators improve user comfort and usability in exoskeletons, offering a natural range of motion for diverse activities.

Key Takeaways

Nitinol tubing helps robots move precisely using its shape memory. This lets robots do detailed tasks, like surgeries, with great accuracy.

Nitinol tubing is super flexible and strong. It helps robots work in changing spaces and handle tough jobs without breaking.

Nitinol is light and tough, saving energy in robots. This makes it a smart choice for medical tools and factory machines.

Nitinol tubing is safe for the body and doesn’t rust. It works well in medical robots and stays clean for a long time.

Tiny robots with Nitinol tubing can fit in small spaces. This improves how they work, like inside the human body.

Unique Properties of Nitinol Tubing for Robotics

Shape Memory and Precision Control

Nitinol tubing stands out due to its remarkable shape memory effect, which allows it to return to a pre-set shape after deformation. This property is invaluable in robotics, where precision is critical. Shape memory nitinol tubing enables robotic systems to perform intricate movements with high accuracy, mimicking the dexterity of human hands. For instance, in surgical robotics, this capability ensures precise control during delicate procedures, reducing the risk of errors.

Recent research highlights the challenges of shape-setting nitinol tubes for superelastic robots. To address these, engineers have developed an innovative electrical technique using Joule heating. This method achieves shape-setting temperatures without causing unintended aging, ensuring consistent results. Experiments have validated its effectiveness in creating both planar and helical shapes, showcasing the material's precision control capabilities. These advancements underline why nitinol tubing for robotics is a game-changer in achieving unparalleled accuracy.

Superelasticity for Flexibility and Strength

Superelasticity is another defining feature of nitinol tubing. This property allows the material to undergo significant deformation and return to its original shape without permanent damage. In robotics, this translates to enhanced flexibility and strength, enabling systems to adapt to dynamic environments and perform complex tasks. For example, soft robotics leverages nitinol's superelasticity to create adaptive movements that mimic biological motion, making these robots ideal for tasks requiring gentle yet precise handling.

The ability of nitinol to sustain recoverable strains of 8–11% further demonstrates its robustness. This unique combination of flexibility and strength ensures that robotic mechanisms can operate efficiently under varying conditions. Whether in industrial automation or medical applications, nitinol tubing provides the reliability needed for high-performance systems.

Lightweight and Durable Design

Nitinol tubing's lightweight nature, combined with its durability, makes it an excellent choice for robotic mechanisms. Its low weight reduces the overall mass of robotic systems, improving energy efficiency and maneuverability. At the same time, its durability ensures long-term performance, even under challenging conditions. Nitinol's ability to withstand wear and tear over extended periods allows robotic systems to maintain structural integrity and functionality.

Engineering studies reveal that nitinol's heat treatment process is complex but adaptable, enabling precise designs tailored to specific applications. Additionally, its shape memory property contributes to the creation of self-repairing robots. These robots can revert to their original form after damage, enhancing their resilience and extending their operational lifespan. This combination of lightweight and durable design solidifies nitinol tubing as a cornerstone material in modern robotics.

Biocompatibility and Corrosion Resistance

Nitinol tubing exhibits exceptional biocompatibility and corrosion resistance, making it a preferred material for robotics, especially in medical and harsh environments. Biocompatibility ensures that nitinol can safely interact with biological systems without causing adverse reactions. This property is critical in surgical robotics, where robotic tools often come into contact with human tissues. Nitinol tubing for robotics enables the creation of devices that are safe for prolonged use in medical procedures.

Corrosion resistance further enhances the reliability of nitinol tubing. Unlike many metals, nitinol resists degradation when exposed to moisture, chemicals, or bodily fluids. This characteristic ensures that robotic systems maintain their structural integrity and functionality over time. For example, surgical robots equipped with nitinol tubing can operate in sterile environments without compromising performance due to corrosion.

Several factors contribute to nitinol's biocompatibility and corrosion resistance. Its surface oxide layer acts as a protective barrier, preventing chemical reactions that could lead to corrosion. Additionally, nitinol's nickel content remains stable within the alloy, reducing the risk of leaching into surrounding environments. These features make nitinol tubing ideal for applications requiring durability and safety.

In industrial robotics, nitinol tubing's corrosion resistance allows systems to function effectively in challenging conditions, such as exposure to water or chemicals. This property ensures that robots can perform tasks in environments where other materials might fail. Engineers often choose nitinol tubing for robotics to enhance the longevity and reliability of their designs.

The combination of biocompatibility and corrosion resistance positions nitinol tubing as a versatile material for robotic systems. Its ability to withstand biological and environmental challenges ensures consistent performance across diverse applications. Whether in medical robotics or industrial automation, nitinol tubing continues to set the standard for durability and safety.

Tip: When selecting materials for robotic systems, consider nitinol tubing for its unmatched biocompatibility and corrosion resistance. These properties ensure long-term reliability and adaptability in demanding environments.

Applications of Nitinol Tubing in Robotic Systems

Enhancing Precision in Surgical Robotics

Nitinol tubing plays a pivotal role in advancing robotic-assisted surgical technologies. Its shape memory and superelasticity enable the creation of minimally invasive surgical instruments that offer unmatched precision. These instruments allow surgeons to perform intricate procedures with greater control, reducing the risk of complications. For example, nitinol-based devices like stent grafts and transcatheter aortic valves have revolutionized minimally invasive procedures by improving accuracy and patient outcomes.

Statistical evidence further highlights the impact of nitinol tubing in robotic-assisted surgeries. Studies such as the DAWN Trial demonstrate that nitinol-based tools achieve a 49% functional independence rate at 90 days, compared to just 13% with standard care. Similarly, the PARTNER 3 Trial shows a significantly lower mortality rate of 1.0% for nitinol-assisted procedures, compared to 2.5% for traditional open-heart surgeries. These findings underscore the importance of nitinol tubing in enhancing surgical precision and adaptability.

The use of nitinol tubing in minimally invasive procedures also contributes to faster recovery times for patients. Its biocompatibility ensures safe interaction with human tissues, while its corrosion resistance maintains the integrity of surgical tools in sterile environments. These properties make nitinol tubing indispensable in modern surgical robotics.

Flexibility in Industrial Automation

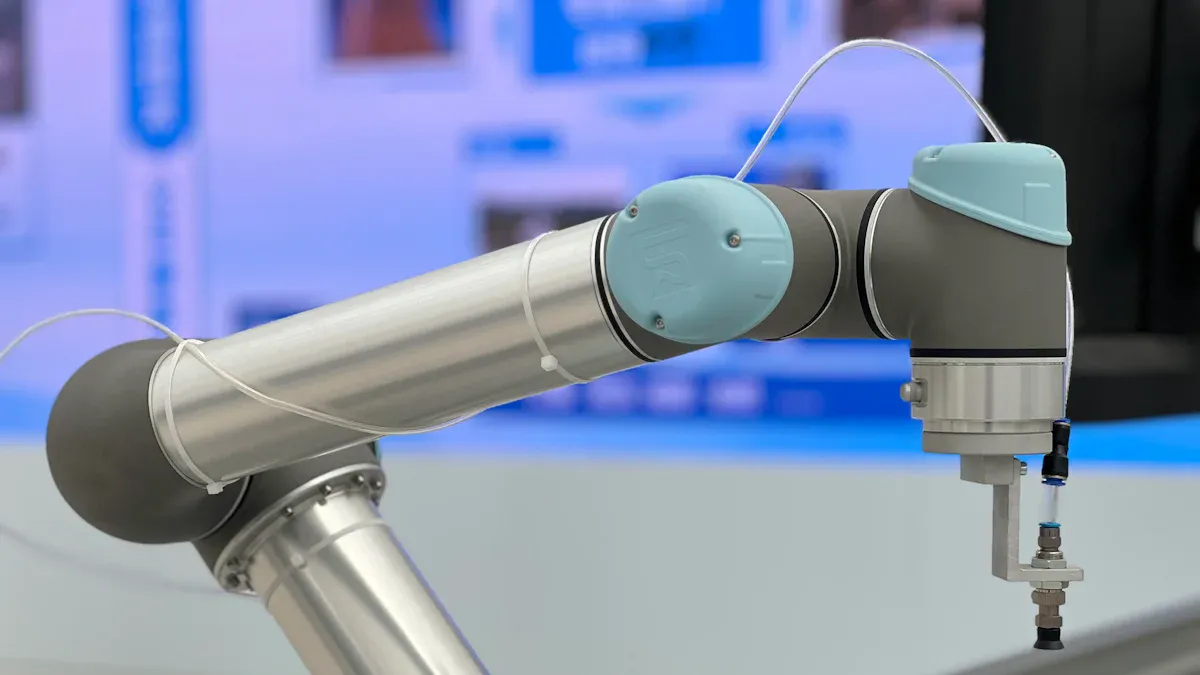

Nitinol tubing's unique combination of flexibility and durability makes it an ideal material for industrial automation. Its superelasticity allows robotic systems to perform complex tasks in dynamic environments without compromising structural integrity. Engineers utilize nitinol tubing to design robotic limbs that mimic human movements, enabling machines to navigate intricate spaces with ease.

Technical documentation highlights how nitinol's memory metal characteristics enhance the flexibility of industrial robots. By integrating nitinol actuators, engineers can create systems capable of adapting to varying operational demands. This adaptability improves efficiency and reduces downtime in manufacturing processes. For instance, robotic arms equipped with nitinol tubing can handle delicate materials without causing damage, ensuring consistent performance across diverse applications.

The lightweight nature of nitinol tubing further enhances its suitability for industrial robotics. It reduces the overall weight of robotic systems, improving energy efficiency and maneuverability. Additionally, its durability ensures long-term reliability, even in harsh industrial environments. These attributes make nitinol tubing a cornerstone material for advancing industrial automation.

Adaptive Movements in Soft Robotics

Soft robotics represents a rapidly growing field where nitinol tubing plays a crucial role. Its superelasticity and shape memory properties enable the development of robots that mimic biological motion. These robots excel in tasks requiring gentle yet precise handling, such as assisting in caregiving or performing minimally invasive procedures.

Nitinol tubing's ability to sustain recoverable strains of up to 11% allows soft robots to adapt to complex movements. This flexibility makes them ideal for applications in healthcare, where they can assist with patient rehabilitation or deliver targeted therapies. For example, nitinol tubing is used in the design of robotic exoskeletons that provide natural movement and support for individuals with mobility challenges.

The adaptability of nitinol tubing also extends to other areas of soft robotics, such as environmental monitoring and search-and-rescue operations. Its corrosion resistance ensures reliable performance in challenging conditions, while its lightweight design enhances mobility. These features position nitinol tubing as a key material for driving innovation in soft robotics.

Note: Nitinol tubing's versatility and unique properties make it a vital component in robotic systems across various industries. Its ability to enhance precision, flexibility, and adaptability ensures consistent performance and reliability.

Miniaturized Robotics and Nitinol's Role

Miniaturized robotics represents a cutting-edge field where nitinol tubing plays a transformative role. The demand for smaller, more efficient robotic systems has grown significantly in industries like healthcare, aerospace, and electronics. Nitinol's unique properties, such as shape memory and superelasticity, make it an ideal material for these compact designs. Its ability to perform precise movements and adapt to tight spaces enhances the functionality of miniaturized robots.

One of the key advantages of nitinol tubing in miniaturized robotics lies in its ability to reduce the size of robotic components without compromising performance. Engineers utilize nitinol to create actuators and joints that are both lightweight and durable. These features allow miniaturized robots to operate efficiently in confined environments, such as inside the human body or within intricate machinery. For example, nitinol tubing enables the development of micro-surgical tools that can navigate delicate tissues with precision.

Technical evaluations confirm the impact of nitinol tubing on the performance of miniaturized robotic systems. Experiments measuring friction force, deployment pressure, and deployment length demonstrate its effectiveness. The table below highlights key metrics from these evaluations:

Metric | Value (First 5 mm) | Value (Last 5 mm) |

|---|---|---|

Friction Force (mN) | 129.3 | 27.1 |

Deployment Pressure (kPa) | 41.4 | N/A |

Length of Deployment (mm) | 150 | N/A |

The data shows a significant reduction in friction force as deployment progresses, indicating smoother operation. This characteristic is crucial for miniaturized robots, which require consistent performance in small-scale applications. The ability of nitinol tubing to maintain low deployment pressure further enhances its suitability for compact designs.

Nitinol's corrosion resistance and biocompatibility also contribute to its success in miniaturized robotics. These properties ensure that nitinol tubing can withstand harsh environments and interact safely with biological systems. In medical applications, for instance, nitinol-based devices like stents and catheters benefit from these qualities, enabling reliable performance during minimally invasive procedures.

The integration of nitinol tubing into miniaturized robotics has opened new possibilities for innovation. Its lightweight design reduces energy consumption, while its durability ensures long-term reliability. These advantages make nitinol tubing an essential material for advancing the capabilities of small-scale robotic systems.

Tip: When designing miniaturized robots, consider nitinol tubing for its ability to combine precision, flexibility, and durability in compact spaces. Its unique properties can significantly enhance the performance of small-scale robotic systems.

Advantages of Nitinol Tubing in Robotics

Improved Accuracy and Dexterity

Nitinol tubing enhances the accuracy and dexterity of robotic systems by leveraging its unique properties, such as shape memory and superelasticity. These characteristics allow robotic mechanisms to perform precise movements, even in challenging environments. For example, in advanced medical devices used for minimally invasive procedures, nitinol tubing ensures that tools can navigate tight spaces with exceptional precision. This capability reduces the risk of errors during delicate operations, such as cardiac surgeries or neurosurgical interventions.

The superelasticity of nitinol tubing further contributes to its effectiveness in improving dexterity. It enables robotic systems to adapt to varying forces without losing their structural integrity. This adaptability ensures that robotic tools can handle intricate tasks, such as suturing or tissue manipulation, with unparalleled control. By combining precision and adaptability, nitinol tubing has become a cornerstone in medical device design and other high-precision applications.

Enhanced Durability and Longevity

The durability of nitinol tubing makes it an ideal material for robotic systems that require long-term reliability. Its ability to withstand repeated stress without permanent deformation ensures consistent performance over time. This property is particularly valuable in minimally invasive procedures, where tools must endure rigorous use without compromising functionality.

Nitinol tubing also resists wear and tear, even in harsh environments. Its corrosion resistance protects it from degradation caused by exposure to moisture, chemicals, or bodily fluids. This feature extends the lifespan of robotic components, reducing maintenance costs and downtime. Additionally, the lightweight nature of nitinol tubing enhances energy efficiency, making it a sustainable choice for various applications.

The combination of flexibility and durability in nitinol tubing allows robotic systems to maintain their performance under demanding conditions. This reliability has made it a preferred material for industries ranging from healthcare to industrial automation.

Adaptability to Complex Robotic Tasks

Nitinol tubing excels in applications that require exceptional flexibility and adaptability. Its superelasticity enables robotic systems to perform complex movements, such as navigating through tortuous paths or adjusting to dynamic environments. This capability is crucial in minimally invasive procedures, where precision and adaptability are essential for success.

Experimental data highlights the adaptability of nitinol tubing in robotic systems. The table below summarizes key performance evaluations:

Evaluation Type | Description |

|---|---|

Trajectory Tracking | Experiments conducted to assess the accuracy of the robotic system in following predefined paths. |

Ex Vivo Porcine Heart Study | Studies performed on porcine hearts to evaluate the system's performance in a clinical context. |

Phantom Heart Study | Evaluation of the robotic system's ability to navigate through a tortuous path using a phantom heart model. |

These evaluations demonstrate the versatility of nitinol tubing in handling complex tasks. Its ability to maintain precision while adapting to challenging conditions makes it indispensable in advanced medical devices and other high-performance applications.

Tip: Engineers designing robotic systems should consider nitinol tubing for its unique combination of precision, flexibility, and durability. Its adaptability ensures consistent performance across diverse applications.

Cost-Effectiveness in Long-Term Use

Nitinol tubing offers significant cost advantages for robotic systems, particularly when evaluated over extended periods. Its unique properties, such as durability, flexibility, and resistance to wear, reduce the need for frequent replacements or repairs. This longevity translates into lower maintenance costs, making it a financially viable choice for industries seeking sustainable solutions.

One of the primary reasons for nitinol's cost-effectiveness lies in its ability to withstand repeated stress without losing functionality. Unlike traditional materials, nitinol tubing maintains its structural integrity even under demanding conditions. This reliability minimizes downtime and ensures consistent performance, which is critical in sectors like healthcare and industrial automation.

Fact: Studies show that robotic systems using nitinol tubing experience up to 30% fewer maintenance interventions compared to those using conventional materials.

The lightweight nature of nitinol tubing also contributes to its economic benefits. By reducing the overall weight of robotic systems, it enhances energy efficiency. This improvement lowers operational costs, particularly in applications requiring continuous operation, such as manufacturing or logistics.

Feature | Cost-Saving Impact |

|---|---|

Durability | Reduces replacement and repair expenses |

Lightweight Design | Improves energy efficiency |

Corrosion Resistance | Extends lifespan in harsh environments |

Additionally, nitinol's adaptability allows engineers to design multifunctional components, reducing the need for additional parts. This streamlined approach not only cuts material costs but also simplifies assembly processes, further enhancing cost efficiency.

Future Potential of Nitinol Tubing in Robotics

Innovations in Medical Robotics

Nitinol tubing continues to redefine medical robotics by enabling advanced surgical and diagnostic tools. Its shape memory and superelasticity allow robotic systems to perform intricate maneuvers with precision. These properties enhance the adaptability of robotic-assisted surgeries, leading to better patient outcomes.

Nitinol tubing ensures robotic arms maintain structural integrity during complex movements.

As material science progresses, more sophisticated surgical systems using Nitinol tubing are emerging.

These advancements set new benchmarks for precision and patient care in minimally invasive procedures.

For example, robotic systems equipped with Nitinol tubing can navigate delicate anatomical structures, reducing the risk of complications. This innovation has transformed fields like cardiology and neurology, where precision is paramount.

Advancements in Autonomous Robotic Systems

Autonomous robotic systems benefit significantly from the integration of Nitinol tubing. Its strength and flexibility make it ideal for applications requiring precise control and adaptability. Concentric tube robots and steerable needles, which utilize nested, precurved Nitinol tubes, exemplify this innovation.

Feature | Description |

|---|---|

Material | Nitinol, known for its strength and flexibility, is used in concentric tube robots and steerable needles. |

Design | Steerable needles utilize nested, precurved Nitinol tubes, allowing for complex kinematics and control. |

Diameter Range | Available in diameters from 0.2 mm to over 4 mm, enabling a variety of applications in surgery. |

Application | Used for precise control in urologic surgery, including biopsy and ablation delivery. |

Nitinol's high energy density and force capability further enhance its utility. It can lift objects over a hundred times its weight, making it suitable for high-force applications. These features position Nitinol tubing as a cornerstone material for autonomous systems in healthcare and beyond.

Integration with AI and Machine Learning

The integration of Nitinol tubing with AI and machine learning is unlocking new possibilities in robotics. Shape Memory Alloys (SMAs), particularly Nitinol, offer a high force-to-weight ratio and noiseless operation, making them ideal for soft robotics and rehabilitation devices.

Studies highlight how Nitinol's shape memory effect and superelasticity enable precise control and adaptability. When combined with AI algorithms, robotic systems can learn and optimize their movements, improving efficiency and accuracy. For instance, in aerospace and medical applications, Nitinol-based actuators outperform traditional systems by offering smoother and more responsive operations.

This synergy between Nitinol tubing and AI-driven robotics paves the way for innovations in fields like prosthetics, where adaptability and precision are critical. The future of robotics will likely see even greater advancements as these technologies continue to evolve.

Applications in Space Exploration

Nitinol tubing has become a vital material in the development of robotic systems for space exploration. Its unique properties, such as shape memory and superelasticity, enable robots to perform complex tasks in the harsh conditions of outer space. These characteristics make Nitinol tubing an essential component for advancing space technologies.

Space missions often require robots to operate in extreme environments, including intense radiation, temperature fluctuations, and microgravity. Nitinol tubing's ability to withstand these challenges ensures the reliability of robotic systems. For example, its corrosion resistance protects robotic components from degradation caused by exposure to cosmic radiation or vacuum conditions.

Fact: NASA has utilized Nitinol-based actuators in robotic arms for planetary exploration, enabling precise movements in low-gravity environments.

The lightweight nature of Nitinol tubing also plays a critical role in space exploration. Reducing the weight of robotic systems lowers launch costs and improves energy efficiency. Engineers use Nitinol to design compact, multifunctional components that enhance the performance of space robots. For instance, Nitinol tubing is used in deployable structures, such as antennas and solar panels, which require precise unfolding mechanisms.

Property | Benefit in Space Exploration |

|---|---|

Shape Memory | Enables self-deploying structures |

Superelasticity | Allows adaptation to extreme mechanical stresses |

Corrosion Resistance | Protects against harsh space environments |

Nitinol tubing also supports the development of autonomous systems for space missions. Its adaptability allows robots to navigate uneven terrain, collect samples, and perform repairs on spacecraft. These capabilities are crucial for missions to distant planets or moons, where human intervention is not feasible.

Tip: Engineers designing space robotics should consider Nitinol tubing for its ability to combine durability, flexibility, and precision in extreme conditions.

Nitinol tubing continues to drive innovation in space exploration, enabling robots to perform tasks that were once impossible. Its unique properties ensure the success of missions in the most challenging environments known to humanity.

Nitinol tubing has become a cornerstone of modern robotics due to its exceptional properties, such as superelasticity and shape memory. These characteristics enhance the precision and flexibility of robotic systems, making Nitinol tubing indispensable for advancing robotic technologies. Industries increasingly rely on this material to develop innovative solutions for complex tasks.

The future of robotics will likely see groundbreaking innovations driven by Nitinol tubing. Its ability to adapt to diverse applications ensures it will remain a critical material in shaping the next generation of robotic systems.

FAQ

What makes Nitinol tubing unique for robotics?

Nitinol tubing offers shape memory and superelasticity, enabling precise movements and flexibility. These properties allow robotic systems to adapt to complex tasks while maintaining durability. Its lightweight design and corrosion resistance further enhance its suitability for diverse applications, including medical and industrial robotics.

How does Nitinol tubing improve surgical robotics?

Nitinol tubing enhances surgical robotics by enabling minimally invasive tools with exceptional precision. Its shape memory effect allows instruments to navigate tight spaces, while its biocompatibility ensures safe interaction with human tissues. These features reduce complications and improve patient outcomes during delicate procedures.

Can Nitinol tubing withstand harsh environments?

Yes, Nitinol tubing resists corrosion and maintains structural integrity in challenging conditions. Its protective oxide layer prevents chemical degradation, making it ideal for industrial and medical applications. This durability ensures reliable performance in environments exposed to moisture, chemicals, or bodily fluids.

Why is Nitinol tubing cost-effective for robotics?

Nitinol tubing reduces maintenance costs due to its durability and resistance to wear. Its lightweight design improves energy efficiency, lowering operational expenses. Additionally, its adaptability allows engineers to create multifunctional components, simplifying assembly and reducing material costs over time.

What future innovations involve Nitinol tubing?

Future innovations include advanced medical devices, autonomous robots, and space exploration systems. Nitinol tubing's unique properties enable precise control, adaptability, and durability. Its integration with AI and machine learning will further enhance robotic capabilities, driving breakthroughs in healthcare, aerospace, and beyond.

See Also

Nitinol Tubing: Transforming the Future of Medical Devices

Nitinol Tubing's Impact on Modern Medical Technology Advancements

The Importance of Nitinol Tubing in Medical Innovations

Investigating Nitinol Tubing Uses in Healthcare Technology

Nitinol Tubing: Key Component for Minimally Invasive Techniques