How is Nitinol tubing processed and what equipment is used

Manufacturers make nitinol tubing act in a special way by using a careful process. They must be exact at every step. The nickel-to-titanium ratio and size are very important. These things decide how the tubing bends and remembers its shape. Making nitinol tubing needs advanced Nitinol Tubing processing equipment. This equipment keeps the tubing pure and even inside. It also helps the tubing meet tough rules. These steps help nitinol work well in medical and aerospace jobs. Small mistakes in the process can make the tubing not work right or break.

Key Takeaways

Careful mixing and weighing of nickel and titanium help nitinol tubing bend well and keep its shape. Advanced melting and casting methods make the tubing pure and strong by controlling tiny bits and grain size. Hot working, tube drawing, and heat treatment shape the tubing and make it flexible and tough. Laser cutting, electropolishing, and ultrasonic cleaning make smooth and exact tubes that do not rust and follow strict medical rules. Careful checking and mechanical testing make sure the tubing is safe, works well, and is great for hard medical and aerospace uses.

Alloying and Melting

Advanced Weighing

Making nitinol tubing starts with picking the right materials. Engineers use very pure nickel and titanium. They measure these metals with special weighing tools. The tools are very accurate. If the nickel-to-titanium ratio is off, the tubing may not bend or remember its shape. The weighing system checks every batch before mixing. This makes sure the tubing meets strict rules for medical and aerospace jobs. Careful picking and weighing help control how the tubing works.

Tip: Being exact when weighing helps nitinol tubing work the same way every time.

Aspect | Details |

|---|---|

Nickel Content | 54.5-57% by weight, with tight tolerance of ±0.05% |

Titanium Content | Balance of the alloy (remainder after nickel) |

Oxygen Impurity Level | Below 500 ppm |

Carbon Impurity Level | Below 300 ppm |

Nitrogen Impurity Level | Below 50 ppm |

Composition Verification | Inductively Coupled Plasma (ICP) Spectroscopy |

Impurity Control | Vacuum Induction Melting and Vacuum Arc Remelting processes to minimize impurities |

Vacuum Arc Remelting (VAR)

After weighing, the team puts the pure nickel and titanium into the Vacuum Arc Remelting furnace. The VAR process melts the metals in a vacuum. This step gets rid of unwanted gases and impurities. The vacuum keeps the nitinol tubing clean and pure. Engineers watch the melting to make sure the metals mix well. The VAR furnace helps control what is in the tubing and keeps it pure. This is very important for making nitinol tubing.

Ingot Casting

When the VAR process is done, the melted nitinol goes into molds. The cooling system controls how fast the tubing gets solid. Slow cooling makes bigger grains. Fast cooling makes smaller grains. Directional solidification helps grains line up better. Continuous casting uses quick cooling for a more even microstructure. Engineers change cooling speeds for each tubing job. Careful casting helps the tubing have the right strength and flexibility.

Hot Working and Tube Forming

Forging and Rolling

Engineers heat nitinol alloy to very high temperatures. The temperature is between 600°C and 1050°C. Forging and rolling machines squeeze and stretch the nitinol. These machines work while the tubing is still hot. This helps make the grains inside the tubing smaller and even. Small grains make the tubing stronger and harder. Heat and pressure together can make grains even smaller. The grains line up better, which helps the tubing bend and last longer. After hot working, engineers use cold working to make the tubing stronger. Cold working adds stress inside the tubing. A heat treatment is needed to remove these stresses. Forging and rolling are important steps for shaping nitinol tubing.

Note: Special temperature control systems keep the heat just right. Sensors and controllers help the tubing stay at the correct temperature. This stops the tubing from getting too hot or cooling too fast. Good temperature control protects the tubing’s structure.

Capillary Nitinol Tubes

Capillary nitinol tubes need very exact sizes. This is extra important for medical uses. Special machines help make sure the tubes are the right size. For tubes with an outer diameter of 0.3 mm or less, the size can be as close as ±0.005 mm. The wall thickness can be as close as ±0.010 mm. Laser micrometers, ultrasonic gauges, optical comparators, and bore gauges check these sizes. These tools find even tiny mistakes. This is very important for tubes used in medical devices.

Tube Size (OD) | OD Tolerance (mm) | Wall Thickness Tolerance (mm) | Measurement Equipment |

|---|---|---|---|

≤ 0.3 mm | ±0.005 | ±0.010 | Laser micrometers, ultrasonic gauges, bore gauges |

> 0.3 mm | ±0.010 | ±0.020 | Optical comparators, laser micrometers |

Making capillary nitinol tubes uses many steps. These steps include vacuum melting, cold drawing with mandrels, heat treatment, laser cutting, grinding, polishing, and electropolishing. Quality checks follow strict rules like ASTM F2063 and ISO 13485. These steps make sure the tubes have the right size and smooth surface.

Gun Drilling

Gun drilling is important for making capillary nitinol tubes. This method makes hollow tubes from solid bars. It gives the tubes a smooth inside and keeps the shape even. This helps the tubes bend and last longer. Gun drilling is better than milling or turning for nitinol. It makes the tubes more exact. Gun drilling can take more time and waste some material. But it is needed for high-quality tubing. This is very important for medical tubes like stents. These tubes must be very round and smooth inside.

Tip: Gun drilling keeps the inside size of capillary nitinol tubes the same. This is very important for super elastic nitinol tubing in medical devices.

Tube Drawing

After gun drilling, tube drawing makes the tubing even better. The tubing is pulled through hard mandrels and diamond dies. This step makes the tubing smaller and smoother. The tubing gets about 30% smaller in area each time. This makes the tubing stronger and helps it bend well. Tube drawing is done many times to get the final size. Annealing between steps keeps the tubing round and smooth. Bull blocks or spools pull the tubing through the dies. This keeps the tension and size just right.

Tube drawing is repeated to reach the final size and thickness. Each time, the tubing gets stronger and smoother. This also helps the tubing last longer. Keeping the size exact is always important. Even small mistakes can change how the tubing works.

Block Quote: Tube drawing and special measuring tools help make capillary nitinol tubes very exact and strong.

Heat Treatment and Shape Setting

Automated Salt Bath Ovens

Engineers use automated salt bath ovens to heat treat nitinol tubing. These ovens keep the temperature very steady. This is important for setting the shape of nitinol. Workers put the tubing all the way into a hot salt bath. This makes sure the tubing heats up evenly and does not rust. The temperature stays between 1350°F and 1850°F, and it does not change much. The tubing is heated and cooled many times. This helps control how the inside of the tubing changes. Special control panels watch and record the temperature. The kind of salt is picked for the metal and what is needed. Salt bath heating is fast and even. It stops the tubing from bending or cracking. This step helps nitinol remember its shape and work well.

Aspect | Details |

|---|---|

Temperature Range | 1350°F – 1850°F |

Temperature Control | Uniformity within ±4°F |

Heating Method | Full submersion in molten salt bath |

Heating Cycles | Multiple cycles for optimal microstructure |

Salt Mixture | Selected for metal and treatment goals |

Benefits | Prevents oxidation, uniform heating, reduces distortion |

Effect on Shape Memory | Enables shape setting and enhances memory/hyperelastic properties |

Monitoring | Specialized control panels document temperature profiles |

Tip: Salt bath heat treating helps tubing keep its shape. It also makes it work better in medical and airplane parts.

Mandrels and Fixtures

When setting the shape of nitinol, workers put the tubing on strong mandrels or special fixtures. These tools hold the tubing in the right shape during heating. The heat treatment happens between 455°C and 565°C. The fixture is strong so the tubing does not bend or move. Metal fixtures can take high heat and pressure. Some fixtures are made to be used once to save money and time. Copper fixtures can keep the tubing size very close to what is needed. Mandrels and fixtures are very important for shape setting nitinol. They keep the tubing in place so it remembers the right shape. Hard shapes need special fixtures, but easy shapes can use simple ones with set heating times.

Block Quote: Mandrels and fixtures help nitinol tubing get the right shape every time. This is very important for medical tools.

Quenching Systems

After heating, workers use quenching systems to set the shape of nitinol tubing. The most common way is to cool the tubing fast in water. Tubing that is hot is put in water to cool quickly. This controls how the inside of the tubing changes. Fast cooling stops unwanted changes and keeps the right transformation temperature. Cooling slowly in a furnace lets more changes happen and raises the transformation temperature. The way the tubing is cooled changes how it works in the end. Water quenching makes tubing that remembers its shape and bends well. Furnace cooling can change the temperature for special uses.

Note: How fast the tubing cools decides how well it keeps its shape and memory.

Cutting and Surface Finishing

Laser Cutting

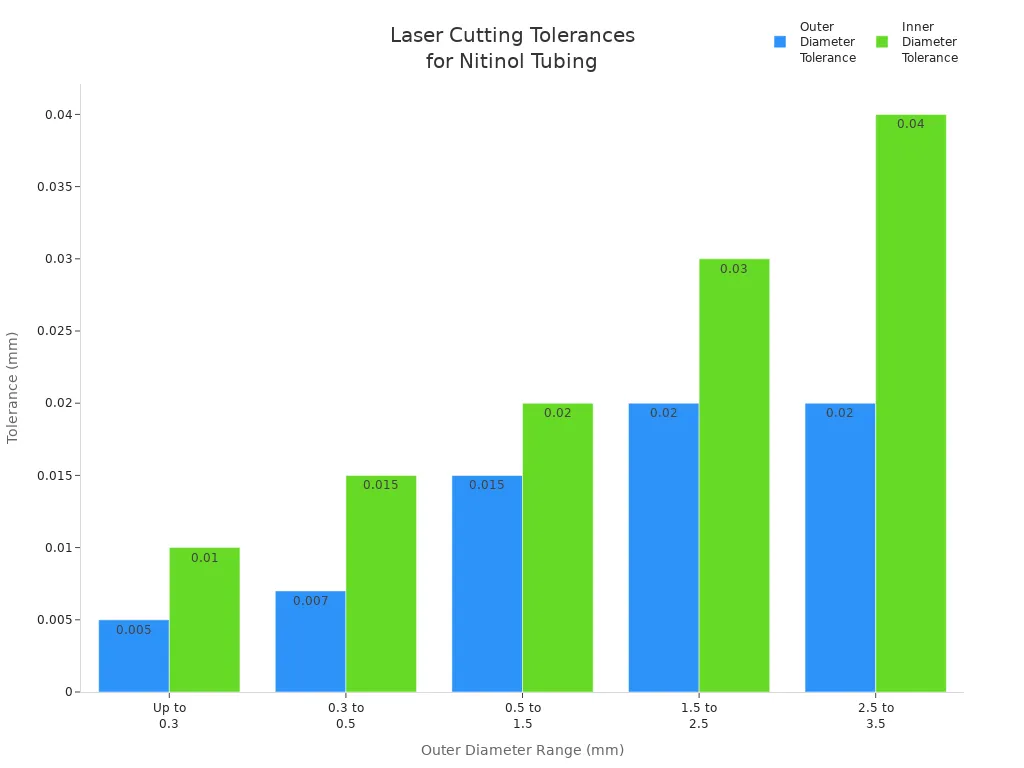

Laser cutting machines shape nitinol tubing very accurately. Operators use special systems to make complex shapes in capillary nitinol tubes. These machines can cut with tiny measurements, which is important for medical devices. Some technology can cut as close as ±0.00025 inches. The laser beam is very thin, between 0.001 and 0.002 inches wide. This lets the machine make very small cuts. Advanced lasers use short pulses, so they do not heat the tubing too much. This helps the tubing keep its shape memory. Special software and measuring tools check for mistakes. Laser interferometry helps keep the cuts the same every time. Precision stages help the machines move in tiny steps. This makes sure the tubing is high quality and super elastic.

Outer Diameter Range (mm) | Outer Diameter Tolerance (mm) | Inner Diameter Tolerance (mm) |

|---|---|---|

Up to 0.3 | ±0.005 | ±0.010 |

0.3 to 0.5 | ±0.007 | ±0.015 |

0.5 to 1.5 | ±0.015 | ±0.020 |

1.5 to 2.5 | ±0.020 | ±0.030 |

2.5 to 3.5 | ±0.020 | ±0.040 |

Laser cutting helps capillary nitinol tubes meet strict rules. This is important for medical and aerospace jobs.

Electropolishing

Electropolishing makes nitinol tubing smoother and stops rust. Technicians use this process to take away tiny bumps and flaws. The tubing gets very smooth, less than 0.5 μm roughness. This smooth surface helps stop cracks and rust from starting. The process makes a thin titanium dioxide layer on the tubing. This layer protects the tubing and stops nickel from coming out. The layer is important for medical tubes. Electropolishing also helps the tubing last longer by removing tiny cracks. It works better than mechanical polishing for smoothness and rust protection. Before electropolishing, workers remove burrs and clean the tubing. This makes the tubing even better.

Electropolishing takes away tiny flaws and bumps.

The process makes a protective layer to stop rust.

The tubing lasts longer and is stronger.

The finish is shiny, smooth, and good for medical devices.

Electropolished capillary nitinol tubes are stronger and resist rust. They are safe for medical use.

Ultrasonic Cleaning

Ultrasonic cleaning takes dirt, oil, and oxides off nitinol tubing. Operators use sound waves to make bubbles that clean the tubing. This step is needed before sterilizing tubes for medical devices. Special cleaning liquids help the bubbles work better. Tests like ultrasonic indicators and protein checks make sure the tubing is clean. Other tests include checking for germs, chemicals, and harmful things. Following ISO 13485 and ASTM F2516 rules keeps the tubing safe and high quality. Workers keep records and follow rules from the FDA and ISO to prove the tubing is clean.

Ultrasonic cleaning removes dirt, oil, and oxides.

Tests check that the tubing is clean.

Following ISO and ASTM rules keeps the tubing safe.

Ultrasonic cleaning makes sure capillary nitinol tubes are clean and safe for medical use.

Nitinol Tubing Processing Equipment and Quality Control

Inspection Tools

Manufacturers use special equipment to check nitinol tubing. Laser micrometers and optical comparators measure the outside size. Bore gauges and air gauges check the inside size. Ultrasonic thickness gauges look at wall thickness. Profilometers check if the surface is smooth. These tools help keep the tubing the right size. They also make sure the tubing is good for medical use.

Measurement Aspect | Inspection Tool(s) | Typical Dimensional Range / Notes |

|---|---|---|

Outer Diameter | Laser micrometry | Around 1.61 mm |

Inner Diameter | Bore gauges, air gauges | N/A |

Wall Thickness | Ultrasonic testing | 0.1 mm to 15 mm |

Surface Finish | Electropolishing, profilometers | Enhances dimensional accuracy and performance |

Tip: Using exact inspection tools helps nitinol tubing meet strict rules for medical and airplane jobs.

Ultrasonic Inspection

Ultrasonic inspection uses sound waves to find problems inside tubing. Technicians use this method to look for cracks or other issues. The tubing does not get damaged during testing. This step is important for safety, especially in medical devices. Ultrasonic inspection helps make sure there are no hidden problems. The equipment can find very small mistakes. This helps keep the tubing safe and high quality.

Mechanical Testing

Mechanical testing checks how strong nitinol tubing is. Technicians bend the tubing to test its strength. They use diamond-, Z-, or C-shaped pieces for testing. These tests show how tubing works in real life. Rules like ISO 5840 and USFDA say tubing must last a long time. Some tests go up to 400–600 million bends. Special equipment like electron beam refining makes tubing stronger. Mechanical testing also checks if tubing can resist rust. This helps tubing last longer and stay safe. Manufacturers follow ASTM rules and use computer models to check results. These tests help make sure tubing is reliable.

Mechanical testing checks if tubing is strong and resists rust.

Quality control makes sure tubing meets world standards.

Manufacturers use many steps to make nitinol tubing. They use special machines at each step.

Getting the right materials makes sure the tubing is safe and works well.

Melting and heating help make the inside of the alloy better.

Drawing tubes, heating, and finishing give the tubing its memory and ability to bend.

Careful checks make sure the tubing is good for medical and industrial jobs.

Every step needs careful work and skill. This is why nitinol tubing is great for tough jobs.

FAQ

What makes nitinol tubing different from other metal tubes?

Nitinol tubing can remember its shape and bend a lot. Special machines help control how much nickel and titanium are inside. These features make nitinol tubing good for medical and airplane uses.

How do manufacturers ensure nitinol tubing meets strict standards?

Workers use high-tech tools like laser micrometers and ultrasonic gauges. They follow rules from ASTM and ISO. Every batch is checked for size, purity, and smoothness.

Can nitinol tubing be customized for special uses?

Engineers make nitinol tubing for different jobs. They change the mix of metals, tube size, and shape. Special tools and heat help make tubing for unique medical or factory devices.

Why is electropolishing important for nitinol tubing?

Electropolishing takes away tiny flaws and adds a protective layer. This helps stop rust and makes the tubing safe for the body. Medical tools need smooth, clean tubing to stop cracks and nickel from coming out.

See Also

The Process Behind Manufacturing Nitinol Tubing For Medicine

Nitinol Tubing Transforming The Future Of Medical Equipment

The Importance Of Nitinol Tubing In Modern Medical Uses

Choosing The Right Nitinol Tubing Supplier For Your Requirements

Comprehensive Guide To Manufacturing And Components Of Nitinol