Why Nitinol Tubing is Crucial for Modern Surgical Techniques

Nitinol tubing in minimally invasive surgery has transformed how surgeons approach complex procedures. Its shape memory and superelasticity allow medical devices to adapt seamlessly to the human body, enhancing precision and reducing procedural risks. Studies show that nitinol implants lower rejection rates by 30% compared to traditional metals, while devices like guidewires achieve a 98% success rate in vessel crossing. Patients benefit from quicker recovery and reduced pain, with a 20% improvement in outcomes. These advancements make nitinol tubing a cornerstone of modern surgical innovation.

Key Takeaways

Nitinol tubing can return to its shape and bend easily. This helps tools fit the body during small surgeries.

Nitinol is safe for the body and causes less swelling. This makes surgeries safer and helps patients heal faster.

Nitinol is strong and bends without breaking. It works well for tools like stents and guidewires in tough conditions.

Studies show nitinol implants help patients get better with fewer problems. Surgeries using nitinol are more successful.

New ways to make nitinol will create more uses for it. This will improve healthcare and make surgeries better.

Unique Properties of Nitinol Tubing in Minimally Invasive Surgery

Shape Memory and Superelasticity

Nitinol tubing stands out in minimally invasive procedures due to its remarkable shape memory and superelasticity. These properties allow nitinol to return to its original shape after deformation, making it ideal for devices like stents and guidewires. Shape memory enables nitinol tubing to adapt to the body’s temperature, ensuring precise deployment during surgery. Superelasticity provides flexibility, allowing the material to endure significant strain without permanent deformation.

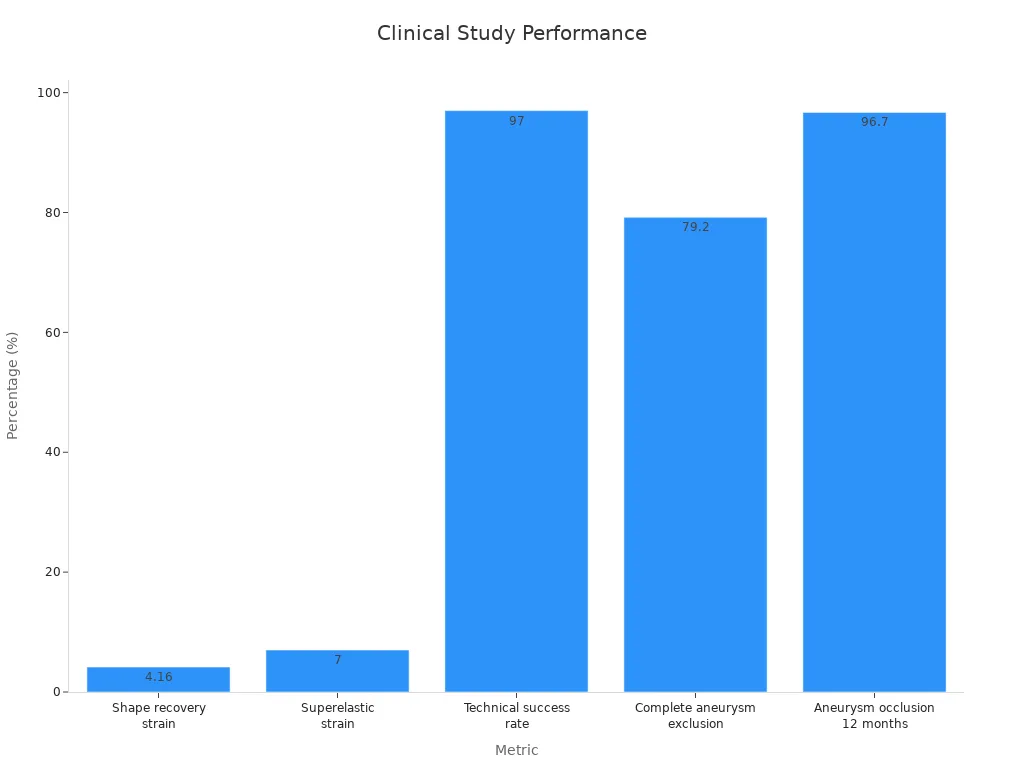

Clinical studies highlight the performance of nitinol tubing in surgical applications. For example, a study evaluating its shape memory performance reported the following results:

Metric | Result |

|---|---|

Shape recovery strain | 4.16% |

Superelastic strain | 7% |

Technical success rate | |

Complete aneurysm exclusion | 79.2% (57 of 72 patients) |

Aneurysm occlusion at 12 months | 96.7% (29 of 30 patients) |

Additionally, advanced testing methods like Differential Scanning Calorimetry (DSC) and Bend Free Recovery (BFR) ensure that nitinol tubing meets the rigorous demands of surgical applications. These tests measure transformation temperatures and assess shape recovery after deformation, further validating the material's reliability.

Biocompatibility and Corrosion Resistance

The biocompatibility and corrosion resistance of nitinol tubing make it a preferred choice for medical devices. Its low rejection rates and reduced inflammation risks ensure safer outcomes for patients. Unlike alternative materials such as stainless steel, nitinol offers superior corrosion resistance, with a breakdown potential of up to 1000 mV. This property enhances its durability in the human body, even in challenging environments like blood vessels.

The following table compares nitinol tubing with alternative materials:

Property | Nitinol Tubing | Alternative Materials (e.g., Stainless Steel) |

|---|---|---|

Corrosion Resistance | Exceptional, breakdown potential up to 1000 mV | Lower corrosion resistance |

Biocompatibility | Low rejection rates, reduced inflammation risk | Higher rejection rates |

Mechanical Stability | Remarkable kink resistance, maintains stability under strain | Less flexible, prone to kinking |

Nitinol’s biocompatibility ensures that it integrates seamlessly with the body, minimizing complications. Its corrosion resistance also extends the lifespan of medical devices, reducing the need for replacements and improving patient outcomes.

Durability and Flexibility

Durability and flexibility are critical for medical devices used in minimally invasive procedures, and nitinol tubing excels in both areas. Its exceptional fatigue life allows it to withstand repeated stress without failure, making it suitable for applications like self-expanding stents and heart valves. Studies comparing tube processing methods reveal that the manufacturing process significantly influences the durability of nitinol tubing.

Tube Processing Method | |

|---|---|

TM-1 | Correlated with microstructural aspects and fatigue behaviors. |

TM-2 | Compared against TM-1 to assess fatigue life improvements. |

Research also highlights nitinol’s ability to resist fatigue crack nucleation, ensuring long-term performance in demanding medical environments. Its flexibility allows it to navigate complex anatomies, such as curved blood vessels, without compromising structural integrity. This combination of durability and flexibility makes nitinol tubing indispensable in modern surgical techniques.

Enhancing Minimally Invasive Procedures with Nitinol Tubing

Precision and Control in Surgery

Nitinol tubing plays a pivotal role in enhancing precision during minimally invasive procedures. Its unique properties, such as shape memory and superelasticity, allow surgeons to achieve unparalleled control over medical devices. These characteristics ensure that nitinol-based tools can adapt to the dynamic environment of the human body, maintaining their functionality even under significant strain.

Clinical studies validate the precision and control provided by nitinol tubing. For instance, research has demonstrated its biocompatibility and corrosion resistance, which are critical for surgical success. The following table highlights key findings from notable studies:

Study | Findings |

|---|---|

Castleman et al. (1976) | Demonstrated biocompatibility of nitinol alloy as an implant material. |

Putters et al. (1992) | Compared cell culture effects of nitinol, nickel, and titanium. |

Ryhänen et al. (1997) | Evaluated biocompatibility and corrosion behavior in human cell cultures. |

These studies underscore the reliability of nitinol tubing in surgical applications, making it a cornerstone for achieving precision in complex procedures.

Flexibility for Complex Anatomies

The flexibility of nitinol tubing is essential for navigating the intricate pathways of the human body. Its superelastic behavior allows medical devices to bend and flex without permanent deformation, ensuring they can adapt to complex anatomical structures. This flexibility is particularly valuable in procedures involving curved or narrow blood vessels.

Key attributes of nitinol tubing that support its adaptability include:

Shape memory properties, enabling devices to return to their original shape after deformation.

Superelasticity, which allows significant deformation without damage.

The ability of nitinol stents to compress for insertion and expand to their intended shape inside the body.

Guidewires and catheters that bend and flex without breaking, ensuring safe navigation through challenging pathways.

These features make nitinol tubing indispensable for minimally invasive procedures, where precision and adaptability are critical.

Improved Patient Outcomes

The use of nitinol tubing in medical devices has led to significantly improved patient outcomes. Its biocompatibility reduces the risk of rejection and inflammation, while its durability ensures long-term performance. Clinical trials have shown that nitinol stents reduce restenosis rates, leading to better long-term results for patients.

Additional findings from clinical research include:

Nitinol stents used in coronary artery disease treatment improve durability and patency rates, with reported rates between 43% and 90% at 12 months.

Many trials report enhanced patency rates in the femoropopliteal artery when nitinol stents are used.

Nitinol guidewires enhance the precision of minimally invasive procedures, facilitating better navigation through vascular pathways.

These advancements highlight the transformative impact of nitinol tubing on patient care, making it a cornerstone of modern surgical innovation.

Key Applications of Nitinol Tubing in Medical Devices

Stents and Vascular Implants

Nitinol tubing plays a vital role in the development of stents and vascular implants. Its shape memory and superelasticity allow stents to compress for insertion and expand precisely within blood vessels. These properties ensure optimal vessel patency and reduce the risk of restenosis. Nitinol’s biocompatibility minimizes tissue reactions, with histological evaluations scoring between 0 and 1, indicating minimal inflammation. Additionally, nitinol stents achieve a sustained 30% reduction in intraocular pressure over six months, enhancing patient outcomes.

Manufacturing techniques significantly impact the fatigue life of nitinol tubing used in stents. Studies show that TM-1 processing results in fatigue life 2-3 times greater than TM-2, ensuring long-term durability. The following table highlights key technical specifications for nitinol tubing in stents:

Nominal OD | OD Tolerances | Wall Thickness | WT Tolerances |

|---|---|---|---|

> 0.80mm | ±0.005mm | 0.05–0.12mm | ±0.0075mm |

0.801-2.80mm | ±0.010mm | 0.13–0.26mm | ±0.010mm |

0.281-6.00mm | ±0.015mm | 0.27–0.40mm | ±0.013mm |

These attributes make nitinol tubing indispensable for stents and vascular implants, ensuring precision and reliability in minimally invasive procedures.

Guidewires and Catheters

Guidewires and catheters represent another critical application of nitinol tubing in medical devices. Nitinol’s flexibility and kink resistance allow guidewires to navigate complex vascular pathways without compromising structural integrity. Its biocompatibility reduces adverse reactions, ensuring safer outcomes for patients. Nitinol tubing withstands repeated stress, maintaining consistent performance in advanced medical applications.

Clinical trials, such as the MISAGO 1 and ORION studies, demonstrate the superiority of nitinol stents over traditional angioplasty for treating superficial femoral artery lesions. These trials confirm that nitinol-based devices enhance vessel patency while improving flexibility. Key benefits of nitinol guidewires and catheters include:

Reduced mechanical trauma to tissues, leading to faster recovery.

Reliable performance during complex procedures.

Enhanced precision in minimally invasive procedures.

These features highlight the importance of nitinol tubing in guidewires and catheters, making it a cornerstone of modern surgical techniques.

Surgical Instruments and Endoscopic Tools

Nitinol tubing is widely used in surgical instruments and endoscopic tools due to its durability and adaptability. Various designs, such as cable-ring mechanisms and flexible tubular structures, leverage nitinol’s unique properties to improve surgical precision. Manufacturing techniques include rectangular cutouts for arthroscopy tools and triangular cuts for manipulators, ensuring optimal performance in specialized applications.

Finite element analyses aid in designing compliant bending regions in nitinol tubes, enhancing their flexibility for endoscopic procedures. For example, nitinol tubing is used in a 10 mm tool for steering endoscopic cameras, allowing surgeons to navigate complex anatomical structures with ease. These innovations demonstrate the versatility of nitinol tubing in surgical instruments, supporting its role in minimally invasive procedures.

Future Potential of Nitinol Tubing in Healthcare

Emerging Applications in Medical Devices

Nitinol tubing continues to expand its role in advanced medical devices, with researchers exploring new applications that enhance surgical precision and adaptability. Robotic-assisted surgeries represent a promising area where nitinol’s flexibility and biocompatibility are critical. These properties allow robotic instruments to perform complex movements while minimizing tissue damage. Additionally, nitinol tubing is being investigated for use in next-generation stents with innovative coatings. These coatings aim to improve biocompatibility and reduce complications like neointimal hyperplasia, further advancing minimally invasive procedures.

The customization of nitinol tubing for specific medical conditions is another emerging trend. Additive manufacturing techniques, such as 3D printing, are enabling the production of highly tailored devices. This innovation ensures that nitinol-based tools meet the unique anatomical and procedural needs of patients, solidifying their role in high-performance medical devices.

Advancements in Manufacturing

Recent advancements in manufacturing have significantly improved the performance of nitinol tubing in advanced medical applications. Optimizing nitinol’s shape memory effect and superelasticity has enhanced its mechanical strength and ductility. These improvements ensure that nitinol tubing can withstand the rigorous demands of advanced medical devices. The addition of ternary and quaternary elements has also expanded its operating temperature range, making it suitable for more challenging environments.

Thermal shape-setting techniques have seen notable progress, offering greater precision and repeatability in production. Multi-modal characterization methods, including metallography and micro-computed tomography, are now used to analyze nitinol’s microstructure. These techniques provide valuable insights into fatigue performance, enabling manufacturers to produce tubing with superior durability and reliability.

Role in Healthcare Innovation

Nitinol tubing plays a pivotal role in driving healthcare innovation. Its unique properties, such as shape memory and flexibility, make it indispensable for minimally invasive procedures. The demand for nitinol in advanced medical devices continues to grow, fueled by an aging population and the increasing prevalence of chronic diseases. By 2028, the global nitinol market is projected to reach $31.4 billion, reflecting its critical importance in modern medicine.

The ability of nitinol tubing to be pre-shaped and expand within the body has revolutionized devices like stents and guidewires. These innovations reduce patient recovery times and improve surgical outcomes. As the healthcare industry evolves, nitinol tubing will remain at the forefront of medical advancements, enabling the development of cutting-edge solutions for complex medical challenges.

Nitinol tubing has become a cornerstone of minimally invasive procedures due to its unique properties. Its shape memory and superelasticity enhance precision and flexibility, while its biocompatibility ensures safer patient outcomes. These qualities have revolutionized medical devices, enabling advanced surgical techniques that improve recovery times and reduce complications.

Ongoing advancements in manufacturing and material science will further expand nitinol’s applications in healthcare. From robotic-assisted surgeries to next-generation implants, nitinol tubing continues to drive innovation, solidifying its role as a critical component in modern medicine.

Its transformative impact underscores its importance in shaping the future of surgical care.

FAQ

What makes nitinol tubing unique compared to other materials?

Nitinol tubing stands out due to its shape memory, superelasticity, and biocompatibility. These properties allow it to adapt to the human body, resist corrosion, and maintain durability under stress. Its ability to return to its original shape after deformation makes it ideal for medical devices.

How does nitinol tubing improve patient outcomes?

Nitinol tubing reduces complications like inflammation and rejection. Its flexibility and precision enhance surgical success rates, while its durability ensures long-term device performance. Patients experience faster recovery times and fewer follow-up procedures, improving overall satisfaction and health outcomes.

Are there any limitations to using nitinol tubing?

Nitinol tubing requires precise manufacturing to optimize its properties. Improper processing can affect its shape memory and fatigue resistance. Additionally, its cost is higher than traditional materials, which may limit its use in some healthcare settings.

Tip: Advanced manufacturing techniques, like thermal shape-setting, help overcome these challenges.

What types of medical devices use nitinol tubing?

Nitinol tubing is used in stents, guidewires, catheters, and surgical instruments. It also plays a role in endoscopic tools and robotic-assisted surgical devices. Its adaptability and durability make it essential for minimally invasive procedures.

How does manufacturing impact nitinol tubing's performance?

Manufacturing processes, such as thermal shape-setting and additive manufacturing, directly influence nitinol tubing's mechanical properties. These methods optimize its shape memory, superelasticity, and fatigue resistance, ensuring reliable performance in medical applications.

Note: Multi-modal characterization techniques, like micro-computed tomography, enhance quality control during production.

See Also

The Importance of Nitinol Tubing in Minimally Invasive Surgery

Nitinol Tubing's Critical Role in Modern Medical Technologies

Nitinol Tubing's Contribution to Progress in Medical Technology