Why Nitinol Tubing is Revolutionizing Minimally Invasive Surgery in 2025

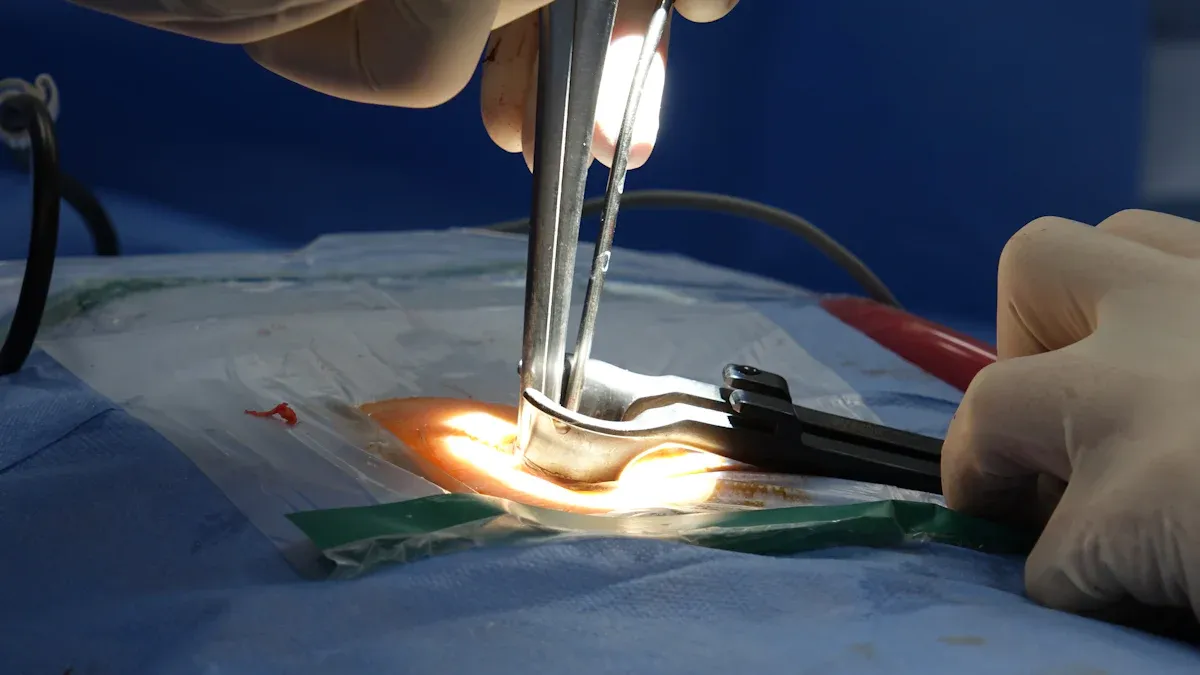

Nitinol tubing has become a game-changer in modern medicine. Its ability to combine precision, flexibility, and biocompatibility makes it indispensable for advanced surgical tools. Surgeons rely on nitinol tubing to perform minimally invasive procedures with greater accuracy and control. This innovation reduces patient trauma and accelerates recovery times. By enabling the creation of cutting-edge medical devices, Nitinol Tubing for Minimally Invasive Surgery has set a new standard for surgical care. Its unique properties not only improve outcomes but also redefine what is possible in the operating room.

Key Takeaways

Nitinol tubing improves surgery by remembering shapes and fitting well.

Its superelasticity makes it bendy, helping doctors reach tricky spots.

It is safe for the body, leading to quicker healing after surgery.

Nitinol tubing is strong and lasts through many uses in operations.

New ideas aim to make nitinol tubing more custom and eco-friendly.

Unique Properties of Nitinol Tubing for Minimally Invasive Surgery

Shape Memory and Its Role in Surgical Precision

Nitinol tubing stands out due to its remarkable shape memory effect, which plays a critical role in enhancing surgical precision. This property allows the material to return to its original shape after deformation when exposed to specific temperatures. Surgeons benefit from this unique characteristic, as it enables the creation of advanced medical devices that adapt to the human body’s dynamic environment. For example, shape memory ensures that stents or other implants expand precisely to fit the target anatomy, reducing the risk of complications.

Technical research highlights the impressive performance of nitinol tubing under stress. Studies have shown high-cycle fatigue strain limits ranging from 0.4% to 0.8%, demonstrating its ability to withstand repeated stress during surgical procedures. Improvements in material cleanliness have further enhanced its fatigue life, ensuring the reliability of surgical tools. Additionally, uniaxial tension tests have revealed the non-linear mechanical properties of nitinol, which are essential for designing devices that require both flexibility and precision.

Superelasticity for Enhanced Flexibility and Control

The superelasticity of nitinol tubing is another game-changing property that has revolutionized minimally invasive surgery. Unlike traditional materials, super elastic nitinol tubes can undergo significant deformation and return to their original shape without permanent damage. This feature provides surgeons with enhanced flexibility and control during complex procedures, such as navigating tortuous blood vessels or accessing hard-to-reach areas of the body.

Superelasticity also contributes to the development of advanced medical devices that maintain their performance under challenging conditions. For instance, guidewires made from nitinol tubing can bend and twist through intricate anatomical pathways while maintaining their structural integrity. This level of adaptability reduces the risk of device failure and ensures consistent performance, even in the most demanding surgical environments.

Biocompatibility and Safety in Medical Applications

Biocompatibility is a cornerstone of nitinol tubing’s success in medical applications. Its ability to integrate seamlessly with the human body ensures patient safety and long-term reliability. Regulatory compliance with FDA and international standards further underscores its suitability for use in advanced medical devices.

Aspect | Details |

|---|---|

Regulatory Standards | Compliance with FDA and international standards ensures patient safety and device reliability. |

Biocompatibility Testing | Adherence to ISO 10993 standards evaluates cytotoxicity, sensitization, irritation, and more. |

Clinical Evidence | Long-term studies show excellent biocompatibility profiles for Nitinol implants over 10 years. |

Surface Treatment | Electropolishing and passivation create a titanium oxide layer that prevents nickel leaching. |

Manufacturing Consistency | Advanced techniques ensure batch-to-batch consistency and compliance with ASTM F2063 standards. |

Safety Record | Decades of clinical use with minimal adverse reactions and strong corrosion resistance. |

These rigorous standards and assessments ensure that nitinol tubing remains a trusted material for minimally invasive surgery. Its surface treatments, such as electropolishing, enhance its biocompatibility by forming a protective titanium oxide layer. This prevents nickel leaching, which could otherwise pose risks to patients. With decades of proven safety and reliability, nitinol tubing continues to set the benchmark for medical-grade materials.

How Nitinol Tubing Enhances Minimally Invasive Procedures

Precision and Control in Complex Surgeries

Nitinol tubing has redefined precision in minimally invasive procedures. Its unique properties, such as shape memory and superelasticity, allow surgeons to perform complex surgeries with unparalleled control. Devices made from nitinol tubing can adapt to intricate anatomical structures, ensuring accurate deployment and reducing the risk of errors. For instance, stents crafted from nitinol tubing expand precisely to fit the target area, maintaining their position even in dynamic environments.

The material's flexibility and durability further enhance surgical outcomes. According to surgical case studies, nitinol tubing enables navigation through challenging pathways while maintaining structural integrity. This adaptability leads to better efficacy in procedures, ultimately improving patient outcomes.

Attribute | Impact on Surgery |

|---|---|

Flexibility | Enables navigation through intricate pathways |

Shape Memory | Ensures accurate deployment of devices |

Durability | Maintains structural integrity under repeated use |

Adaptability | Enhances efficacy of procedures, leading to better outcomes |

Nitinol's superelasticity also plays a critical role. It allows devices to bend and twist without permanent deformation, making it easier to access hard-to-reach areas. This capability ensures that surgeons can operate with confidence, even in the most demanding scenarios. By combining precision with control, nitinol tubing has become a cornerstone of modern surgical innovation.

Reduced Trauma and Faster Recovery for Patients

Minimally invasive procedures aim to reduce patient trauma, and nitinol tubing excels in achieving this goal. Its biocompatibility and flexibility minimize tissue damage during surgeries, leading to faster recovery times. Studies have shown that devices made from nitinol tubing cause minimal tissue reactions post-implantation. Histological evaluations revealed scores ranging from 0 to 1, indicating reduced trauma and excellent biocompatibility.

The absence of significant inflammatory responses further highlights the safety of nitinol tubing. Unlike traditional materials, it does not trigger adverse reactions, ensuring a smoother healing process. Patients benefit from shorter hospital stays and quicker returns to daily activities, which significantly improves their quality of life.

Minimal tissue reactions post-implantation, with histological scores of 0 to 1.

No significant inflammatory responses observed in clinical evaluations.

Comparable tissue response outcomes between nitinol-based devices and control groups.

By reducing trauma and accelerating recovery, nitinol tubing not only enhances surgical outcomes but also improves patient satisfaction. Its role in minimally invasive procedures underscores its importance in modern medicine.

Improved Durability and Performance of Medical Devices

The durability of nitinol tubing sets it apart from other materials used in medical devices. Its exceptional fatigue resistance and durability ensure that devices can withstand the rigors of repeated use. For example, endovascular stents made from nitinol tubing endure up to 400 million cycles of arterial pressure, demonstrating their reliability in demanding applications.

Medical device manufacturers prioritize high-purity nitinol to enhance performance and longevity. Advanced processing techniques, such as low-temperature aging and laser shock peening, further improve the material's fatigue properties. These innovations allow nitinol tubing to maintain its structural integrity under extreme conditions, reducing the likelihood of device failure.

Evidence Type | Description |

|---|---|

Durability Testing | Devices endure significant fatigue cycles under clinical loading conditions. |

Material Purity | High-purity nitinol reduces the risk of fractures and enhances reliability. |

Processing Techniques | Techniques like laser shock peening improve fatigue resistance and longevity. |

The superior performance of nitinol tubing enables the creation of medical devices that deliver consistent results. Its ability to combine durability with flexibility makes it an ideal choice for minimally invasive procedures. By ensuring long-term reliability, nitinol tubing contributes to improved patient outcomes and sets a new standard for medical device performance.

Key Medical Applications of Nitinol Tubing

Stents: Supporting Blood Flow with Precision

Nitinol tubing has revolutionized the design of stents, making them indispensable in restoring blood flow during minimally invasive procedures. Its shape memory and superelasticity allow stents to expand precisely within blood vessels, ensuring optimal support and reducing the risk of restenosis. Advanced stent technologies, such as drug-eluting stents, further enhance outcomes by releasing medication to prevent blockages.

Clinical studies highlight the effectiveness of nitinol-based stents. For example, Mewissen (2004) reported a 98% technical success rate and 92% primary stent patency at six months in 137 lower limb cases. Similarly, Zeller et al. (2008) observed significant clinical improvement in patients with superficial femoral artery (SFA) lesions, with a mean Rutherford category improvement from 2.75 to 0.94. These findings underscore the reliability of nitinol tubing in high-performance medical devices.

Study | Findings | Outcome Measures |

|---|---|---|

Mewissen (2004) | 137 lower limbs treated with SMART stents | 98% technical success, 92% patency at 6 months |

Zeller et al (2008) | 110 patients with SFA lesions | 96% technical success, 23.3% restenosis at 1 year |

Kickuth et al (2007) | 35 patients with severe claudication | 82% patency at 6 months, 100% limb salvage rate |

Guidewires: Navigating Complex Anatomies with Ease

Guidewires made from nitinol tubing offer unmatched flexibility and control, enabling surgeons to navigate complex anatomical pathways with ease. Their superelasticity allows them to bend and twist through tortuous blood vessels without losing structural integrity. This adaptability reduces the risk of complications and ensures consistent performance during procedures.

The biocompatibility of nitinol tubing enhances patient safety, making it a preferred material for guidewires. Its ability to maintain performance under challenging conditions ensures that surgeons can rely on these high-performance medical devices in critical situations. By combining precision with durability, nitinol guidewires have become essential tools in modern medicine.

Surgical Instruments: Enabling Advanced Techniques

Nitinol tubing has paved the way for the development of advanced surgical instruments. Its unique properties, such as shape memory and superelasticity, allow for the creation of tools that adapt to the dynamic environment of the human body. These instruments enable surgeons to perform minimally invasive procedures with greater accuracy and control.

For example, nitinol-based instruments can reach hard-to-access areas while maintaining their functionality. Their durability ensures long-term reliability, even under repeated use. By enhancing the precision and efficiency of surgical techniques, nitinol tubing continues to drive innovation in the medical field.

Future Innovations in Nitinol Tubing for Medicine

Emerging Applications in New Surgical Fields

Nitinol tubing is poised to expand its role in new surgical fields, revolutionizing minimally invasive medical procedures. Its unique combination of flexibility, strength, and biocompatibility makes it ideal for advanced techniques in minimally invasive medicine. Researchers are exploring its use in robotic-assisted surgeries, where precision and adaptability are critical. These applications allow surgeons to perform complex procedures with greater accuracy, reducing trauma and improving patient outcomes.

The global nitinol market reflects this growing demand. Projections indicate that the market size will reach $4.76 billion by 2034, with a compound annual growth rate (CAGR) of 7.60%. The tubing segment is expected to lead this growth, driven by its increasing adoption in vascular, orthopedic, and neurological procedures. Artificial intelligence is also playing a pivotal role in optimizing nitinol's properties, enabling the development of devices tailored to specific medical needs.

Advancements in Manufacturing and Customization

Manufacturing innovations are transforming nitinol tubing into a highly customizable material for minimally invasive procedures. Advanced techniques now allow for precise tailoring of tubing to meet patient-specific requirements. This customization enhances the performance of medical devices, improving recovery rates and overall patient care. For example, nitinol tubing used in stents adapts seamlessly to the body's environment, ensuring optimal blood flow and reducing complications.

The material's durability and flexibility have also led to a 30% lower rejection rate compared to traditional metals. Manufacturers are leveraging technologies like laser shock peening and low-temperature aging to improve fatigue resistance and structural integrity. These advancements ensure that nitinol tubing maintains its performance even under extreme conditions, making it indispensable for high-stakes medical applications.

Sustainability and Eco-Friendly Innovations

As the medical industry prioritizes sustainability, nitinol tubing production is undergoing significant eco-friendly transformations. Researchers are developing recycling methods to minimize waste and repurpose nitinol scrap into usable material. These efforts reduce the environmental impact of production while promoting resource efficiency.

Energy-efficient manufacturing processes, such as induction melting and powder metallurgy, are also gaining traction. These methods lower energy consumption and carbon emissions, aligning with global sustainability goals. Additionally, new alloy compositions are being designed to require less energy during production, further reducing their ecological footprint. By adopting renewable energy sources and sustainable practices, the nitinol industry is setting a benchmark for environmentally responsible innovation.

🌱 Note: While nitinol tubing offers groundbreaking benefits for minimally invasive procedures, its production must balance innovation with sustainability to ensure a greener future for medical advancements.

Nitinol tubing has transformed minimally invasive surgery by combining precision, flexibility, and biocompatibility. Its ability to improve surgical accuracy, enhance patient recovery, and boost device performance highlights its critical role in modern medicine.

Key Benefits:

Reduces trauma and speeds up recovery.

Enhances the durability of medical devices.

Enables advanced surgical techniques.

🚀 Future Outlook: As technology evolves, Nitinol tubing will continue to drive innovation, shaping the future of surgery with sustainable and cutting-edge solutions. Its potential remains limitless, making it a cornerstone of medical advancements.

FAQ

What makes Nitinol tubing superior to traditional materials in surgery?

Nitinol tubing offers unmatched flexibility, shape memory, and biocompatibility. These properties enable precise device deployment, reduced trauma, and faster recovery. Traditional materials lack the adaptability and durability required for complex procedures, making Nitinol the preferred choice for minimally invasive surgeries.

💡 Tip: Nitinol's superelasticity ensures devices perform reliably, even in challenging conditions.

Is Nitinol tubing safe for long-term use in the human body?

Yes, Nitinol tubing is highly biocompatible and adheres to strict FDA and ISO standards. Surface treatments, like electropolishing, create a protective titanium oxide layer that prevents nickel leaching. Decades of clinical use demonstrate its safety and reliability in long-term medical applications.

Can Nitinol tubing be customized for specific medical needs?

Absolutely! Advanced manufacturing techniques allow precise customization of Nitinol tubing. Surgeons and device manufacturers can tailor its dimensions, flexibility, and fatigue resistance to meet unique patient and procedural requirements. This adaptability ensures optimal performance and better surgical outcomes.

How does Nitinol tubing improve patient recovery times?

Nitinol tubing minimizes tissue damage during procedures due to its flexibility and biocompatibility. Devices made from Nitinol adapt seamlessly to the body, reducing inflammation and promoting faster healing. Patients experience shorter hospital stays and quicker returns to daily activities.

🚀 Fact: Studies show Nitinol-based devices cause minimal tissue reactions, ensuring smoother recoveries.

What are the environmental impacts of producing Nitinol tubing?

The industry is adopting eco-friendly practices, such as recycling Nitinol scrap and using energy-efficient manufacturing methods. These innovations reduce waste and carbon emissions, aligning with global sustainability goals. Nitinol tubing production is evolving to balance medical advancements with environmental responsibility.

🌱 Note: Sustainable production ensures a greener future for medical innovation.

See Also

The Importance of Nitinol Tubing in Minimally Invasive Surgery

Nitinol Tubing's Impact on the Future of Medical Devices

Nitinol Tubes: Pioneering the Next Generation of Medical Devices

Nitinol Tubing's Contribution to the Evolution of Medical Technology

The Critical Role of Nitinol Tubing in Modern Medical Applications