How Medical Nitinol Tubing Achieves High Purity and Performance

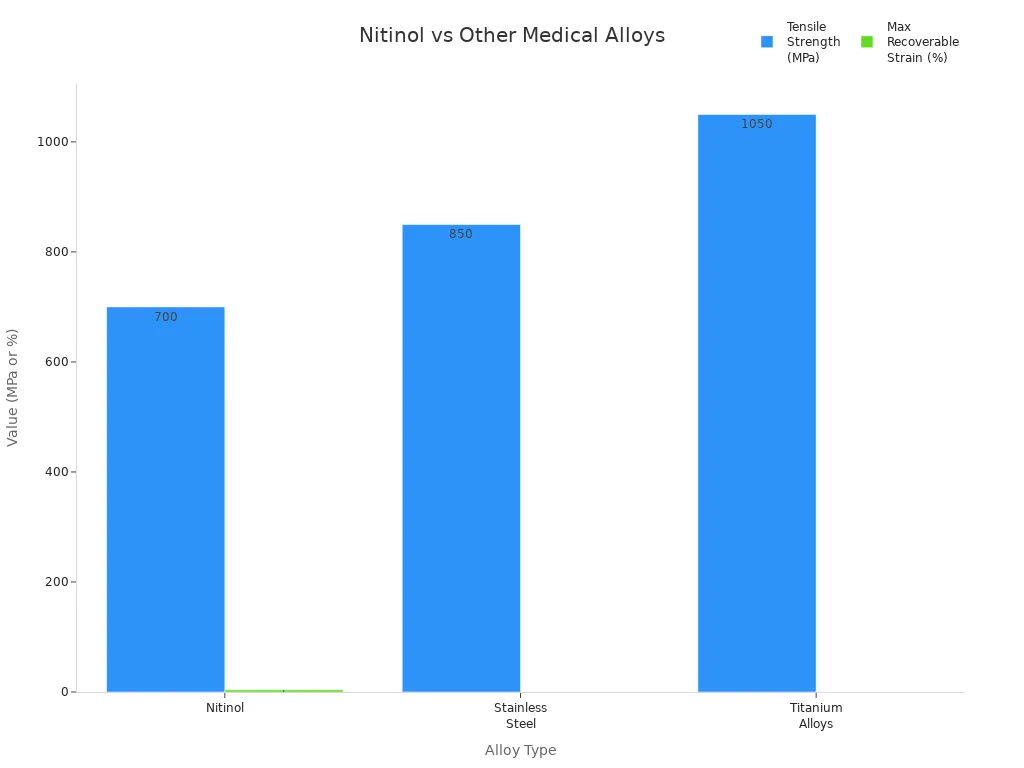

Nitinol is unique in medical devices due to its superelasticity and shape memory properties. These characteristics allow nitinol tubing to return to its original shape after bending or heating, making it ideal for Nitinol Tubing medical applications that require flexibility and reliability. Every stage, from selecting the material to surface treatment, is carefully monitored to ensure nitinol remains pure and performs consistently. Unlike stainless steel and titanium alloys, nitinol offers a distinctive combination of strength, durability, and excellent biocompatibility.

Nitinol (Superelastic & Shape Memory) | Stainless Steel | Titanium Alloys | |

|---|---|---|---|

Tensile Strength (MPa) | 500 - 900 | 600 - 1100+ | 900 - 1200 |

Maximum Recoverable Strain | Up to ~4% (superelastic, at 37°C, no heat) | Does not exhibit superelasticity | Does not exhibit superelasticity |

Maximum Strain after Heating | Up to ~8% (shape memory effect) | N/A | N/A |

Fatigue Life | Up to 400 million cycles at 0.55% strain amplitude | Significantly lower fatigue life | Lower fatigue life compared to nitinol |

Shape Recovery Mechanism | Phase transformation (stress or temperature induced) | None | None |

Biocompatibility & Corrosion | High, with stable titanium oxide layer preventing nickel leakage | Good corrosion resistance | Excellent corrosion resistance |

Rigorous process controls and adherence to medical standards ensure patient safety and enhance the longevity of devices using Nitinol Tubing medical applications.

Key Takeaways

Nitinol tubing is special because it can bend and return to its shape. It is flexible, strong, and safe for use in medical devices.

Makers keep nitinol pure by melting it in a vacuum. They control the mix of metals very carefully. They also use exact ways to shape it, like gun drilling and annealing.

Cleaning, pickling, and passivation are used on the surface. These steps help stop rust and make nitinol safer for the body.

Careful testing and certifications check every batch of nitinol tubing. This makes sure it is safe and high quality for medical use.

Nitinol tubing is used in stents, catheters, and implants. It bends easily, goes back to its shape, and works well inside the body.

Material Selection

Alloy Purity

Manufacturers pick nitinol for medical tubing because it has special features and must be very pure. The purity of the nickel-titanium alloy is important for how well it works in medical devices. If nitinol is very pure, it is less likely to cause bad reactions in the body. Biocompatibility is very important because the tubing touches human tissue. Studies show nitinol tubing lowers the chance of problems like blood clots and swelling. This makes it good for delicate uses, like neurovascular stents.

Superelasticity and shape memory only work if the alloy is made just right. Even tiny bits of other stuff can mess up these features. High purity also helps nitinol tubing last longer and handle lots of bending. Manufacturers check the size, wall thickness, and roundness very carefully. This makes sure the tubing fits well in tricky blood vessels and works with other medical tools.

Note: Surface finish, like electropolishing, makes nitinol even safer for the body and helps it slide more easily when used in devices.

Supplier Standards

Medical device companies need their nitinol suppliers to follow strict rules. Good suppliers must have certifications like ISO 13485 and follow FDA rules. These show the supplier uses strong quality systems. Keeping quality the same means every batch of nitinol tubing is safe and works well.

When picking a supplier, companies look for:

A history of making medical-grade nitinol

Proof that they can track and follow rules for each batch

The ability to cut and punch nitinol in special ways for different devices

Suppliers who meet these rules help companies make safe, high-quality nitinol tubing for advanced medical uses.

Melting & Alloying

Vacuum Melting

Manufacturers use vacuum melting to make nitinol very pure. This process takes out gases and things that should not be in the metal. Melting nitinol in a vacuum stops oxygen and other elements from getting in. Even a little bit of contamination can change how nitinol works. Vacuum melting keeps nickel and titanium balanced. It also makes sure the tubing has superelasticity and shape memory for medical devices.

Tip: Vacuum melting makes nitinol more pure and helps every batch work the same way.

Composition Control

It is important to control the mix of nickel and titanium. Technicians check the amounts very carefully. They use special tools to measure during and after melting. The right mix gives nitinol its special features. If the mix changes, the tubing may not bend or return to shape. Manufacturers use a table to keep track of each batch:

Batch Number | Nickel (%) | Titanium (%) | Other Elements (ppm) |

|---|---|---|---|

101 | 55.8 | 44.2 | <50 |

102 | 56.0 | 44.0 | <50 |

Careful control of the mix helps nitinol tubing meet medical rules. This makes sure devices are safe and work well for patients.

Forming

Gun Drilling

Manufacturers use gun drilling to make a hollow center in nitinol tubing. They start with a solid nitinol rod. A special drill goes through the middle and removes material. This makes a straight and even channel inside the tube. Gun drilling lines up the inside and outside surfaces almost perfectly. The wall thickness stays very close to the target, within 0.01 mm. The inside surface is very smooth, at or below 0.1 μm. These tight limits help the tubing work well in tough places.

Aspect | Detail |

|---|---|

Process | Gun drilling of solid nitinol rod |

Concentricity Achieved | Over 99% |

Wall Thickness Tolerance | Within 0.01 mm |

Surface Roughness | At or below 0.1 μm |

Quality Control Tools | Laser micrometers, ultrasonic thickness gauges |

Importance | Ensures uniform mechanical properties, prevents device failure, supports durability of nitinol stents |

Laser micrometers and ultrasonic thickness gauges check each tube. These tools make sure the tubing meets strict medical standards. Accurate size and smooth surfaces help stop device problems. They also help nitinol stents last longer.

Tip: Careful gun drilling makes nitinol tubing stronger and safer for medical use.

Drawing & Annealing

After gun drilling, drawing makes the tube thinner and shapes it better. Drawing pulls the tube through dies to make it more even. Each time the tube goes through a die, it gets thinner and smoother. This step makes the tubing stronger and more accurate in size.

Annealing comes after drawing. The tubing is heated to a set temperature and then cooled down. This step takes away stress inside the metal. It also brings back superelastic and shape memory features. If annealing is not done right, the tubing may not bend or return to shape.

Key steps for making nitinol tubing are:

Hot working and extrusion to shape the first ingot and make it even.

Seamless tube drawing and gun drilling for high accuracy and straightness.

Cold working and annealing to fine-tune size and strength.

Heat treatment to set the final shape and keep superelasticity.

Manufacturers also use laser cutting for special shapes and shape setting for each device. These steps help nitinol tubing fit many kinds of medical devices.

Keeping superelasticity and shape memory during forming is very important. Each step must protect these special features. High purity and even alloy mix, made by careful work, help nitinol tubing work well in the body. Accurate size and smooth finish, from drawing and finishing, help stop problems and make implants last longer.

Note: New methods like laser cutting and additive manufacturing let companies make nitinol tubing for special medical needs, making treatments better.

Surface Treatment

Cleaning & Pickling

Manufacturers clean and pickle nitinol tubing to remove unwanted stuff. These steps make the surface smooth and clean. Cleaning gets rid of oils, dust, and leftover bits from before. Workers use ultrasonic baths or special liquids for cleaning. Pickling uses gentle acids to take away surface oxides and other impurities. This step gets the tubing ready for more treatment and makes it look better.

A clean surface helps nitinol work well in medical devices. It lowers the chance of contamination and helps with biocompatibility. Doctors need tubing that will not cause irritation or bad reactions. Clean nitinol also sticks better to coatings or glue used in some devices.

Tip: Cleaning and pickling done the same way each time keep nitinol tubing pure for medical use.

Passivation

Passivation makes a protective layer on nitinol tubing. This layer is usually made of titanium oxide. The tubing is put in certain chemicals, like nitric acid or citric acid. These chemicals react with the metal and form a thin, stable film.

This film stops corrosion and keeps nickel from leaking out. Medical devices need this barrier to keep patients safe. Passivation also helps the tubing last longer inside the body.

After passivation, manufacturers test the tubing. They check if the layer covers everything and measure how thick it is. Good passivation makes sure nitinol tubing meets tough medical rules.

Main benefits of passivation:

Better resistance to corrosion

Better biocompatibility

Longer life for devices

Note: Cleaning, pickling, and passivation are important for making nitinol tubing safe and strong for medical use.

Quality & Compliance

Testing Methods

Manufacturers use strict tests to check nitinol tubing. They test every batch with special tools and keep good records. These tests make sure the tubing is safe for the body and works well.

Surface finish is checked to be very smooth, usually Ra ≤ 0.1 μm.

Size is checked with laser cutting, as close as ±0.005 mm.

Fatigue tests see how the tubing handles bending many times.

Radial force tests check the tubing’s strength and flexibility.

Manufacturers use SPC and risk tools to find problems early. This helps keep production steady and safe. Each batch has full records, like material certificates and test results. This makes it easy to find and fix problems fast, keeping patients safe.

Tip: Good testing and records help stop recalls and make sure only the best nitinol tubing goes to hospitals.

Certification

Rules guide every step of making nitinol tubing. Standards like ISO 13485 and ASTM F2063 set rules for size, material, and how it works. Manufacturers must follow FDA and EU rules, which need strong tests, checks, and clear records. These rules make sure the tubing is safe for the body.

Companies must show their nitinol tubing meets all these rules. They write down every step, from checking materials to final tests. Supplier checks and tracking systems help keep things reliable. Certification proves the tubing is ready for medical devices and meets top safety rules.

Note: Certification and following rules help doctors and patients trust the quality and safety of nitinol tubing.

Nitinol Tubing Medical Applications

Device Uses

Nitinol tubing medical applications help in many health treatments. Doctors use nitinol tubing in stent applications, catheters, and implants. Stent applications use nitinol’s ability to open up and go back to its shape inside blood vessels. Surgeons pick nitinol tubing medical applications for surgeries that do not need big cuts. Catheters made from nitinol tubing can bend and move through tight spaces without folding. Implants like heart valve frames and bone anchors use nitinol tubing medical applications because it is strong and bends easily.

The table below lists nitinol tubing medical applications and their main benefits:

Application | Benefit of Nitinol Tubing |

|---|---|

Superelasticity, shape recovery | |

Catheters | Flexibility, kink resistance |

Implants | Biocompatibility, durability |

Doctors trust nitinol tubing medical applications for devices that must work well inside the body.

Performance Needs

Stent applications need nitinol tubing medical applications to be very pure and work just right. Superelasticity lets stents squeeze down for delivery and open up where needed. Shape memory helps the device go back to its shape after it is placed. Biocompatibility lowers the chance of swelling or the body rejecting it.

Nitinol tubing medical applications must follow strict rules. Makers check every step to keep nitinol pure and the same each time. This careful work helps stent applications last longer and work better. Patients get safer treatments and heal faster.

Superelasticity helps devices move with the body.

Shape memory lets devices change with body heat.

Biocompatibility keeps tissue and blood safe from harm.

High purity and good performance in nitinol tubing medical applications help doctors save lives and help patients get better.

Every part of making tubing is important for purity and performance. Careful checks and controls help meet medical rules and keep patients safe.

New ideas and inventions keep improving the industry.

Experts think the world market for medical tubing will grow by 8-10% each year for five years.

The market could be worth USD 4.5 billion by 2030 because of new medical tools and more use in small surgeries.

FAQ

What makes nitinol tubing different from other medical metals?

Nitinol tubing is special because it can bend and go back to its shape. This is called superelasticity and shape memory. Doctors pick nitinol tubing for tools that must be strong and flexible.

How do manufacturers ensure nitinol tubing is safe for the body?

Manufacturers clean, pickle, and passivate the tubing very carefully. They test each batch to check for purity and smooth surfaces. These steps help stop bad reactions and keep patients safe.

Why is high purity important in nitinol tubing?

High purity helps stop allergies and makes nitinol safer for the body. Pure nitinol tubing lasts longer and works better in devices. It also helps stop the device from breaking.

Where do doctors use nitinol tubing in medicine?

Doctors use nitinol tubing in stents, catheters, and implants. These devices need tubing that bends, stretches, and goes back to shape. Nitinol tubing helps make treatments easier and work better.