Why Nitinol Tubing is Revolutionizing Medical Applications

Nitinol tubing has become a cornerstone of innovation in medical nitinol tubing applications. Its unique properties, including shape memory, superelasticity, and biocompatibility, allow for the development of cutting-edge medical devices that significantly enhance healthcare. The rising demand for nitinol-based solutions reflects its impact.

The market for nitinol medical devices is projected to grow from $1.51 billion in 2023 to $2.28 billion by 2031, with a CAGR of 5.3%.

Clinical studies show nitinol devices improve patient outcomes, such as a 49% functional independence rate in stroke patients treated with nitinol stent retrievers.

These advancements highlight nitinol tubing's transformative role in modern medicine and its diverse medical nitinol tubing applications.

Key Takeaways

Nitinol tubing has special traits like shape memory and flexibility. These traits make medical tools work better and help patients more.

The need for nitinol medical tools is growing fast. This shows people want new and better healthcare options.

Nitinol is safe for long-term use in the body. It lowers bad reactions and makes patients feel more comfortable.

Nitinol tubing bends easily to fit tricky body parts. This makes it great for surgeries that don’t need big cuts.

Nitinol lasts a long time and costs less to make. This means fewer replacements, helping doctors and patients save money.

Unique Properties of Nitinol Tubing

Nitinol tubing stands out in the medical field due to its remarkable properties, including shape memory, superelasticity, and biocompatibility. These characteristics enable the development of innovative medical devices that improve patient care and procedural efficiency.

Shape Memory Effect in Medical Devices

The shape memory effect (SME) is one of the most defining features of nitinol tubing. This property allows the material to return to its original shape after deformation when exposed to a specific temperature. In medical applications, this capability is crucial for devices that need to adapt to the human body’s dynamic environment. For instance, nitinol stents can be compressed for insertion and then expand to their intended shape once inside the body, ensuring precise placement and functionality.

Research highlights the importance of phase transformation temperature and electrolyte temperature in optimizing the shape memory effect. These parameters play a critical role in the polishing and shape-setting processes of nitinol tubing. By fine-tuning these factors, manufacturers can enhance the performance of medical devices, ensuring they meet the rigorous demands of clinical applications.

Superelasticity for Enhanced Flexibility

Superelasticity is another key property of nitinol tubing, enabling it to undergo significant deformation and return to its original shape without permanent damage. This flexibility is particularly valuable in medical devices that navigate complex anatomical structures, such as guidewires and catheters. The ability to bend and flex without breaking ensures both safety and effectiveness during medical procedures.

Performance tests validate the superelasticity of nitinol tubing through various methods:

Mechanical Property Validation: Tensile testing establishes stress-strain relationships, focusing on the superelastic plateau.

Fatigue Testing: Evaluates the material's endurance against repeated deformation cycles, ensuring long-term durability.

Electrochemical Testing: Assesses resistance to corrosive environments, confirming suitability for diverse medical applications.

Surface Finish Inspection: Advanced microscopy identifies potential stress concentration points, enhancing reliability.

These rigorous tests ensure that nitinol tubing meets the highest standards of performance and safety, making it indispensable in modern medical technology.

Biocompatibility and Safety in Medical Applications

The biocompatibility of nitinol is a critical factor in its widespread use in medical devices. This property ensures that nitinol tubing interacts safely with human tissues, minimizing the risk of adverse reactions. The long-term biocompatibility of nitinol has been extensively studied, confirming its suitability for implants and other devices that remain in the body for extended periods.

Nitinol tubing’s resistance to corrosion further enhances its safety profile. In the human body, exposure to fluids and varying pH levels can lead to material degradation. However, nitinol’s unique composition and surface treatments provide exceptional resistance, ensuring durability and reliability. This makes it an ideal choice for applications such as cardiovascular stents, orthopedic implants, and endoscopic instruments.

Note: The combination of shape memory and superelasticity, along with biocompatibility, positions nitinol tubing as a game-changing material in the medical field. Its ability to adapt, endure, and integrate seamlessly with the human body underscores its transformative impact on healthcare.

Medical Nitinol Tubing Applications

Cardiovascular Devices and Vascular Grafts

Nitinol tubing has become a cornerstone in the development of cardiovascular devices. Its unique properties, such as superelasticity and biocompatibility, make it ideal for creating stents, vascular grafts, and nitinol guidewires. These devices play a critical role in treating conditions like arterial blockages and aneurysms.

Nitinol's superelasticity allows stents to be compressed for insertion and then expand to their intended shape, ensuring a precise fit within blood vessels.

The material's biocompatibility and corrosion resistance enhance the safety and longevity of cardiovascular devices, reducing the need for replacements.

Nitinol's flexibility and ability to conform to the body's natural contours improve patient comfort during procedures.

Self-expanding stents made from nitinol tubing are particularly transformative. These stents adapt to the dynamic environment of blood vessels, maintaining their shape and functionality even under varying pressures. Additionally, nitinol catheters and guidewires enable precise navigation through complex vascular pathways, ensuring successful outcomes in minimally invasive procedures.

Orthopedic Implants and Bone Fixation

Orthopedic implants represent another significant area where nitinol tubing excels. The material's shape memory and superelasticity allow it to adapt to the body's movements, making it an excellent choice for bone fixation and joint stabilization. Nitinol's durability ensures that these implants withstand the mechanical stresses of daily activities.

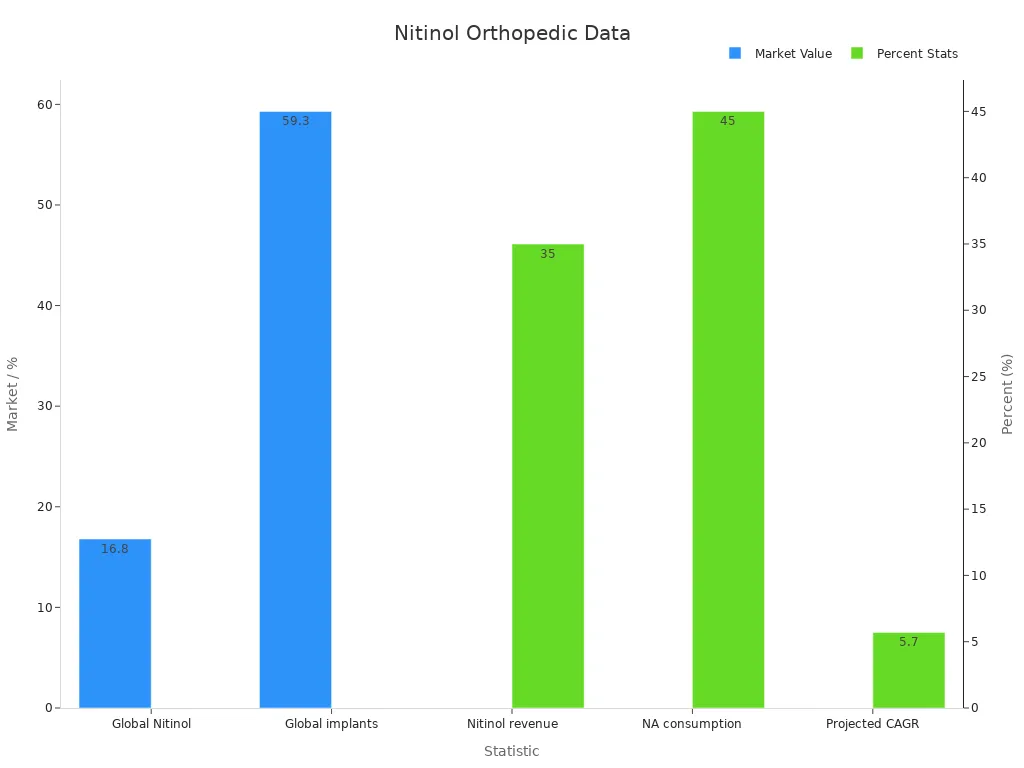

The global prevalence of nitinol tubing in orthopedic implants highlights its importance:

Statistic | Value |

|---|---|

Global Nitinol market size | $16.8 billion in 2023 |

Nitinol tubing revenue share | ~35% of total revenue |

North America consumption share | ~45% |

Global orthopedic implants market | $59.3 billion in 2023 |

Projected CAGR for orthopedic market | 5.7% through 2030 |

Nitinol's biocompatibility further enhances its suitability for orthopedic applications. It minimizes the risk of adverse reactions, ensuring long-term safety for patients. This makes nitinol tubing indispensable in the design of advanced orthopedic implants.

Endoscopic Instruments for Minimally Invasive Procedures

Minimally invasive procedures rely heavily on the flexibility and precision of nitinol tubing. Endoscopic instruments, such as nitinol guidewires and catheters, benefit from the material's ability to navigate tight and complex anatomical structures. These tools enable surgeons to perform procedures with minimal trauma to surrounding tissues.

Nitinol's superelasticity ensures that these instruments can bend and flex without breaking, even under repeated use. This durability reduces the risk of complications during procedures. Additionally, nitinol tubing's resistance to corrosion ensures that these instruments maintain their integrity in the challenging environments of the human body.

Drug delivery systems also leverage nitinol tubing for precise and controlled medication administration. The material's adaptability allows for the creation of devices that conform to the body's natural contours, ensuring accurate delivery to targeted areas. This innovation has revolutionized the field of minimally invasive surgical tools, improving patient outcomes and recovery times.

Tip: The integration of nitinol tubing in minimally invasive procedures has significantly reduced recovery times and improved patient comfort, making it a game-changer in modern medicine.

Advantages of Nitinol Tubing in Manufacturing

Durability and Corrosion Resistance

Nitinol tubing offers exceptional durability and resistance to corrosion, making it a preferred material for medical applications. Its ability to withstand repeated stress cycles without failure ensures reliability in devices like vascular dilation tools. Unlike stainless steel or titanium alloys, nitinol exhibits superior biocompatibility and corrosion resistance, reducing the risk of adverse reactions and ensuring long-term performance in the body’s harsh internal environment.

Property | Nitinol | Other Materials |

|---|---|---|

Elasticity | Exceptional elasticity | Limited flexibility |

Superelasticity | Withstands significant strain | Limited strain capacity |

Flexibility | Highly flexible without kinking | Often rigid or less flexible |

Recent advancements in material science have further enhanced nitinol tubing’s durability. Improved processing techniques now allow for greater precision, optimizing its superelasticity and thermal memory. These innovations ensure that nitinol tubing meets the rigorous demands of modern medical devices.

Design Flexibility for Complex Anatomical Structures

Nitinol tubing’s unique properties make it highly adaptable to complex anatomical structures. Its superelasticity allows it to flex and bend without permanent deformation, enabling it to navigate intricate vascular systems. This maneuverability is critical for medical devices like catheters and guidewires, which must traverse challenging pathways without kinking.

Property | Description |

|---|---|

Superelastic Properties | Allows significant reversible strain, ensuring flexibility. |

Biocompatibility | Proven compatibility with biological tissues through in vitro and in vivo studies. |

Phase Transformation | Enables adaptation to complex anatomical structures. |

Maneuverability | Navigates vascular systems without kinking, enhancing usability. |

Reversible Strain | Capable of 6-8% reversible strain, ideal for flexible applications. |

This design flexibility also extends to nitinol’s ability to conform to the body’s natural contours. Its phase transformation properties ensure that it adapts seamlessly to dynamic environments, making it indispensable in advanced medical devices.

Cost-Effectiveness in Medical Device Production

Nitinol tubing offers significant cost advantages in medical device manufacturing. Its durability reduces the need for frequent replacements, lowering long-term costs for healthcare providers. Additionally, its unique properties allow manufacturers to create multifunctional devices, minimizing the need for additional components.

Enhanced processing methods have improved production efficiency, enabling the creation of high-quality nitinol tubing at scale. These advancements reduce waste and streamline manufacturing, making nitinol an economically viable choice for medical applications. Its ability to combine durability, flexibility, and biocompatibility in a single material further underscores its cost-effectiveness.

Note: The combination of durability, design flexibility, and cost-effectiveness makes nitinol tubing a cornerstone of modern medical device manufacturing. Its transformative impact continues to shape the future of healthcare.

Nitinol tubing has revolutionized medical applications through its unique properties. Its shape memory effect and superelasticity allow devices to adapt to dynamic environments, improving surgical precision and reducing procedure times. Nitinol’s biocompatibility ensures safety in implants, minimizing adverse reactions and enhancing patient comfort.

The material’s versatility is evident in its use across cardiovascular, orthopedic, and endoscopic devices. Self-expanding stents made from nitinol tubing provide less invasive treatment options, while orthopedic implants benefit from its durability and ability to mimic natural anatomical structures. Endoscopic instruments leverage nitinol’s flexibility to navigate complex pathways, improving outcomes in minimally invasive procedures.

Manufacturing advantages further solidify nitinol tubing’s role as a game-changing material. Its durability reduces the need for replacements, while design flexibility enables the creation of complex geometries tailored to human anatomy. Clinical studies confirm nitinol’s reliability, with long-term data showcasing its ability to withstand millions of fatigue cycles. These attributes make nitinol tubing indispensable in modern medical device production.

Note: Nitinol tubing’s transformative impact on healthcare stems from its adaptability, durability, and safety. Its contributions to medical devices continue to shape the future of medicine, offering innovative solutions that enhance patient outcomes and procedural efficiency.

FAQ

What makes nitinol unique compared to other materials in medical applications?

Nitinol stands out due to its shape memory, superelasticity, and biocompatibility. These properties allow it to adapt to the human body, making it ideal for advanced medical devices like stents, implants, and guidewires.

How does nitinol improve minimally invasive procedures?

Nitinol’s flexibility and superelasticity enable medical instruments to navigate complex anatomical pathways. This reduces trauma to surrounding tissues, shortens recovery times, and enhances procedural precision.

Is nitinol safe for long-term use in the human body?

Yes, nitinol is highly biocompatible and resistant to corrosion. These qualities ensure its safety and durability for long-term applications, such as implants and cardiovascular devices.

Can nitinol tubing be customized for specific medical needs?

Manufacturers can tailor nitinol tubing to meet specific requirements by adjusting its shape memory and superelastic properties. This customization ensures compatibility with diverse medical applications.

Why is nitinol considered cost-effective in medical device production?

Nitinol’s durability reduces the need for frequent replacements. Its unique properties also allow for multifunctional designs, minimizing additional components and lowering overall production costs.

See Also

Nitinol Tubing: Transforming The Future Of Medical Devices

The Importance Of Nitinol Tubing In Modern Medical Uses

Nitinol Tubing's Contribution To Progressing Medical Technologies