Comparing Nitinol Tubing Manufacturing Processes for Optimal Mechanical Properties

Comparative studies show that the TM-1 nitinol tubing manufacturing process provides the best mechanical properties. This is especially true for nitinol tubing, where the Nitinol Tubing manufacturing process significantly impacts fatigue life and surface quality.

Manufacturing Process | Fatigue Life | Surface Quality |

|---|---|---|

TM-1 | Highest | High concentricity |

TM-2 | Lower | Less uniform |

Careful control of heat treatment, thermomechanical processing, and purity throughout the Nitinol Tubing manufacturing process ensures that nitinol meets strict standards for medical device production. Experts emphasize that every step in the Nitinol Tubing manufacturing process affects nitinol’s superelasticity, durability, and reliability in clinical applications.

Key Takeaways

Picking the best way to make nitinol tubing helps it get stronger. It also makes the surface smoother and helps it last longer.

Watching heat, cold work, and finishing closely helps tubing keep its shape. It also lets it bend and stay tough.

Keeping the tubing very pure stops weak spots and cracks. This makes the tubing safer and helps it last longer.

Additive manufacturing lets you change designs easily. But it needs more polishing and heating to be as good and safe as regular tubing.

For medical devices, working with experts who follow strict rules helps tubing fit well. It also makes sure the tubing works every time.

Nitinol Tubing Manufacturing Process Overview

Key Steps in Nitinol Tubing Production

Making nitinol tubing takes many careful steps. Each step changes how the tubing will work in the end. The table below shows the main steps and how they affect the tubing:

Manufacturing Step | Influence on Mechanical Properties and Final Performance |

|---|---|

Melting and Alloying | This step sets what is in the alloy and how pure it is. Even a little oxygen or carbon can make the tubing weaker and less tough. |

Hot Working | This step makes the grains smaller by heating and shaping. Smaller grains help the tubing be stronger and last longer. |

Cold Working and Drawing | This step shapes the tubing at room temperature. It makes the tubing stronger, but it must be done carefully so the tubing does not get too brittle. |

Heat Treatment | This step removes stress and gives the tubing its special shape memory and superelasticity. Good heat treatment makes the tubing bend better and last longer. |

Surface Finishing | This step smooths out the surface and helps stop rust. A smooth finish is very important for safety and for the tubing to last longer. |

Note: Keeping the nickel-titanium ratio just right and using special tube making methods, like vacuum annealing and electropolishing, can make the tubing last two or three times longer than normal.

Importance of Processing Parameters

How the tubing is made depends on some important things. These things decide if the tubing will work well and last long:

Heat treatment gives the tubing its shape memory and superelasticity by setting the right temperatures.

Surface finishing, like polishing and electropolishing, helps stop rust and makes the tubing safe for the body, which is very important for medical use.

Making sure the alloy mix is just right helps the tubing stay strong and even.

Shaping the tubing early with hot working makes the grains smaller and lowers stress inside, which keeps the tubing’s good qualities.

Careful checks, like testing without breaking the tubing and measuring it, find problems early and make sure the tubing meets strict rules.

Using machines and AI in tube making helps make the tubing the same every time and finds problems faster.

The way nitinol tubing is made uses these steps to get the best mechanical properties. Each step, from melting to finishing, shows why picking the right tube making method matters. Companies that use the best ways to make tubing get nitinol tubing that is stronger, lasts longer, and works better.

Nitinol Properties and Processing Effects

Shape Memory and Superelasticity

Nitinol is special because it can remember its shape. It also stretches more than most metals and goes back to normal. This happens because of how the tubing is made. When engineers heat nitinol, the atoms move and lock in a new way. That is what gives nitinol its shape memory. Superelasticity means nitinol can bend a lot and not break. Medical devices use these features to fit inside the body and then change shape when needed.

How the tubing is made, like heating and smoothing the surface, controls when nitinol changes. This helps the tubing work well in real life. For example, heating nitinol just right sets the austenite finish temperature. This is important for superelasticity. Smoothing the surface, like with electropolishing, takes away defects and helps stop rust. This makes the tubing safer for people.

Microstructure and Phase Control

Controlling the microstructure is important for strong nitinol tubing. Microstructure means things like grain size and how phases are spread out. Steps like hot working and cold drawing make the grains smaller and the tubing stronger. The table below shows how these features change nitinol’s properties:

Aspect | Observation/Result | Effect on Mechanical Properties |

|---|---|---|

Microstructure | Smaller grains make tubing harder and stronger | Tubing lasts longer and is tougher |

Secondary Phases | Ni4Ti3 helps superelasticity; NiTi2 changes hardness | Lets tubing work better for different jobs |

Chemical Composition Effects | Ti-rich layers help shape memory but lower superelasticity | Balances shape memory and how much it can bend |

Careful control of things like heat and cooling changes the microstructure. For example, a Ti-rich layer helps shape memory but can lower superelasticity. New ways to make tubing, like WAAM, let engineers change the microstructure and phases. This helps make nitinol tubing with special features for new uses.

Tip: Keeping the microstructure the same during tube making helps nitinol tubing work well every time.

Heat Treatment in Nitinol Tubing

Temperature Ranges and Effects

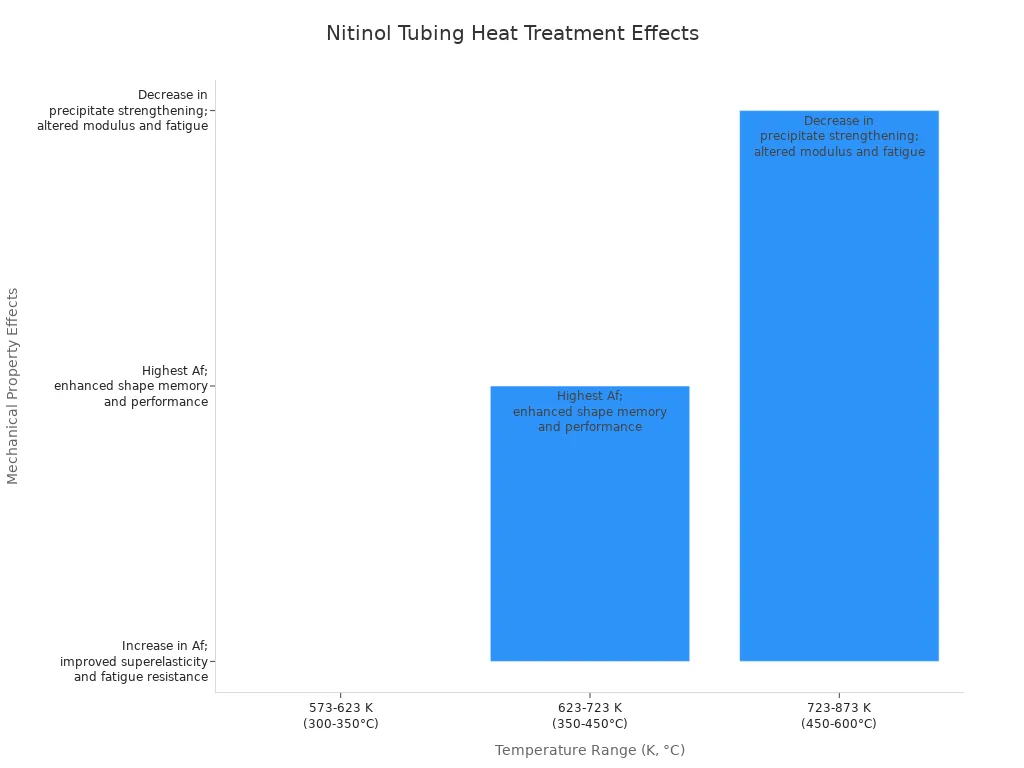

Heat treatment is very important for nitinol tubing. It helps give the tubing its special features. Makers use certain temperatures to change the inside structure. They also control how nitinol changes between phases. The table below shows what happens at different heat treatment temperatures:

Heat Treatment Temperature Range (K) | Approx. °C | Microstructural/Phase Effects | Mechanical Property Effects |

|---|---|---|---|

573 - 623 | 300 - 350 | Makes R-phase and two-stage changes; lots of Ni4Ti3 forms | Transformation temperatures go up; tubing bends better and lasts longer |

623 - 723 | 350 - 450 | Best amount of Ni4Ti3 forms; nickel drops in the mix | Highest Af temperature; tubing remembers shapes and works well |

723 - 873 | 450 - 600 | Faster mixing; Ni4Ti3 goes away at high end, so only one change happens | Less strengthening; superelastic stress changes; tubing bends and lasts differently |

Makers pick the right temperature for the tubing they want. Lower temperatures make tiny particles that make tubing stronger. Higher temperatures can melt these particles and change how tubing acts. The chart below shows how tubing strength and bending change with temperature:

Note: How long the tubing is heated matters too, but temperature changes nitinol the most.

Shape Setting and Austenitic Finish Temperature

Shape setting makes nitinol tubing hold a certain shape. Engineers heat the tubing, bend it, and cool it to keep that shape. This sets the Af temperature, which is very important for how nitinol works.

The austenitic phase makes nitinol strong and tough.

Af is usually close to 50°C, when nitinol gets hard and strong.

Shape memory and superelasticity need this change to happen.

Medical stents and airplane parts need Af set for their jobs.

The nickel-titanium mix controls Af. More nickel lowers Af. More titanium raises Af.

Heat treatments and adding copper or hafnium can change Af and help tubing last longer.

When Af matches the job’s temperature, nitinol tubing works best. For example, medical tubing should have Af just under body temperature. This keeps tubing safe and bendy inside people.

Tip: Changing Af helps engineers make nitinol tubing fit each job, making it safer and better.

Thermomechanical Processing

Grain Refinement and Mechanical Properties

Grain refinement is very important for nitinol tubing. When makers cool the metal fast or use special methods like selective laser melting, they make smaller grains inside. Smaller grains make the tubing harder and stronger. For example, tubing made this way is harder than tubing made with old methods. Rotary friction welding also makes small grains at the weld. This keeps the tubing strong and helps it remember its shape.

Small grains do more than make tubing strong. They help the tubing bend without breaking. Some steps, like equal channel angular pressing, make grains even smaller. This makes the tubing stronger and better at handling stress. The tubing stays flexible and keeps its superelasticity. Making grains smaller does not make the tubing weaker or easier to break. Nitinol tubing stays safe and works well for tough jobs.

Note: Tubing with small grains is strong and flexible, so it works well for medical and industrial uses.

Cold Working and Annealing

Cold working shapes nitinol tubing when it is cool. This step makes the inside better and helps the tubing last longer. It also gets rid of holes and bad bits, so the tubing is stronger. Cold working lets the tubing bend many times without breaking.

After cold working, annealing is needed. Annealing at about 450°C takes away stress and makes the inside better. This step helps the tubing bend and remember shapes by making phase changes stable. But if annealing is not done right, grains can get too big and the tubing gets weaker. Makers must balance cold working and annealing to get the best tubing.

Cold working makes tubing strong and helps it last longer.

Annealing makes tubing bendy and helps it remember shapes, but too much can make it weak.

Aging can add tiny particles that make tubing even stronger.

Careful steps make sure nitinol tubing is strong, bendy, and lasts a long time.

Fatigue Life of Nitinol Tubing

Impact of Manufacturing Methods

How nitinol tubing is made changes how long it lasts. Different ways of making tubing affect how it handles bending and stretching over and over. TM-1 and TM-2 are two main ways to make nitinol tubing. TM-1 uses special diamond tools and hard rods. This keeps the tubing straight and smooth. TM-2 uses carbide tools and rough cleaning. This can leave small flaws and rough spots.

TM-1 makes tubing that lasts longer and has fewer cracks. TM-2 tubing has more flaws. These flaws can start cracks. When tubing bends a lot, cracks get bigger and make it weaker. TM-2 makes more places where cracks can start. TM-1 helps close gaps and makes the tubing stronger.

Note: How the tubing is made is just as important as what it is made from.

High-Cycle Fatigue Performance

Tests show TM-1 tubing lasts much longer than TM-2. TM-1 can bend two or three times more before breaking. At 10^7 bends, TM-1 keeps its shape and strength better. TM-1 tubing is stronger and lasts longer. TM-1 even matches TM-2 tubing made from purer nitinol.

The table below shows the differences:

Manufacturing Method | High-Cycle Fatigue Endurance | Fatigue Strength | Surface Quality |

|---|---|---|---|

TM-1 | 2–3x higher | Higher | Smoother |

TM-2 | Lower | Lower | Less uniform |

How long tubing lasts depends on the size and number of inclusions. TM-2 tubing has bigger inclusions, which makes it weaker. TM-1 makes the inside more even. This helps stop cracks during lots of bending. TM-2 can cause uneven stress, making tubing weaker.

Special steps like low-temperature aging and pre-strain help tubing last longer. These steps are important for medical devices that bend many times. High-cycle fatigue performance is very important for tubing that must bend and flex a lot without breaking.

Purity and Melting Control in Nitinol

Impurities and Mechanical Performance

Purity is very important for how nitinol tubing works. If carbon or oxygen get into the alloy, they make things called carbides and oxides. These are non-metallic inclusions. Inclusions are weak spots in the tubing. They collect stress and can start cracks. Cracks make the tubing break sooner when it bends a lot. The size and shape of inclusions matter too. Bigger or oddly shaped inclusions make the tubing more likely to fail.

Makers use special melting methods to keep out these impurities. Vacuum induction melting and vacuum arc remelting help keep carbon and oxygen low. Using pure materials also helps stop bad inclusions from forming. When there are fewer inclusions, the tubing lasts longer. Some studies show tubing with less inclusions can last five times longer than normal tubing.

Surface finishing, like polishing or etching, helps the tubing last even longer. These steps take away surface problems that could make inclusions worse. A smooth surface also helps the tubing be safe in the body. This is important for medical devices.

Quality Control Measures

Strict quality checks make sure nitinol tubing is pure and works well. Makers follow ASTM F2063 rules to limit carbon and oxygen. They use vacuum melting to stop contamination when making the alloy. Every batch gets tested for strength, rust resistance, and safety in the body.

Quality control starts with very pure nickel and titanium, usually above 99.9%. Special tools like ICP-MS and XRF find even tiny bits of bad elements. During melting, careful control of heat and pressure keeps the alloy the same. After melting, mixing makes sure all parts are spread out evenly.

Makers also use software and process checks to watch every step. Labs with special approval test each batch to make sure it meets the rules. Good records and tracking help keep nitinol tubing safe for important jobs.

Tip: Good quality checks and special melting methods help nitinol tubing stay pure for tough jobs, especially in medicine.

Additive Manufacturing and Nitinol Tubing

Internal Stresses and Defects

Additive manufacturing, like laser powder bed fusion, builds nitinol tubing layer by layer. Lasers melt metal powder to make each layer. When each layer cools, it creates stress inside the tubing. These stresses are not even everywhere. They change based on how fast the laser moves, how close the lines are, and how much energy is used. If the laser moves slower or lines are closer, stress goes up. But after a point, using more energy can lower the stress.

These stress patterns can make different crystals and phases inside the tubing. Some spots may have more martensite or the R-phase. This means the tubing can act differently in different places. Overlapping scans can also make tiny cracks. These cracks are not as common in tubing made the old way. Traditional nitinol tubing gets checked with special tools to find and fix defects. Surface treatments like electropolishing help smooth out flaws and make tubing safer. Additive manufacturing needs extra steps to lower stress and fix defects so the tubing is as good as traditional tubing.

Note: Careful control and extra steps help lower stress and fix defects in additively made nitinol tubing.

Nickel Loss and Surface Quality

Nickel is very important for how nitinol tubing bends and returns to shape. During additive manufacturing, some nickel can be lost, usually about 1–2%. Losing nickel changes the temperatures where nitinol switches between phases. For example, the austenitic finish temperature can drop to 23–29 °C. The martensitic start can fall to 7.5–10.5 °C. These changes affect how well the tubing works, especially for medical devices that need to move just right.

Surface quality is also important. Additive manufacturing often leaves the tubing rough and full of tiny holes near the surface. This roughness can make the tubing weaker and less safe for the body. Laser polishing with CO2 lasers can smooth the surface by up to 91% and fix small holes. But some polishing, like femtosecond lasers, can change the surface layer and affect how the tubing acts.

Factor | Impact on Tubing Performance |

|---|---|

Nickel Loss | Lowers phase change temperatures, affects shape memory |

Surface Roughness | Weakens tubing, may reduce safety |

Laser Polishing | Smooths surface, improves strength |

Tip: Keeping the right amount of nickel and using good surface finishing steps help make sure additively made nitinol tubing is strong and safe.

Comparison of Nitinol Tubing Manufacturing Methods

Mechanical Properties Table

The way nitinol tubing is made changes how it works. Each method changes things like how long it lasts, how strong it is, and how well it bends. The table below shows how regular and additive manufacturing are different:

Aspect | Conventional Manufacturing | Additive Manufacturing (LPBF) |

|---|---|---|

Microstructure | Randomly oriented grains | Columnar grains with strong <001> texture |

Grain Orientation | Isotropic properties | Anisotropic properties |

Defects | Fewer process-related defects | More defects: nickel loss, porosity, stress |

Fatigue Life | High, uniform across tubing | Lower, varies with build direction |

Tensile Strength | Consistent, high | Tailorable, but can be inconsistent |

Superelasticity | Stable, reliable | May require post-processing to optimize |

Flexibility | Predictable, high | Can be designed, but less uniform |

Geometrical Complexity | Limited | Enables complex, custom shapes |

Material Waste | Higher | Lower |

Regular manufacturing makes tubing that is strong and bends the same way everywhere. The grains inside point in all directions, so the tubing is even. Additive manufacturing builds tubing one layer at a time. This makes the grains line up and act differently in each direction. Additive tubing can have more problems inside, like tiny holes and less nickel. These problems can make the tubing weaker and not bend as well. Extra steps, like heating, are often needed to fix these problems and make the tubing work better.

Tip: For medical devices that need to bend a lot and stay strong, regular manufacturing is usually best.

Process-Specific Challenges

Each way of making nitinol tubing has its own problems. These problems can make the tubing less safe, especially for important uses.

Manufacturing Method | Process-Specific Challenges | Effect on Product Reliability |

|---|---|---|

Laser Cutting | Heat generation causes heat-affected zones (HAZ) and microcracks; requires precise control | Microcracks and HAZ reduce structural integrity and fatigue resistance |

Shape Setting | Needs precise temperature control to maintain shape memory and superelasticity | Inconsistent shape setting degrades functional performance and reliability |

Machining | Tool wear and thermal damage due to superelasticity; needs optimized parameters | Surface defects and microcracks compromise strength and fatigue life |

Surface Finishing | Must remove irregularities and contaminants; uses electropolishing and chemical etching | Enhances biocompatibility, reduces corrosion, improves device longevity |

Regulatory & Cost | Compliance with strict standards and high costs | Delays and increased costs affect production efficiency and availability |

Innovations | Cryogenic machining, pulse-shaping, advanced cooling reduce heat and tool wear | Improve surface integrity, reduce defects, and enhance reliability |

Laser cutting and welding use heat, which can make weak spots. These weak spots can crack and make the tubing break sooner.

New ways, like femtosecond lasers and pulse-shaping, use less heat. These help stop cracks and keep the tubing strong.

Surface finishing, like electropolishing, smooths out cracks and takes away dirt. This makes the tubing safer for the body and helps it last longer.

Chemical etching also removes bad spots on the surface, making the tubing stronger and better at bending.

Following rules and using special machines can cost a lot and slow down making tubing. This can make it harder to get good tubing quickly.

Choosing how to make nitinol tubing means thinking about these problems. Good tubing needs careful heat control, fixing flaws, and checking quality. New ideas, like cooling with special methods, help make tubing last longer and work better.

Note: The way tubing is made changes how long it lasts, how well it bends, and how safe it is. Makers must pick the right method to get strong, safe tubing that works well.

Nitinol in Medical Device Manufacturing

Application-Specific Process Selection

Nitinol tubing is used in many medical devices. These include stents, catheters, and guidewires. Makers pick how to make the tubing based on what each device needs. For example, neurovascular stents need very thin walls and small sizes. They also must last a long time without breaking. These things help the stents move through tiny blood vessels and keep working as the body moves.

Makers work with suppliers who know a lot about nitinol.

Suppliers change the nickel-titanium mix to get the right shape memory and superelasticity.

Getting the size just right, like the outer diameter and wall thickness, helps the tubing fit each device.

Surface finishing, such as electropolishing, makes the tubing safer for the body and smoother.

Custom jobs, like special cutting and bending, help make tubing for each device.

Making medical devices also needs special certifications. The table below shows some important rules:

Certification/Requirement | Description | Impact on Process Selection and Cost |

|---|---|---|

ISO 13485 | Quality rules for medical devices | Makes sure standards are met; adds 20-25% to costs |

FDA Compliance | Proves safety and checks with real patients | Shows safety; clinical trials can cost over $5 million |

Biocompatibility Testing | Checks if safe for the body | Needed for safety; makes products cost more |

When designing with nitinol, makers must pick steps that fit both the job and the rules.

Reliability and Performance Considerations

Nitinol tubing is special because it can bend and return to shape. This helps devices recover after bending or stretching. The tubing can stretch over 5% and still go back to normal. A titanium oxide layer keeps nickel from leaking out. This keeps implants safe and stops bad reactions in the body.

New ways of making tubing, like laser cutting and drawing, help get the size just right.

Special tests, like ultrasonic and eddy current, find problems without breaking the tubing.

Surface finishing, such as electropolishing, helps stop rust and makes the tubing safer for people.

Special coatings, like hydrophilic or antimicrobial layers, make devices even safer and better.

Using nitinol helps engineers make devices that last a long time. Tests show nitinol stents and implants keep their shape and work well for years. Makers trust these features to make safe medical devices and help patients feel better.

Tip: When makers and skilled suppliers work together, they make safer and better devices with nitinol.

Future Trends in Nitinol Tubing

Emerging Technologies

Manufacturers are finding new ways to make nitinol tubing better. They use advanced surface finishing and precise cutting. New forming methods also help improve tubing. The table below shows some new technologies that change how nitinol tubing is made:

Emerging Technology | Description / Role in Manufacturing | Mechanical Property Improvement Impact |

|---|---|---|

Electropolishing | Smooths and cleans tubing surfaces | Improves fatigue resistance and durability |

Laser Cutting | Shapes and patterns tubing with high precision | Reduces stress points and boosts reliability |

Shape Setting | Uses heat to set shape memory effect | Controls superelastic properties |

Braiding | Creates complex tube structures | Increases flexibility and strength |

Centerless Grinding | Refines diameter and surface finish | Enhances consistency and accuracy |

CNC Machining | Computer-controlled shaping and finishing | Delivers repeatable mechanical performance |

Photochemical Machining | Etches fine features without stress | Preserves material properties |

Microforming | Forms intricate shapes with minimal damage | Improves mechanical behavior |

Gun Drilling | Drills precise internal geometries | Enhances reliability and surface integrity |

Custom Laser Systems | Tailors laser solutions for specific needs | Raises precision and quality |

Polymer Coatings | Applies advanced surface treatments | Boosts durability and biocompatibility |

Sutureless Coverings | Adds innovative coverings for medical use | Protects tubing while keeping flexibility |

These new methods help nitinol tubing work better in medical devices, robots, and airplanes. Manufacturers use electropolishing and laser cutting to make tubing with fewer problems. These steps help tubing last longer and bend more times. Precision processes like gun drilling and custom lasers help make tubing that is always the same and works well.

Research Opportunities

Scientists are looking for ways to make nitinol tubing even stronger. They study the nickel-titanium mix to help tubing bend better and remember shapes. New heat treatment methods help tubing last longer and not break easily. Surface finishing, like laser polishing, makes tubing smoother and removes flaws.

Researchers also try additive manufacturing and 3D printing to make tubing with special shapes. They want to lower costs and make sure tubing is always good quality. Some new ideas include putting sensors inside nitinol tubing for health and engineering uses.

Recent progress shows it is important to control transition temperature and fatigue resistance. Strict rules like ASTM F2063 help keep medical nitinol safe. Better supply chains and new ways to make tubing have made it faster to get and easier to find. These changes help make life-saving devices and open new uses for nitinol tubing.

Tip: More research and new ways to make tubing will help nitinol tubing meet the needs of doctors and engineers.

Recent studies show some steps make nitinol tubing work best. These steps include vacuum arc remelting, hot working, cold drawing, and careful heat treatment. The table below shows how each step helps:

Step | Impact on Mechanical Properties and Applications |

|---|---|

Vacuum Arc Remelting | High purity, consistent transformation temperatures |

Hot Working | Uniform grain structure, increased strength |

Cold Drawing | Precise dimensions, tailored thermoelastic properties |

Heat Treatment | Shape memory, superelasticity |

Surface Processing | Improved corrosion resistance, biocompatibility |

To pick the right process for medical devices, experts suggest these tips. First, ask suppliers if they will give samples for testing. Next, visit their factories to see how they make tubing and check quality. Look at how well suppliers can customize tubing for special needs. Make sure they have the right certifications and follow important rules. Compare different suppliers for quality, price, and how reliable they are. Think about cost, but also how long the tubing will last. Choose suppliers who have a good history with following rules.

Scientists keep working to make nitinol tubing better. They create new alloys and improve how the surface is finished. They use 3D printing to make tubing with special shapes. Adding sensors and using AI helps make smarter devices and helps patients do better.

FAQ

What makes nitinol tubing different from other metal tubes?

Nitinol tubing can bend and go back to its shape. This is because it has shape memory and superelasticity. Most other metals do not do this. Medical devices use nitinol because it is strong and flexible.

How does heat treatment affect nitinol tubing?

Heat treatment helps nitinol tubing remember its shape. It also makes it bendy and last longer. If the temperature is wrong, the tubing can get weak. It can also change when the tubing switches phases.

Why is purity important in nitinol tubing?

Purity helps nitinol tubing stay strong and last longer. If there is carbon or oxygen, weak spots can form. These weak spots can turn into cracks. Cracks can make the tubing break early, which is bad for medical devices.

Can additive manufacturing produce medical-grade nitinol tubing?

Additive manufacturing can make tubing with special shapes. But it often makes more rough spots and tiny flaws. Extra steps like polishing and heating are needed. These steps help the tubing meet tough medical rules.

What are the main uses of nitinol tubing in medicine?

Stents

Guidewires

Catheters

Doctors use nitinol tubing because it bends easily. It also goes back to its shape. This helps devices move safely inside the body.

See Also

The Process Behind Manufacturing Nitinol Tubing For Medicine

Evaluating Tensile Strength Between Nitinol And Stainless Steel Tubing

Choosing The Right Nitinol Tubing Supplier To Fit Your Needs

Comprehensive Guide To Nitinol Parts And Production Methods

Nitinol Tubing Transforming The Future Of Medical Device Technology