How Nitinol Tubing Powers Precision in Minimally Invasive Surgical Graspers

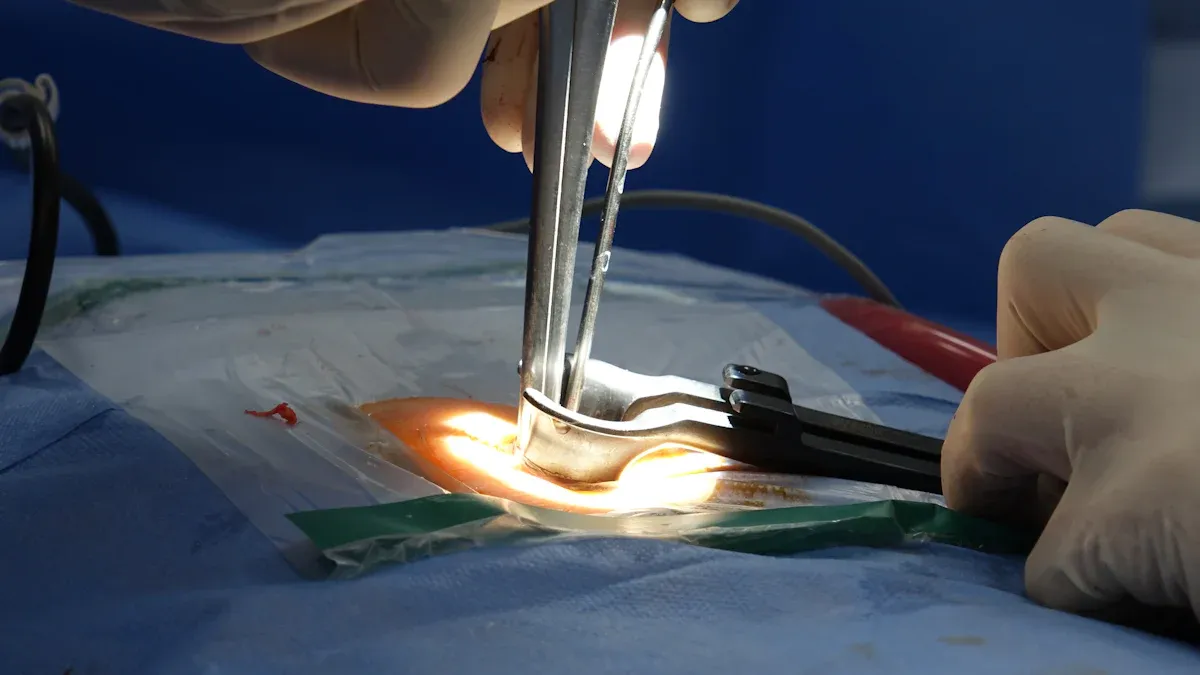

Nitinol tubing in minimally invasive surgical graspers plays a crucial role in allowing surgeons to maneuver these tools with exceptional precision. This specialized nitinol tubing is valued for its superelasticity, shape memory, and excellent wear resistance. These properties enable the tubing to bend and return to its original shape repeatedly, even after extensive use in surgical procedures. The outer diameter of the nitinol tubing in minimally invasive surgical graspers is controlled with a tight tolerance of ±0.005 mm, while the wall thickness tolerance is maintained at ±0.0075 mm, ensuring the graspers perform with high accuracy.

Surgeons prefer nitinol tubing in minimally invasive surgical graspers because it minimizes tissue trauma. It can withstand high burst pressures exceeding 400 bar and offers remarkable flexibility. Additionally, nitinol is biocompatible and corrosion-resistant, making it safe for use inside the body during surgery.

Performance Metric | Numerical Value / Description |

|---|---|

Fatigue Life | 2-3 times greater at 10^7 cycles |

OD Tolerance | ±0.005 mm (when OD is more than 0.80 mm) |

Wall Thickness Tolerance | ±0.0075 mm (when thickness is 0.05–0.12 mm) |

Burst Pressure Threshold | More than 400 bar |

Biocompatibility Scores | Histological scores 0-1; no big inflammation |

Key Takeaways

Nitinol tubing bends very easily and goes back to its shape. This makes surgical graspers work well and be very reliable in small surgeries. Its strong, bendy, and body-safe features help stop tissue harm. It also lowers the chance of allergies and keeps people safe inside the body. New designs like laser-cut shapes and cableless actuation give better control. They also make tools simpler and help surgeries go faster. Nitinol tubing is better than old materials. It lasts longer, bends more without breaking, and gives surgeons better feel. In the future, nitinol tubing will have smart devices and custom shapes. These will make surgeries even safer and help patients heal faster.

Nitinol Tubing in Minimally Invasive Surgical Graspers

Shape Memory and Superelasticity

Nitinol tubing is special because it remembers its shape. If you bend or twist it, it goes back to how it was before. It can stretch or squeeze a lot, sometimes up to 10%, and not break. This helps doctors move graspers through small or curved places in the body. When a doctor bends the grasper, the nitinol tubing quickly returns to its first shape. This makes the tool easy to use and very dependable.

Experts test nitinol tubing’s shape memory with special methods. These tests show nitinol can handle strains of 5% to 8%. It keeps working even after being bent millions of times. That is why nitinol tubing is great for surgery tools used again and again.

Property / Test | Evidence / Result |

|---|---|

Superelasticity and Shape Memory Effect | Nitinol tubing can stretch over 4% and up to 10% with special processing. It bends and goes back to its shape without staying bent. |

Mechanical Testing | Differential Scanning Calorimetry finds important temperatures for shape memory. Bend Free Recovery checks how well it returns to shape. Tensile Testing proves it is superelastic and strong against breaking. |

Clinical Success Rate | Nitinol tubing works well in 97% of cases (70 out of 72 patients). This shows ASTM F2063 certified nitinol tubing is reliable. |

Long-term Safety | After 12 months, 96.7% of patients (29 out of 30) had good results. This means nitinol tubing is safe and lasts a long time. |

Nitinol stents and graspers use these features to move through blood vessels or tight spaces. The tubing’s shape memory helps doctors do surgery with fewer problems.

Flexibility and Strength

Nitinol tubing is both bendy and strong. It bends easily but does not break or lose its shape. This lets surgical tools move through twisty paths in the body. At the same time, nitinol tubing stays strong when pushed or pulled. It does not snap or get bent out of shape.

Nitinol tubing passes tough tests for strength, bending, and rust resistance.

Tests show nitinol tubing can bend more than 10 million times and still work.

Each tube is checked to make sure it is safe for medical use.

Test Parameter | Measurement/Result |

|---|---|

Elastic Modulus | 28 GPa |

Poisson’s Ratio | 0.3 |

Tensile Strength | 100 MPa |

Flexibility (Solitaire FR) | 0.38 ± 0.11 N |

Flexibility (Trevo XP ProVue) | 0.91 ± 0.11 N |

Flexibility (Stent D) | 0.59 ± 0.05 N |

Nitinol tubing bends better than stainless steel. Stainless steel is strong, but it does not bend as well and can stay bent. Nitinol tubing keeps its shape and strength, even after many uses. This means graspers, stents, catheters, and guidewires made from nitinol move smoothly and safely inside the body.

Nitinol tubing lets devices keep working after being bent many times. This helps doctors do better surgeries and helps patients heal faster.

Biocompatibility and MRI Safety

Nitinol tubing is trusted in medicine because it is safe for the body. It does not cause bad reactions. Its surface has a thin titanium oxide layer that stops nickel from leaking out. This layer keeps tissues safe. Studies show nitinol tubing does not let out much nickel and does not rust easily. These things lower the chance of swelling or allergies.

Tests check if nitinol tubing is safe for blood, genes, and cell growth.

Electropolished nitinol surfaces stop platelets from sticking and help cells grow.

The tubing meets FDA and ISO 13485 rules for medical devices.

Nitinol tubing is also safe for MRI scans. It is not magnetic, so it does not move or get hot in strong magnets. This makes nitinol tubing perfect for surgeries that use MRI machines. Doctors can use these tools during MRI scans without worry.

Because it is safe and does not rust, nitinol tubing is a top pick for graspers, stents, catheters, and guidewires used in minimally invasive surgery.

Integration in Graspers

Laser-Cut and Coaxial Designs

Engineers use special ways to shape nitinol tubing for surgical graspers. They often use lasers to cut patterns into the tubing. These patterns help the tubing bend in certain directions. This makes the grasper flexible and easy to steer. Laser-cut nitinol tubing can make tricky shapes. These shapes help the tool move through tight places in the body.

Coaxial designs use two or more nitinol tubes, one inside another. This makes the grasper stronger and easier to control. The inner tube can move or turn inside the outer tube. This lets the surgeon steer the tip very well. These designs help the grasper reach hard-to-get spots during surgery.

Laser-cut and coaxial nitinol tubing make graspers work better and easier to use. These ways also help the tubing stay strong, even after lots of bending.

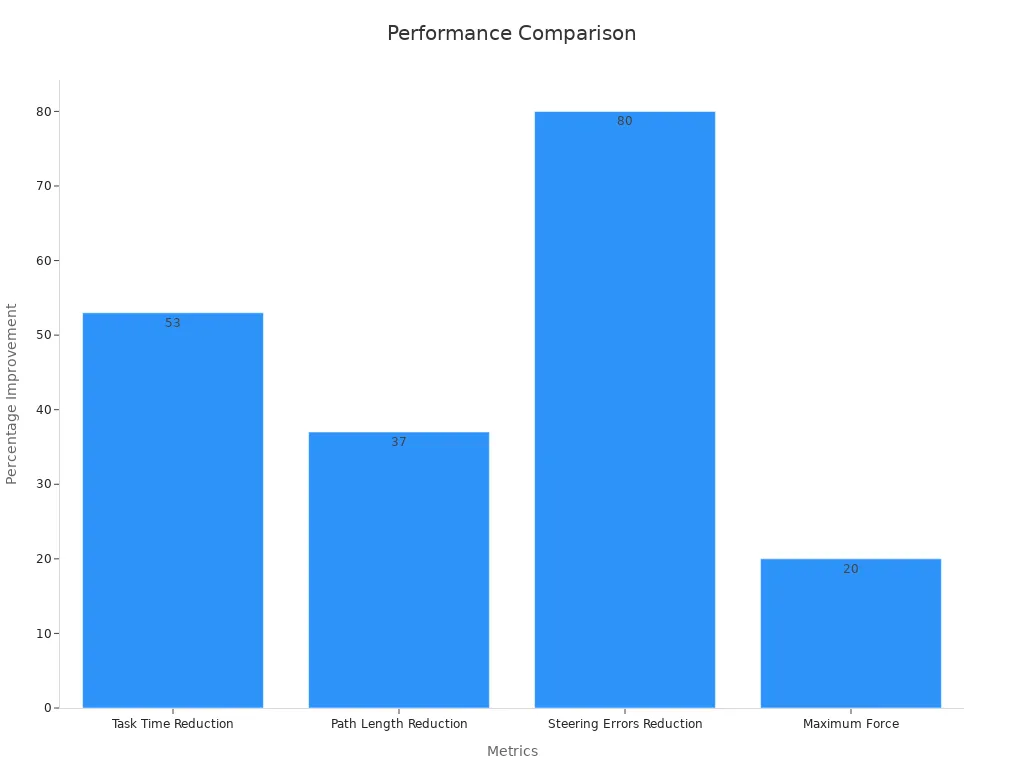

Cableless Actuation and Steering

Old graspers use cables to move the tip. These cables can stretch, wear out, or break. Nitinol tubing lets the tip move without cables. The tubing itself bends and moves the tip. This makes the grasper simpler and stronger.

Cableless actuation helps surgeons control the grasper better. The tubing moves fast and matches the surgeon’s hand. This makes surgery go smoother. Studies show cableless actuation works better than using cables.

Performance Metric | Cableless Actuation & Steering Result | Comparison to Traditional Cable Systems |

|---|---|---|

Task Time Reduction | 53% average reduction between first and last attempts | Significant improvement in efficiency |

Path Length Reduction | 37% average reduction | Indicates more precise instrument control |

Steering Errors Reduction | 80% average reduction | Demonstrates improved steering accuracy |

Maximum Force | Increased by 20% | Slight increase, possibly due to additional degrees of freedom |

Learning Curve | Stabilizes after 4-5 attempts, similar to conventional tools | No additional training time despite added complexity |

Assembly/Disassembly Time | 65 s / 12 s, shorter than 110 s average for conventional tools | Faster cleaning and sterilization process |

Component Reduction | 17 fewer parts in shaft and tip; ~20 fewer actuation components | Simplifies design, reduces potential failure points |

Usability | 60% users efficient at first attempt; all within 3 attempts | Intuitive handle interface comparable to traditional systems |

Cableless nitinol tubing systems have fewer parts in the grasper. This makes the tool lighter and easier to clean. Surgeons can put these graspers together and take them apart quickly. This helps with cleaning and sterilizing. The tubing also lets the grasper squeeze harder, giving the surgeon more control during surgery.

Tip Control and Miniaturization

Nitinol tubing helps make the tips of graspers small and easy to move. Thin-walled nitinol tubing, sometimes only 0.05 mm thick, lets engineers build tiny and bendy tools. These small graspers can go deep in the body and move very carefully.

Metric | Early Deployment (First 5 mm) | Later Deployment (Last 5 mm) |

|---|---|---|

Friction Force (mN) | 129.3 | 27.1 |

Deployment Pressure (kPa) | 41.4 | N/A |

Deployment Length (mm) | 150 | N/A |

Thin-walled nitinol tubing bends 32% to 40% more than thicker needles.

These tiny tools do well in puncture tests and hardly bend when reaching organs.

Wall thickness stays within ±0.005 mm, so every grasper works the same.

Nitinol tubing’s shape memory helps the tip go back to its shape after bending. This is important for robotic and minimally invasive surgeries. New ways, like electrical Joule heating, help set the tubing’s shape without making it weaker. This keeps the tubing bendy and strong, which helps the grasper tip work better.

Small nitinol tubing graspers give surgeons more control and reach during surgery. These tools help lower tissue damage and help patients heal faster.

Performance vs. Other Materials

Precision and Responsiveness

Nitinol tubing helps doctors be more exact and quick in surgery. Special ways of making nitinol tubing, like laser cutting and heat, keep its size very exact. This lets doctors use graspers and stents with trust. Electropolishing makes a safe layer on the tubing. This layer stops rust and makes it safer for the body.

Nitinol tubing changes fast when force or movement changes. Some nitinol tools have sensors that feel small pressure changes. These sensors help stop tissue damage. Nitinol tubing tools react to the doctor’s hand right away. This gives feedback and helps place the device better. Nitinol tubing keeps its shape and works well after many uses. This means patients do better after surgery.

Metric | Nitinol Tubing | Traditional Materials (e.g., Steel) |

|---|---|---|

550-900 MPa | 480-2000 MPa | |

Up to 10^7 cycles | Lower fatigue life | |

Dimensional Accuracy | Tight tolerances | Less stringent tolerances |

Operational Life | 300-500% longer | Frequent replacements |

Corrosion Resistance | Excellent | Good to moderate |

Biocompatibility | Excellent | Moderate to good |

Flexibility vs. Stainless Steel

Nitinol tubing is much more bendy than stainless steel. It can go back to its shape after being bent a lot. Stainless steel does not have superelasticity. Nitinol tubing bends 32% to 40% more than thick steel needles. This lets nitinol tools move through tricky body parts in surgery.

Nitinol tubing can bend millions of times and still work.

Stainless steel is stiff and does not remember its shape, so it is not good for tools that bend a lot.

Nitinol tubing’s superelasticity helps tools snap back to shape, which keeps patients safer.

Impact on Patient Outcomes

Nitinol tubing helps patients get better results. It is safe for the body and lowers swelling and rejection by 30% compared to other metals. Guidewires made from nitinol tubing cross blood vessels 98% of the time. Catheters made with nitinol tubing work 92% of the time without big problems. Nitinol tubing’s bendiness lets doctors make smaller cuts. This means less pain, less scarring, and faster healing for patients.

Long studies show nitinol stents and tools keep working well over time. Patients have fewer problems and need fewer extra surgeries. Big trials like DAWN and PARTNER 3 show people do better and live longer with nitinol tools. Nitinol tubing’s strength and superelasticity help patients heal faster and get back to normal life sooner after surgery.

Applications in Minimally Invasive Surgical Instruments

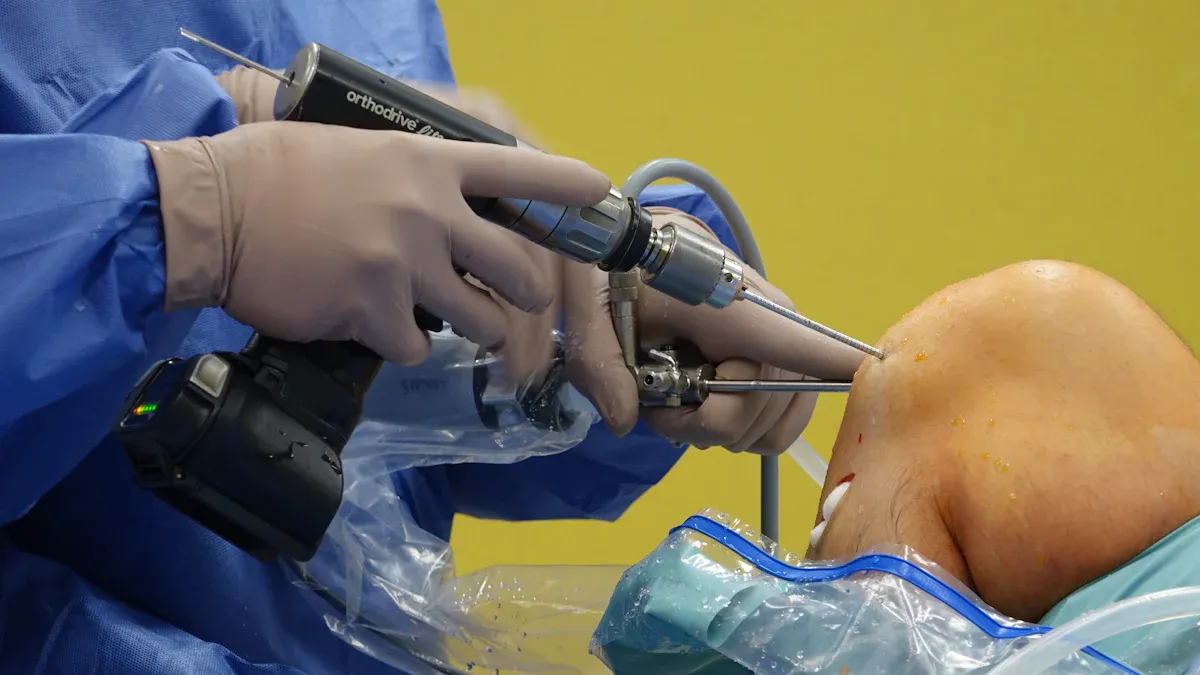

Robotic and Endoscopic Systems

Nitinol tubing has changed how doctors use robots and endoscopes. Engineers put nitinol tubing in robot arms to help them move very carefully. In one study, a robot for the lungs used two nitinol tube arms inside a 10 mm bronchoscope. Each arm had two curved nitinol tubes, so the robot could move in eight ways. Brushless DC motors helped control the arms for gentle movement. Tests on animals showed the robot could clear airways with less force. This means patients have less injury and heal faster.

Another example is a robot endoscope for ear surgery. It used a nitinol sheath with notches to bend and reach hidden spots. The endoscope could see 74% of the sinus tympani in a 3D ear model. The design made sure the nitinol tubing stayed strong and flexible. These uses help doctors reach deep places with less risk and better results for patients.

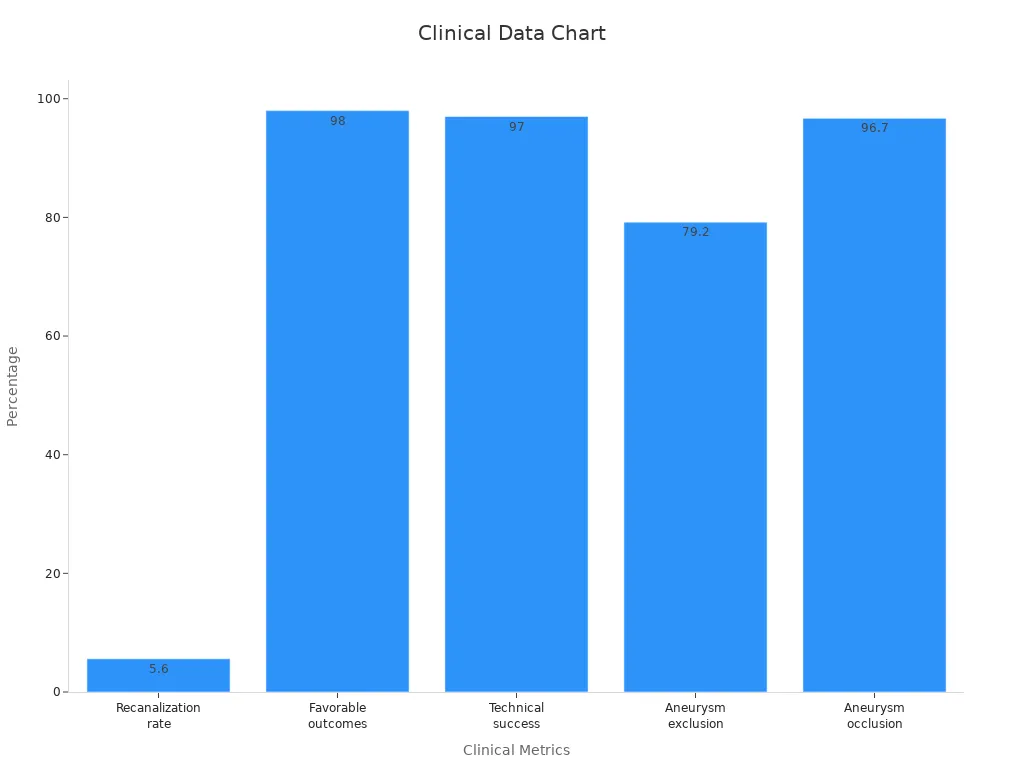

MRI-Guided Procedures

Doctors use nitinol tubing in MRI-guided procedures because it is safe in strong magnets. Nitinol stents and catheters can be used during MRI scans without moving or getting hot. This keeps patients safe and lets doctors see inside the body while working. A special catheter with short nitinol parts and Kevlar braiding did not heat up in MRI tests. This shows nitinol tubing works well in these cases.

Clinical Metric | Result/Outcome |

|---|---|

Complete or near-complete occlusion | Up to 89% within 18 months |

Recanalization rate | 5.6% |

Favorable patient outcomes | 98% |

Technical success rate (AccuPath) | 97% (70 of 72 patients) |

Complete aneurysm exclusion (AccuPath) | 79.2% (57 of 72 patients) |

Aneurysm occlusion at 12 months (AccuPath) | 96.7% (29 of 30 patients) |

Morbidity and mortality rates (flow-diverting stents) | 5% and 4% respectively |

Reduction in complication rates | Up to 25% reduction due to nitinol flexibility |

Procedural efficiency improvement | 20-30% reduction in operating time with robotic assistance |

Doctors also use special designs to keep nitinol tubing safe in MRI. They use short pieces or break up the tubing to stop heating. These steps help catheters and guidewires work safely in MRI surgeries. This helps patients get better results and heal faster.

Reusable and Advanced Graspers

Reusable graspers made with nitinol tubing last a long time and save money. One advanced grasper can be taken apart and put back together over 70 times with no damage. This means doctors can use the same tool for at least 30 surgeries. It takes about 65 seconds to put together and 12 seconds to take apart. The handle connects in 6 seconds and comes off in 7 seconds. Most people learn to steer the grasper after three tries, and mistakes drop quickly.

Performance Aspect | Statistic / Result |

|---|---|

Durability | 70+ reuses, no wear; safe for 30+ procedures |

Assembly Time | 65 s (SD 43), range 27–308 s |

Disassembly Time | 12 s (SD 7), range 3–39 s |

Handle Connection/Removal Time | 6 s / 7 s |

Learning Curve | 3 attempts to master steering; errors drop to 1.25 by 6th attempt |

Articulation Range | Jaw: 159°; Pitch: 110° |

Tip Opening | 52°–60° |

Force Endurance | 10 N load, 10+ times, no damage |

Component Reduction | 1.5 million fewer disposals annually if widely adopted |

Reusable nitinol tubing graspers make less waste and help the planet. They also give doctors better control, so patients get better and heal faster. Catheters and guidewires made with nitinol tubing can be used again safely. These tools are important in many uses of nitinol tubing. They help doctors do surgery with high precision, so patients recover better and have fewer problems.

Future of Nitinol in Surgery

Next-Generation Designs

Researchers are always finding new ways to use nitinol tubing in surgery. Studies by Zilla and others show nitinol meshes help blood vessel grafts last longer and have fewer problems. Nitinol tubing is special because it does not wear out easily. It can last through hundreds of millions of uses in heart implants. New ways to make nitinol, like 3D printing and laser cutting, help engineers build detailed devices for each patient. These new designs match a patient’s body and help doctors be more exact.

Coatings now help stop nickel from coming out of nitinol tubing, making it even safer for people. Experts think the market for nitinol tubing will grow by 9.1% each year from 2025 to 2030. By 2032, the value of nitinol tubing in medical tools will be twice as much as today. New ideas include using AI and robots to check quality and make production better for the planet. These changes make devices stronger, more exact, and better for the environment. Smart nitinol devices that watch how they work in real time are being made now. These will help keep patients safer and improve results.

Experts say the future of nitinol tubing in medicine depends on these new designs and better ways to make them.

Emerging Innovations

Nitinol keeps helping doctors find new ways to treat patients. Reports say that making nitinol devices smaller, safer for the body, and better at remembering shapes are important new features. These things help doctors use nitinol in more types of surgeries, like heart, bone, and urinary surgeries. Additive manufacturing lets engineers make tricky, custom implants, and new coatings help devices last longer.

Market studies show self-expanding nitinol stents can change shape to fit inside the body. The market for non-blood vessel stents should grow from $1.30 billion in 2024 to $1.98 billion by 2030. Rules and teamwork between companies help push research and new ideas forward. As digital tools and smart features become more common, nitinol tubing will be a big part of the next big changes in surgery.

Nitinol tubing makes a big difference for doctors using minimally invasive surgical graspers. Its superelasticity, shape memory, and biocompatibility help doctors make smaller cuts. This means there is less damage to the body. Nitinol lowers rejection by 30%. It helps doctors cross blood vessels 98% of the time. Catheters made with nitinol work well 92% of the time without big problems. These features help patients heal faster and need fewer extra surgeries. New designs and smart technology will keep nitinol important in surgery.

FAQ

What makes nitinol tubing special for surgical graspers?

Nitinol tubing bends easily and returns to its original shape. It stays strong after many uses. Doctors trust it because it helps them work in small spaces with great control.

Is nitinol tubing safe for the human body?

Yes. Nitinol tubing has a special surface that keeps nickel from leaking out. Doctors use it because it does not cause swelling or allergic reactions in most patients.

Can doctors use nitinol tools during MRI scans?

Nitinol tubing does not react to magnets. Doctors can safely use nitinol tools during MRI scans. The tubing does not move or heat up in the scanner.

How long do nitinol graspers last?

Nitinol graspers last through many surgeries.

Tests show they can be reused over 70 times.

They keep working well and do not break easily.

See Also

Discovering How Nitinol Tubing Benefits Healthcare Equipment

Understanding Nitinol Tubing's Impact On Medical Innovations

The Importance Of Nitinol Tubing In Modern Medical Uses