What is Nitinol Tubing and How Does It Enhance Transcatheter Heart Valve Delivery Systems

Nitinol tubing for transcatheter heart valve delivery systems is made from a nickel-titanium metal mix. It has special features like bending easily and remembering its shape. These characteristics occur because it changes between two forms, Austenite and Martensite. Nitinol can revert to its original shape after being bent, which is particularly beneficial during heart valve surgeries, where it adapts to complex body shapes. Nitinol’s behavior, such as changing pressure when used, enhances accuracy. It can withstand millions of heartbeats, making it strong and reliable. This makes nitinol tubing for transcatheter heart valve delivery systems extremely important.

Key Takeaways

Nitinol tubing is made of nickel and titanium. It bends easily and goes back to its shape, which helps in heart surgeries.

Nitinol's superelasticity lets tools move through tight blood vessels safely. This makes surgeries less risky.

Its shape memory helps place heart valves correctly. This lowers mistakes and helps patients heal faster.

Nitinol is safe for the body and does not rust. It is strong and lasts long in medical devices.

AccuPath improves nitinol tubing, making it tougher and bendable. This helps patients have better results after heart surgeries.

Unique Features of Nitinol Tubing for Medical Devices

Superelasticity Helps in Heart Valve Delivery

Nitinol can bend a lot and still return to its shape. This is called superelasticity, and it’s very useful in heart surgeries. Medical tools made from nitinol can squeeze through small blood vessels. Once inside, they expand back to their original shape.

This bending ability helps heart valves work well in the moving heart. Scientists test nitinol’s shape recovery using the Bend Free Recovery (BFR) test. This ensures nitinol stays strong during heart surgeries.

Shape Memory for Accurate Placement

Nitinol can "remember" its shape and return to it with heat. This helps doctors place heart valves correctly, even in tricky body areas. Tests like Differential Scanning Calorimetry (DSC) check nitinol’s temperature changes. These tests make sure nitinol works as needed in surgeries.

Shape memory reduces mistakes and keeps patients safe. It also makes nitinol tubing strong for repeated use. This is why nitinol is trusted for advanced medical tools.

Safe and Long-Lasting Material

Nitinol is safe for the body and doesn’t rust easily. Its smooth surface stops harmful clots from forming during surgeries. Special polishing methods make nitinol even more resistant to rust.

Studies show polished nitinol can handle high stress without breaking. Tests prove it stays strong over time. Rust spots can weaken nitinol, so keeping it rust-free is very important.

Feature | Explanation |

|---|---|

Body-Safe Material | Works well with human tissue without causing harm. |

Rust Resistance | Polished nitinol can handle high stress without corroding. |

Superelasticity | Bends easily and returns to its shape without damage. |

Shape Memory | Remembers its shape and returns to it with heat. |

Strong Under Stress | Stays reliable even after many uses. |

Durable Material | Keeps working well for a long time. |

These features make nitinol tubing perfect for heart surgeries and other medical uses.

Benefits of Nitinol Tubing for Transcatheter Heart Valve Delivery Systems

Flexibility for Moving Through Complex Body Paths

Nitinol tubing is very flexible and bends easily. This makes it great for moving through the body's tricky pathways. Its superelasticity lets it bend and return to its shape. This is helpful in surgeries where tools go through narrow blood vessels. Nitinol's flexibility lowers the chance of hurting blood vessels.

Studies show nitinol's flexibility improves how tools work:

Tests like ANOVA and t-tests prove nitinol works better in tight spaces.

Its superelasticity helps stents keep their shape in tough spots.

Nitinol tubing reduces vessel damage, making surgeries safer and better.

This flexibility helps surgeries succeed and keeps patients safe. It’s why nitinol is key in advanced heart tools.

Strength for Long-Lasting Use

Nitinol is strong and lasts a long time. Its shape memory and superelasticity help it stay useful. It can handle stress and bending without breaking.

Tests show nitinol's strength over time:

It can stretch up to 6% without damage.

Fatigue tests show nitinol lasts through 400 million cycles in the heart.

Its shape memory and strength make it reliable for years.

These features make nitinol perfect for tools that need to last. It’s ideal for heart valve delivery systems.

Accuracy in Placing Heart Valves

Placing heart valves needs to be very accurate. Nitinol tubing can return to its shape with heat. This helps doctors place valves in the right spot. It lowers mistakes and improves surgery success.

Nitinol also keeps its shape under pressure. This helps valves expand and fit perfectly. Its accuracy reduces problems and improves patient recovery. This makes nitinol tubing a trusted choice for heart surgeries.

Real-World Uses of Nitinol Tubing in Medical Tools

Examples of Heart Valve Systems Using Nitinol Tubing

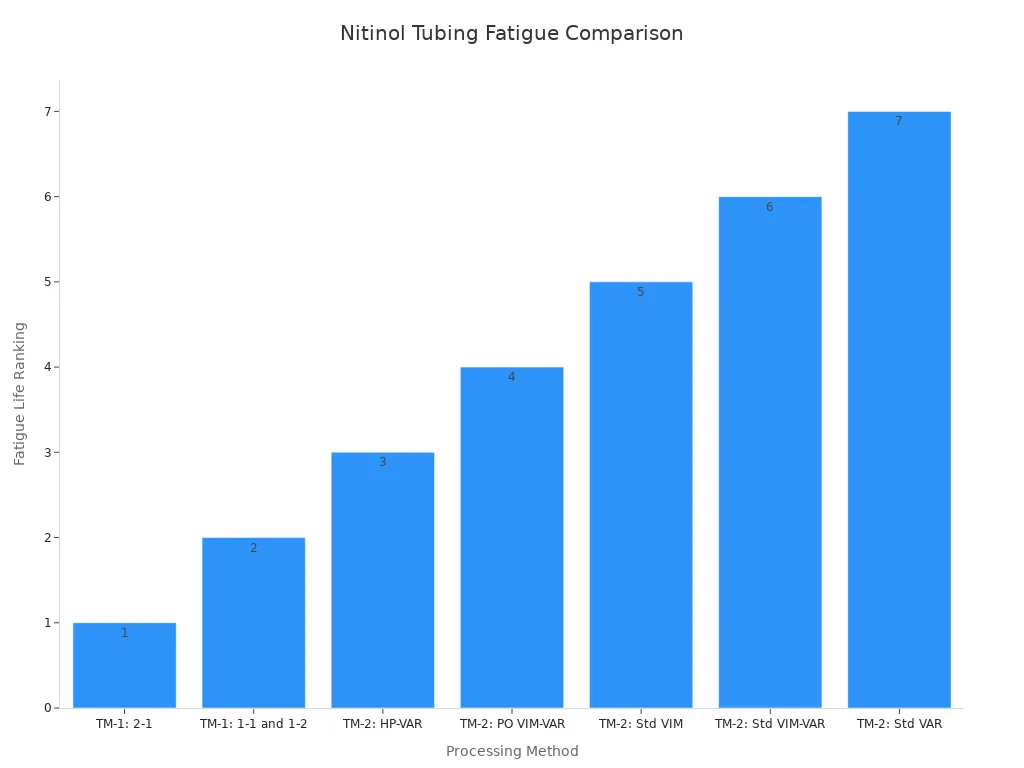

Nitinol tubing is key in heart valve systems. It helps make tools strong and accurate for heart problems. Different ways to process nitinol improve its ability to handle stress. Studies compare how well nitinol lasts under pressure, as shown below:

Processing Method | Fatigue Life Rank | Notes |

|---|---|---|

TM-1: 2-1 | 1 | Best at handling stress in all tests |

TM-1: 1-1 and 1-2 | 2 | Almost the same as TM-1: 2-1 |

TM-2: HP-VAR | 3 | Similar to TM-1: 1-1 and 1-2 after many cycles |

TM-2: PO VIM-VAR | 4 | Slightly weaker than HP-VAR |

TM-2: Std VIM | 5 | Handles stress less effectively |

TM-2: Std VIM-VAR | 6 | Performs worse under stress |

TM-2: Std VAR | 7 | Weakest at handling stress |

Choosing the right processing method makes nitinol work better in medical tools.

AccuPath’s Improvements in Nitinol Tubing

AccuPath is a leader in making better nitinol tubing. They use advanced methods to improve nitinol’s bending ability, shape memory, and safety for the body. Their special processes make nitinol stronger and less likely to rust. This makes their tubing perfect for heart valve systems. AccuPath focuses on making tools that are safe and last a long time.

AccuPath also works on new ideas to help nitinol tubing move through tricky body areas. Their improvements give doctors better tools to help patients recover faster.

Studies Showing Better Patient Results

Tests show nitinol tubing helps heart surgeries succeed. One example is the LuX-Valve, used for fixing severe heart valve leaks. Patients had better heart valve function and less strain on their hearts. After one year, tests showed smaller heart sizes and better heart movement. No major problems like misplaced valves or leaks were found.

These results prove nitinol tubing is safe and works well. It helps doctors place valves correctly and improves patient health over time.

Nitinol tubing has changed medical tools with its special abilities. It can bend and go back to its shape, called superelasticity. Its shape memory helps place devices accurately during tough surgeries. Nitinol is safe for the body, making it great for long-term use. These traits make it perfect for heart valve delivery systems.

Nitinol tubing is flexible, so it moves through tricky body parts easily. It is strong and lasts a long time, working well over years. Its accuracy helps doctors do better surgeries, improving patient health. These features have improved how heart valve systems work.

AccuPath has helped make nitinol tubing even better. They’ve made it stronger, safer, and more flexible for medical use. Their work keeps improving healthcare tools and setting higher standards for patient care.

FAQ

What makes nitinol tubing special for medical use?

Nitinol tubing is unique because of its superelasticity, shape memory, and biocompatibility. It can bend, return to its shape, and work safely with human tissue. Its strength helps it last a long time in medical tools.

How does nitinol help heart valve systems?

Nitinol improves heart valve systems by offering flexibility to move through blood vessels, precision for placing valves correctly, and durability to handle millions of heartbeats. These qualities make surgeries better and help patients recover faster.

Is nitinol tubing safe for people?

Yes, nitinol tubing is very biocompatible and doesn’t rust easily. Its smooth surface lowers the chance of blood clots, making it safe for long-term use in devices like heart valves.

Can nitinol tubing be used many times?

Nitinol tubing is made to handle repeated stress. It can go through millions of cycles without breaking or losing its shape. This makes it perfect for tools that need to last, like heart valve systems.

Why is AccuPath a top innovator in nitinol tubing?

AccuPath uses advanced methods to improve nitinol’s flexibility, shape memory, and ability to resist rust. Their work creates safer and stronger medical tools, raising the quality of heart valve systems.

💡 Tip: Nitinol’s special traits make it a big step forward in modern medical tools, especially for surgeries that don’t need big cuts.

See Also

Nitinol Tubing's Impact on Modern Medical Innovations

Transforming Medical Devices Through Nitinol Tubing Advances

The Importance of Nitinol Tubing in Minimally Invasive Surgery