How Nitinol Tubing Improves Heart Valve Delivery Systems

Nitinol tubing for heart valve delivery systems significantly improves the performance of these devices. It revolutionizes how doctors perform less invasive heart procedures by offering unique properties. Nitinol tubing for heart valve delivery systems is highly flexible, has excellent shape memory, and is biocompatible, allowing it to navigate complex blood vessels with ease. This tubing can compress inside catheters and then expand at body temperature, making the delivery process smoother. Devices incorporating nitinol tubing for heart valve delivery systems are durable and reliable, with tests showing they can last up to 15 years. Research indicates these devices enhance blood flow, reduce complications, and help patients regain mobility faster. Overall, nitinol tubing for heart valve delivery systems makes heart procedures safer, more effective, and improves patient outcomes through less invasive surgery.

Key Takeaways

Nitinol tubing can bend and go back to its shape. This helps doctors put heart valves in the right place through small cuts. Its strength and flexibility help devices last for years. This makes heart surgeries safer and more dependable. Nitinol tubing does not rust and is safe in the body. This lowers risks during heart surgeries. Using nitinol tubing helps more surgeries succeed. It also lowers problems and helps patients heal faster. New ways to make nitinol tubing make it exact and smooth. This helps heart devices fit better and helps patients do better.

Nitinol Tubing Properties

Shape Memory and Superelasticity

Nitinol tubing is special because it has shape memory and superelasticity. These features help it bend and twist without breaking. It can move through tricky blood vessels and still keep its shape. Doctors can squeeze nitinol tubing to fit inside small catheters. When it gets to the right spot, it goes back to its original shape because of body heat. This helps doctors put heart valves in the right place.

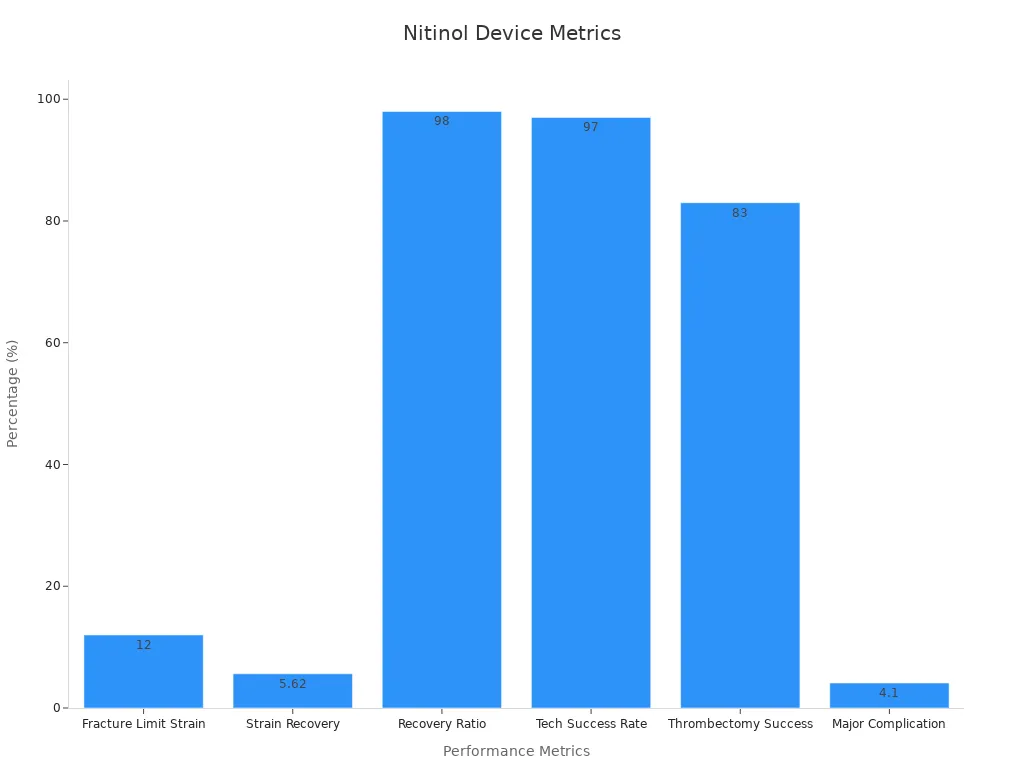

Superelasticity means nitinol tubing can stretch a lot and snap back fast. This is important for moving through curvy blood vessels. Nitinol tubing can stretch up to 400-500% and still stay strong. It also has a 98% recovery ratio, so it almost never breaks. Its flexibility helps doctors guide it smoothly, making heart procedures safer and better.

Aspect | Quantitative Evidence / Metric | Impact on Device Performance |

|---|---|---|

Shape Memory Effect | Precise shape recovery | Ensures accurate stent deployment in complex anatomy |

Strain Recovery | 5.62% | Returns to original shape after deformation |

Recovery Ratio | 98% | Minimizes mechanical failure |

Maximum Strain Endurance | 400-500% | Handles extreme deformation |

Technical Success Rate | 97% | Reliable device deployment |

Nitinol tubing is strong and lasts a long time. Its inside diameter can be very exact, as close as ±0.025 mm. It can bend up to 10 million times without breaking. These things make nitinol tubing safe for heart devices.

Biocompatibility and Corrosion Resistance

It is important for heart device materials to be safe and not rust. Nitinol tubing is good at both. Its surface makes a titanium dioxide layer that stops rust. This layer also keeps nickel from leaking out, which protects the body. Special treatments like electropolishing and nitric acid make nitinol tubing even better at fighting rust.

Nitinol tubing is safe to leave in the body for a long time. Studies show it stays strong even in tough places like blood vessels. The smooth surface helps stop rust spots, which can cause cracks. Because of this, nitinol tubing works well in heart valve delivery systems.

Property / Specification | Description / Values |

|---|---|

Mechanical Properties | Superelasticity, shape memory effect, fatigue resistance, durability, elasticity, thermal conductivity |

Inner Diameter Tolerances | For nominal OD ≤ 1.5 mm: ±0.025 mm; 1.5 mm < OD ≤ 6.5 mm: ±0.050 mm; >6.5 mm: ±0.075 mm |

Fatigue Resistance | Up to 10 million bends |

Biocompatibility & Corrosion | Electropolished surfaces show high corrosion resistance (breakdown potential up to 1000 mV) |

Nitinol tubing’s shape memory and superelasticity, plus its safety and rust resistance, help heart devices work well for many years. These features let doctors do less invasive heart surgeries with good results and fewer problems.

Benefits for Heart Valve Delivery

Flexibility and Navigation

Nitinol tubing helps doctors do less invasive heart surgeries. It bends and twists but keeps its shape. This makes it easier to move through the body’s tricky blood vessels. Catheter systems use nitinol tubing to get through narrow and curvy paths. Superelasticity lets the tubing go back to its shape after bending. Doctors can guide the catheter even in hard-to-reach places.

Studies show nitinol tubing helps with flexibility and navigation. In some procedures, doctors succeed 97% of the time. Up to 89% of aneurysms close within 18 months. Surgery times and problems can drop by 25%. These facts show nitinol tubing makes heart surgeries safer and quicker.

Metric | Result |

|---|---|

Technical success rate in neurovascular procedures | 97% |

Complete aneurysm occlusion within 18 months | Up to 89% |

Reduction in operating times and complication rates | Up to 25% |

Nitinol tubing also helps catheters move gently. Its flexibility lowers the chance of hurting blood vessels. Patients are safer and have fewer risks during heart valve surgeries.

Durability and Strength

Doctors want heart devices that last a long time. Nitinol tubing is strong and can be used for many years. Tests show it can bend up to 10 million times without breaking. This means it can flex a lot and still work. Nitinol’s strength-to-weight ratio is great for catheters.

Special processing makes nitinol tubing even stronger. Small changes and cold work help it last longer. Nitinol tubing does not bend out of shape, even in the moving heart. This makes sure heart devices keep working well.

Nitinol tubing’s strength and flexibility help doctors trust their tools. Patients have fewer problems and better results over time.

Experts say nitinol tubing works best when designed and tested carefully. Good testing and making methods make nitinol tubing even stronger for heart valve delivery.

Precision in Deployment

Putting heart valves in the right place is very important. Nitinol tubing helps doctors do this with great accuracy. It is made with tight size controls, as close as ±0.005 mm. This makes sure heart devices fit and work as they should.

Modern laser cutting gives nitinol tubing smooth and neat edges. This means less extra work is needed and keeps the tubing flexible. Tests show nitinol tubing stays strong and keeps its shape when used.

Metric Category | Supporting Quantitative Details |

|---|---|

Dimensional Accuracy | Tolerances as tight as ±0.005 mm for diameters ≤ 0.3 mm |

Laser Cutting System | Photolithography-based laser machining with 55 W power output |

Surface Quality | Burr-free edges and fine finishes |

Catheter heart devices need this accuracy for less invasive surgeries. Nitinol tubing’s flexibility helps put valves in the right spot. This lowers the chance of leaks or mistakes. Patients get better results and heal faster.

Nitinol tubing’s flexibility and strength make heart surgeries safer and more reliable. These features make it a top choice for today’s heart devices.

Applications of Nitinol Tubing

Transcatheter Heart Valve Systems

Nitinol tubing is very important in new heart devices. Top transcatheter heart valve systems use nitinol tubing to help treat heart valve disease. The NaviGate valved stent has a nitinol frame with special parts called winglets and graspers. These parts help hold the device on the mitral valve and stop leaks or movement. Doctors tested this system in animals. The nitinol tubing kept the valve in place and did not get damaged. X-rays and ultrasound showed the valve stayed in the right spot.

Other systems, like the Tendyne valve, use nitinol tubing for a frame that can expand and be moved by doctors. Medtronic’s TMV valve uses a nitinol frame with arms for strong support. These designs show nitinol tubing gives these systems strength, flexibility, and a safe hold.

Performance Metric | Description / Result |

|---|---|

Mean Aortic Valve Gradients | Stable and low over 2-10 years in major clinical trials |

Effective Orifice Area (EOA) | Comparable or better than surgical valves over time |

Valve Durability | Low valve degeneration at 5 years; lower structural valve deterioration at 10 years |

Paravalvular Leak (PVL) Rates | Minimal or no moderate or greater PVL in multiple trials |

Radial Strength and Frame Design | High radial strength and adaptive sealing with braided nitinol frames |

Hemodynamics | Good blood flow and tissue growth over years |

Transcatheter heart valve systems with nitinol tubing can be made for different patients. These systems also help with new uses in heart care. This makes them important for the future of treating heart problems.

Real-World Outcomes

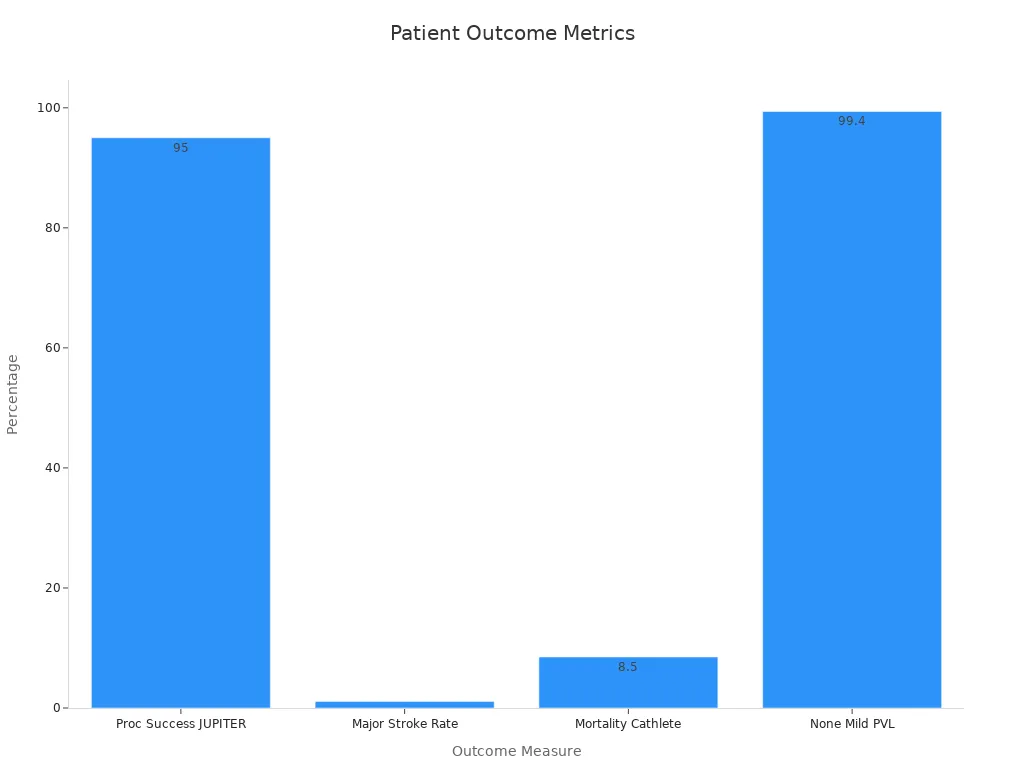

Doctors and patients see real benefits from nitinol tubing in these systems. Studies show high success and safety. In the JUPITER Registry, doctors had a 95% success rate. The Cathlete Plus system had almost 98% success. Major stroke rates were low at 1.1%. The death rate for the Cathlete Plus system was 8.5%. Most patients, about 99.4%, had no or only small leaks after surgery. No serious leaks happened.

These results show nitinol tubing helps doctors put valves in the right place. Strong frames and good anchoring lower the risk of leaks and other problems. Older patients with severe aortic stenosis do better with these new systems. Nitinol tubing helps make heart treatments safer and more dependable. As more doctors use these systems, patients get better care and results.

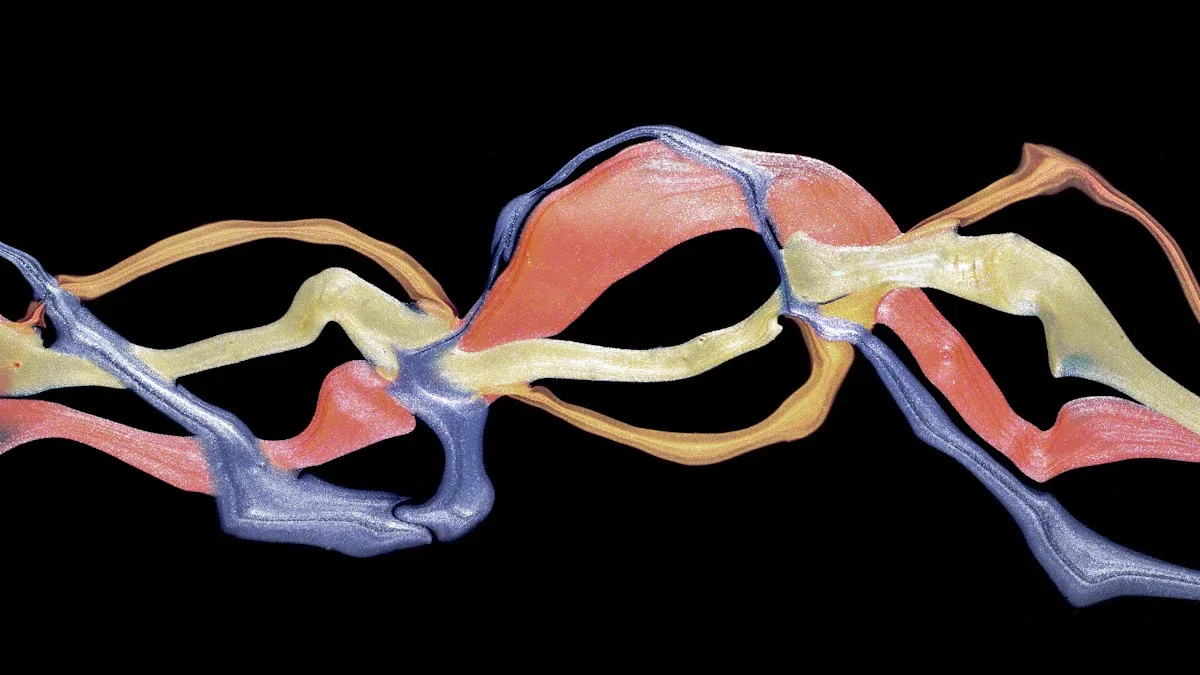

Nitinol tubing makes heart valve delivery systems flexible and strong. It also lets doctors control the devices very well. These features help doctors do safer heart surgeries with smaller cuts. Nitinol does not rust and can last in the body for many years. New ways to use nitinol include 3D printing, laser cutting, and nanotechnology. These help make better heart devices. Experts think more people will need nitinol tubing as heart care grows. Advanced materials like nitinol will change how doctors treat heart problems in the future.

FAQ

What makes nitinol tubing different from other metals in heart valve systems?

Nitinol tubing can bend and go back to its shape. Other metals cannot do this. Nitinol tubing also does not rust. It works well inside the body.

How long can nitinol tubing last in the body?

Studies say nitinol tubing can last up to 15 years. It is strong and does not rust. This helps it stay safe for a long time.

Is nitinol tubing safe for patients with metal allergies?

Nitinol tubing has a titanium dioxide layer on it. This layer stops nickel from leaking out. Most people with metal allergies do not have problems. Doctors still check for allergies before using it.

Can doctors use nitinol tubing in other medical devices?

Device Type | Use of Nitinol Tubing |

|---|---|

Stents | Yes |

Guidewires | Yes |

Orthopedic implants | Yes |

Surgical tools | Yes |

Doctors use nitinol tubing in many tools. This is because it is strong and bends easily.

See Also

Transforming Medical Devices Through Innovative Nitinol Tubing

Nitinol Tubing's Impact On Progressing Medical Technology

Discovering Nitinol Tubing Uses In Modern Healthcare Devices

The Importance Of Nitinol Tubing In Medical Innovations

The Manufacturing Process Behind Medical Grade Nitinol Tubing