3 key Nitinol tubing fatigue life testing standards explained

Nitinol tubing fatigue life testing standards are very important for making safe medical devices. The main standards are ASTM F3211, ASTM F2516, and ISO 25539-1. These standards help companies lower risk and keep good records. They also make sure nitinol lasts a long time, sometimes up to 400 million cycles. Medical devices like stents and heart valves need these tough rules. Other certifications like ISO 13485:2016 and CE marking help with rules and keep patients safe.

Key Takeaways

ASTM F3211, ASTM F2516, and ISO 25539-1 are the main rules for testing how long nitinol tubing lasts when stressed.

These rules help engineers check nitinol’s strength and how much it can bend. This makes sure medical devices like stents and heart valves are safe and work well.

Following these rules gives good test results. The results show nitinol can handle many stress cycles, sometimes up to 400 million.

Using the right testing rule helps companies find weak spots early. This lets them make better device designs for safer use by patients.

Testing the same way each time and keeping clear records builds trust with doctors, patients, and regulators. This makes nitinol a good choice for medical devices that need to last a long time.

ASTM F3211

Purpose

ASTM F3211 gives a clear way to test how long nitinol memory alloy capillary tubes last. This standard uses a fatigue-to-fracture method. It checks how many times nitinol can be stressed before it breaks. Many medical devices, like stents and implants, use nitinol because it has special features. The standard helps engineers see how nitinol acts in real life. When companies follow ASTM F3211, they make sure their nitinol memory alloy capillary tubes are safe.

Key Requirements

ASTM F3211 lists important steps for testing nitinol. The standard says nitinol memory alloy capillary tubes must face repeated stress cycles. Testers count the cycles until the tube breaks. The standard explains how to set up the test tools and control things like temperature and humidity. ASTM F3211 wants testers to keep careful records of each test. They must write down the nitinol type, tube size, and stress levels. These steps help make sure nitinol tubing fatigue life testing standards give results that can be trusted.

Tip: Always use the same test setup and conditions for every batch of nitinol memory alloy capillary tubes. This practice helps compare results and spot any problems early.

Relevance for Nitinol

Nitinol memory alloy capillary tubes are used in many medical devices. ASTM F3211 gives companies a trusted way to test how long these tubes last. The standard helps show how nitinol will work inside the body. Fatigue testing checks if nitinol can handle bending, twisting, and stretching over time. By using ASTM F3211, companies can show their nitinol memory alloy capillary tubes are safe and strong for medical devices. This standard helps patients and meets rules for nitinol tubing in implants.

ASTM F2516

Overview

ASTM F2516 is an important rule for testing nitinol memory alloy capillary tubes. This rule looks at how nitinol acts when stretched or pulled. It helps engineers learn about nitinol’s superelastic properties and shape memory effect. These features let nitinol memory alloy capillary tubes bend and go back to their shape. The rule makes sure nitinol tubing is safe and works well. Over the years, ASTM F2516 has changed how companies test nitinol. Now, results are more trusted and easier to compare.

Testing Procedures

ASTM F2516 gives clear steps for testing nitinol memory alloy capillary tubes. Testers stretch the tubes and repeat the pulling many times. They use video or automatic tools to measure how much the tube stretches. During tests, nitinol memory alloy capillary tubes face stress from 500 MPa to 900 MPa. The tubes keep their shape memory at these stress levels. Fatigue tests use repeated strains, often at 6%, to see when the tubes break. The table below lists important details from ASTM F2516:

Parameter | Description and Values |

|---|---|

Test Standard | ASTM F2516 for uniaxial tension and cyclic tensile tests on nitinol tubing |

Cyclic Test Strain | 6% strain applied during cyclic tensile testing |

Upper Plateau Strength | Tensile strength measured at 3% strain on the first loading curve |

Lower Plateau Strength | Tensile strength measured at 2.5% strain on the unloading curve |

Residual Elongation | Difference in tensile strain at 7 MPa between loading and unloading curves |

Tensile Strain at Failure | Maximum tensile strain reached before failure |

Strain Measurement | Video or automatic contacting extensometers recommended |

Application to Nitinol Tubing

Medical devices use nitinol memory alloy capillary tubes because they are strong and flexible. ASTM F2516 helps engineers test these tubes in ways that match real use. Studies show nitinol tubing tested with ASTM F2516 can last through millions of cycles. Tests use diamond-shaped pieces cut from nitinol memory alloy capillary tubes. These pieces are tested in salty water at body temperature. The tests show how making the tubes changes their fatigue life. The rule also lets engineers use computer models to guess how nitinol will work in devices. By using ASTM F2516, companies make sure their nitinol tubing fatigue life testing standards are safe and work well for medical devices.

ISO 25539-1

Scope

ISO 25539-1 tells how to test nitinol memory alloy capillary tubes for use in endovascular medical devices. This standard explains every step of fatigue testing for nitinol. It says how to get samples ready, control the test, and write down results. The standard tries to copy how nitinol is used inside the body. It needs the temperature to stay at 37 ± 2 °C, which is like the human body. The standard also wants a lot of cycles, sometimes up to 400 million, to show long-term use. When engineers follow ISO 25539-1, they can check if nitinol memory alloy capillary tubes are safe and strong enough for medical devices.

Fatigue Testing Criteria

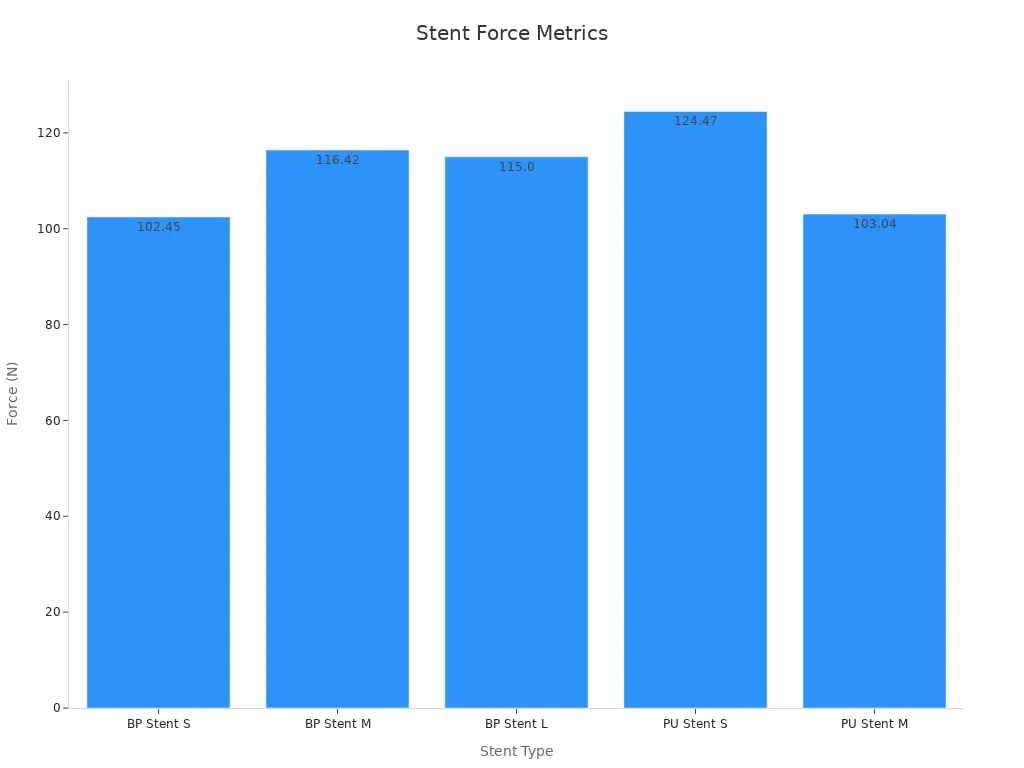

ISO 25539-1 gives simple rules for fatigue testing nitinol. It needs machines that can measure force and control how fast the tubes are stretched. The standard says to use repeated stress cycles to see how long nitinol memory alloy capillary tubes last. Testers must count the cycles until the tube breaks or until they reach the set number, which can be like 10 years of use. The standard also says to report numbers like average, highest, lowest, and standard deviation of tensile strength. The table below lists some important numbers from ISO 25539-1 fatigue testing:

Test Parameter | Value | Statistical Measure |

|---|---|---|

Fatigue Testing Cycles | 400 million cycles | No strut breakage observed |

Radial Crush Force (BP Stent S) | 102.45 N | ± 4.63 N (standard deviation) |

Radial Crush Force (BP Stent M) | 116.42 N | ± 4.20 N (standard deviation) |

Radial Crush Force (BP Stent L) | 115.00 N | ± 5.00 N (standard deviation) |

Radial Crush Force (PU Stent S) | 124.47 N | ± 16.70 N (standard deviation) |

Radial Crush Force (PU Stent M) | 103.04 N | ± 5.83 N (standard deviation) |

These numbers show nitinol memory alloy capillary tubes can handle many cycles and strong forces without breaking. This means they have great fatigue resistance.

Impact on Nitinol Tubing

ISO 25539-1 is very important for nitinol tubing fatigue life testing standards. The standard helps companies show that nitinol memory alloy capillary tubes can last through millions of stress cycles. This matters for medical devices that need to work for many years inside the body. The standard’s tough rules for fatigue testing help make sure nitinol is safe and reliable. By using ISO 25539-1, engineers can compare results from different batches and companies. The standard also helps with getting approval by giving a trusted way to test fatigue. Nitinol memory alloy capillary tubes tested with ISO 25539-1 show strong results, so they are a good choice for medical devices that need to last and bend.

Other Nitinol Tubing Fatigue Life Testing Standards

ASTM E2948

ASTM E2948 shows how to test the fatigue life of small medical devices made from nitinol. This standard looks at how nitinol acts when it bends and flexes again and again. Engineers use ASTM E2948 to see if nitinol tubing can handle daily stress inside the body. The standard helps find weak spots in the tubing before it is used by patients. ASTM E2948 works with astm f2063 standards to make sure nitinol follows strict quality rules. Many companies use this standard to check that nitinol tubing has a strong and safe biocompatible surface.

ASTM F2082

ASTM F2082 explains rotary beam fatigue testing for nitinol wires and tubing. In this test, nitinol samples spin while stress is put on them. This helps engineers see how long the material lasts before it breaks. ASTM F2082 is good for comparing nitinol from different suppliers. The standard also helps astm f2063 standards by checking for problems that could cause early failure.

Many case studies use rotary beam fatigue testing to compare nitinol wires from different suppliers.

Inclusions, surface defects, and microstructural purity are important for how cracks start and grow in nitinol.

Researchers use statistical models like the bilinear uniform scatter band and Gumbel distribution to study fatigue data and inclusion sizes.

Studies often follow astm f2063 standards for microcleanliness and use other standards for extreme value and fatigue data analysis.

Results show a strong link between inclusion size and fatigue limits. Some models treat inclusions as small cracks to guess how long nitinol will last.

ASTM F2082 helps engineers choose nitinol tubing that is safe and works well.

ASTM F2477

ASTM F2477 gives a way to test how tough nitinol tubing is in fake body conditions. This standard uses repeated loading and unloading to see how nitinol holds up over time. ASTM F2477 works with astm f2063 standards to make sure nitinol tubing can handle real-world stress. The standard helps engineers pick the right nitinol for devices that need to last many years. ASTM F2477 also helps companies show that their nitinol tubing meets strict medical device rules.

Note: Picking the right standard depends on the device, the type of nitinol, and the test needed. ASTM E2948, ASTM F2082, and ASTM F2477 each give special ways to check nitinol tubing. Using the correct standard makes sure nitinol meets astm f2063 standards and works well in medical devices.

Comparison of Nitinol Tubing Fatigue Life Testing Standards

Key Differences

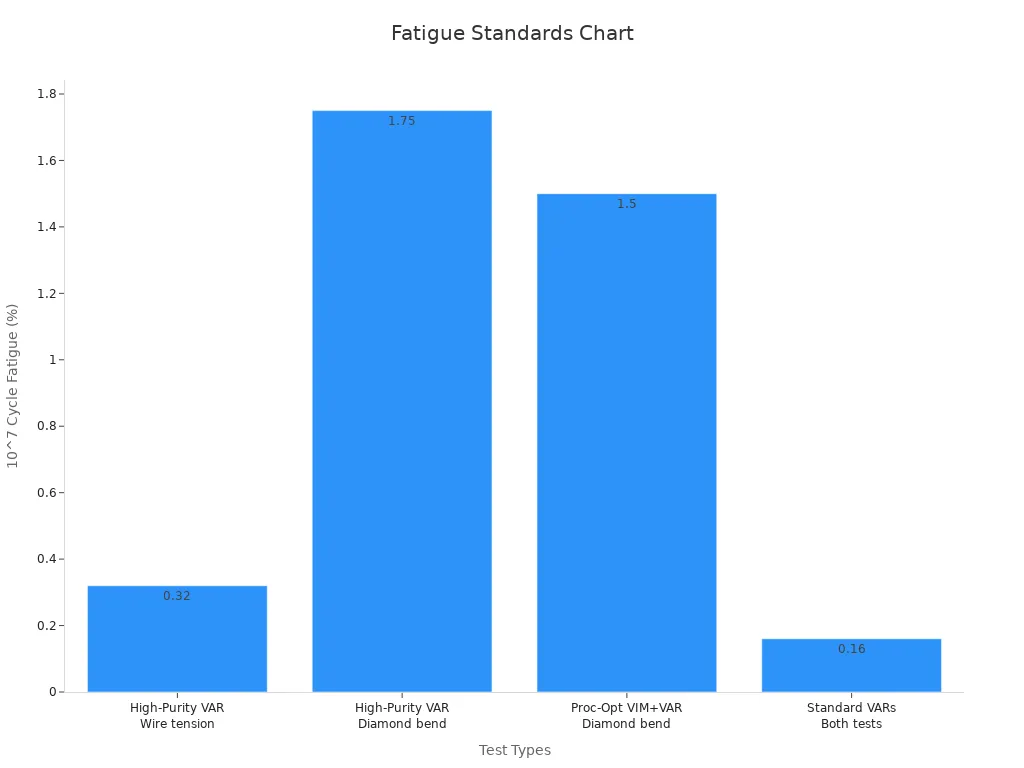

Nitinol tubing fatigue life testing standards are not all the same. They use different ways to test and report fatigue. Each standard has its own test methods, sample shapes, and test speeds. Some standards use wire tension–tension tests. Others use tubing bending with diamond-shaped samples. The way you test changes the fatigue strain limit you find. It also changes how well nitinol performs in tests.

The table below shows how nitinol grades and test methods affect results:

Nitinol Alloy Grade | Testing Method | 10⁷-Cycle Fatigue Strain Limit | Key Observations |

|---|---|---|---|

High-Purity VAR | Wire tension–tension | 0.32% | Highest fatigue resistance; fewer and smaller non-metallic inclusions |

High-Purity VAR | Tubing bending (diamond) | 1.75% | Superior fatigue life under bending fatigue testing |

Process-Optimized VIM+VAR | Tubing bending (diamond) | 1.5% | Slightly lower than High-Purity VAR; improved fatigue resistance |

Standard VAR, VIM, VIM+VAR | Both methods | ~0.16% (approximate) | Higher inclusion size and density; lower fatigue performance |

Studies show sputtered nitinol thin-film samples do better. They can reach a fatigue strain limit of about 1.75%. This is almost twice as high as standard nitinol alloys. This happens because they are more pure and have fewer inclusions. Test speed matters too. If you raise the speed from 100 to 35,000 RPM, cycles to fracture almost double. But the test setup, whether unguided or guided, does not change fatigue life much. These facts show that purity and test conditions both change how long nitinol tubing lasts.

Note: The amount of stressed material and how stress spreads also matter. This means different standards may give different results for the same nitinol tubing.

Similarities

Even though they are different, nitinol tubing fatigue life testing standards have things in common. Most standards:

Use ASTM E2948 as a guide for fatigue testing steps.

Test in deionized water or phosphate buffered saline at 37 °C to copy body conditions.

Figure out strain using wire diameter and radius of curvature.

Use the same machines, like Blockwise Engineering wire fatigue testers.

Keep testing until the sample breaks or hits a set number of cycles, usually between one million and one hundred million.

Use test speeds from 72 RPM, like a heart rate, up to 9,000 RPM for faster tests.

Show that both test speed and strain affect fatigue life, which helps labs compare results.

These shared steps help make sure nitinol tubing tested by different standards is still safe and reliable for medical devices.

Practical Implications for Nitinol Testing

Test Outcomes

Engineers use nitinol testing standards to learn how long tubes or wires last. These tests show if nitinol can bend and stretch many times without breaking. Companies check for cracks, shape changes, or if the tube gets weaker. Good test results help teams pick the right nitinol for medical devices.

Testers compare batches to find the best ones.

Results help make better designs for things that bend a lot.

Test data helps guess how nitinol will work inside the body.

Tip: When test results are always the same, it is easier to follow rules for medical devices and earn trust from doctors and patients.

Device Safety

Device safety depends on how well nitinol handles stress over time. Medical devices like stents and heart valves must work for many years. Testing standards help engineers find weak spots before devices are used by patients.

Nitinol’s strong fatigue resistance means it can be used again and again in the body. This makes nitinol a good choice for many medical devices. When companies follow strict testing rules, they lower the chance of device failure. Patients get safer treatments and devices that last longer.

Safety checks look for cracks, breaks, or shape changes in nitinol.

Engineers use test results to make devices better and stop problems.

Regulators need proof that nitinol devices are safe.

Note: Careful testing and strong rules keep patients safe and help companies keep a good name.

ASTM F3211, ASTM F2516, and ISO 25539-1 are the main rules for testing how long nitinol tubing lasts.

These rules help engineers check if nitinol is safe and can last a long time in medical devices.

Using these rules gives results that people can trust and believe.

For the best results, teams should read all the rules and talk to experts about nitinol testing.

FAQ

What is nitinol and why do medical devices use it?

Nitinol is a metal made from nickel and titanium. Medical devices use nitinol because it can bend and then go back to its shape. This helps things like stents and heart valves work well in the body.

How do fatigue life testing standards help device safety?

Fatigue life testing standards show how long nitinol tubing lasts when stressed over and over. These rules help engineers find weak spots early. Devices that pass these tests are less likely to break inside the body.

Why do companies use different testing standards for nitinol tubing?

Different standards test nitinol in different ways. Some look at bending, while others check stretching or twisting. Companies pick the standard that matches how their device will be used in the body.

How many cycles should nitinol tubing survive in fatigue tests?

Most rules say nitinol tubing should last through millions of cycles. Some tests go up to 400 million cycles. This big number shows the tubing can last for many years inside a person.

Do regulators require specific nitinol testing standards?

Regulators often want proof that companies used trusted standards like ASTM F3211, ASTM F2516, or ISO 25539-1. Using these rules helps companies get their medical devices approved faster.