What is Nitinol tubing used for in endoscopic instruments

Nitinol tubing for endoscopic instruments is made from a nickel-titanium metal mix. It is special because it is super stretchy, remembers shapes, and is safe for the body. These features make it great for medical tools, especially in endoscopy. For example:

Its flexibility (Young’s modulus of 60 GPa) helps during use.

It can bend up to 6% and still return to shape.

Its strength (1133 MPa) makes it tough under pressure.

In small surgeries, Nitinol tubing for endoscopic instruments helps tools move easily and safely. It adjusts to tricky body paths, lowers mistakes, and protects tissues, leading to better results.

Key Takeaways

Nitinol tubing is bendable and won’t break easily, making it great for tight spaces in endoscopic surgeries.

It can return to its original shape after bending, helping doctors place tools like stents correctly.

Nitinol is safe for the body and lowers the chance of bad reactions during surgery.

It doesn’t kink, which makes it strong and dependable for long-term medical use.

Using Nitinol tubing in endoscopic tools helps protect patients and improves surgery results by causing less harm to tissues.

Properties of Nitinol tubing for endoscopic instruments

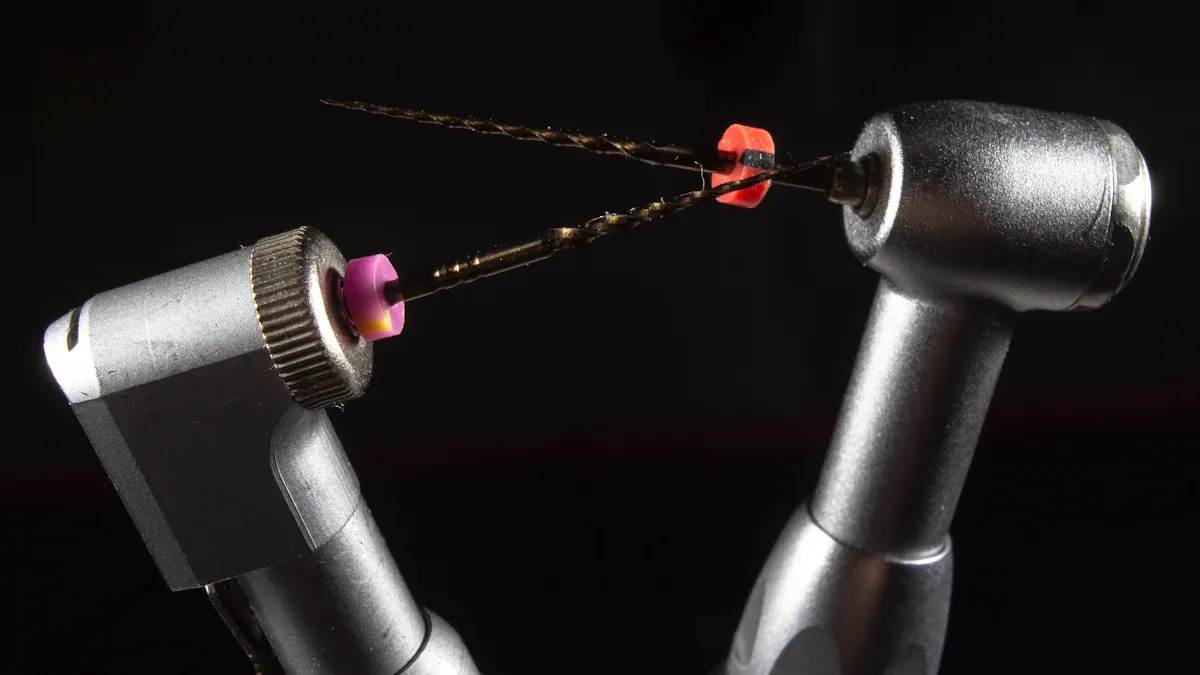

Superelasticity and its role in flexibility

Nitinol tubing is special because it can stretch and return to shape. This feature helps during endoscopic procedures where tools move through tight spaces.

It can bend a lot without breaking, making it useful.

Studies show its flexibility changes with heat and pulling force.

As the temperature rises, it needs more force to bend, ensuring it works well.

Compared to other materials, Nitinol tubing bends more without damage. For example, stainless steel bends only 1% before breaking, but Nitinol can stretch up to 10%. This makes Nitinol tubing better for precise and tough procedures.

Material | How It Bends | Max Stretch | Reaction to Stress |

|---|---|---|---|

Nitinol | Super stretchy | Up to 10% | Returns to original shape |

Stainless Steel | Stiff and limited | ~1% | Breaks under stress |

Biological Tissues | Flexible | Up to 10% | Changes shape naturally |

Shape memory and its impact on device functionality

Nitinol tubing can "remember" its shape after being bent. This helps tools change shape during use and return to normal afterward.

This is useful for devices like stent systems. The tubing can squeeze through small spaces and then go back to its original shape to place the stent correctly. Shape memory ensures tools work well and reduce mistakes during surgeries.

Biocompatibility and patient safety

Nitinol tubing is safe for the body and doesn’t cause bad reactions. Its nickel-titanium mix works well with human tissues.

Doctors trust Nitinol tools because they resist rust and stay strong in the body. This means tools work well even in tough conditions. Using Nitinol tubing makes treatments safer and more effective.

Tip: Nitinol’s safety and rust resistance make it great for implants and surgical tools.

Kink resistance and durability in medical applications

Nitinol tubing is special in medicine because it resists kinks and lasts long. Medical tools made from Nitinol stay strong even when bent or under pressure. This is very helpful for procedures in tight or curved body areas.

Nitinol guidewires are flexible and resist kinks. They move smoothly in tricky spots without losing performance.

High-quality Nitinol tubing lowers the chance of breaking, making it great for stents that face years of body stress.

The material and finish of Nitinol tubing make it strong against wear, so it works well even after many uses.

Another big benefit of Nitinol tubing is its strength over time. It handles stress for a long time, making it reliable for important medical tasks. For example, stents made with Nitinol tubing can handle crushing forces and keep their shape. This strength lowers risks and helps patients recover better.

Note: Nitinol tubing’s kink and crush resistance make it perfect for medical tools needing both flexibility and strength.

Compared to other materials, Nitinol tubing keeps its shape and works well in tough situations. Stainless steel, for example, might bend too much and lose its strength, but Nitinol stays in its original form. This makes Nitinol tools trustworthy for safe and accurate procedures.

Advantages of Nitinol tubing in endoscopic instruments

Better movement in tricky body areas

Nitinol tubing is very flexible and adapts easily. This makes it great for moving through hard-to-reach body parts. Its superelasticity and shape memory help tools move smoothly in tight or curved spaces. These features lower the chance of hurting nearby tissues during surgeries.

It can bounce back after being bent. For example, Nitinol tubing can recover from 5.62% strain and has a 98% recovery rate. This means it can handle a lot of bending without breaking, making it reliable in tough situations.

Feature | Value |

|---|---|

Strain Recovery | 5.62% |

Recovery Rate | 98% |

Use in Small Surgeries | Important |

These special traits make Nitinol tubing perfect for tools like flexible stents. These stents need to move through narrow blood vessels while staying strong and useful.

Tip: Nitinol tubing returns to its shape after bending. This helps tools work well in tricky body areas.

Accurate tools for small surgeries

Small surgeries need tools that are both precise and dependable. Nitinol tubing is great for this. Its superelasticity lets doctors guide tools carefully, even in sensitive areas. This helps avoid damage to nearby tissues.

For instance, stents made with Nitinol tubing can be placed exactly where needed. The tubing's shape memory ensures the stent opens to the right size and position. This reduces mistakes and improves surgery results.

Also, Nitinol tubing doesn’t kink easily, which makes it more reliable. It keeps its shape and works well, even in tough conditions. This is why it’s a top choice for surgeries needing precision.

Safer for tissues

A big benefit of Nitinol tubing is that it protects tissues during surgeries. Its flexibility and body-safe material make it gentle on human tissues. This lowers the risk of irritation or injury, helping patients heal faster.

Stents made from Nitinol tubing are especially good at this. Their superelasticity lets them fit the body’s shape without pressing too hard. This reduces problems and speeds up recovery.

Plus, Nitinol tubing resists kinks and bending damage. This keeps tools working well throughout the surgery. Its reliability makes it a safer option for small medical procedures.

Note: Using Nitinol tubing improves patient safety and makes surgeries more successful.

Reliable deployment mechanisms for medical tools

Reliability is very important when using medical tools in endoscopy. Nitinol tubing is special because it helps tools work smoothly and accurately. Its features, like superelasticity and shape memory, make it great for tricky medical tasks.

A big advantage of Nitinol tubing is how it stays strong under stress. For example, stent systems use its shape memory to expand and fit perfectly. This lowers the chance of mistakes, which can cause problems. Even in tight or curved body areas, Nitinol tubing works well and stays dependable.

Another benefit is its ability to resist bending damage. Unlike older materials, Nitinol tubing stays strong after many uses. This makes it perfect for guidewires and catheters that need to bend and twist a lot. These tools keep their shape and work reliably during procedures.

Here’s a comparison to show why Nitinol tubing is better:

Property | Nitinol Tubing | Traditional Materials (e.g., Stainless Steel) |

|---|---|---|

Super Elasticity | Yes | No |

Biocompatibility | High | Moderate |

Compression Maintenance | Stays strong over time | Weakens over time |

Fatigue/Kink Resistance | High | Lower |

Similarity to Bone | Yes | No |

Impact on Weightbearing | Allows faster recovery | Slower recovery |

This table shows why Nitinol tubing is the best choice. It bends easily, is safe for the body, and stays strong over time. Its kink resistance and flexibility make it reliable for medical tools.

Tip: Using tools made with Nitinol tubing can make surgeries safer and faster, helping patients recover better.

With Nitinol tubing, tools are both strong and accurate. This is very important for small surgeries. Whether placing a stent or using a catheter, Nitinol tubing gives doctors confidence to work carefully and successfully.

Comparison of Nitinol tubing with other materials

Nitinol vs. stainless steel: Flexibility and durability

Nitinol bends easily without breaking, unlike stainless steel. Stainless steel can only stretch about 1% before it snaps. Nitinol’s superelasticity makes it better for tight or curved spaces.

Nitinol is also more durable than stainless steel. It resists kinks and keeps its shape after many uses. Stainless steel may weaken over time in similar conditions. For tools like stents and guidewires, nitinol lasts longer and works better.

Property | Nitinol | Stainless Steel |

|---|---|---|

Flexibility | High (up to 10% strain) | Low (~1% strain) |

Durability | Excellent | Moderate |

Nitinol vs. polymer tubing: Strength and shape retention

Nitinol is stronger than polymer tubing. Polymers are light and flexible but not strong enough for tough medical tasks. Nitinol combines strength and flexibility, making it great for tools under stress.

Nitinol also keeps its shape better than polymers. It can return to its original form after bending. Polymers may stay bent or lose their shape under pressure. This makes nitinol ideal for stent systems that need precision and reliability.

Tip: Use nitinol for tools needing strength and flexibility.

Cost-effectiveness and long-term performance

Nitinol costs more upfront but saves money over time. Its durability means fewer replacements, lowering long-term costs. It’s also safe for the body and resists wear, making it reliable for medical use.

For example, nitinol stents stay strong for years without failing. This improves patient recovery and reduces healthcare expenses. When considering both cost and performance, nitinol tubing is a smart choice for medical tools.

Applications of Nitinol tubing in endoscopic instruments

Guidewires and catheters

Guidewires and catheters use Nitinol for better flexibility and strength. Its superelasticity helps these tools move through curved body paths easily. Nitinol guidewires are great for vascular procedures. They safely reach hard-to-access areas without losing shape.

Catheters made with Nitinol resist kinks and stay durable. This keeps them working well in tough conditions. Whether it’s a guidewire or catheter, Nitinol ensures smooth and accurate movement. It bends and returns to its original shape, making it dependable for doctors.

Tip: Tools with Nitinol improve safety and make surgeries easier.

Stent delivery systems

Stent systems often use Nitinol tubing because it expands on its own. When placed with a catheter, Nitinol stents grow to the right size and shape. This helps keep blood flowing properly during vascular procedures.

Nitinol’s shape memory lets stents compress for easy insertion. Once in place, they expand perfectly at the target area. This lowers risks and ensures they work well for a long time. Its body-safe material also reduces bad reactions in patients.

Note: Nitinol’s expanding ability makes stent systems safer and more precise.

Biopsy and retrieval tools

Biopsy and retrieval tools use Nitinol tubing for flexibility and strength. These tools need to bend and twist, and Nitinol makes sure they don’t break. Its superelasticity allows smooth movement in tight spaces.

For example, retrieval tools use Nitinol to grab and remove objects or tissues carefully. Its expanding feature helps hold items securely during use. This makes Nitinol tubing perfect for delicate medical procedures.

Tip: Nitinol tools improve accuracy and protect tissues during surgeries.

Nitinol tubing is special because it is stretchy, remembers shapes, and is safe for the body. These features make it important for tools used in endoscopy. Its bendability and toughness help medical tools work more accurately. Nitinol makes small surgeries safer by lowering risks and improving results. It adjusts to tricky body shapes, so tools work well even in hard spots. Using nitinol tools helps doctors give better care and helps patients heal faster.

FAQ

Why is Nitinol tubing better than other materials?

Nitinol tubing is flexible, strong, and remembers its shape. These features help tools move through tight spaces without breaking. Unlike stainless steel, Nitinol bends easily, making it great for small surgeries.

Can Nitinol tubing cause allergies?

Nitinol tubing is safe for the body and doesn’t cause allergies. Its nickel-titanium mix doesn’t rust and works well with human tissues. Doctors trust it for surgeries involving direct contact with the body.

How does Nitinol tubing make surgeries more accurate?

Nitinol bends and adjusts to the body’s shape during surgery. This helps tools like stents and catheters fit perfectly. Its shape memory lets tools return to normal, lowering mistakes in procedures.

Is Nitinol tubing good for long-term use?

Yes, Nitinol tubing stays strong and keeps its shape for years. It doesn’t kink or wear out easily, making it great for stents and implants. You can count on it to work well over time.

Why does Nitinol tubing cost more?

Making Nitinol tubing takes special processes because of its unique features. It costs more upfront but lasts longer, saving money on replacements. Its reliability also helps patients recover better.

See Also

The Importance of Nitinol Tubing in Minimally Invasive Surgery

The Process Behind Nitinol Tubing Production for Healthcare

The Significance of Nitinol Tubing in Modern Medicine

Investigating Nitinol Tubing Uses in Medical Devices

Nitinol Tubing's Contribution to Progress in Medical Technology