Understanding the Corrosion Resistance of Nitinol Tubing for Healthcare Use

Nitinol tubing offers exceptional corrosion resistance due to the formation of a thin titanium oxide layer on its surface. This naturally occurring layer acts as a robust shield, providing outstanding nitinol tubing corrosion resistance by protecting medical-grade nitinol from aggressive body fluids. It also significantly reduces the risk of nickel ion release. Because of this superior corrosion resistance, nitinol tubing is widely used in medical devices to ensure patient safety and enhance device longevity. Additionally, surface treatments such as electropolishing and passivation further improve this protective barrier, boosting the corrosion resistance of nitinol tubing even more. Medical-grade nitinol is unique, combining high corrosion resistance with shape memory and superelasticity, making it an ideal material for healthcare applications. The table below highlights how nitinol compares to other metals commonly used in medical devices:

Material | Corrosion Resistance Characteristics | Unique Properties Relevant to Medical Use |

|---|---|---|

Nitinol | Excellent corrosion resistance in harsh body environments; surface treatments like electropolishing and passivation enhance nitinol tubing corrosion resistance and reduce nickel ion release | Superelasticity, shape memory effect, high biocompatibility |

Stainless Steel | Good corrosion resistance but less effective at reducing nickel ion release compared to treated nitinol | Widely used, moderate corrosion resistance |

Cobalt-Chromium | Good to moderate corrosion resistance; lacks superelasticity and shape memory | High strength, commonly used in implants |

Key Takeaways

Nitinol tubing does not rust easily because it has a thin, strong titanium oxide layer. This layer stops harmful body fluids and keeps nickel inside. This makes nitinol safe for use in medicine.

Surface preparation methods like electropolishing and chemical etching make the surface smooth and even. These methods make the oxide layer stronger and help stop nickel from coming out.

Medical-grade nitinol is safe for the body, bends easily, and lasts a long time. It lets medical devices bend many times without breaking. This helps patients heal faster.

Nitinol is better than stainless steel and cobalt-chromium in some ways. It resists rust better, lets out fewer ions, and has special shape memory. This makes it great for flexible medical tools.

New ways of making and treating nitinol tubing keep it safe and strong for a long time. This is important for devices like stents, catheters, and guidewires.

Nitinol Tubing Corrosion Resistance

Titanium Oxide Layer

Flexible nitinol tubing resists corrosion because it has a thin titanium oxide layer. This layer forms when titanium atoms reach the surface and mix with oxygen. Heat treatments between 400°C and 600°C help this layer grow thicker. Titanium oxide forms more easily than nickel oxide. The titanium oxide layer is usually less than 100 nanometers thick. Even at room temperature, a natural oxide layer appears, but heat makes it stronger.

The titanium oxide layer works like a shield. It blocks harmful body fluids and stops nickel ions from getting out. Under this layer, there is more nickel and less titanium, but the oxide keeps nickel inside the tube. This helps nitinol tubing stay safe and resist corrosion. It is good for long-term medical use.

Tests show that passivation and coatings make the titanium oxide layer stable. ASTM tests prove that thicker oxide layers lower nickel release and help blood compatibility. Electropolishing and chemical passivation make the layer smoother and stronger. This lowers the chance of corrosion. Animal studies show that nitinol tubing with better surfaces releases less nickel and causes fewer reactions. Reviews say the titanium oxide layer stops corrosion and nickel ion leaks in the body. Lab and animal studies show that treated nitinol tubes stay safe in blood and fluids.

Manufacturers use special heat and finishing steps to grow a thick, strong titanium oxide layer. This layer is important for safety and stopping allergies. Clinical data shows that treated nitinol tubing rarely causes allergic problems, even after years. Careful manufacturing keeps the oxide layer good, making nitinol tubing safe and strong.

Key facts about titanium oxide layer:

Titanium oxide forms because titanium reacts faster than nickel.

High heat makes the oxide layer thicker.

The layer is thin, even, and blocks nickel release.

Surface finishing makes the layer better for medical use.

The process uses heat, mixing, and chemical changes.

Surface Preparation

Surface preparation is very important for flexible nitinol tubing. Polishing, electropolishing, and chemical etching are common ways to make the surface better. These steps help create a smooth and clean surface for medical devices.

Surface Preparation Method | Purpose / Benefit | Notes / Potential Issues |

|---|---|---|

Polishing (rough, fine, buffing) | Makes the surface smooth for medical tools | Removes flaws and improves finish |

Electropolishing | Makes surface smoother and safer for the body | Lowers nickel release and stops blood clots |

Abrasive Surface Cleaning | Takes away oxides and dirt | Can leave tiny scratches |

Centerless Grinding | Makes tubing smooth and the right size | Needed for making stents |

Tungsten Carbide Dies | Fixes surface problems | Makes tubing stronger under pressure |

Vacuum Induction Melting (VIM) | Removes oxides and dirt from the alloy | Makes the alloy cleaner |

Vacuum Arc Remelting (VAR) | Cleans alloy by melting it again | Makes alloy stronger and cleaner |

Control of Oxidizing Environments | Stops surface problems and thickness changes | Needs careful control |

Polishing has rough, fine, and buffing steps. These steps take away flaws and make the tube smooth. Electropolishing uses electricity to make the surface even smoother and lower nickel release. Chemical etching removes areas changed by heat, making the surface more even and resistant to corrosion.

Different ways to prepare the surface change the thickness and evenness of the titanium oxide layer. Electropolishing and mechanical polishing make thinner and more even oxide layers, which lower nickel release. Chemical etching makes the surface more even by removing heat-damaged spots. Thermal oxidation makes thicker oxide layers, but these can crack and let out more nickel. Air furnace treatments make medium-thick oxide layers and let out some nickel.

Surface Preparation Technique | Oxide Layer Thickness Characteristics | Uniformity and Additional Notes | Correlation with Nickel Release |

|---|---|---|---|

Electropolishing (EP) | Thinner oxide layer | More even; less nickel-rich areas | Strong link to less nickel release |

Mechanical Polishing (MP) | Thinner oxide layer | More even; uses chemical etching | Better corrosion resistance |

Thermal Oxidation (OT, SP) | Thicker oxide layer (up to ~10 microns) | Less even; can crack | More nickel release |

Air Furnace (AF) | Medium oxide thickness | Not polished after heating | Some nickel release |

Surface preparation steps like electropolishing and chemical etching are needed for strong nitinol tubing corrosion resistance. These steps keep the titanium oxide layer thin, even, and stable, which is important for safety and stopping corrosion. Medical-grade nitinol tubing uses these advanced steps, making it a trusted material for tough healthcare jobs.

Nitinol Properties in Healthcare

Biocompatibility

Nitinol is special in medicine because it works well with the body and does not rust easily. Medical-grade nitinol wire and tubing are used a lot in medical tools. They are safe for body tissues. The titanium oxide layer on nitinol keeps nickel ions from getting into the body. This makes nitinol safe to use. Surface treatments like electropolishing and plasma coating make this layer even better. These steps help nitinol stay safe for a long time.

Studies show nitinol implants are rejected about 30% less than other metals. Nitinol has superelasticity and shape memory. These help devices change shape inside the body. This means less tissue damage during surgery and better healing. Medical-grade nitinol wire is also very strong. It can bend many times without breaking. This helps devices last longer and work well.

Property | Nitinol | Stainless Steel (AISI 316L) | Ti–6Al–4V |

|---|---|---|---|

Shape Memory Effect | Present (unique) | Absent | Absent |

Superelasticity | Present | Absent | Absent |

Fatigue Resistance | Superior | Lower | Lower |

Corrosion Resistance | High (enhanced by surface treatments) | Moderate | Moderate |

Biocompatibility | Comparable or better than steel | Standard medical grade | Standard medical grade |

Nitinol shape memory alloys are setting new rules for safety and rust resistance in medicine. Makers use strict checks and certifications to make sure medical-grade nitinol is safe.

Durability and Safety

Medical-grade nitinol wire and tubing are very strong and last a long time. Devices made from nitinol can bend millions of times and do not break. This means nitinol lasts longer than steel or other metals.

Research shows that special ways of making nitinol, like Electron Beam Refining, make it last twice as long. Stents and heart valve frames made from nitinol keep their shape and strength for years. Nitinol tubing also saves money because it does not need to be replaced often.

Aspect | Nitinol Tubing Benefits | Traditional Materials (e.g., Steel) |

|---|---|---|

Durability | Exceptional durability reducing maintenance | Requires regular maintenance and inspections |

Operational Life | Extended by 300-500% in dynamic applications | Frequent replacements due to fatigue and work hardening |

Total Costs | Lower total ownership costs due to less downtime | Higher costs from frequent replacements and downtime |

ASTM F2063 certification proves nitinol tubing is safe.

Medical-grade nitinol must pass tests for strength, rust resistance, and safety with the body.

Makers use vacuum arc remelting and other steps to remove bad stuff and make nitinol stronger.

Devices with certified nitinol tubing are more flexible, reliable, and safe for a long time.

Nitinol’s strength and safety make it a top pick for important medical tools. It can bounce back from bending and does not rust, so it works well in tough medical jobs.

Nitinol Tubing and Wire Applications

Medical Nitinol Wire Uses

Medical nitinol wire is used in many flexible medical tools. Doctors and engineers pick medical grade nitinol wire because it bends easily. It goes back to its original shape after bending. This helps in heart and bone surgeries. In the heart, medical nitinol wire makes stents and guidewires. These can squeeze small for delivery. They expand inside the body to keep blood vessels open.

In bone surgery, medical nitinol wire helps fix broken bones. Bone staples and plates made from this wire hold bones together. They let bones move naturally. This helps bones heal faster and lowers problems. Dentists use nitinol wire in braces. The wire slowly moves teeth into place. This makes treatment quicker and more comfortable.

Medical grade nitinol wire is special because of superelasticity, shape memory, and biocompatibility. These features make it safe for long-term use in the body.

The table below lists common uses for nitinol wire:

Application Area | Use Case | Benefit |

|---|---|---|

Cardiovascular | Stents, guidewires | Keeps vessels open, resists kinking |

Orthopedics | Bone staples, plates | Promotes stable healing, allows movement |

Dentistry | Orthodontic archwires | Moves teeth gently and efficiently |

Stents, Catheters, Guidewires

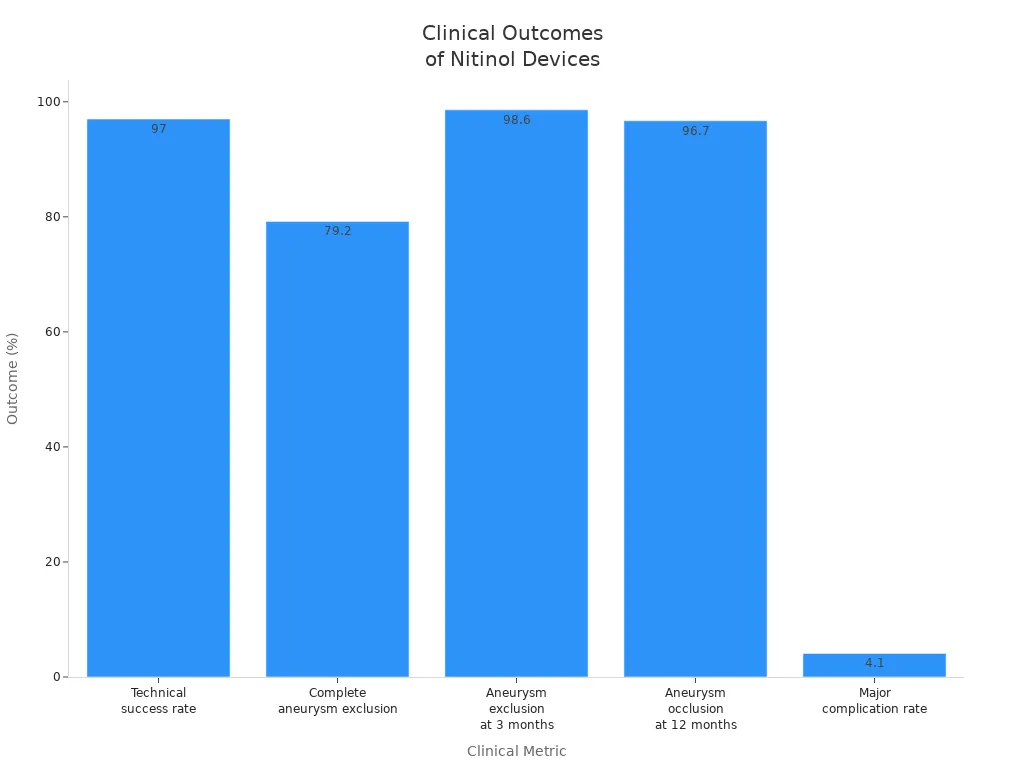

Flexible nitinol tubing is important in many medical procedures. Doctors use flexible nitinol tubing to make stents, catheters, and guidewires. These help treat heart disease and blocked arteries. Flexible nitinol tubing bends and twists through narrow blood vessels. It does not break easily. This lets doctors use smaller cuts. Patients feel less pain and heal faster.

Stents made from flexible nitinol tubing expand by themselves inside blood vessels. They keep arteries open and help blood flow. Some stents near the heart last over 400 million cycles.

Catheters with flexible nitinol tubing reach target areas 92% of the time. They cause few problems. They work well in delicate surgeries, like those in the brain or small vessels.

Guidewires using flexible nitinol tubing succeed 98% of the time in tough or twisted vessels. Their kink resistance and shape memory help doctors steer them safely.

Flexible nitinol tubing is also used in robotic surgical tools. These tools help doctors be more accurate and lower risks during surgery. Nitinol wire in medical devices causes less tissue damage. It leaves smaller scars and helps patients recover faster. Flexible nitinol tubing supports new surgical methods and helps people heal quickly.

Nitinol tubing and wire uses have changed how doctors do surgery. Flexible nitinol tubing lets doctors treat patients in safer and easier ways.

Comparison with Other Metals

Stainless Steel

Many medical devices use stainless steel because it is strong. It is also easy to shape into different forms. Stainless steel resists rust because it has chromium in it. But if the surface gets scratched, it can start to rust. This is more likely in salty body fluids. Nitinol makes a titanium oxide layer that protects it from rust and nickel leaks. This layer stays strong even if the tube bends. That is why nitinol is better for devices that need to last inside the body.

Nitinol resists rust very well, especially after special treatments.

Tests show nitinol works better than steel in tough medical places.

Stainless steel can rust if scratched, but nitinol’s layer keeps working.

Both metals are safe for medical use, but nitinol’s surface treatments make it more reliable.

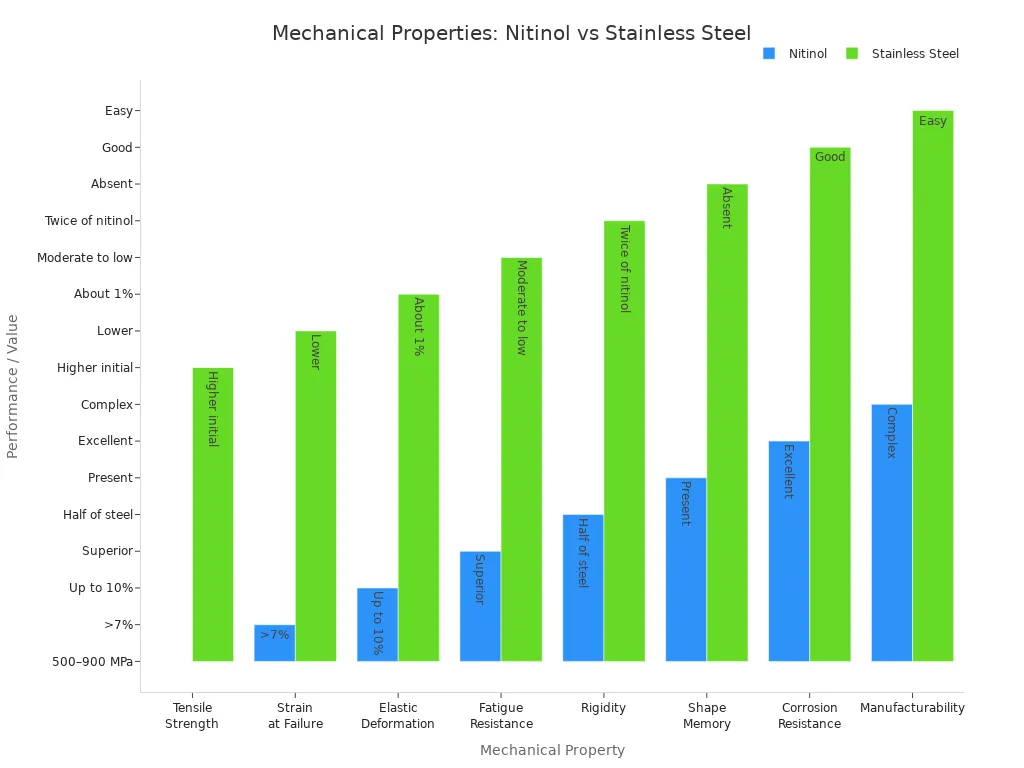

The table below shows how nitinol tubing and stainless steel tubing compare:

Property / Aspect | Nitinol Tubing | Stainless Steel Tubing |

|---|---|---|

Tensile Strength (Ultimate) | 500–900 MPa; some up to 1512 MPa | Higher at first, but drops after welding/use |

Strain at Failure | Over 7%, with superelasticity | Breaks at lower strain |

Elastic Deformation Capacity | Up to 10% strain | About 1% strain |

Fatigue Resistance | Superior; up to 1 billion cycles | Moderate to low at high cycles |

Rigidity (Stiffness) | About half as stiff as steel | Twice as stiff as nitinol |

Shape Memory Effect | Present | Absent |

Corrosion Resistance | Excellent, stable oxide layer | Good, but can pit and rust |

Manufacturability | More complex and costly | Easier and cheaper |

Application Suitability | Best for flexible, moving devices | Best for rigid, load-bearing devices |

Nitinol can bend and return to its shape. This is great for stents and catheters. Stainless steel is better for tools and bone parts that must stay stiff.

Cobalt-Chromium Alloys

Cobalt-chromium alloys are also used in medical devices. These alloys are very strong and can handle many bends. But they can let out cobalt and chromium ions. These ions might cause allergies or be harmful. Nitinol lets out fewer ions because its smooth oxide layer blocks them. This makes nitinol safer for long-term use in the body.

Aspect | Nitinol (Nickel-Titanium) | Cobalt-Chromium Alloy |

|---|---|---|

Ion Release | Lower nickel ion release, less allergy risk | Possible cobalt/chromium ion release, allergy risk |

Surface Characteristics | Smooth oxide layer, reduces blood clots | Needs careful treatment, risk of pitting corrosion |

Corrosion Resistance | High, stable after polishing | Good if processed well, but can pit |

Clinical Implications | Lower thrombosis risk, better healing, fewer repeat procedures | Higher thrombosis risk, closer monitoring needed |

Cobalt-chromium alloys work well in some implants. But nitinol’s lower ion release and better rust resistance make it a better choice for long-term devices. Nitinol’s smooth surface also helps blood vessels heal and lowers blood clot risk.

Long-Term Performance

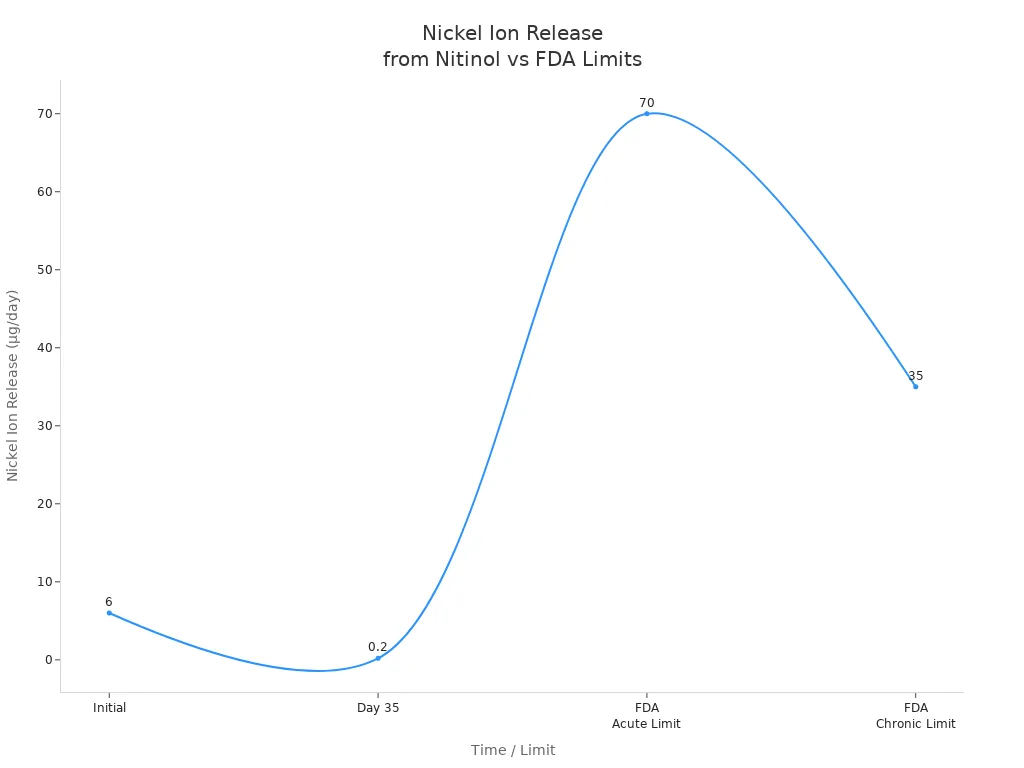

Nickel Ion Release

Nickel ion release is a big worry for nitinol medical devices. The titanium oxide layer on nitinol tubing acts like a shield. This layer forms when titanium meets oxygen. It makes a thin but tough cover. In the body, this layer stays strong most of the time. If things get acidic, the layer can break for a short time. But nitinol fixes the layer fast. This stops too much nickel from getting out. This self-fixing helps keep nickel low and keeps patients safe from allergies.

Studies show the titanium oxide layer’s quality is important. Devices with a smooth, good layer let out less nickel. They cause fewer problems in the body. Surface treatments like electropolishing take away nickel-rich spots. They make the oxide layer smoother. This lowers the chance of nickel leaking into tissues. It also means less swelling. Even thin oxide layers block most nickel from getting out. Some new coatings, like tantalum oxide, make the barrier even stronger.

The titanium oxide layer on nitinol blocks nickel and fixes itself. This makes nitinol tubing safe for long-term use.

Manufacturing and Innovations

Makers use new ways to make nitinol tubing resist corrosion better. These ways help devices stay safe and work well for a long time.

Electropolishing and passivation make the surface smooth. They remove stress and make the oxide layer stronger.

Heat treatments like annealing and shape setting help the crystal structure. This helps the material fight corrosion.

Non-destructive tests like ultrasonic and eddy current checks find problems early.

Cleaning and polishing take away dirt and make the surface even. This lowers friction and helps stop corrosion.

New methods like laser cutting and additive manufacturing allow custom shapes and better surfaces.

Better surface finishing helps nitinol work well in the body. Electropolished surfaces let out less nickel and lower allergy risks. Smooth surfaces lower blood clot risks and help vessels heal. Coatings like parylene lower friction and wear. This makes devices last longer. These steps help nitinol medical devices stay strong, safe, and useful for many years.

A smooth surface and strong titanium oxide layer help nitinol tubing resist corrosion. Electropolishing makes the surface smooth. This lowers the chance of device problems. It also helps keep patients safe. Tests show devices with this technology work well. They have few problems and high success rates.

Scientists keep looking for better coatings and ways to make nitinol tubing. These new ideas help medical devices last longer. They also make future healthcare tools better.

FAQ

What makes nitinol tubing safe for medical use?

Nitinol tubing has a titanium oxide layer. This layer stops nickel from getting out. Doctors use nitinol because it does not rust. It helps keep patients safe.

How does surface preparation improve nitinol tubing?

Surface preparation takes away flaws and smooths the tubing. Electropolishing and chemical etching make a strong oxide layer. This layer is even and lowers nickel release. It also helps stop corrosion.

Tip: Smooth surfaces help medical devices last longer. They also work better inside the body.

Can nitinol tubing cause allergies?

Nitinol tubing almost never causes allergies. The titanium oxide layer keeps nickel inside. Most people do not have problems with nitinol devices.

Where do doctors use nitinol tubing?

Doctors use nitinol tubing in stents, catheters, and guidewires. Nitinol lets these devices bend and go back to shape. It helps with heart, bone, and dental treatments.

Device Type | Nitinol Benefit |

|---|---|

Stent | Expands and does not kink |

Catheter | Flexible and strong |

Guidewire | Easy to move |

See Also

Discovering How Nitinol Tubing Enhances Healthcare Technology

The Process Behind Manufacturing Nitinol Tubing For Medicine

The Importance Of Nitinol Tubing In Modern Medical Use

Ways Nitinol Tubing Is Transforming Medical Device Innovation

Evaluating Tensile Strength Between Nitinol Tubing And Steel