How Nitinol Tubing Transforms Cardiovascular Devices

Nitinol tubing in cardiovascular devices has redefined modern medical treatments by introducing groundbreaking capabilities. Its unique properties, including shape memory and superelasticity, allow devices to adapt seamlessly to the dynamic environment of the human body. For instance, nitinol stents, designed larger than the target vessel size, resist external radial forces effectively. These stents also demonstrate superior flexibility, enabling delivery through standard microcatheters. Furthermore, the biocompatibility of nitinol tubing minimizes the risk of adverse reactions, ensuring safer and more reliable outcomes. Clinical studies consistently highlight its durability, particularly in challenging applications like the superficial femoral artery, where fatigue resistance is critical. By leveraging these advantages, nitinol tubing in cardiovascular devices continues to enhance patient care and treatment success rates.

Key Takeaways

Nitinol tubing has special traits like shape memory and flexibility. These help heart devices adjust to the body, improving treatments.

Nitinol is safe for the body and causes fewer bad reactions. This makes it a better choice for long-term medical use.

Its bendability helps with small surgeries, making recovery faster and easier.

Nitinol tubing is strong and works well in tough situations. This helps patients get better results over time.

Nitinol devices can be customized to fit each patient’s needs. This improves accuracy and makes treatments more personal.

Understanding Nitinol Tubing

Composition and Structure

Nitinol tubing, a cornerstone of cardiovascular medical devices, derives its unique properties from its composition and structure. It is primarily composed of nickel (54.5% to 57%) and titanium, as specified by ASTM International standards. The manufacturing process begins with vacuum induction melting or vacuum arc remelting to create nitinol ingots. These ingots undergo forging and hot rolling to form billets, which are then drawn into wires or gun-drilled into tubes. This meticulous process ensures the material's consistency and quality.

Nitinol exhibits two distinct crystal phases: austenite and martensite. Austenite remains stable at higher temperatures, while martensite dominates at lower temperatures. The reversible transformation between these phases underpins the material's shape memory and superelasticity. Studies on texture evolution and fatigue performance further highlight the critical role of structure-property relationships in optimizing nitinol tubing for medical devices.

Shape Memory and Superelasticity

The shape memory and superelasticity of nitinol tubing revolutionize its application in cardiovascular medical devices. Shape memory allows the material to return to its original form after deformation when exposed to specific temperatures. Superelasticity, on the other hand, enables the tubing to withstand significant strain without permanent deformation. These properties are particularly beneficial in dynamic environments like the human body.

Experimental measurements validate these characteristics. For instance, elongation and force tests conducted in temperature-controlled environments demonstrate the phase transformations that drive these behaviors. Isothermal experiments further reveal how force varies with elongation at different temperatures. This data underscores the reliability of superelastic nitinol in demanding applications, such as stents and guidewires.

Biocompatibility and Corrosion Resistance

Biocompatibility in healthcare is a critical factor for materials used in medical devices. Nitinol tubing excels in this regard, offering exceptional biocompatibility and corrosion resistance. Clinical assessments confirm its ability to resist various forms of corrosion, including pitting, galvanic, and fretting corrosion. For example, ASTM F2129 testing evaluates its susceptibility to pitting corrosion, ensuring its safety in long-term medical applications.

Additionally, nitinol's resistance to metal ion release minimizes the risk of adverse health effects, such as toxicity. This makes it an ideal choice for cardiovascular medical devices, where prolonged contact with bodily fluids is inevitable. Its durability and resistance to environmental factors contribute to the fatigue strength of a finished component, ensuring reliable performance over time.

Benefits of Nitinol Tubing in Cardiovascular Devices

Flexibility and Adaptability

Nitinol tubing offers unmatched flexibility and adaptability, making it a cornerstone in cardiovascular device innovation. Its superelasticity allows devices to navigate intricate anatomical pathways with ease, reducing procedural risks and improving clinical outcomes. This flexibility is particularly beneficial in minimally invasive procedures, where precise navigation through complex vascular systems is essential. Additionally, nitinol's ability to conform to varying vessel sizes enables customized treatment options, resulting in less discomfort and faster healing for patients.

Benefit | Description | Impact on Patient Outcomes |

|---|---|---|

Flexibility | Nitinol enhances minimally invasive procedures by providing flexibility. | Reduces procedural risks and improves outcomes. |

Adaptability | Its superelasticity allows devices to navigate intricate pathways. | Leads to better clinical results. |

Customized Treatment | Flexibility allows for tailored solutions. | Results in less discomfort and faster healing. |

The combination of flexibility and adaptability ensures that nitinol tubing remains a preferred material for advanced cardiovascular devices.

Durability and Fatigue Life of Nitinol

The durability and fatigue behavior of nitinol tubing set it apart from other materials used in cardiovascular devices. Nitinol demonstrates a nearly bimodal distribution of fatigue fractures, highlighting its superior fatigue resistance. Its high-cycle fatigue limit, achieved through reduced defects, ensures long-term reliability in demanding applications. Recent advancements in material cleanliness have further enhanced the fatigue life of nitinol, making it ideal for devices subjected to repetitive stress, such as stents and guidewires.

Evidence Description | Impact on Durability and Fatigue Life |

|---|---|

The typical nearly bimodal distribution of fatigue fractures observed in testing. | Highlights the variability in fatigue performance of nitinol. |

An increased high-cycle fatigue limit due to fewer potent defects. | Indicates improved fatigue resistance in nitinol tubing. |

Recent improvements in material cleanliness leading to notable increases in fatigue life. | Suggests enhanced durability of nitinol compared to other materials. |

This exceptional fatigue behavior ensures that nitinol tubing maintains its structural integrity over extended periods, even in challenging environments.

Design Versatility for Minimally Invasive Procedures

Nitinol tubing's design versatility has revolutionized minimally invasive procedures. Recent advancements, such as low-cost prototyping and patient-specific designs, have expanded its applications in cardiovascular care. These innovations allow for the creation of implants tailored to individual patient needs, enhancing treatment precision. Nitinol tubing is now used in a wide range of devices, including stent grafts, occluders, and implantable sensors, further demonstrating its adaptability.

Advancement Type | Description |

|---|---|

Low-cost prototyping | Efficient methods for shaping nitinol structures, enhancing versatility in medical applications. |

Patient-specific designs | Methodologies for designing and fabricating implants tailored to individual patient needs. |

Applications in medical devices | Examples include implantable sensors, occluders, stone extractors, stent grafts, and valves. |

This versatility not only supports the development of innovative devices but also ensures that nitinol tubing continues to play a pivotal role in advancing minimally invasive procedures.

Applications of Nitinol Tubing in Cardiovascular Treatments

Stents and Vessel Support

Nitinol tubing has revolutionized the design and performance of stents, particularly self-expanding stents, in cardiovascular treatments. These stents leverage the shape memory and superelasticity of nitinol to adapt to vessel dynamics, ensuring optimal support and patency. Clinical trials have consistently demonstrated their effectiveness:

The MISAGO 1 trial compared nitinol stent implantation to percutaneous transluminal angioplasty in superficial femoral artery lesions, highlighting superior outcomes.

The first clinical trial of nitinol self-expanding everolimus-eluting stents for peripheral arterial occlusive disease showed significant improvements in patients with severe arterial conditions.

The ORION trial validated the Boston Scientific Epic Stent's ability to maintain vessel patency while enhancing flexibility.

These advancements underscore the reliability of nitinol stents in addressing complex vascular challenges. Their biocompatibility and corrosion resistance further enhance patient safety, making them indispensable in modern cardiovascular treatments.

Guidewires for Complex Anatomy

Guidewires constructed from nitinol tubing offer unmatched precision and flexibility, enabling effective navigation through intricate anatomical pathways. The superelastic properties of nitinol allow these advanced guidewires to maintain structural integrity while adapting to challenging environments. Studies have shown that nitinol guidewires excel in bending performance and trackability, crucial for minimally invasive procedures.

A smart guidewire developed using nitinol demonstrated significant bending capabilities while maintaining low surrounding temperatures, reducing the risk of adverse reactions. Additionally, evaluations confirmed enhanced thrombogenic response and thermal effects, ensuring safe and efficient interventions. These innovations have elevated the performance of guidewires, making them essential tools for navigating complex vascular structures.

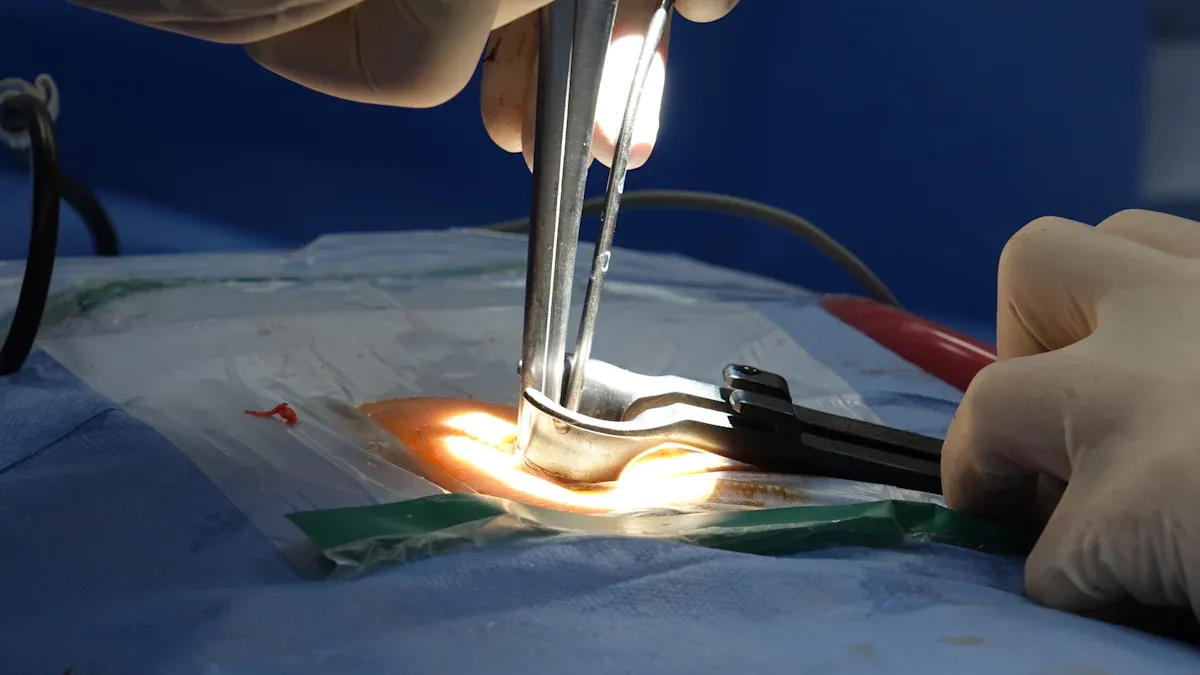

Catheters for Precision Procedures

Catheters made from nitinol tubing have transformed precision procedures in cardiovascular care. Their flexibility and adaptability allow for seamless navigation through narrow and tortuous pathways, ensuring accurate delivery of therapeutic agents. Nitinol catheters exhibit exceptional durability, maintaining their performance under repetitive stress during prolonged interventions.

The material's biocompatibility minimizes the risk of complications, while its corrosion resistance ensures long-term reliability. These attributes make nitinol catheters ideal for procedures requiring high precision, such as balloon angioplasty and drug delivery. As advancements continue, nitinol tubing remains central to the development of innovative catheter designs that improve procedural outcomes and patient comfort.

Emerging Applications in Cardiovascular Devices

Nitinol tubing continues to drive innovation in cardiovascular treatments, enabling the development of groundbreaking devices that address complex medical challenges. Recent advancements have expanded its applications, offering new possibilities for improving patient care.

Nitinol Stents: These stents utilize the shape memory and superelasticity of nitinol to enhance blood flow and minimize the risk of blockages. Their ability to adapt to vessel dynamics ensures long-term patency and reliability.

Guidewires: Nitinol guidewires provide unmatched flexibility and precision, making them indispensable for navigating intricate vascular pathways. Their superelastic properties reduce the risk of vessel damage during procedures.

Heart Valve Frames: Frames made from nitinol tubing support replacement valves, adapting seamlessly to the heart's movement and pressure. This ensures durability and optimal performance over time.

Occlusion Devices: These devices effectively block abnormal blood flow, leveraging nitinol's strength and flexibility to achieve precise and reliable results.

The versatility of nitinol tubing has also paved the way for emerging technologies, such as implantable sensors and bioresorbable scaffolds. Implantable sensors, constructed with nitinol, monitor cardiovascular health in real time, providing critical data for personalized treatment plans. Bioresorbable scaffolds, designed to dissolve after fulfilling their purpose, represent a significant leap forward in reducing long-term complications.

Note: The adaptability of nitinol tubing allows engineers to design devices tailored to individual patient needs, further enhancing treatment outcomes.

As research progresses, the potential applications of nitinol tubing in cardiovascular care continue to grow. Its unique properties make it a cornerstone of innovation, ensuring that future devices remain at the forefront of medical advancements.

Impact of Nitinol Tubing on Patient Outcomes

Enhanced Safety and Reduced Risks

Nitinol tubing significantly enhances safety in cardiovascular procedures by reducing risks associated with traditional materials. Its biocompatibility minimizes adverse reactions, such as inflammation or thrombosis, ensuring safer long-term use. The material's corrosion resistance further prevents complications caused by metal degradation in the body. Devices made from nitinol tubing, such as stents and guidewires, maintain structural integrity under stress, reducing the likelihood of device failure during critical interventions. These attributes collectively improve patient outcomes by lowering procedural risks and enhancing reliability.

Faster Recovery and Improved Comfort

Nitinol-based devices contribute to faster recovery and greater comfort for patients undergoing cardiovascular treatments. Their flexibility and adaptability allow for minimally invasive procedures, which result in smaller incisions and reduced trauma to surrounding tissues. This leads to quicker healing and less postoperative pain. Clinical data highlights the advantages of nitinol devices over traditional materials:

Metric | Nitinol Devices | Traditional Materials |

|---|---|---|

Recovery Improvement | 20% | N/A |

Pain Level Reduction | Quicker recovery | N/A |

Risk of Complications | Lower | N/A |

These improvements in recovery metrics demonstrate how nitinol tubing enhances patient outcomes by promoting comfort and reducing recovery times.

Long-Term Success in Cardiovascular Treatments

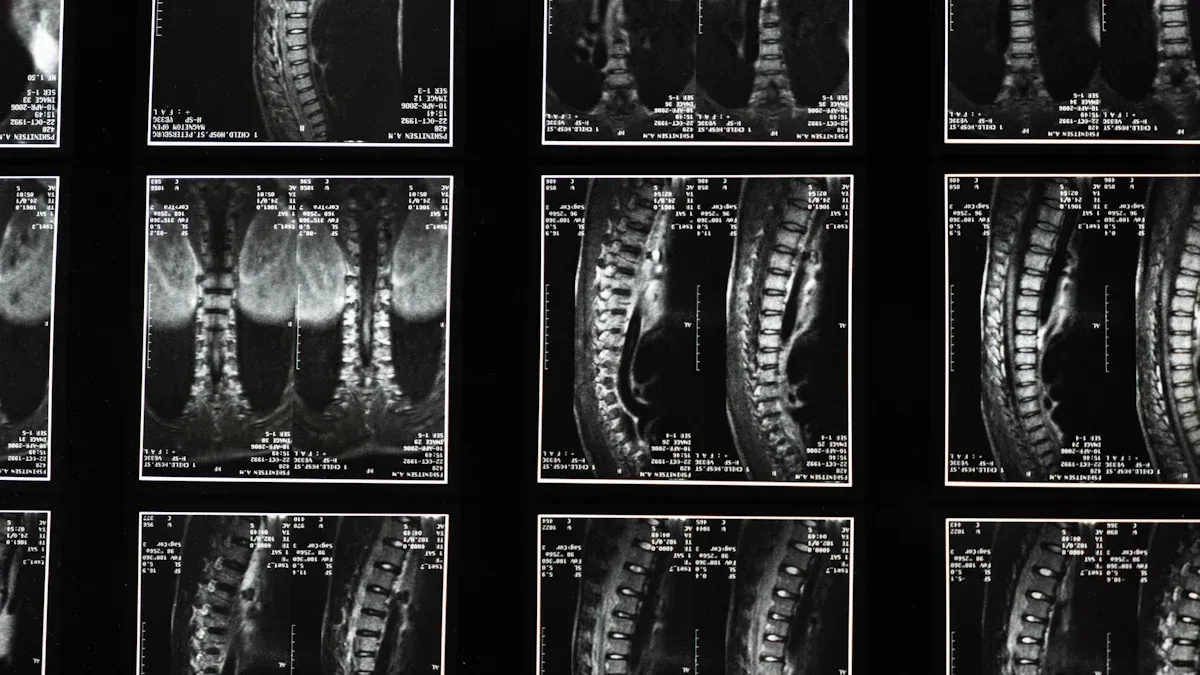

The long-term success of cardiovascular treatments relies heavily on the durability and performance of nitinol tubing. Devices such as stents and guidewires made from nitinol have shown exceptional effectiveness in treating coronary artery disease and other vascular conditions. Key findings from clinical studies include:

Nitinol stents reduce restenosis rates, ensuring better long-term vessel patency.

Guidewires constructed from nitinol improve precision during minimally invasive procedures, enhancing overall treatment outcomes.

Additionally, the material's high-cycle fatigue life and improved cleanliness contribute to its reliability over extended periods.

Aspect | Findings |

|---|---|

Fatigue Life | High-cycle fatigue strain limits of 0.4–0.8 percent observed in studies. |

Material Cleanliness | Enhanced cleanliness has increased fatigue life significantly. |

Processing Methods | Tube processing methods impact fatigue life, with TM-1 and TM-2 showing varied results. |

These attributes ensure that nitinol tubing continues to support successful cardiovascular treatments, improving patient outcomes and reducing complications over time.

Nitinol tubing has revolutionized cardiovascular devices by introducing innovative designs that prioritize durability and biocompatibility. Its use in stents, guidewires, and catheters has elevated treatment precision and reliability, leading to better patient outcomes.

Key Insight: The adaptability of nitinol tubing ensures its continued relevance in addressing complex cardiovascular challenges.

As advancements in material science progress, nitinol tubing will remain a cornerstone of innovation, driving the development of next-generation devices that redefine cardiovascular care.

FAQ

What makes nitinol tubing unique for cardiovascular devices?

Nitinol tubing stands out due to its shape memory, superelasticity, and biocompatibility. These properties allow it to adapt to dynamic environments, resist deformation, and minimize adverse reactions, making it ideal for stents, guidewires, and catheters.

Tip: Nitinol's ability to return to its original shape ensures reliable performance in demanding medical applications.

How does nitinol tubing improve patient outcomes?

Nitinol tubing enhances patient outcomes by enabling minimally invasive procedures, reducing recovery times, and improving device reliability. Its flexibility and durability ensure precise navigation through complex anatomy, leading to safer and more effective treatments.

Are there any risks associated with nitinol tubing?

Nitinol tubing is highly biocompatible and corrosion-resistant, minimizing risks like inflammation or metal ion release. However, proper device design and manufacturing are crucial to ensure safety and optimal performance in medical applications.

Can nitinol tubing be customized for individual patients?

Yes, nitinol tubing can be tailored to meet specific patient needs. Advances in low-cost prototyping and patient-specific designs allow engineers to create devices that align with unique anatomical and procedural requirements.

Note: Customization enhances treatment precision and comfort, especially in complex cardiovascular cases.

What future advancements are expected for nitinol tubing?

Emerging technologies like bioresorbable scaffolds and implantable sensors are expanding nitinol's applications. Researchers are also exploring ways to further improve its fatigue life and adaptability, ensuring its continued role in next-generation cardiovascular devices.

Key Insight: Nitinol tubing's versatility ensures its relevance in addressing evolving medical challenges.

See Also

Nitinol Tubing's Impact on the Future of Medical Devices

Nitinol Tubing's Contribution to Progressing Medical Technology

The Manufacturing Process of Nitinol Tubing for Healthcare