How to Perform Biocompatibility Testing for Nitinol Tubing

You must approach nitinol tubing with a focus on safety at every stage. Regulatory compliance protects both patients and device reliability. Nitinol’s unique traits—like nickel release and the effects of surface modification—demand careful control. Certified nitinol tubing meets strict standards and reduces complication rates by up to 25%. As you prepare for Nitinol tubing biocompatibility testing methods, consider the critical data below:

Parameter | Standard/Requirement |

|---|---|

Biocompatibility Testing | ISO 10993, FDA, ASTM F2063 |

Fatigue Life | >600 million cycles |

Nickel Release | <75 ppb with proper passivation |

OD Tolerance | ±0.005mm for OD > 0.80mm |

Certified Nitinol Tubing | Up to 25% reduction in complication rates |

Safety | Highest priority in all testing and documentation |

Biocompatibility and safety remain your top priorities as you select, execute, and document each step.

Key Takeaways

Always use certified nitinol tubing that meets ISO 10993-1 and ASTM F2063 standards to ensure safety and quality in medical devices.

Prepare nitinol tubing with thorough cleaning and advanced surface treatments like electropolishing to reduce nickel release and improve biocompatibility.

Perform key biocompatibility tests including cytotoxicity, nickel release, mechanical strength, and histopathology to confirm safety and durability.

Keep detailed records of all preparation, testing, and sterilization steps to support traceability and regulatory approval.

Follow validated protocols and use proper controls during testing to ensure reliable results and meet regulatory requirements.

Standards and Requirements

When you plan biocompatibility testing for nitinol tubing, you must start with three main criteria. First, consider how long the device will contact the body. Second, think about the type of body contact, such as skin, blood, or tissue. Third, look at how the device will be used in medical applications. These factors guide your choice of tests and help you meet strict medical standards.

ISO 10993-1

You should always follow ISO 10993-1 when you test nitinol for medical use. This standard gives you a framework for evaluating the safety of materials in medical devices. It covers tests for cytotoxicity, sensitization, irritation, and systemic toxicity. ISO 10993-1 helps you make sure that certified nitinol tubing is safe for patients in all medical applications. You can use this standard to select the right tests for your device and document your results for regulatory approval.

FDA Guidance

The FDA provides clear guidance for biocompatibility testing of nitinol in medical devices. If your device is an implant, you must perform a 60-day nickel release test. This test checks how much nickel comes out of the nitinol over time. The FDA also expects you to follow ISO 10993-1 and show that your certified nitinol tubing meets all safety requirements. You need to keep detailed records of your testing and results to support your medical device submission.

ASTM F2063

ASTM F2063 sets the requirements for medical grade nitinol. You must use this standard to confirm the material’s identity and quality. ASTM F2063 covers mechanical properties like shape recovery strain, superelastic strain, and tensile strength. It also requires you to measure transformation temperatures using Differential Scanning Calorimetry. For biocompatibility, ASTM F2063 points you to ISO 10993 for tests like cytotoxicity and sensitization. Long-term clinical data show that nitinol implants made to this standard perform well in medical applications, with very few adverse reactions.

Tip: Always use certified nitinol tubing that meets ASTM F2063 and ISO 10993-1. This ensures your medical device is safe and effective for all medical applications.

Sample Preparation

Cleaning and Surface Treatment

You must start with thorough cleaning and surface treatment to prepare nitinol tubing for medical use. Post-processing steps remove impurities and create a smooth, protective titanium dioxide layer. This layer reduces nickel ion release and improves biocompatibility. Advanced techniques like magnetic abrasive finishing (MAF) and electropolishing can lower surface roughness and help prevent bacterial adhesion.

Parameter | Initial Value | Final Value (After Advanced MAF Polishing) |

|---|---|---|

Surface Roughness Ra (Ø 200 μm) | 140 nm | 20 nm |

Surface Roughness Ra (Ø 400 μm) | 280 nm | 30 nm |

Reduction in Bacterial Adhesion | N/A | >83.48% for Staphylococcus aureus |

Reduction in Bacterial Adhesion | N/A | >70.67% for Escherichia coli |

Electropolishing further reduces surface roughness to Ra <0.1 μm. Smoother nitinol surfaces lower tissue irritation and nickel release, which increases safety for patients. These treatments also boost corrosion resistance and device longevity. You can expect certified nitinol tubing to withstand up to 10 million bending cycles after proper surface finishing.

Sterilization

Sterilization is a critical step before you use nitinol tubing in any medical device. Smooth surfaces from advanced cleaning make sterilization more effective by reducing places where bacteria can hide. You should use validated sterilization methods, such as autoclaving or ethylene oxide, to ensure all contaminants are removed. Proper sterilization supports regulatory compliance and patient safety.

Note: Smoother nitinol surfaces not only prevent bacterial adhesion but also help you achieve better sterilization results.

Documentation

You must document every step of sample preparation for nitinol tubing. Keep records of cleaning, surface treatment, and sterilization processes. Traceability is essential. You should log batch numbers, process parameters, and inspection results. This documentation proves that you used certified nitinol tubing and followed all regulatory standards. Good records help you pass audits and support your regulatory submissions.

Tip: Detailed documentation ensures you can trace each piece of nitinol tubing from raw material to finished device.

Nitinol Tubing Biocompatibility Testing Methods

When you perform nitinol tubing biocompatibility testing methods, you must select tests based on how the device will be used, how long it will contact the body, and what type of body contact occurs. Surface modifications and post-processing steps can change test outcomes, so you need to consider these factors during planning. The main tests include cytotoxicity, sensitization, irritation, systemic toxicity, hemocompatibility, nickel release, and histopathology. Each test helps you confirm that nitinol tubing is safe for medical applications and meets regulatory standards.

Chemical Characterization

You start by analyzing the chemical makeup and surface quality of nitinol tubing. Chemical characterization ensures that the tubing meets purity and composition standards for medical use. You use techniques like potentiodynamic polarization and electrochemical impedance spectroscopy to measure corrosion resistance and surface integrity. These methods help you confirm that the tubing forms a stable oxide layer, which reduces nickel ion release and improves safety.

Evidence Aspect | Quantifiable Detail |

|---|---|

Material Purity Standard | Compliance with ASTM F2063 for high-purity nickel and titanium |

Corrosion Resistance | Breakdown potential > 600 mV indicates corrosion resistance |

Nickel Ion Release (Day 1) | 6.0 ± 1.2 µg/day, below acute tolerable limit of 70 µg/day |

You also measure the thickness and uniformity of the oxide layer. A thinner, more uniform layer improves corrosion resistance and reduces the risk of nickel leaching. You can optimize machining processes by adjusting electrolytes, which helps you achieve the best surface quality for medical applications.

Mechanical Characterization

Mechanical testing confirms that nitinol tubing can withstand the physical demands of medical devices. You measure properties like tensile strength, elasticity, and fatigue life. For example, you compress a nitinol stent to a specific diameter and record the reaction force. This test shows how much support the stent provides inside the body.

Reaction force during compression: Shows the supporting force of the stent.

Elongation deformation: Measures how much the stent stretches under pressure.

Bending stiffness (EI): Indicates how flexible or stiff the tubing is.

Maximum von Mises stress: Reveals stress distribution and helps you avoid failure.

You use both experimental tests and computer simulations to validate these properties. Nitinol tubing must endure over 600 million cardiac cycles without failure, making it suitable for long-term medical applications.

Biological Testing

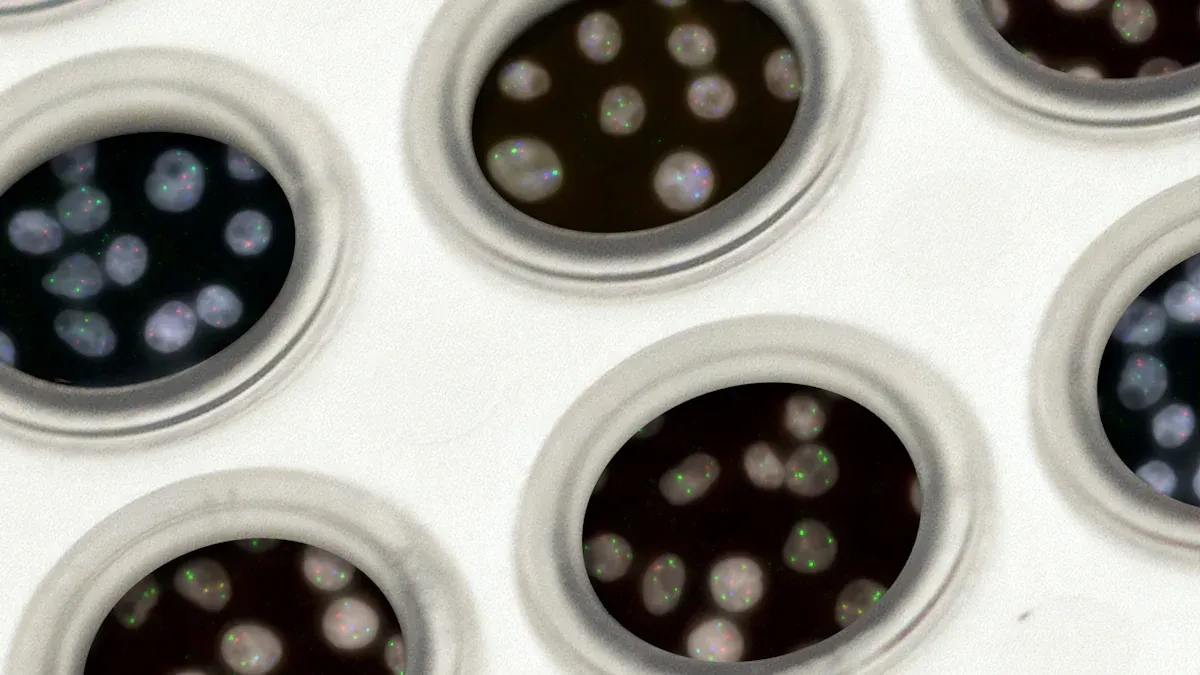

You need to confirm that nitinol tubing does not harm living cells or cause allergic reactions. Biological testing includes cytotoxicity, sensitization, irritation, systemic toxicity, and hemocompatibility. You use the MEM elution assay with L929 mouse fibroblast cells to check for cytotoxicity. This test scores cell reactions from 0 (no effect) to 4 (severe effect). You compare the results to regulatory limits to ensure patient safety.

Biological testing also measures how much nickel ion is released and whether it stays below toxic thresholds. For example, the IC50 value for nickel ion is 0.106 mmol/L, but actual patient exposure from medical devices is much lower. You follow ISO 10993 standards, starting with in vitro tests and moving to animal studies only if needed. This approach reduces unnecessary animal testing and focuses on clinical relevance.

Nickel Release Testing

Nickel release testing is critical for nitinol tubing biocompatibility testing methods. You measure how much nickel leaches from the tubing over time using immersion tests and advanced detection methods like ICP-MS. The FDA recommends following ASTM standards for these tests. You perform 60-day immersion tests to simulate long-term exposure in the body.

Parameter | Quantitative Evidence |

|---|---|

Nickel Ion Release (Day 1) | 6.0 ± 1.2 µg/day, max 7.6 µg/day |

Nickel Ion Release (Day 6) | 1 µg/day |

Nickel Ion Release (Day 35) | 0.2 µg/day |

FDA Tolerable Limits for Ni | Acute: 70 µg/day; Chronic: 35 µg/day |

You find that electropolished nitinol tubing releases less nickel than heat-treated tubing. In animal studies, polished stents show lower nickel levels in tissue and blood, with fewer adverse reactions. You use these results to validate your surface finishing processes and ensure compliance with medical regulations.

Tip: Always use nickel release data to guide your choice of surface treatments and confirm that your tubing meets FDA and ISO limits for medical applications.

Histopathology

Histopathology helps you understand how tissues respond to nitinol tubing after implantation. You examine tissue samples under a microscope to look for inflammation, tissue encapsulation, and other reactions. Most studies show minimal tissue response, with histological scores ranging from 0 to 1. Acute inflammation is rare and usually resolves over time. By 180 days, tissue forms a thin, mature fibrous capsule around the tubing.

Minimal acute inflammation observed after implantation.

Tissue encapsulation matures over time, forming a stable barrier.

Histological scoring remains low, indicating good biocompatibility.

Nitinol tubing maintains long-term corrosion resistance and durability in clinical settings.

You rely on trained pathologists to interpret these findings and assess the clinical relevance. Similar tissue responses between test and control devices do not always mean the tubing is fully biocompatible. You must consider the context and severity of any reactions before making conclusions about safety in medical applications.

Note: Histopathology provides essential data for regulatory submissions and helps you demonstrate the long-term safety of nitinol tubing in medical devices.

Test Execution and Analysis

Controls and Protocols

You must always use well-defined controls and follow validated protocols during biocompatibility testing. Controls help you compare results and spot any unexpected reactions. For example, ISO 10993-5 and ISO 10993-23 outline how to select positive and negative controls for cytotoxicity and irritation tests. These protocols require you to use medical device polymers with known properties and prepare extracts according to ISO 10993-12. Proper training for laboratory staff ensures everyone follows the same steps, reducing errors and improving consistency.

Aspect | Evidence Summary |

|---|---|

ISO 10993 Standards | ISO 10993-5 and ISO 10993-23 specify test methods, protocols, and acceptance criteria. |

Control Selection | Use well-characterized positive and negative controls; follow ISO 10993-12 for extract prep. |

Statistical Validation | Round robin studies confirm reproducibility and accuracy of protocols. |

Regulatory Compliance | Agencies require data aligned with ISO protocols. |

Training | Training and harmonization reduce variability. |

Challenges | Variability in protocol interpretation and regulatory skepticism exist. |

Tip: Always document your controls and protocols to support regulatory submissions and audits.

Data Interpretation

You need to analyze your testing results using reliable methods. Metallographic analysis and dimensionless modeling help you understand fatigue strain limits in Nitinol tubing. You should look at inclusion shape, size, and orientation, as these factors affect fatigue damage risk. Fatigue simulations and finite element modeling can show you where cracks might start. Surface roughness measurements, regulated by ASTM F2063, also play a key role in implant performance. A constant life model, based on statistical analysis, predicts fatigue life with 90% reliability at 95% confidence. This approach helps you interpret testing data and make informed decisions about device safety.

Use metallographic and microscopy analysis to define inclusion geometry.

Apply fatigue simulations to identify high-risk regions.

Monitor surface roughness and oxide layer quality for better performance.

Troubleshooting

Common issues in biocompatibility testing include unexpected cytotoxicity, early fatigue fractures, or corrosion. You can address these problems by reviewing your protocols and checking material purity. Clinical case studies show that lower purity Nitinol increases fracture risk and device failure. High-purity tubing withstands millions of cycles without breaking. Surface modifications, such as electropolishing, improve corrosion resistance and reduce complications. If you see early thrombus formation or neointima growth, consider multidisciplinary research and adjust your material selection or surface treatment.

Evidence Type | Description |

|---|---|

Documented Cases | Fatigue fractures linked to lower purity Nitinol. |

Performance Stats | High-purity Nitinol improves durability and cycle life. |

Risk Assessment | Fracture risk correlates with inclusions or voids in the material. |

Note: Careful review of protocols and material quality helps you solve most testing challenges and ensures reliable device performance.

Documentation and Submission

Test Reports

You need to create detailed test reports for every Nitinol tubing project. These reports should include all the steps, results, and methods used during testing. You must describe each component, such as the Nitinol backbone, polymer covering, and any markers. Include information about how you made the tubing, like laser welding, annealing, and surface finishing. Use both experimental and simulation data to show how the tubing performs under stress and temperature changes.

Test Method | Purpose |

|---|---|

Differential Scanning Calorimetry | Measures transformation temperatures, such as Austenite Finish (Af). |

Bend Free Recovery | Checks shape recovery and superelasticity. |

Tensile Strength Testing | Confirms strength and resistance to deformation. |

Thermal Analysis | Shows shape memory and superelastic properties. |

You should also add quantitative results, such as radial force, tensile load, and fatigue life. Use images, tables, and graphs to make your findings clear. Always include traceability records from raw material to final inspection. This helps prove the tubing meets all quality and safety standards.

Compliance Summary

A compliance summary shows that your Nitinol tubing meets all regulatory and safety requirements. You must list the standards followed, such as ISO 10993 for biocompatibility and ASTM F2063 for material quality. Include key benchmarks and tolerances in a table for easy review.

Parameter | Benchmark / Tolerance |

|---|---|

Wall thickness tolerance | ±15 µm |

Diameter tolerance | ±20 µm |

Tensile strength | 500–900 MPa |

Fatigue life cycles | Up to 600 million cycles |

Biocompatibility testing ensures the tubing is safe and non-toxic.

Mechanical and fatigue tests confirm strength and durability.

Nickel release testing protects patients from harmful exposure.

Traceability and surface treatments improve long-term safety.

Tip: Always use automated data capture and laser marking to support traceability and compliance.

Regulatory Submission

You must prepare a complete package for regulatory submission. This includes your test reports, compliance summary, and a risk assessment. Explain how you addressed all possible risks and justified the tubing’s use in medical devices. Use clear tables and summary statements to show that your tubing meets all safety and quality standards. Regulatory agencies, such as the FDA, require proof that your testing followed approved protocols and that your tubing is safe for patients.

Note: Good documentation and clear risk assessment help you gain regulatory approval and protect patient safety.

You ensure safety at every stage when you test nitinol tubing for medical use. You clean, treat, and document each sample. You check corrosion, nickel release, and drug delivery. The table below shows key performance indicators for nitinol in medical applications:

Parameter | Optimized Value (470°C Heat Treatment) |

|---|---|

Corrosion Current Density | 18.8 nA/cm² |

Corrosion Rate | 0.0002 mm/year |

Drug Release (5 hrs) | 80% |

You protect patient safety by following standards and tracking every result. You keep up with new best practices to maintain safety in all medical applications.

FAQ

What is the most important test for Nitinol tubing biocompatibility?

You should always prioritize nickel release testing. This test checks if the tubing releases safe levels of nickel. Regulatory agencies require this data to ensure patient safety. Nickel release results also help you select the best surface treatments.

How do you reduce nickel ion release from Nitinol tubing?

You can use advanced surface treatments like electropolishing or magnetic abrasive finishing. These methods create a smooth, protective oxide layer. This layer lowers nickel ion release and improves biocompatibility.

Why do you need to document every step in biocompatibility testing?

Good documentation proves you followed standards and used certified materials. You need these records for audits and regulatory submissions. Detailed logs also help you trace any issues back to their source.

Can you reuse Nitinol tubing after sterilization?

You should not reuse Nitinol tubing in medical devices. Reuse increases the risk of contamination and device failure. Always use new, certified tubing for each patient to ensure safety.

What standards must you follow for Nitinol tubing in medical devices?

Standard | Purpose |

|---|---|

ISO 10993-1 | Biocompatibility testing |

ASTM F2063 | Material quality |

FDA Guidance | Regulatory compliance |

You must follow these standards to meet safety and quality requirements.

See Also

The Process Behind Manufacturing Nitinol Tubing For Medicine

A Deep Dive Into Nitinol Tubing Uses In Healthcare

Nitinol Versus Stainless Steel: Tensile Strength Comparison

The Importance Of Nitinol Tubing In Modern Medical Fields

Nitinol Tubing Transforming The Future Of Medical Technology