What Makes Nitinol Tubing Biocompatible for Medical Devices

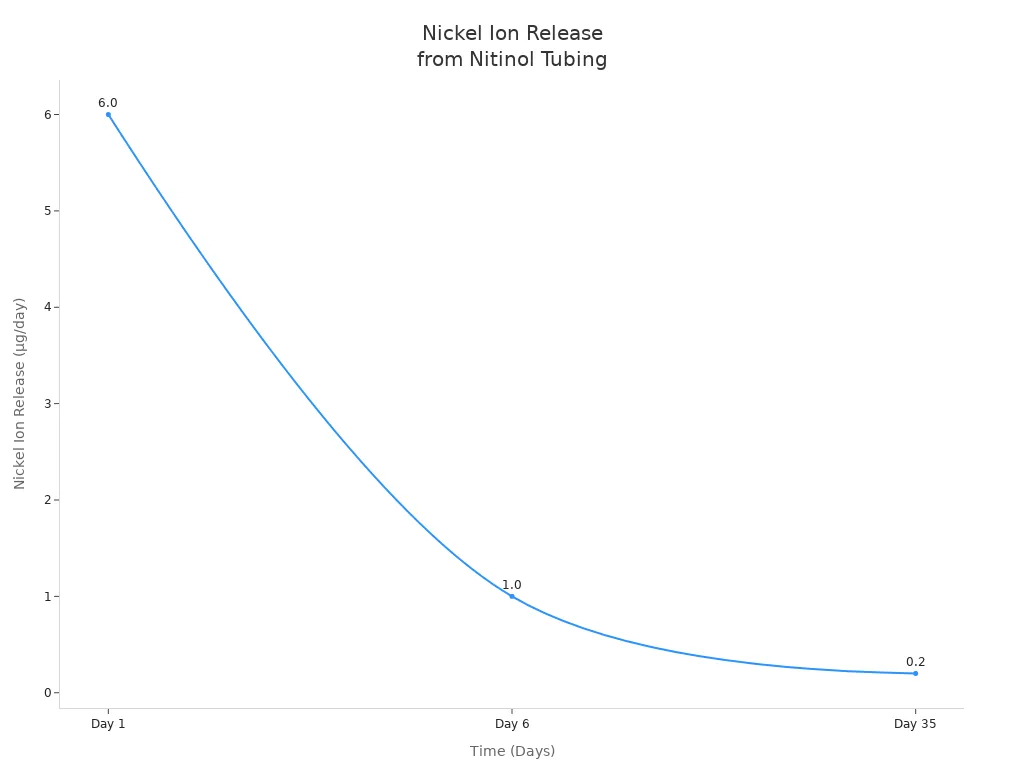

Nitinol tubing biocompatibility makes it very safe for use inside the body. Medical professionals trust nitinol tubing because it easily bends and returns to its original shape without losing strength. This tubing is strong, corrosion-resistant, and ideal for medical devices. Studies on nitinol tubing biocompatibility show it releases very low levels of nickel, far below unsafe limits. The table below highlights these findings. Additionally, electropolishing nitinol tubing enhances its biocompatibility by reducing nickel release and preventing bacterial growth, ensuring it performs reliably within the body.

Parameter/Aspect | Supporting Data/Statistics |

|---|---|

Nickel Ion Release (Day 1) | About 6.0 ± 1.2 µg/day, much less than FDA’s limit of 70 µg/day |

Nickel Ion Release (Day 6) | 1 µg/day, less than the chronic limit of 35 µg/day |

Nickel Ion Release (Day 35) | 0.2 µg/day, stays very low |

Histopathology Findings | Very little swelling, strong tissue forms by 180 days |

Mechanical Durability | Lasts through more than 600 million bends |

Surface Treatment Effects | Electropolishing cuts nickel and germs by over 70% |

Standards Compliance | Follows ISO 10993, ASTM F2063, and FDA rules |

Key Takeaways

Nitinol tubing is very safe for the body. It bends easily and goes back to its shape. It does not rust or get damaged easily.

There is a special titanium dioxide layer on nitinol tubing. This layer stops nickel from leaking out. It also helps the body accept the device. The body does not swell or have allergies because of it.

Surface treatments like electropolishing make nitinol tubing smoother. These treatments lower the amount of nickel that comes out. They also make nitinol tubing safer and last longer.

Nitinol tubing is used in implants, catheters, and surgical tools. It lasts a long time and works well in small spaces. It is also safe to use during MRI scans.

Nitinol tubing is better than stainless steel in many ways. It bends more and does not rust as much. It also causes fewer blood clots. This makes it a great choice for medical devices.

Nitinol Tubing Biocompatibility

Biocompatibility Defined

Biocompatibility means a material can be used in the body safely. It should not hurt people or cause problems. For medical devices, this is very important. ISO 10993-1 says biocompatibility is when a device works well with the body. The device should not cause swelling or allergies. Makers of medical devices must check for risks from start to finish. They look for things like dirt, leftover stuff, and how the material changes over time. The FDA and other groups need tests to make sure nitinol tubing biocompatibility is safe. These tests check for cell damage, allergies, and how much nickel comes out.

Medical devices must pass many tests before doctors use them. These tests help make sure nitinol tubing biocompatibility is safe for long-term use.

Key things for nitinol tubing biocompatibility are:

Transformation temperatures let the tube change shape safely.

Flexibility and strength help the tube bend and return to shape.

Surface treatments like electropolishing make the tube smooth and lower nickel release.

Following rules like ASTM F2063 and ISO 10993-1.

Watching nickel release and rust closely.

Clean making steps stop dirt from getting in.

Titanium Dioxide Layer

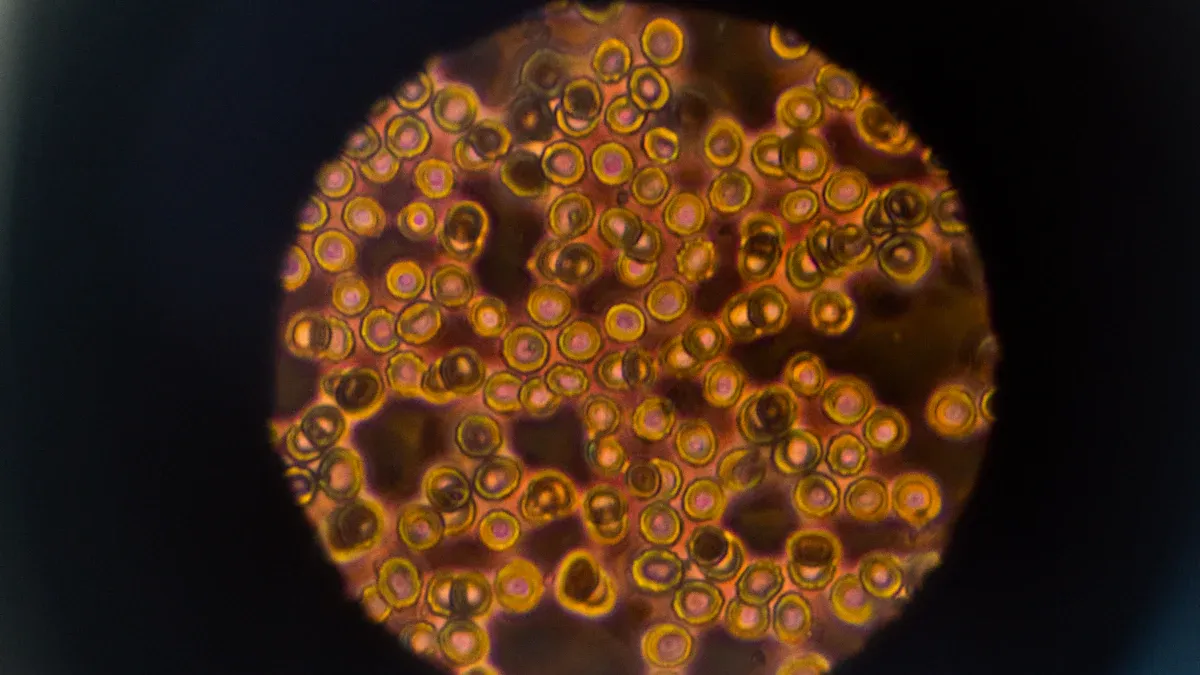

A titanium dioxide layer forms on every nitinol tube during making. This layer is very important for nitinol tubing biocompatibility. When the tube is heated and meets air, a thin, strong titanium dioxide (TiO2) layer grows. Makers use steps like passivation and electropolishing to make this layer better. Passivation, especially with boiling water, helps make a nickel-free titanium dioxide layer. Electropolishing makes the surface smooth and helps the layer form evenly.

The titanium dioxide layer acts like a shield. It stops nickel from leaking out and keeps the tube from rusting. This layer also helps the body accept the tube, lowering swelling or allergy risks. If the layer gets damaged, it can fix itself by forming again. This keeps nitinol tubing biocompatibility high even in tough places.

Surface Treatment Method | Effect on TiO2 Layer Formation | Corrosion Resistance Impact | Toxicity Reduction / Biocompatibility Impact |

|---|---|---|---|

Electropolishing | Forms a smooth, dense, nickel-free TiO2 layer | Increases breakdown potential to ~0.99 V/SCE, higher than mechanical polishing (0.53 V/SCE) | Reduces nickel ion release, lowering allergy and toxicity risks |

Anodisation in molybdate | Builds thick, smooth TiO2 layer | Enhances resistance to rust and pitting corrosion | Prevents nickel leakage, improving safety |

Electropolishing + PEO | Produces nickel-free TiO2 layer with no reported issues | Strong corrosion resistance | Improves biocompatibility and durability |

Magnetoelectropolishing | Creates very smooth, nickel-free TiO2 layer | Significantly reduces corrosion rate | Safer for patients with nickel allergies |

Titanium Nitride (TiN) Coating | Provides additional protective coating | Can reduce corrosion rate by half (requires crack inspection) | Adds durability but requires monitoring |

Corrosion Resistance

Corrosion resistance is a big reason nitinol tubing biocompatibility is strong. The titanium dioxide layer protects the tube from rust and stops nickel from leaking. This is important because nickel can cause allergies or other problems. Studies show electropolished nitinol tubes have higher breakdown potential and lower rust rates than tubes polished by machines. For example, electropolished surfaces can reach about 990 mV, while machine-polished ones reach about 530 mV. This means electropolished nitinol tubes are less likely to rust.

Surface Condition | Breakdown Potential (mV) | Corrosion Rate (mm/year) | Surface Roughness (nm) | Biological Response |

|---|---|---|---|---|

Electropolished Surface | ~990 (0.99 V/SCE) | 0.003 | 13.17 | Low nickel release, low inflammation |

Mechanical Polish | ~530 (0.53 V/SCE) | 0.008 | 28.77 | Higher nickel release, moderate inflammation |

Oxidized Tube | ~350 | N/A | N/A | Higher tissue response |

Electrochemical studies show if the titanium dioxide layer gets hurt, it can fix itself fast. This process is called repassivation. It helps keep the tube safe even in acidic parts of the body. Because of this, nitinol tubing biocompatibility and rust resistance make it a top choice for implants and other medical devices.

Groups like the FDA need many tests to check for rust resistance and nickel release. These include:

Cytotoxicity testing checks if the tube hurts cells.

Sensitization testing checks for allergies.

Chemical checks find out what is in the tube.

Nickel ion release testing over 30-60 days.

Surface treatment checks make sure coatings work well.

Studies by Hamann et al., Ulacia et al., and Gill et al. show nitinol tubing biocompatibility is high when the titanium dioxide layer is strong and the surface is well-treated.

Medical Applications of Nitinol Tubing

Nitinol tube is used in many medical tools. Doctors and engineers pick nitinol tube because it has special features. It can bend and return to its shape. This helps it fit into tricky body parts. These features make nitinol tube great for implants, catheters, and surgery tools.

Implants and Stents

Nitinol tube is found in implants like stents, heart valve frames, and bone devices. These implants need to bend and go back to their shape. Nitinol tube does this job well. In heart devices, nitinol tube helps stents open blocked arteries. It keeps them open so blood can flow. Brain stents use nitinol tube to fix vessel problems. Bone staples and fracture fixers also use nitinol tube. These implants give steady pressure and help bones heal fast. Studies show nitinol tube helps surgeries work better and lowers pain. The table below lists the main uses and benefits:

Medical Application Area | Common Devices/Uses | Key Benefits and Clinical Outcomes |

|---|---|---|

Cardiovascular Devices | Stents, heart valve frames, catheters | Superelasticity, shape memory, improved artery patency, reduced restenosis |

Neurovascular Devices | Neurovascular stents, microcatheters | High flexibility, 98% success rate, safe for brain vessels |

Orthopedic Implants | Bone staples, fracture fixers, spinal implants | Steady pressure, faster healing, fewer complications |

Catheters and Surgical Devices

Catheters made with nitinol tube can bend and twist easily. They move through blood vessels without breaking. Doctors use these catheters for heart, brain, and kidney work. Nitinol tube gives catheters superelasticity and shape memory. This lets catheters move in tight spaces and go back to their shape. Nitinol tube also fights rust and damage, so catheters last longer. Compared to steel, nitinol tube catheters are tougher and last more bends. These catheters help doctors do less risky surgeries. Nitinol tube can be shaped for special needs, which helps surgeries go better.

MRI Compatibility

Nitinol tube is not magnetic. It does not move or get hot in MRI scans. This makes nitinol tube safe for people with implants or catheters who need MRI. MRI pictures stay clear because nitinol tube makes fewer problems than steel. Studies show nitinol tube only gets a little warmer in MRI. The MISAGO 1 trial found nitinol tube stents work well and stay safe in MRI. This MRI safety is a big reason nitinol tubing is used in medicine.

Nitinol tube is known for being flexible, strong, and safe. These traits help many implants, catheters, and surgery tools. Nitinol tube is important in today’s medical care.

Safety

Nickel Allergy

Nickel allergy worries many people who need medical devices. Some think nickel in nitinol tubing might cause allergies. But studies show allergies from nitinol implants almost never happen. Out of over 4,000 patients with nitinol implants, only two had allergy symptoms. One person got a rash and red skin soon after getting the device. Another person felt itchy a year later. Both got better after doctors took out the device. So, nickel allergy from nitinol happens in about 0.05% of cases. Nitinol lets out less nickel than stainless steel, which lowers the risk.

Doctors have put nitinol stents in people who already have nickel allergies. These patients did not get swelling or allergy signs during checkups. The titanium dioxide layer on nitinol tubing acts like a shield. It stops nickel from leaking and keeps the body safe. This layer helps nitinol tubing work well in catheters and implants.

Most people with nitinol implants do not get allergies, even if they are sensitive to nickel.

Long-Term Use

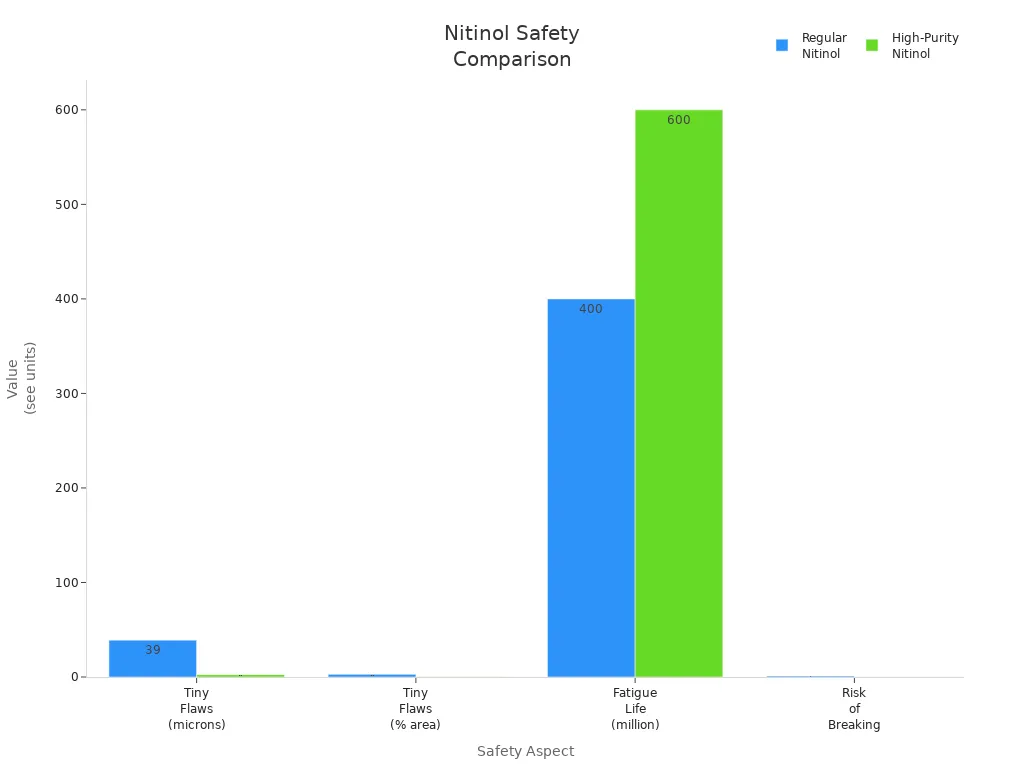

Doctors and engineers trust nitinol tubing for implants that stay in the body. Nitinol tubing lasts a long time inside people. It can bend millions of times and not break. This matters for stents, heart valves, and catheters that move with the body. High-purity nitinol has fewer tiny flaws and lasts even longer. The table below shows how regular and high-purity nitinol compare:

Aspect | Regular Nitinol | High-Purity Nitinol |

|---|---|---|

Tiny Flaws (NMI) | Up to 39 microns, 2.8% area | Less than 2.5 microns, 0.15% area |

Fatigue Life | 400 million cycles for stents | 600 million cycles for heart valves |

Risk of Breaking | Higher risk | Much lower risk |

Nitinol tubing does not crack or break easily because it is superelastic and has shape memory. Fatigue fracture is the most common way nitinol tubing fails, but this is rare with good material. Most nitinol catheters and implants last for years. Electropolishing makes the tubing smoother and stronger. Doctors use nitinol tubing in long-term implants because it stays safe and works well for a long time.

Nitinol tubing’s safety over time depends on how it handles stress inside the body. Research helps doctors learn more about nitinol in different places.

Electropolishing and Surface Treatments

Surface treatments help keep nitinol tubing safe. Electropolishing takes away nickel-rich layers and makes the surface smooth. This lowers how much nickel can come out of the tubing. It also helps stop rust and damage. Smooth surfaces help prevent blood clots and lower the chance of the body reacting to the device.

Other treatments, like plasma modification and anodization, add extra protection. These methods make the oxide layer better, so nickel does not leak out. They also help the body accept the device by helping cells grow and heal. Heat treatments under special conditions keep the surface strong and safe.

Electropolishing and surface treatments:

Take away nickel-rich layers, so less nickel comes out.

Make the surface smoother, which lowers blood clot risk.

Add protective oxide layers, blocking nickel and stopping swelling.

Help catheters and implants last longer in the body.

Nitinol tubing suppliers must follow strict rules to keep products safe. The FDA says all nitinol tubing makers must register and meet quality standards. Manufacturers need ISO 13485 certification, which means they use safe materials and clean steps. Clinical data shows nitinol tubing works well in catheters and implants, with high success and few problems. FDA registration means any issues are tracked and fixed fast.

FDA and ISO rules help make sure nitinol tubing is safe for catheters, long-term implants, and other medical devices.

Comparison

Nitinol vs. Stainless Steel

Nitinol and stainless steel are both used in medical devices. Nitinol tubing is very flexible and can return to its shape. It also does not rust easily. Stainless steel is strong and has chromium, which helps stop rust. But it can still get small pits if conditions are harsh. Nitinol gets special surface treatments like electropolishing. This makes a stable oxide layer. The layer lowers nickel ion release and makes biocompatibility better. Animal tests show nitinol causes fewer blood clots and less damage to blood vessels than stainless steel. Clinical studies say both materials have about the same stroke rates for stent patients. But nitinol devices cause fewer blood clots right after surgery. Nitinol has 36% less fibrin(ogen) sticking and 63% less platelets sticking. Both materials follow strict safety rules. But nitinol usually works better in tough medical situations.

Property | Nitinol Tubing | Stainless Steel Tubing |

|---|---|---|

Flexibility | High (shape memory, superelastic) | Moderate |

Corrosion Resistance | Excellent (stable oxide layer) | Good (chromium content) |

Biocompatibility | Superior after surface treatment | Reliable, but more vessel injury |

Thrombogenicity | Lower (fewer clots) | Higher (more clots) |

Durability | Lasts longer in body | May pit or rust over time |

Imaging Compatibility | Radiopaque, MRI safe | MRI safe, less radiopaque |

Nitinol’s smooth surface and shape memory help make it a top pick for implants and stents in medical devices.

Advantages and Limitations

Nitinol tubing has many good points compared to other materials. Devices made from nitinol can bend and go back to their shape. This helps doctors do less invasive surgeries. Nitinol does not get tired or rust easily, so it is safe for long use. Its biocompatibility means the body reacts less and heals better. Thin nitinol tubes stay strong and flexible. This helps them move through tricky body parts. These things help patients get better and have fewer problems.

Main advantages of nitinol tubing:

Great shape memory for placing devices

Strong against repeated use

Better at fighting rust than stainless steel and titanium

Very strong and superelastic for lasting longer

Shows up well in imaging

Lasts a long time, so fewer replacements

But nitinol tubing also has some problems. Making it costs more money. The nickel-titanium mix must be just right. Special machines are needed to make it. Cutting and shaping nitinol is hard because it gets tough and heats up fast. Quality checks must find even tiny problems to keep people safe. Surface treatments like electropolishing are needed to stop rust and help biocompatibility. Changes in temperature can change how nitinol works. Doing the same thing over and over can cause tiny cracks. The medical device industry needs skilled suppliers to work with nitinol.

Limitations of nitinol tubing:

Costs more to make

Hard to cut and shape

Needs careful quality checks

Can be hurt by salty environments

Works differently if temperature changes

Tiny cracks can form from heat

Picking nitinol tubing for medical devices takes skill and care, but its good points are often worth the effort.

Nitinol tubing is a safe choice for medical devices. It works well because of its special features and surface treatments. These make it good for implants and surgery tools.

It bends easily and goes back to its shape, so devices work well.

Treatments like electropolishing and anodization help stop rust and lower bad reactions.

Scientists keep studying new smart ideas, AI ways to make tubing, and better designs to help nitinol work even better.

Doctors say to use tubing from trusted suppliers and test it for each use. Patients and makers should talk to experts to get the best results.

FAQ

What is nitinol tubing made of?

Nitinol tubing has nickel and titanium mixed together. These metals make a strong alloy. This mix lets nitinol remember its shape and stretch without breaking.

Can people with metal allergies use nitinol devices?

Most people with metal allergies can use nitinol devices. The titanium dioxide layer keeps nickel from touching the body. Allergic reactions almost never happen.

How does nitinol tubing stay safe inside the body?

A thin titanium dioxide layer forms on nitinol tubing. This layer stops rust and keeps nickel from leaking out. Electropolishing makes the tubing even safer for the body.

Is nitinol tubing safe for MRI scans?

Nitinol tubing is safe for MRI scans. It does not move or get hot during the scan. Doctors can use MRI on patients with nitinol implants without any trouble.

Why do doctors choose nitinol tubing for implants?

Doctors pick nitinol tubing because it bends and goes back to shape. It does not rust and lasts a long time. These things help devices work well and keep people safe.

See Also

The Process Behind Producing Nitinol Tubing For Medicine

Nitinol Tubing Transforming The Future Of Medical Devices

A Deep Dive Into Nitinol Tubing Uses In Healthcare