What is Nitinol Tubing with a 37℃ Af Temperature and How is it Used in Medicine

Nitinol tubing with 37℃ Af temperature describes a special alloy tube that changes its shape or stiffness right at human body temperature. This nitinol tubing activates its key properties at 37℃, which matches the normal temperature inside the body. Medical devices made from nitinol tubing with 37℃ Af temperature work best because they respond exactly when placed in the body. Studies show that 37℃ serves as the standard for cell health and blood clotting, with significant changes seen at higher temperatures. This makes nitinol tubing reliable and safe for use in medical devices that must perform accurately inside patients.

Key Takeaways

Nitinol tubing with a 37℃ Af temperature changes shape or stiffness exactly at body temperature, making it ideal for medical devices.

This tubing combines strength, flexibility, and smart temperature response to improve safety and performance inside the body.

Doctors use nitinol tubing in stents, catheters, and implants because it bends easily and returns to its original shape at 37℃.

The precise control of the Af temperature ensures devices activate only inside the body, preventing damage during storage or handling.

Nitinol tubing’s biocompatibility and durability help patients recover faster with fewer complications in many medical treatments.

Nitinol Tubing with 37℃ Af Temperature

What is Nitinol Tubing

Nitinol tubing stands out as a unique material in the world of medical devices. This tubing comes from a special metal called nitinol. Nitinol belongs to a group of metals known as shape memory alloys. These alloys can return to their original shape after bending or stretching. Nitinol tubing shows this property because of its special atomic structure.

Doctors and engineers use nitinol tubing in many applications. They choose it for its flexibility and strength. Strong nitinol tubing can bend without breaking. This makes it perfect for devices that move inside the body. Nitinol tubing also resists corrosion, so it lasts longer in medical environments.

Nitinol tubing with 37℃ af temperature offers even more benefits. This type of tubing changes its properties right at body temperature. Medical teams rely on nitinol tubing for stents, catheters, and other devices. These applications demand materials that can adapt quickly and safely. Nitinol tubing meets these needs because it combines strength, flexibility, and smart temperature response.

Note: Nitinol tubing with 37℃ af temperature helps doctors create devices that work only when inside the body. This feature protects patients and improves results.

Af Temperature Explained

The term "Af temperature" refers to the temperature at which nitinol finishes changing from one phase to another. Scientists call this the nitinol transition temperature. For nitinol tubing with 37℃ af temperature, this change happens at 37 degrees Celsius, which matches the average human body temperature.

Nitinol transition temperature plays a key role in how nitinol tubing works. When nitinol tubing enters the body, the heat triggers a change in its structure. This change gives the tubing its special properties. For example, strong nitinol tubing can become more flexible or stiffer at this exact temperature. This feature allows doctors to insert devices easily and then have them activate once inside the patient.

Nitinol shape memory alloys depend on precise control of the nitinol transition temperature. Engineers set the Af temperature during manufacturing. They do this by adjusting the mix of nickel and titanium in the alloy. Nitinol tubing with 37℃ af temperature ensures that devices respond only at body temperature, not before. This control prevents unwanted changes during storage or handling.

The nitinol transition temperature also affects many applications. Medical teams use nitinol tubing in stents, guidewires, and orthopedic implants. Each application needs the tubing to perform in a certain way. By setting the Af temperature at 37℃, nitinol tubing meets the strict demands of these medical applications.

Tip: Always check the nitinol transition temperature when choosing nitinol tubing for medical applications. The right temperature ensures safety and performance.

Nitinol tubing with 37℃ af temperature has become a standard in modern medicine. Its ability to change at body temperature supports many life-saving applications. Strong nitinol tubing, with its precise nitinol transition temperature, continues to shape the future of medical technology.

Nitinol Science

Shape Memory Effect

Nitinol tubing shows a unique property called the shape memory effect. This means nitinol tubing can "remember" its original shape. When doctors bend or twist nitinol tubing, it can return to its first form after heating. Scientists call this the shape-memory effect. Nitinol shape memory alloys change their structure at certain temperatures. The most important temperature is the austenite finish temperature, or Af. For nitinol tubing with a 37℃ Af, this change happens at body temperature.

Experimental studies show that nitinol tubing can recover up to 8% strain. This means nitinol tubing can stretch or bend and still return to its original shape. At low temperatures, nitinol tubing forms a phase called martensite. When heated, it changes to a phase called austenite. This switch lets nitinol tubing recover its shape. Researchers use special measurements to track these changes. They measure how much nitinol tubing stretches and how well it returns to its shape. These tests prove that nitinol shape memory alloys work well in many applications. Doctors use the shape memory effect in stents, guidewires, and other medical devices. The shape-memory effect helps nitinol tubing perform safely inside the body.

Note: The shape memory effect in nitinol tubing allows devices to be inserted in a compact form and then expand to their working shape at body temperature.

Superelasticity

Superelastic nitinol gives nitinol tubing another important property. When nitinol tubing is at body temperature, it can bend or stretch much more than regular metals. After bending, superelastic nitinol tubing snaps back to its original shape. This makes nitinol tubing very useful in medical applications that need flexibility and strength.

The performance of superelastic nitinol tubing depends on its microstructure. Scientists test nitinol tubing by bending or stretching it millions of times. They measure how much strain nitinol tubing can handle before it breaks. The table below shows how different types of nitinol tubing perform in these tests:

Parameter / Alloy Type | Standard-grade Nitinol | Process-Optimized Nitinol | High-Purity Nitinol |

|---|---|---|---|

Fatigue test type | Tension, bending | Same | Same |

Test conditions | 37°C, 6% prestrain | Same | Same |

10^7-cycle fatigue strain limit (wire) | ~0.16% | N/A | 0.32% |

10^7-cycle fatigue strain limit (bend) | ~0.75% | 1.5% | 1.75% |

Inclusion size and density | Larger, more | Smaller | Smallest, fewest |

Fatigue resistance | Baseline | ~2× higher | Highest |

Superelastic nitinol tubing with high purity lasts longer and bends more times before breaking. This makes it ideal for applications like stents, catheters, and orthopedic devices. Nitinol shape memory alloys with superelasticity help doctors treat patients safely and effectively. The superelastic property also means nitinol tubing can handle the stress of moving inside the body without losing its shape. Superelastic nitinol supports many medical applications where flexibility and durability are critical.

Why 37℃ Af Matters

Human Body Temperature

Human body temperature stays close to 37℃ in healthy people. This temperature is important for many body functions. Nitinol works best when its nitinol transition temperature matches this value. When doctors use nitinol in vascular medical devices, they need the material to change shape or stiffness only at body temperature. This precise control helps nitinol tubing perform as expected inside the body.

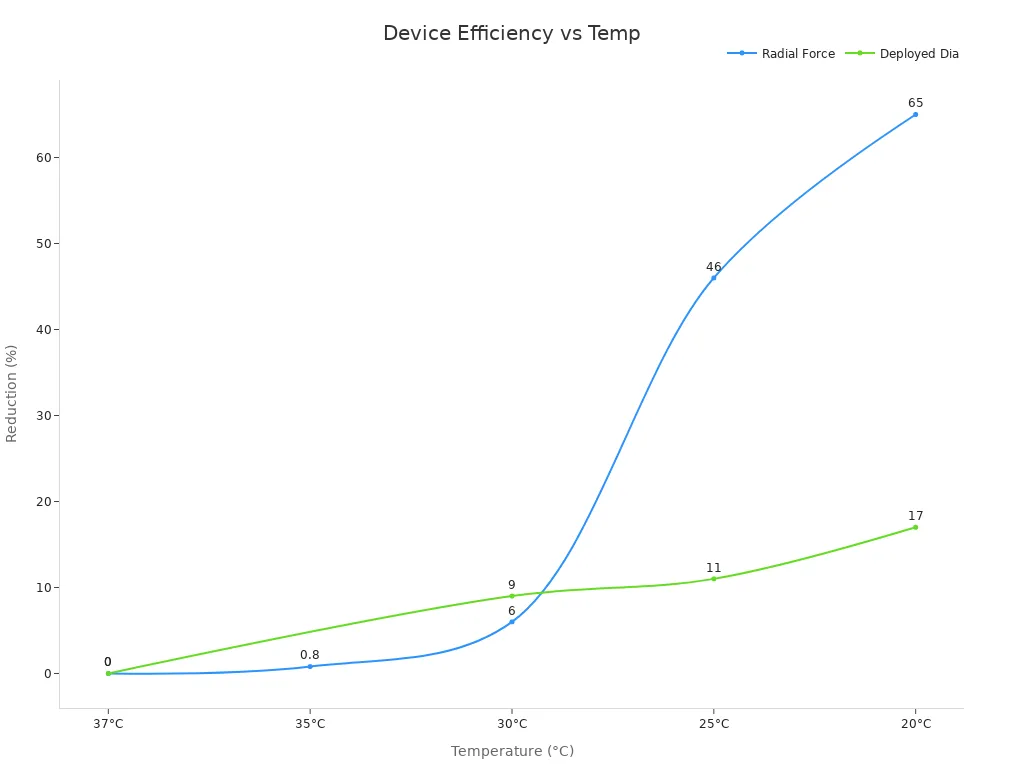

The nitinol transition temperature affects how well nitinol expands or contracts. If the temperature drops below 37℃, nitinol loses some of its force and size. The table below shows how nitinol vascular devices respond to different temperatures:

Temperature (°C) | Radial Expansive Force Reduction (%) | Deployed Diameter Reduction (%) |

|---|---|---|

37 (normal body) | 0 (baseline) | 0 (baseline) |

35 | 0.8% ± 0.6% (not significant) | No significant change |

30 | 6% ± 0.2% (significant) | 9% (not significant) |

25 | 46% ± 14.9% (significant) | 11% (significant) |

20 | 65% (significant) | 17% (significant) |

This data shows that nitinol vascular devices keep their full strength and size at 37℃. When the temperature falls, the devices lose force and do not work as well. This temperature sensitivity means that nitinol transition temperature must match body temperature for safe and reliable use.

Device Performance

Nitinol medical devices depend on the nitinol transition temperature for proper function. When the Af temperature is set at 37℃, nitinol tubing activates its shape memory and superelastic properties only inside the body. This feature is critical for vascular stents, catheters, and other medical devices. Devices stay flexible during placement and become strong when they reach body temperature.

The chart below shows how nitinol vascular device performance drops as temperature decreases:

Doctors rely on nitinol transition temperature to ensure that vascular devices open fully and stay in place. Controlling Af temperature during manufacturing allows engineers to match device activation to human body temperature. This careful design improves patient safety and device success. Nitinol’s temperature sensitivity makes it ideal for medical devices that must respond only at the right moment.

Tip: Matching the nitinol transition temperature to 37℃ helps vascular medical devices work safely and effectively inside the body.

Medical Applications of Nitinol Tubing

Stents and Vascular Devices

Doctors use nitinol tubing in many vascular grafts and stents. These nitinol stents help keep blood vessels open after procedures. The 37℃ Af temperature allows nitinol stents to change shape and expand only when they reach body temperature. This feature makes nitinol stents self-deploying stents, which means they open up on their own inside the body. Nitinol tubing gives these vascular grafts the ability to fit tightly against vessel walls, reducing the risk of movement or blockage.

Nitinol stents show high reliability and durability. In one clinical study, 30 sheep received iliac vein stents made from nitinol tubing. None of the nitinol stents showed damage or fractures after implantation. Doctors also found that nitinol stents lower inflammation and rejection risks. They measured inflammation by checking white blood cell counts and found significant improvements. The flexibility and superelasticity of nitinol tubing allow doctors to place vascular grafts with great accuracy. This reduces trauma and helps patients recover faster.

Nitinol stents resist corrosion and mechanical stress. These properties help nitinol stents last longer in complex vascular systems. Patients with nitinol stents often report less pain after surgery and heal more quickly. Nitinol’s biocompatibility helps these vascular grafts blend with human tissue, leading to better long-term results. Clinical data show that nitinol stents improve success rates in cardiovascular procedures and support better patient outcomes.

Nitinol tubing with a 37℃ Af temperature ensures that vascular grafts and stents activate only inside the body, making procedures safer and more effective.

Catheters and Guidewires

Catheters and guidewires made from nitinol tubing play a key role in many medical applications. Doctors use these devices to reach narrow or twisted blood vessels. The superelasticity of nitinol tubing lets catheters and guidewires bend and move through the vascular system without breaking. This flexibility helps doctors guide the devices to the right spot with less risk of injury.

Nitinol tubing in catheters and guidewires activates its special properties at 37℃. This means the devices stay flexible and adjustable during insertion, then become strong and stable inside the body. In clinical practice, nitinol guidewires achieved a 98% vessel crossing success rate. Catheters using nitinol tubing were delivered successfully in 92% of cases. These high success rates show the reliability of nitinol tubing in vascular grafts and other applications.

Patients with nitinol-based implants experience fewer complications. Studies show a 30% lower rejection rate compared to traditional metal implants. Doctors also report no major complications after using nitinol guidewires. Improved manufacturing methods have increased the fatigue life of nitinol tubing, making it even more durable for cardiovascular applications. Patients often feel less pain and recover faster after procedures with nitinol-based catheters and guidewires.

Tip: Nitinol tubing in catheters and guidewires helps doctors perform complex vascular procedures with greater safety and precision.

Orthopedic and Minimally Invasive Devices

Nitinol tubing supports many orthopedic implants and minimally invasive surgical tools. Doctors use nitinol tubing in bone anchors, spinal implants, and flexible surgical instruments. The 37℃ Af temperature allows these devices to change shape or stiffness only when inside the body. This property helps doctors insert implants in a compact form and then have them expand or lock in place at body temperature.

Orthopedic implants made from nitinol tubing adapt to the patient’s anatomy. This reduces the risk of implant movement and improves healing. Nitinol’s superelasticity allows implants and grafts to handle repeated stress without breaking. Applications of superelastic nitinol tubes include bone staples and flexible fixation devices. These applications of nitinol help patients recover faster and with less pain.

Minimally invasive surgical tools made from nitinol tubing can bend and return to their original shape. This flexibility allows doctors to reach hard-to-access areas during surgery. Nitinol tubing also resists corrosion, making it safe for long-term use in implants and vascular grafts. Doctors choose nitinol tubing for many medical applications because it combines strength, flexibility, and precise temperature response.

Note: Nitinol tubing with a 37℃ Af temperature improves the performance of orthopedic implants, vascular grafts, and minimally invasive devices, leading to better patient outcomes.

Safety and Patient Outcomes

Biocompatibility

Nitinol tubing offers excellent biocompatibility and corrosion resistance, making it a trusted choice for vascular grafts and other medical devices. Clinical studies show that nitinol-based implants remain safe and compatible with human tissues for over 10 years, with very few complications. In animal studies, vascular grafts made from nitinol tubing supported new tissue growth within just 30 days. Researchers use several tests to check the safety of nitinol tubing, including:

Cytotoxicity

Sensitization

Irritation

Systemic toxicity

Genotoxicity

Surface treatments like electropolishing create a protective TiO2 layer on nitinol tubing, which helps prevent nickel from leaching out. This layer also improves corrosion resistance. Some grafts use coatings such as TiN to further lower corrosion rates. Modified electropolishing (MEP) helps cells stick better to the surface, which supports faster healing and better integration with the body. These features make nitinol tubing a reliable and safe material for long-term vascular grafts and nitinol stents.

Reliability in Medical Devices

Doctors and engineers trust nitinol tubing for its proven reliability in vascular grafts and nitinol stents. The material can recover from bending and stretching, which is important for devices that move inside the body. The table below shows key reliability metrics for nitinol tubing:

Reliability Metric | Value | Description |

|---|---|---|

Strain Recovery | 5.62% | Shows how well nitinol tubing returns to its shape after bending |

Recovery Ratio | 98% | Demonstrates strong superelasticity and durability |

Nitinol tubing passes strict fatigue and fracture tests. Heart valves made from nitinol tubing can last through 600 million cycles, while vascular grafts and nitinol stents endure up to 10 million cycles. Scientists use advanced imaging and testing to study how nitinol tubing performs under stress. These methods help ensure the safety and long-term reliability of vascular grafts and nitinol stents in real-world use.

Patient Benefits

Patients experience many benefits when doctors use nitinol tubing in vascular grafts and nitinol stents. Clinical trials show that bioresorbable stents made with nitinol tubing lower the risk of restenosis and long-term problems. The FDA has approved several nitinol stents, proving their safety and effectiveness. Compared to older metal stents, nitinol stents provide better treatment for blocked arteries, last longer, and cause fewer complications.

Nitinol tubing allows for personalized grafts that fit each patient’s anatomy. This reduces vessel trauma and supports faster recovery. Technical tests confirm that nitinol tubing stays stable and safe inside the body. Nitinol stents gently expand and match the shape of blood vessels, which helps keep them open and lowers the risk of injury. As more doctors use nitinol tubing in vascular grafts, patients see improved outcomes and enjoy a faster recovery after surgery.

Patients benefit from nitinol tubing in vascular grafts and nitinol stents through safer procedures, fewer complications, and a quicker return to daily life. 🏥

Nitinol tubing with a 37℃ Af temperature gives medical devices a unique advantage. Devices made from this material activate only at body temperature. This feature improves safety and performance for patients. Doctors trust nitinol tubing for its strength and flexibility.

Material science shapes the future of medicine. New discoveries like nitinol tubing help doctors save lives and improve care every day.

Readers can see how smart materials make a real difference in health care.

FAQ

What does "Af temperature" mean in nitinol tubing?

Af temperature stands for "Austenite finish temperature." This is the point where nitinol tubing completes its phase change and shows its special properties. For medical devices, 37℃ Af means the tubing activates right at body temperature.

Why do doctors choose nitinol tubing for stents?

Doctors choose nitinol tubing because it bends easily and returns to its original shape. At 37℃, the tubing expands and fits tightly in blood vessels. This helps keep arteries open and improves patient safety.

Is nitinol tubing safe for long-term use in the body?

Nitinol tubing shows high biocompatibility. Studies show that it resists corrosion and does not harm tissues. Surface treatments like electropolishing add extra protection. Most patients do not experience allergic reactions or complications.

Can nitinol tubing be used in children?

Yes, doctors use nitinol tubing in both adults and children. The tubing adapts to different body sizes and shapes. Pediatric stents and implants made from nitinol tubing help treat heart and blood vessel problems safely.

See Also

The Process Behind Manufacturing Nitinol Tubing For Medicine

Nitinol Tubing’s Impact On Progressing Medical Technology Today

The Importance Of Nitinol Tubing In Modern Medical Uses

A Look Into Nitinol Tubing Uses Within Healthcare Devices

Ways Nitinol Tubing Is Transforming The Medical Device Industry