Essential Tips for Improving Kink Resistance in Nitinol Tubing

You use nitinol tubing to move medical devices safely. Better kink resistance in nitinol tubing helps you go through tricky body parts. This lowers the chance of the tube breaking or getting hurt. Nitinol tubing is bendy and strong. This means it can hurt blood vessels less and cause fewer problems. Tests show that nitinol tubing can help patients get better results. It also makes devices work better. Nitinol has special features. Nitinol tube kink resistance testing allows you to make the tubing even stronger. This helps with new and advanced medical uses.

Key Takeaways

Pick nitinol tubing that is high quality. It should have superelasticity and shape memory. This helps it bend easily. It also goes back to its shape without kinking.

Make sure the wall thickness and diameter are balanced. This keeps the tubing strong and flexible. It helps stop weak spots. Weak spots can cause kinks or make it stiff.

Use reinforcement like braiding and coiling. These methods make the tubing stronger. They also help it bend better. This helps the tubing resist kinks when used.

Test the tubing for kink resistance in real-life situations. This helps find weak spots. It also checks if the tubing keeps its shape after bending.

Work with suppliers you trust. They should control material purity, size, and surface finish. They should also give detailed test results. This makes sure the tubing is safe and reliable.

Application Needs

Clinical Demands

You need nitinol tubing that works well in medical devices. Doctors want tubing that keeps its shape during hard procedures. These are some important needs:

Kink resistance helps fluids move and devices work, even if you bend or twist the tubing.

Durability and fatigue resistance let you use the tubing many times without folding or breaking.

Nitinol tubing has superelasticity and shape memory. You can bend it a lot, and it goes back to its shape.

The nickel-to-titanium ratio and transformation temperature affect how well the tubing resists kinks.

You need to balance tubing size and wall thickness. This keeps the tubing strong and flexible.

Heat treatment, laser cutting, and surface polishing make nitinol tubing stronger and more kink-resistant.

Temperature, moisture, and chemicals can change how the tubing works.

Adding steel or nylon inside the tubing can make it tougher but not stiff.

Quality control tests, like bend and fatigue testing, help make sure the tubing is safe.

Tip: Always make sure your nitinol tubing passes all clinical tests before using it in real procedures.

Use Environment

You use nitinol tubing in many parts of the body. Each place has its own problems. For example, neurovascular procedures need tubing that bends a lot without kinking. Brain vessels are small and twisty, so you need tubing that can handle sharp turns. Nitinol tubing can bend up to 180° and still keep its shape. This helps you move through tight spaces without hurting the tubing or the vessel.

Nitinol tubing also bends millions of times during use. High-purity nitinol can handle this stress and does not crack or break. Surface treatments, like electropolishing, make the tubing smoother and stop corrosion. This is important for long-term use in the body. You also need to think about temperature, moisture, and chemicals in the body. These things can change how nitinol tubing works. By picking the right nitinol and making sure it is pure and finished well, you help your devices last longer and work better.

Material Selection

Nitinol Tubing Properties

When you pick nitinol tubing, you want it to resist kinks. Nitinol tubing is special because it bends but keeps its shape. Even if you twist or bend it, the inside stays open. This lets fluids and tools move through without getting stuck.

Nitinol tubing is very flexible. You can bend it many ways, and it will not stay bent or lose its round shape.

The shape memory effect helps nitinol tubing go back to how it was before. This keeps your device working right.

Superelastic nitinol tubing can stretch a lot. In some tests, it stretches up to 400% in a small artery model and still goes back to normal.

Nitinol tubing keeps its shape better than other materials. For example, self-expanding stents made from nitinol tubing hold their size after bending, while other stents do not.

Nitinol tubing is strong and does not break easily. It can handle millions of bends and twists.

Nitinol tubing does not rust and is safe to use in the body.

Tip: Always make sure your nitinol tubing is flexible, strong, and safe for your device.

Superelasticity & Shape Memory

Nitinol has superelasticity and shape memory, which give it special benefits. At body temperature, nitinol tubing acts like rubber. You can bend it a lot, and it snaps back to its shape. This happens because nitinol changes inside when you put stress on it. The tubing does not stay bent or get damaged like other metals. If you heat nitinol tubing, it remembers and returns to its original shape. This makes nitinol tubing much better at resisting kinks than stainless steel or titanium. Nitinol tubing can stretch more before breaking because it has a lower elastic modulus. You can use nitinol tubing where you need both flexibility and strength. Medical devices like stents and guidewires use nitinol tubing because it keeps working after many bends. You can trust nitinol tubing to keep its shape and stay strong, even in hard situations.

Design & Dimensions

Wall Thickness

You must think about wall thickness when picking nitinol tubing. Wall thickness is important for kink resistance. If the wall is too thin, the tubing can bend too much. This can make weak spots. Weak spots can cause kinks or breaks. If the wall is too thick, the tubing gets stiff. Stiff tubing does not bend well.

Even wall thickness keeps nitinol tubing strong and bendy.

Thicker walls can take more pressure but do not bend as much.

Thinner walls bend more but may kink if not made right.

Factories watch wall thickness closely, often within ±15 microns.

Tip: Always make sure your nitinol tubing has even wall thickness. This helps your device last longer and work better.

Diameter & Tolerances

The diameter of nitinol tubing changes how it moves in the body. It also affects how well it resists kinks. You need tubing with the right diameter for your device. Small changes in diameter can make weak spots. These weak spots lower kink resistance and make tubing less safe.

Factories use many steps to keep diameters within ±0.005 mm for small tubing.

Machines check each piece to make sure it meets size rules, often within ±20 microns.

Keeping the diameter right helps nitinol tubing stay strong and bendy, even after many bends.

Careful control of making steps keeps both diameter and wall thickness even.

Heat treatment can also change the tubing. It can change transformation temperatures and help stop kinks.

Note: When you pick nitinol tubing, always ask about diameter and tolerance controls. This makes sure your tubing works well in real medical use.

Reinforcement Techniques

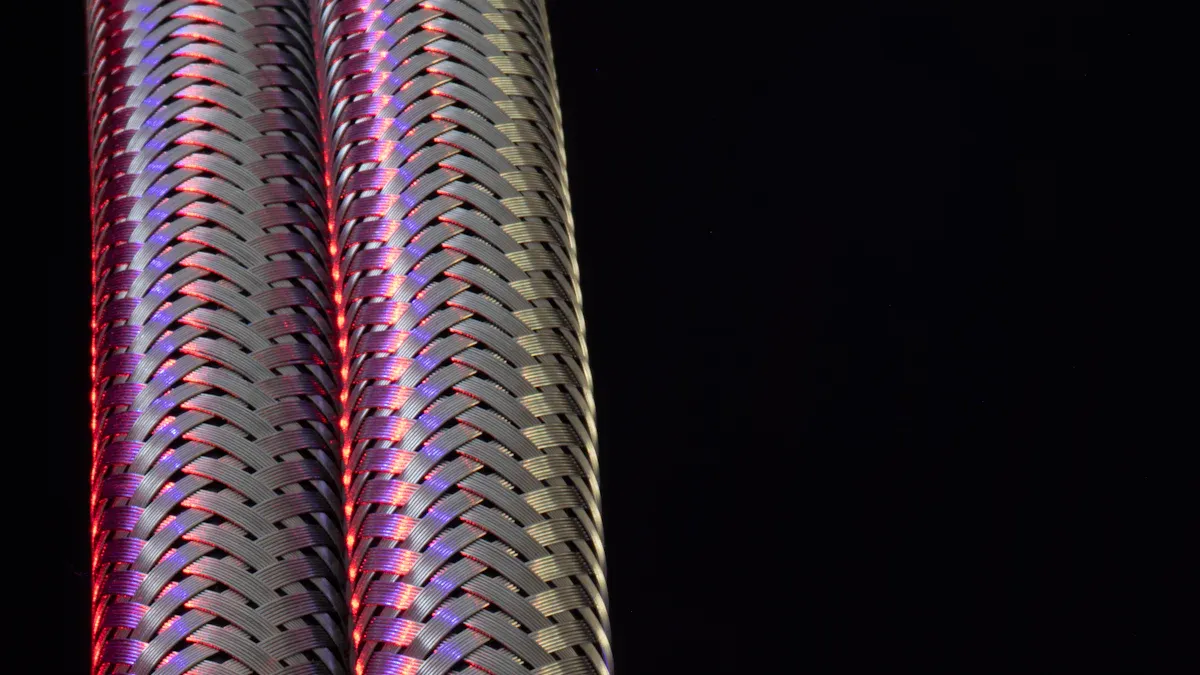

Braiding & Coiling

Braiding and coiling can make nitinol tubing stronger and more bendy. These methods help the tubing move through tight places without kinking. Braiding uses thin wires, like nitinol or nylon, woven together. You can pick different patterns and materials for the right mix of strength and bendiness. Common patterns are diamond, biaxial, and triaxial. Each pattern changes how the tubing bends and fights kinks.

Aspect | Details | Impact on Flexibility and Kink Resistance |

|---|---|---|

Braiding Patterns | - Biaxial: Two yarn sets at opposite angles | Diamond pattern gives great strength and bendiness, so it resists kinks well |

Pick Count | Number of braid crossings in a certain length | More crossings make tubing stronger and bendier, but harder to make |

Braid Angle | Angle where yarns cross each other | Bigger angles make tubing bendier and resist kinks; smaller angles make it stronger |

Wire Thickness | Thicker wires make tubing stronger and stiffer; thinner wires make it bendier | You need to pick the right thickness for both bendiness and strength |

Materials | Stainless Steel: strong, does not rust | Nitinol wires make tubing very bendy and good at resisting kinks |

Post-Braiding Process | Heat treatment (annealing) takes away stress inside | Makes tubing bendier and stops kinks |

Coiling is another way to make nitinol tubing tougher. Coiling wraps a thin wire, often nitinol, around the tubing. This gives extra support and lets the tubing bend without kinking. You can change the coil’s tightness along the tube. Some parts can be softer, others stronger. This helps you control how the tubing bends and resists kinks.

Tip: Changing braid pitch and pick count helps you get the right mix of bendiness and kink resistance. More crossings and bigger angles usually make tubing bendier and less likely to kink, but can be harder to make.

Braided and coiled nitinol tubing can handle lots of bending and twisting. You get better control and can push devices more easily. Nitinol wires in the braid or coil give superelasticity. The tubing bends and snaps back to shape many times without breaking.

Embedded Materials

You can make nitinol tubing work better by putting other materials inside or around it. Adding things like nylon or stainless steel wires makes the tubing stronger and less likely to kink. These materials work with nitinol’s superelasticity to give even more bendiness and kink resistance.

If you put a coil inside a plastic tube, it adds support. This keeps the tubing from folding during sharp bends. The coil, made from nitinol or stainless steel, wraps tightly around the tube. This keeps the tubing open and bendy, even in hard places. Lab tests show that coil reinforcement lets nitinol tubing bend through tighter turns without kinking. The coil’s angle and material change how much kink resistance you get.

You can also use both braiding and coiling together. This makes tubing that fights both kinks and crushing. The tubing stays bendy and strong, even after many uses. Heating the tubing after adding materials helps set its shape and takes away stress. This makes the tubing last longer.

Note: Picking the right materials and ways to reinforce helps you make nitinol tubing that fits each medical device. Always test your tubing to make sure it bends and resists kinks the way you need.

Heat Treatment

Process Methods

You can make nitinol tubing resist kinks better with heat treatment. Heat treatment changes how nitinol acts. It makes nitinol tubing stronger and more bendy. There are many ways to heat treat nitinol tubing:

Annealing and shape setting help nitinol tubing keep its shape. These steps also help stop kinks from forming.

You can use strand annealing, box furnace, molten salt bath, fluidized bed, or Joule heating. Each way lets you control heat and time in different ways.

You must watch the temperature closely. It should be between 475°C and 550°C. This helps nitinol tubing become superelastic and strong.

Using a vacuum or special gas during heat treatment stops nitinol tubing from rusting. This keeps the surface safe and the alloy stable.

Cooling fast, like with water, locks in the right structure. This makes nitinol tubing stronger and more superelastic.

Fixtures and mandrels hold nitinol tubing in place during heat treatment. This helps stop surface problems and makes the tubing resist kinks.

Joule heating gives quick and even heat. It works well for small batches or special shapes. It also helps keep the tubing the right size and stops rust.

Tip: Always pick the best heat treatment for your nitinol tubing. Good heat and cooling control helps your tubing last longer and resist kinks.

Phase Control

You can make nitinol tubing work even better by controlling its phases. Nitinol has two main phases: austenite and martensite. How these phases change affects how nitinol tubing bends and resists kinks.

Heat treatment, like annealing and aging, changes the inside of nitinol tubing. This makes the tubing more superelastic.

By controlling phase changes, you can change how nitinol tubing handles stress and bending.

Grain size and texture are important. Smaller grains make nitinol tubing stronger and help stop kinks.

You can use cold working, heat treatment, and drawing to change grain size and texture. These steps help you fine-tune how the tubing works.

When you control the phases well, nitinol tubing gets better at handling stress and lasts longer. It also works better in tough places.

Note: Careful phase control during heat treatment helps you make nitinol tubing that is flexible and resists kinks.

Surface & Manufacturing

Surface Finish

You want nitinol tubing that is smooth and works well. A smooth surface helps the tubing bend without kinking. If the tubing is polished, it is less likely to crack. Smooth tubing moves through blood vessels more easily. You can choose different finishes, like electropolished or mechanically polished. These finishes take away small bumps and make the tubing stronger. A smooth finish also helps stop corrosion. This is important for tubing that stays in the body a long time. Factories use special tools to check how rough the surface is. They make sure every piece of tubing follows strict rules. This gives you tubing that bends well and lasts longer.

Tip: Always ask your supplier about surface finish choices. A better finish means tubing is safer and resists kinks better.

Supplier Quality

You need a good supplier to get the best tubing. Good suppliers help your tubing resist kinks. Here are some ways they help you:

They use high-purity, medical-grade nitinol that meets ASTM rules.

They follow ISO 13485 and test each batch for strength and size.

They control the outer diameter, inner diameter, and wall thickness.

They use special methods like pilger milling and precision drawing.

They check the chemical makeup and surface of each batch.

They test the tubing to make sure it bends and moves right.

They keep records for every batch, so you can find any problems.

If you work with a certified supplier, your tubing stays the same every time. You avoid weak spots and flaws that cause kinks. You can also pick wall thickness, size, and finish to fit your needs. Good supplier quality keeps nitinol tubing superelastic and with shape memory. These features are important for kink resistance.

Nitinol Tube Kink Resistance Testing

Test Methods

You have to check if nitinol tubing can bend without breaking. Kink resistance testing shows if the tubing will work in real medical devices. There are different ways to test how much bending the tubing can take before it kinks or loses shape.

One way is to bend the tubing around mandrels of different sizes. You keep making the bend tighter until you see a kink or the tube closes halfway. This tells you the smallest bend the tubing can handle. You can use a microscope to look for changes in the tubing. You should also see if the tubing goes back to normal after bending.

Another way is to use a hard, curved vessel model. You put the tubing inside a stiff, curved path like a blood vessel. Then you bend the tubing and see if it keeps its shape or kinks. This test helps you know how the tubing will act in the body.

Here is a table that compares two main test methods for nitinol tube kink resistance testing:

Aspect | Test Method A (Silicone Tube Bending) | Test Method B (Rigid Curved Vessel Model) |

|---|---|---|

Description | Stent put in silicone tube bent around mandrels of different sizes | Stent placed in a hard curved vessel model |

Standard Reference | ISO 25539-2 (D.5.3.6.5), FDA Guidance Document No. 1545 | ISO 25539-2 |

Test Environment | 37°C water bath, no guide wire (worst case) | Not clearly described |

Measurement | Smallest radius without kinking checked with a microscope | Smallest bend without kinking or more than 50% lumen loss |

Balloon Expandable Stent | Kinks at 3.5 mm radius; diameter change about 42% | Similar results suggested |

Self-Expanding Nitinol Stent | Kinks at 21 mm radius; diameter change about 2% | Similar results suggested |

No kinking down to 2 mm radius | Tested for curves like in the body | |

Limitations | Stepped mandrel makes it hard to find exact 50% lumen loss; accuracy ±0.07 mm | Not described |

Recovery Assessment | Stent recovery after bending checked without outside force | Needed by ISO 25539-2 |

Tip: Always use both looking and measuring when you test nitinol tube kink resistance. This helps you find weak spots before using the tubing in real devices.

You should also check if the tubing goes back to its shape after bending. Good nitinol tubing will return to normal. If it does not, you may need to change your design or use a different batch.

Flow Conditions

You need to test nitinol tubing in conditions like the real body. Kink resistance testing works best with water at body temperature, about 37°C. This helps you see how the tubing will act in a patient.

You can set up a test where fluid flows through the tubing while you bend it. Watch for any drop in flow or signs of a kink. If the tubing keeps its shape and lets fluid pass, it has good resistance. You can use colored water or dye to see if the flow stops or slows down.

Some tests use a guide wire inside the tubing. This shows how the tubing will work when delivering a device. You can also test without a guide wire to see the worst case. You should try both ways to get a full picture.

Note: Always test your nitinol tubing with and without fluid flow. This helps you make sure your tubing will not fail during real medical use.

You should repeat kink resistance testing after heat treatment or adding reinforcements. This helps you see if your changes made the tubing better or worse. You can also compare your results to standard values from ISO or FDA documents.

Kink resistance testing gives you the data you need to make safe, strong, and flexible medical devices. You can trust your results when you use the right tests and real-life conditions.

Cost & Value

Upfront vs. Lifecycle

If you pick nitinol tubing that resists kinks better, it costs more at first. This is because making nitinol tubing is hard. Nickel and titanium are expensive materials. Factories need special machines and skilled people to make it. Top suppliers may charge higher prices, but their tubing meets strict rules.

Here is a table that shows what changes the cost and value of nitinol tubing:

Aspect | Details |

|---|---|

Upfront Cost Factors | Hard manufacturing, expensive materials, and supply-demand make the first price higher. |

Clinical Benefits | Better kink resistance and superelasticity lower problems by 12%, making devices safer and stronger. |

Lifecycle Cost Impact | Lower total cost because devices last longer and break less. |

Procurement Strategies | Buying in bulk, long contracts, and talking with suppliers can lower first costs. |

Provider Priorities | 65% of healthcare workers care more about long-term use than saving money at first. |

You pay more at the beginning, but you save later. Nitinol tubing lasts longer and breaks less. Fewer broken devices mean fewer surgeries and less danger for patients. Many hospitals now care more about long-term value than just the cheapest price. Buying a lot at once or signing long contracts can help you pay less at first.

Note: Nitinol’s superelasticity and fatigue resistance help your devices work better and last longer, so the higher first price is worth it.

Maintenance

You do not have to spend much on fixing nitinol tubing if it is high quality. The tubing does not rust and keeps its shape after many bends. This means you do not have to replace devices as often. You also spend less time checking for damage.

Nitinol tubing with a smooth surface needs less cleaning.

Devices with nitinol tubing usually pass more safety tests.

You avoid extra costs from broken devices or recalls.

If you use nitinol tubing that resists kinks, your team works faster and safer. You also protect your money by needing fewer repairs or new devices. Over time, this saves you money and helps you worry less.

Kink Resistance in Device Design

Guidewires

Guidewires must bend and move in small spaces. They should not kink or break. Nitinol tubing helps guidewires stay strong and flexible. The table below shows how design choices help:

Aspect | Description |

|---|---|

Material Properties | Nitinol tubing bends many times and does not break. It has superelasticity and shape memory. |

Surface Treatment | Electropolishing makes the surface smooth. This lowers friction and stops cracks, so the guidewire lasts longer. |

Design Features | Interwoven nitinol wires spread out stress. This design resists kinks and copies how real blood vessels move. |

Clinical Performance | In a study with 264 patients, nitinol stents kept working in 78.9% of cases after 12 months. No stents broke in 243 checked cases. |

Safety and Control | Good kink resistance gives you better control. The guidewire does not collapse or block, so you can move it safely through twisty vessels. |

Guidewires made with nitinol tubing keep their shape. They stay open and let you work safely. Nitinol guidewires help stop sudden blockages or device problems. You can trust them for hard procedures.

Catheters

Catheters must move in the body without folding or kinking. You can make nitinol catheters better by using smart designs:

Make transition zones to spread out strain. This helps the catheter bend smoothly and stops kinks.

Pick the best cross-sectional shape, like a circle or custom design. This balances bending and stiffness.

Change the tip’s shape and size. A soft tip helps you move in tight spaces. A stiff base gives you control.

Use a smooth surface finish. This lowers friction and helps the catheter last longer.

These design steps use nitinol’s special features. You get a catheter that bends, stays strong, and works well under stress. This helps you treat patients safely and well.

You can make nitinol tubing resist kinks better by picking good materials. Using smart designs also helps a lot. It is important to work with skilled makers. New ideas, like segmented nitinol guidewires, work well in tests. Interwoven stents also show strong results in real patients. You should test your tubing often to make sure it works. Working closely with your suppliers helps you learn about new advances. Try out new products, like the Philips OmniWire, to keep your devices safe and working well.

FAQ

What makes nitinol tubing resist kinks better than other metals?

Nitinol tubing bends and returns to its shape because of superelasticity and shape memory. You can twist or bend it, and it will not stay bent. This helps your medical devices work safely.

How do you test kink resistance in nitinol tubing?

You bend the tubing around different-sized mandrels or through curved models. You watch for kinks or changes in shape. You also check if the tubing returns to normal after bending.

Can you improve kink resistance after making the tubing?

Yes! You can use heat treatment, add braiding or coiling, or change the surface finish. These steps help your tubing bend more without kinking.

Why does wall thickness matter for kink resistance?

Wall thickness gives the tubing strength. If the wall is too thin, the tubing may kink. If it is too thick, the tubing becomes stiff. You need the right balance for best results.

What should you ask your supplier about kink resistance?

Ask about material purity.

Request test results for kink resistance.

Find out about surface finish options.

Tip: Good suppliers give you detailed data and help you pick the best tubing.

See Also

A Detailed Approach To Choosing Proper Nitinol Tubing

Tips For Finding The Ideal Nitinol Tubing Supplier

The Process Behind Manufacturing Nitinol Tubing For Medicine

The Importance Of Nitinol Tubing In Modern Medical Use

Comprehensive Overview Of Nitinol Parts And Production Methods