How Nitinol Transforms Robotic Surgery in 2025

Nitinol is transforming robotic surgery by introducing a groundbreaking combination of flexibility and precision. Its unique combination of super-elasticity and shape memory allows surgical instruments to adapt to complex anatomical pathways with remarkable ease. This adaptability ensures accurate placement during procedures, minimizing risks and enhancing outcomes. Nitinol surgical instruments for robotic surgery leverage these properties to improve the precision of minimally invasive techniques. Devices made from nitinol navigate intricate pathways while maintaining structural integrity, a feature critical for reducing procedural errors. By reshaping how medical devices operate, nitinol plays a transformative role in medical devices, setting a new standard for surgical innovation.

Key Takeaways

Nitinol's special traits, like bending and shape memory, improve robotic surgery tools.

Surgical tools with nitinol make smaller cuts, causing less harm and quicker healing.

Nitinol is safe for the body, lowering the chance of bad reactions.

Its flexibility helps tools move through tricky body paths, making surgeries better.

New nitinol ideas will make robotic surgery even better for patients and doctors.

What is Nitinol and Why is it Important?

Shape memory and superelasticity: Key properties of nitinol

Nitinol, a nickel-titanium alloy, stands out due to its remarkable shape memory and super-elasticity. These properties allow nitinol to return to its original shape after deformation, even under extreme conditions. This unique behavior results from its ability to undergo a phase transformation between two crystalline structures: austenite and martensite. When exposed to heat, nitinol "remembers" its original form and reverts to it, making it invaluable for applications requiring precision and adaptability.

Super-elasticity, another defining feature, enables nitinol to endure significant strain without permanent deformation. This property enhances flexibility and structural integrity, especially in robotic surgical tools. Unlike traditional materials, nitinol can bend and twist to navigate complex anatomical pathways while maintaining its strength. These characteristics make it a game-changer in robotic surgery, where precision and flexibility are paramount.

Nitinol's biocompatibility and its significance in medical devices

Biocompatibility is a critical factor in the development of medical devices, and nitinol excels in this area. Its compatibility with human tissues ensures that it can be safely used in various surgical applications. For instance:

Nitinol has demonstrated excellent compatibility with ocular tissues, particularly in glaucoma management through microstents.

Animal studies have shown that nitinol is well-tolerated in anterior segment surgeries.

Its use spans multiple medical fields, including cardiovascular surgery, orthopedics, neurosurgery, and gastrointestinal procedures.

In addition to biocompatibility, nitinol offers corrosion resistance, which further enhances its safety and durability in medical environments. These attributes ensure that nitinol-based instruments perform reliably without causing adverse reactions, making them ideal for robotic surgery.

Why nitinol is ideal for robotic surgical instruments

Nitinol's unique combination of properties makes it the material of choice for robotic surgical instruments. Its shape memory and super-elasticity enable the creation of adaptive components that enhance precision during procedures. These tools can flex and conform to intricate anatomical structures, ensuring accurate navigation and reducing the risk of tissue damage.

The alloy's flexibility allows for the development of smaller, more versatile instruments capable of performing minimally invasive surgeries. Unlike alternative materials, nitinol maintains its structural integrity under stress, ensuring consistent performance. This reliability is crucial in robotic-assisted surgeries, where precision and adaptability directly impact patient outcomes.

By integrating nitinol into robotic surgical tools, manufacturers can create instruments that offer unparalleled precision, flexibility, and biocompatibility. These advancements are transforming the field of robotic surgery, setting new standards for innovation and patient care.

Applications of Nitinol in Robotic Surgical Instruments

Flexible tools for minimally invasive surgical instruments

Nitinol's flexibility has revolutionized the design of minimally invasive surgical instruments. Its superelasticity allows tools to bend and adapt to the body's intricate anatomical structures without losing their shape or breaking. This property is particularly valuable in robotic-assisted surgical technologies, where precision and adaptability in surgical instruments are critical for success.

For example, nitinol tubing, a key component in many robotic surgical systems, exhibits exceptional kink resistance. This ensures that instruments maintain their structural integrity even when navigating tight or curved spaces. Additionally, nitinol's fatigue resistance makes it ideal for repeated use in demanding surgical environments. These characteristics enable surgeons to perform minimally invasive procedures with greater confidence and accuracy, reducing the risk of complications.

Note: AccuPath, a leading manufacturer of nitinol tubing, plays a pivotal role in unlocking nitinol’s potential for creating flexible and durable surgical instruments. Their high-quality tubing is widely used in robotic-assisted surgical technologies, ensuring optimal performance in complex procedures.

Precision-enhancing capabilities in robotic-assisted procedures

Nitinol surgical instruments for robotic surgery excel in enhancing precision during procedures. The material's shape memory allows instruments to return to their original form after deformation, ensuring consistent performance. This capability is crucial in robotic-assisted surgical technologies, where even minor deviations can impact patient outcomes.

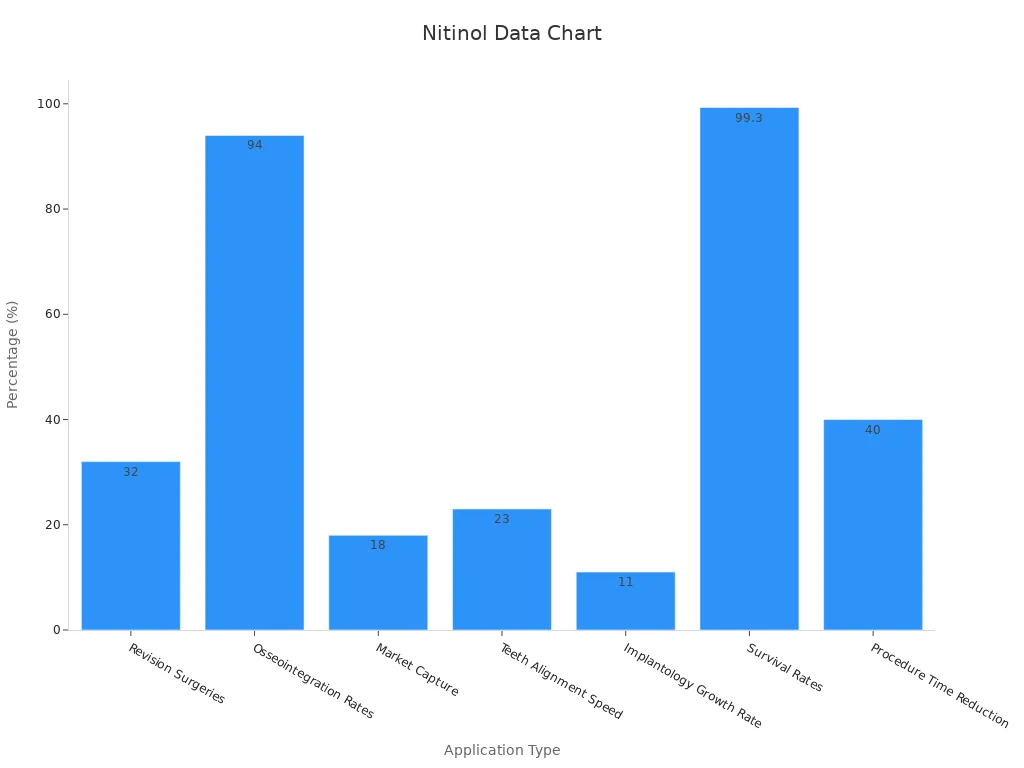

Clinical studies highlight nitinol's effectiveness in improving surgical precision. For instance, nitinol components in surgical robots contribute to a 40% reduction in procedure times for flow diverters, as shown in recent evaluations. Additionally, over 120 discrete nitinol parts are integrated into the arms of leading surgical robots, underscoring the material's importance in achieving unparalleled precision.

Application Type | Quantitative Data |

|---|---|

Procedure Time Reduction | 40% reduction in procedure times for flow diverters using braided Nitinol wires |

Nitinol Components in Surgical Robots | Over 120 discrete Nitinol parts per arm in leading surgical robots |

Surgical Robotics Market Projection | Projected to reach $25 billion by 2028 |

These advancements demonstrate how nitinol enhances the precision and adaptability of robotic-assisted surgical technologies, paving the way for safer and more efficient minimally invasive procedures.

Nitinol tubing for smaller incisions and complex anatomical navigation

Minimally invasive procedures often require small incisions, which can limit the maneuverability of traditional surgical tools. Nitinol tubing addresses this challenge by offering unmatched flexibility and durability. Its ability to navigate confined spaces within the body makes it indispensable for complex anatomical navigation.

Nitinol tubing's role in minimally invasive surgical instruments has been well-documented. The material's superelasticity allows it to adapt to dynamic surgical environments, while its kink resistance prevents folding or failure during use. These properties enable the development of miniaturized devices that can access hard-to-reach areas with minimal trauma to surrounding tissues.

AccuPath's expertise in manufacturing nitinol tubing ensures that these instruments meet the highest standards of quality and performance. Their products are designed to support surgeons in achieving smaller incisions and navigating complex anatomical pathways with ease, ultimately improving patient outcomes.

Advantages of Nitinol in Robotic Surgery

Improved patient outcomes through advanced surgical techniques

Nitinol's unique properties have revolutionized robotic surgery, significantly improving patient outcomes. Its shape memory and superelasticity enable the development of minimally invasive surgical tools that can be compactly inserted and then expand inside the body. This capability allows surgeons to perform procedures with greater precision and less trauma to surrounding tissues.

Clinical studies highlight the impact of nitinol-based instruments on patient outcomes. For instance, the DAWN Trial demonstrated that nitinol stent retrievers for ischemic stroke achieved 49% functional independence at 90 days, compared to 13% with standard care. Similarly, the PARTNER 3 Trial reported a 1.0% mortality rate at one year for nitinol-based TAVR procedures, compared to 2.5% for open-heart surgery. These advancements underscore nitinol's role as a cornerstone feature for devices driving innovation in medical devices.

Reduced recovery times and minimized surgical risks

Nitinol-based instruments enhance surgical outcomes by enabling smaller incisions, which result in less tissue damage and quicker healing. The material's flexibility allows for less invasive procedures, reducing trauma to surrounding tissues and minimizing surgical risks. Patients experience faster recovery times and improved patient comfort and outcomes compared to those treated with conventional materials.

For example:

Nitinol implants adapt to the body's movements, reducing discomfort and promoting faster healing.

The use of nitinol in advanced vascular instruments ensures precise navigation through complex anatomical pathways, minimizing complications.

Biocompatibility, a critical factor in ensuring device reliability, reduces the risk of rejection or inflammation, further enhancing recovery.

These benefits make nitinol an indispensable material in robotic-assisted surgeries, where patient safety and comfort are paramount.

Enhanced durability and overload protection in surgical instruments

Nitinol's durability and overload protection set it apart from traditional materials. Its superelasticity, driven by a stress-induced martensitic transformation, allows surgical instruments to endure significant strain without permanent deformation. This property ensures that nitinol-based instruments maintain their structural integrity even under demanding conditions.

For robotic-assisted procedures, this durability translates to reliable performance and extended instrument lifespan. Nitinol tubing, for instance, resists kinking and fatigue, making it ideal for advanced vascular instruments. Additionally, its ability to withstand repeated use without compromising functionality reduces the need for frequent replacements, lowering costs and improving surgical efficiency.

By combining flexibility, durability, and biocompatibility, nitinol continues to be a critical factor in ensuring device reliability. Its transformative role in robotic surgery highlights its importance as a cornerstone feature for devices that enhance patient care and surgical precision.

The Future of Nitinol in Robotic Surgery by 2025

Emerging trends in nitinol surgical instruments for robotic surgery

The future of nitinol in robotic surgery is shaped by several emerging trends. The growing demand for minimally invasive procedures highlights nitinol's importance. Its properties make it ideal for catheter-based interventions, improving patient outcomes. Advances in additive manufacturing also play a transformative role in medical devices. This technology enables the creation of complex geometries, allowing for rapid prototyping and improved therapeutic results.

Enhanced surface modification techniques further expand nitinol's applications. These innovations improve biocompatibility and extend the lifespan of surgical instruments. Regulatory evolution and standardization ensure reliability, fostering trust in nitinol-based devices. Additionally, the integration of nitinol with digital health technologies leads to smarter, more efficient medical tools. Sustainability and cost-effectiveness also drive its adoption, as nitinol's durability reduces healthcare costs while aligning with environmental goals.

Innovations in sensing technologies integrated with nitinol

Sensing technologies integrated with nitinol are revolutionizing robotic surgery. Nitinol's flexibility and durability make it an excellent material for embedding sensors. These sensors provide real-time feedback during procedures, enhancing precision and safety. For example, nitinol-based robotic arms equipped with force sensors can detect subtle changes in pressure, preventing tissue damage.

The combination of nitinol and smart technologies enables the development of adaptive surgical instruments. These tools adjust to the surgeon's movements, ensuring accurate navigation through complex anatomical pathways. Expert analyses emphasize the growing need for such precise instruments as robotic systems advance. This integration represents a key trend in the evolution of nitinol-based surgical tools.

Advancements in customizable and adaptive surgical tools

Customizable and adaptive surgical tools made from nitinol are transforming patient care. Nitinol's shape memory and superelasticity allow for the creation of complex, patient-specific devices. For instance, life-saving stents can be tailored to fit the unique dimensions of a patient's blood vessels, enhancing treatment efficacy and comfort.

These advancements support the development of next-generation medical devices. Nitinol's unique properties enable the design of tools that adapt to individual patient needs, improving surgical precision. As robotic surgery continues to evolve, the demand for such adaptive instruments will grow. By 2025, nitinol's transformative role in medical devices will further enhance the capabilities of robotic-assisted procedures, setting new standards in surgical innovation.

Nitinol has become a cornerstone of innovation in robotic surgery. Its unmatched flexibility and precision enable the development of advanced surgical tools. These tools improve minimally invasive procedures and enhance patient outcomes. Nitinol's biocompatibility ensures safe integration with human tissues, while its resistance to corrosion increases durability. This corrosion resistance also reduces the risk of device failure, making nitinol-based instruments reliable in demanding surgical environments. By 2025, nitinol will continue to shape the future of robotic surgery. Its transformative properties will drive advancements in medical devices, setting new standards for surgical precision and patient care.

Note: Nitinol's ability to resist corrosion ensures long-lasting performance, even in challenging medical applications.

FAQ

What makes nitinol tubing essential for robotic surgery?

Nitinol tubing offers unmatched flexibility and durability. Its superelasticity allows surgical tools to navigate complex anatomical pathways without losing shape. This reliability ensures consistent performance during minimally invasive procedures, improving outcomes and enhancing patient comfort.

How does superelasticity improve surgical precision?

Superelasticity enables nitinol instruments to bend and adapt without permanent deformation. This property enhances precision by allowing tools to conform to intricate anatomical structures. Surgeons achieve better outcomes with reduced risks and improved reliability during robotic-assisted procedures.

Why is nitinol preferred for minimally invasive surgeries?

Nitinol's biocompatibility and shape memory make it ideal for minimally invasive surgeries. Its ability to expand and adapt inside the body minimizes tissue damage. Patients experience faster recovery times, greater comfort, and improved outcomes compared to traditional materials.

How does nitinol tubing contribute to patient comfort?

Nitinol tubing adapts to dynamic surgical environments, reducing trauma to surrounding tissues. Its flexibility ensures smaller incisions and precise navigation, enhancing patient comfort during and after procedures. This adaptability improves recovery and overall outcomes.

What ensures the reliability of nitinol-based surgical tools?

Nitinol's durability and resistance to fatigue ensure long-lasting performance. Its superelasticity prevents kinking or failure during use, maintaining reliability in demanding surgical environments. These qualities make nitinol tubing indispensable for robotic-assisted surgeries.

See Also

Nitinol Tubing: Shaping the Future of Medical Devices

Nitinol Tubing's Impact on the Evolution of Medical Tech

Nitinol Tubing: Transforming the Landscape of Medical Devices

Investigating Nitinol Tubing Uses in Healthcare Technology

The Importance of Nitinol Tubing in Modern Medical Applications