Exploring Nitinol Neurovascular Guidewires for Surgical Precision

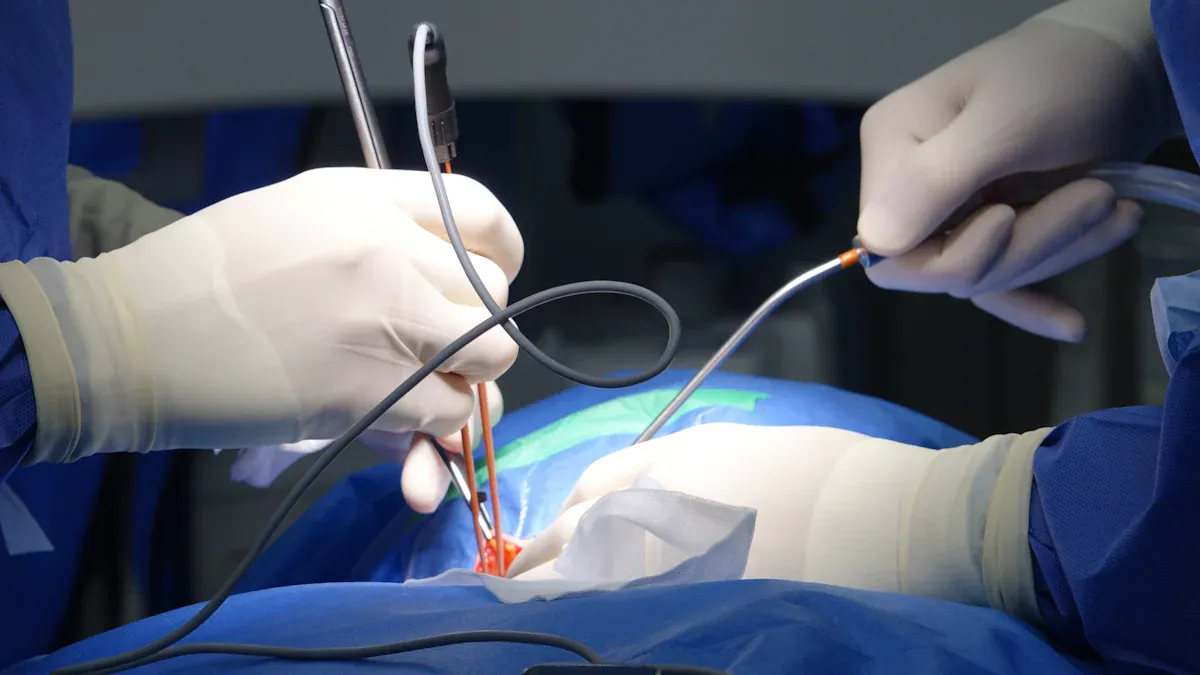

Nitinol Neurovascular Guidewire for Minimally Invasive Surgery represents a groundbreaking advancement in the medical field. These specialized tools leverage the unique properties of nitinol, a metal alloy known for its superelasticity and shape memory. By enabling precise navigation through the intricate vascular system, they facilitate procedures that demand exceptional accuracy.

Their transformative impact on surgical precision is undeniable. Studies reveal that using Nitinol Neurovascular Guidewire for Minimally Invasive Surgery can enhance procedural success rates by 25% and decrease complications by nearly 20%. These advancements not only improve outcomes but also redefine what is achievable in minimally invasive surgery, setting a new standard for patient care.

Key Takeaways

Nitinol guidewires help doctors by being flexible and keeping their shape. This makes it easier to move through tricky blood vessels.

Using nitinol guidewires can make surgeries 25% more successful. They also lower problems by about 20%, helping patients recover better.

Nitinol is safe for the body and doesn’t cause bad reactions. This makes it great for delicate brain and nerve surgeries.

Nitinol doesn’t bend or break easily, so it works well many times. This lowers the chance of hurting blood vessels.

When used with robotic surgery, nitinol guidewires improve accuracy. They make surgeries faster and safer with smaller cuts.

Nitinol: A Material Revolutionizing Minimally Invasive Procedures

Superelasticity and shape memory

Nitinol's superelasticity properties redefine control in surgical applications. This unique material can undergo significant deformation and return to its original shape due to its shape memory effect. Experimental data confirms that nitinol exhibits elasticity, superelasticity, and plasticity, making it ideal for medical devices like stents and guidewires. The stress-induced martensitic transformation allows nitinol to recover from strain without permanent damage, ensuring reliability during procedures.

Medical nitinol wire demonstrates exceptional adaptability, enabling surgeons to navigate complex vascular pathways with ease. This adaptability reduces procedure times and enhances patient comfort. For example, orthodontic devices made from nitinol apply consistent pressure, accelerating teeth alignment. These applications highlight how nitinol's unique properties revolutionize minimally invasive procedures.

Biocompatibility and safety

Nitinol components interact safely with human tissue, minimizing adverse reactions. Their biocompatibility and safety profiles make them suitable for implants and devices used within the body. Unlike some materials, nitinol resists corrosion and fatigue, ensuring durability and longevity in medical applications.

Clinical studies confirm nitinol's suitability for neurovascular guidewires and stents. Its resistance to wear and tear reduces risks associated with foreign materials, providing long-lasting performance. These qualities make nitinol a trusted choice for devices that demand reliability and safety in delicate environments.

Durability and resistance to deformation

Durability is a defining feature of nitinol. Long-term studies illustrate its ability to withstand millions of fatigue cycles, particularly in applications near the heart. Accelerated fatigue testing under clinically relevant conditions ensures nitinol devices meet rigorous durability standards.

The unique properties of nitinol prevent deformation during repeated use. This resistance to mechanical stress makes it ideal for surgical tools like guidewires, which must maintain their integrity in challenging conditions. By understanding the biomechanical environment, researchers continue to optimize nitinol's durability and longevity for medical applications.

Evidence Type | Description |

|---|---|

Improved Flexibility | Nitinol stents provide superior flexibility compared to traditional stents, aiding navigation. |

Reduced Vessel Injury | The flexibility of nitinol stents minimizes damage to blood vessels during placement. |

Better Long-Term Results | Studies indicate that nitinol stents may have better long-term patency rates than traditional stents. |

Features of Nitinol Neurovascular Guidewires

Flexibility for navigating complex anatomy

Nitinol guidewires offer exceptional flexibility and strength, making them indispensable for navigating intricate anatomical structures. Their superelasticity allows them to bend significantly without breaking, ensuring smooth passage through tortuous vascular pathways. This flexibility and shape memory enable nitinol guidewires to return to their original shape after deformation, maintaining their structural integrity during procedures.

Tip: Pre-shaped nitinol guidewires can be tailored for specific surgical applications, enhancing precision in targeting complex lesions.

Key performance outcomes highlight their unmatched maneuverability:

They flex along their length while maintaining torque and trackability, crucial for reaching challenging lesions.

Their kink-resistant design minimizes patient discomfort and facilitates easier navigation.

The core material, whether flexible nitinol or stiff stainless steel, significantly influences their overall flexibility.

AccuPath's Nitinol Tubing plays a vital role in manufacturing these advanced medical guidewires, ensuring consistent quality and reliability for demanding neurovascular procedures.

Resistance to kinking and mechanical stress

Nitinol guidewires excel in resisting kinking and mechanical stress, a critical feature for navigating complex vascular systems. Their superelasticity allows them to endure millions of stress cycles without failure, maintaining their shape and functionality under repeated strain. Fatigue testing reveals that nitinol can survive up to 10⁷ cycles under strain amplitudes ranging from 0.5% to 2.9%, showcasing its durability and reliability.

Note: This resistance to deformation ensures that nitinol guidewires remain effective even in high-stress environments, reducing the risk of procedural complications.

AccuPath's expertise in producing high-quality nitinol tubing ensures that these guidewires meet rigorous durability standards, making them a trusted choice for medical professionals worldwide.

Radiopacity for enhanced visibility

Radiopacity is a defining feature of nitinol guidewires, enabling surgeons to visualize their position during procedures with greater clarity. Imaging studies demonstrate that nitinol DFT® Flat Wire offers superior radiopacity compared to traditional round wires. X-ray comparisons reveal that the flat ribbon design significantly enhances visibility, making it easier to track the guidewire's movement in real time.

This enhanced radiopacity is particularly beneficial in neurovascular procedures, where precision is paramount. Surgeons can rely on nitinol guidewires to navigate delicate anatomical structures with confidence, reducing the likelihood of errors. AccuPath's advanced manufacturing processes ensure that their nitinol tubing delivers optimal radiopacity, supporting safer and more effective surgical outcomes.

Benefits of Nitinol Guidewires in Neurovascular Procedures

Precision in delicate surgical maneuvers

Nitinol guidewires excel in delivering precision and reliability during neurovascular procedures. Their flexibility allows surgeons to navigate complex anatomical structures with ease, while their superelasticity adapts to the varying shapes and sizes of blood vessels. These properties ensure accurate placement and control, even in challenging environments.

Feature | Benefit | Impact on Precision |

|---|---|---|

Flexibility | Allows navigation through complex anatomical structures | Increases control during delicate maneuvers |

Superelasticity | Adapts to various shapes and sizes of vessels | Enhances precision in placement |

Shape memory | Returns to original shape after deformation | Improves accuracy in targeting |

Biocompatibility | Minimizes tissue trauma | Reduces complications during procedures |

Radiopacity | Provides clear visibility under fluoroscopy | Decreases risk of misplacement |

These features enable nitinol guidewires to perform exceptionally well in minimally invasive procedures. Their advanced design minimizes the risk of errors, ensuring precision in difficult terrains. AccuPath's high-quality nitinol tubing plays a pivotal role in manufacturing these guidewires, ensuring consistent performance and reliability for surgeons worldwide.

Note: Nitinol guidewires offer smoother navigation through tortuous vessels, reducing the risk of complications and enhancing procedural outcomes.

Reduced risk of vessel damage

Nitinol guidewires significantly reduce the risk of vessel damage during neurovascular procedures. Their superelasticity and biocompatibility minimize trauma to delicate blood vessels, ensuring safer outcomes for patients. Clinical studies highlight the advantages of nitinol self-expanding stents, which show a marked reduction in acute arterial injury compared to traditional balloon-expandable stents.

Nitinol guidewires reduce vessel trauma by adapting to the natural curvature of blood vessels.

They promote favorable plaque remodeling and minimize neointimal growth, lowering the risk of vessel damage.

Their kink-resistant design ensures smooth navigation, even in high-stress environments.

AccuPath's expertise in producing durable nitinol tubing ensures that these guidewires maintain their structural integrity under repeated use, further reducing the likelihood of vessel injury. This reliability makes them an indispensable tool for surgeons performing delicate neurovascular interventions.

Improved patient outcomes

The use of nitinol guidewires in neurovascular procedures leads to improved patient outcomes. Their advanced properties, including flexibility, radiopacity, and biocompatibility, contribute to better procedural success rates and faster recovery times. Clinical data demonstrates the superiority of nitinol devices over traditional materials in several key metrics:

Metric | Nitinol Devices | Traditional Materials |

|---|---|---|

Recovery Improvement | 20% | N/A |

Pain Level Reduction | Quicker recovery | N/A |

Risk of Complications | Lower | N/A |

Nitinol stents, for example, reduce restenosis rates, ensuring long-term vessel patency. Guidewires constructed from nitinol enhance precision during minimally invasive procedures, leading to better overall treatment outcomes. Patients benefit from reduced pain, quicker recovery, and fewer complications, making nitinol guidewires a cornerstone of modern neurovascular surgery.

AccuPath's commitment to producing high-quality nitinol tubing ensures that these guidewires deliver unmatched performance and reliability. By supporting safer and more effective surgical outcomes, AccuPath continues to set the standard for innovation in minimally invasive medical devices.

Challenges and Mitigation Strategies

Cost considerations and long-term value

Economic studies highlight the importance of balancing cost and value when adopting nitinol guidewires. Hospitals and healthcare systems often evaluate reimbursement pathways before introducing new devices. Several factors influence this decision:

The Centers for Medicare and Medicaid Services (CMS) encourage innovative guidewire use through reimbursement strategies that improve procedural outcomes.

Over half of hospital systems require confirmation of reimbursement pathways before adopting new medical devices.

Devices that reduce recovery times or complications justify higher initial costs due to overall savings in hospitalization.

A study revealed that post-procedure readmissions could cost up to $13,000 per patient. Nitinol guidewires, with their resistance to corrosion and fatigue, offer long-term value by reducing complications and improving patient outcomes. Geographical variations in reimbursement structures also affect adoption rates, with bundled payment arrangements driving higher usage. Healthcare providers increasingly conduct clinical evaluations to ensure investments yield measurable benefits for insurance claims.

Material concerns and manufacturing advancements

Manufacturing nitinol guidewires involves addressing material concerns while leveraging advancements in production techniques. Recent innovations include additive manufacturing and laser cutting, which allow for precise shaping of nitinol components. These techniques enhance efficiency and enable the creation of complex structures that were previously unattainable.

Aspect | Details |

|---|---|

Manufacturing Techniques | Additive manufacturing and laser cutting improve precision and efficiency. |

Precision Machining | CNC machining creates intricate components with minimal human intervention. |

Material Properties | Nitinol's flexibility and biocompatibility make it ideal for medical devices. |

Environmental Considerations | Manufacturers address cost factors, quality control, and environmental impacts. |

Nitinol's resistance to corrosion and fatigue ensures durability in demanding medical applications. These properties make it a preferred material for guidewires, stents, and other devices. Manufacturers continue to refine production processes to meet quality standards and reduce environmental impacts.

Training and clinical adoption

The adoption of nitinol guidewires depends on effective training and clinical integration. Their unique properties, such as shape memory and superelasticity, make them ideal for navigating complex vascular anatomies. These features have led to increased adoption among healthcare providers, with the nitinol guidewire segment projected to dominate the market by 2024.

Advancements in nitinol processing techniques have further enhanced guidewire performance. Surface treatments and alloy compositions improve radiopacity and reduce friction, making nitinol guidewires the preferred choice for minimally invasive procedures. Physicians increasingly favor these devices for neurovascular, peripheral, and urology interventions due to their flexibility and resistance to corrosion and fatigue. Training programs focus on equipping surgeons with the skills needed to maximize the benefits of nitinol guidewires, ensuring safer and more effective outcomes.

Future Potential of Nitinol in Minimally Invasive Surgery

Innovations in guidewire design

Nitinol continues to drive innovation in guidewire design, optimizing performance in minimally invasive techniques. Its superelasticity and shape memory allow guidewires to bend and return to their original shape, making them ideal for navigating complex anatomical pathways. Recent advancements in manufacturing, such as automation and enhanced quality control, have improved the precision and consistency of nitinol guidewires. These developments ensure safer and more effective surgical tools.

Key Point | Description |

|---|---|

Superelasticity and Shape Memory | Enables guidewires to adapt to intricate vascular structures. |

Reduction in Adverse Reactions | Nitinol reduces immune reactions by 95% compared to cobalt-chromium alloys. |

Manufacturing Innovations | Automation enhances production accuracy and reliability. |

These innovations highlight nitinol's potential to transform minimally invasive procedures further, ensuring better outcomes for patients and surgeons alike.

Expanding applications beyond neurovascular procedures

The versatility of nitinol opens doors to applications beyond neurovascular interventions. Its use in angioplasty and stent placement demonstrates its navigational capabilities. Ongoing research and development have introduced drug-eluting nitinol catheters, which enhance treatment efficacy and reduce complications. These advancements improve patient safety and procedural efficiency, showcasing nitinol's adaptability across various medical fields.

Evidence Type | Details |

|---|---|

Projected CAGR | Approximately 8% growth over the next five years due to rising adoption of minimally invasive procedures. |

Clinical Applications | Increasing use in angioplasty and stent placement. |

Innovations in R&D | Development of drug-eluting nitinol catheters to improve outcomes. |

As nitinol's applications expand, its role in optimizing performance in minimally invasive techniques becomes increasingly evident.

Integration with robotic-assisted surgery

Robotic-assisted surgery represents a promising frontier for nitinol guidewires. Their flexibility and durability make them compatible with robotic systems, which require precise and reliable tools. Surgeons can leverage nitinol's properties to navigate challenging anatomical structures with greater accuracy. This integration enhances the performance of robotic systems, reducing the risk of complications and improving patient outcomes.

The combination of nitinol guidewires and robotic-assisted surgery exemplifies the future of minimally invasive medicine. Together, they offer unparalleled precision and efficiency, setting new standards for surgical care.

Nitinol neurovascular guidewires combine flexibility, durability, and radiopacity to deliver unmatched precision in minimally invasive procedures. Their biocompatibility and resistance to deformation ensure safer outcomes and reduced complications. These features make them indispensable in navigating complex vascular anatomies.

Key Insight: Nitinol guidewires redefine surgical precision, enabling breakthroughs in patient care.

Their integration with robotic-assisted systems and expanding applications beyond neurovascular interventions highlight their transformative potential. As innovations in design and manufacturing continue, nitinol guidewires will remain at the forefront of surgical advancements, shaping the future of minimally invasive medicine.

FAQ

What makes nitinol guidewires unique compared to other materials?

Nitinol guidewires stand out due to their superelasticity, shape memory, and biocompatibility. These properties allow them to navigate complex vascular pathways without deforming or causing damage. Their durability and radiopacity further enhance their performance in minimally invasive procedures.

Are nitinol guidewires safe for neurovascular procedures?

Yes, nitinol guidewires are highly safe. Their biocompatibility minimizes adverse tissue reactions, while their flexibility reduces the risk of vessel damage. Clinical studies confirm their reliability and safety in delicate neurovascular interventions.

How do nitinol guidewires improve surgical precision?

Nitinol guidewires enhance precision by offering flexibility, radiopacity, and shape memory. These features allow surgeons to navigate intricate anatomical structures with accuracy. Their kink resistance ensures smooth operation, reducing the likelihood of procedural errors.

What challenges exist with nitinol guidewires?

The primary challenges include higher costs and the need for specialized training. However, their long-term value, reduced complications, and improved patient outcomes justify the investment. Training programs help surgeons maximize their benefits.

Can nitinol guidewires be used in robotic-assisted surgery?

Yes, nitinol guidewires integrate seamlessly with robotic-assisted systems. Their flexibility and durability make them ideal for precise navigation in robotic procedures. This combination enhances surgical accuracy and reduces complications.

Tip: Nitinol guidewires are paving the way for advanced surgical techniques, including robotic-assisted interventions.

See Also

The Importance of Nitinol Tubing in Minimally Invasive Surgery

A Comprehensive Guide to Nitinol Microtubing Production for Neurovascular Use

Investigating Nitinol Tubing Uses in Medical Devices

How Nitinol Tubing Contributes to Medical Technology Innovations

Nitinol Tubing's Impact on Transforming Medical Device Design