Exploring Nitinol Hypotubes for Advanced Robotic Catheter Applications

You find a nitinol hypotube for robotic catheter applications in many robotic catheter systems. This material is special because it remembers its shape. It is very stretchy and works well with the body. Nitinol does not get tired easily, so doctors can trust it. Using a nitinol hypotube helps make catheters more exact and bendy. It also makes them stronger. New ways to make nitinol hypotubes for robotic catheter applications help medical tools get better.

Advancement Type | Description |

|---|---|

Precision Manufacturing | Making nitinol hypotubes for robotic catheter applications with better accuracy and sameness |

High-Purity Nitinol Materials | ELI grade nitinol helps devices work better in the body |

CAD/CAM Integration | Computers help design and make special nitinol hypotubes for robotic catheter applications |

Five-Axis Laser Cutting | Cutting hard shapes in nitinol hypotubes helps devices work better |

3D Printing | Nitinol hypotubes for robotic catheter applications can be made to fit each patient |

Key Takeaways

Nitinol hypotubes are special because they bend a lot. They go back to their original shape. This makes them great for robotic catheters. Using nitinol helps medical devices be more precise and flexible. Doctors can move through tight spaces in the body safely. Nitinol is biocompatible, so it is safe for patients. It helps lower the risk of problems during medical procedures. Advanced manufacturing methods, like laser cutting and 3D printing, make nitinol hypotubes better. These methods improve their quality and how well they work. Using nitinol technology can help patients get better results. It also makes surgeries safer. This makes nitinol a good choice for medical uses.

Nitinol Properties

Superelasticity

Superelasticity is a key feature of nitinol. This nickel-titanium alloy can bend and stretch much more than other metals. Nitinol hypotubes can spring back up to 11%. Stainless steel only springs back about 0.5%. You can bend nitinol a lot without breaking it. In robotic catheter systems, nitinol helps the device move in tight spaces. It also goes back to its original shape.

Nitinol wires can bend and recover at least 2% strain. This helps in robotic catheter applications.

Nitinol’s shape-restoring ability makes it great for flexible medical tools.

Shape Memory

Nitinol has a shape-memory effect. This means it can return to its original shape after heating. The shape-restoring feature works in many temperatures. This is important for medical uses.

The transformation temperatures for nitinol can be from −20°C to +110°C. The Active A(f) temperature shows when the change from martensite to austenite is done.

Active Aᶠ | Temperature Range (°C) | Temperature Range (°F) |

|---|---|---|

≥ 85 °C | 40 °C to 80 °C | 104 °F to 176 °F |

22 °C to 40 °C | 71.6 °F to 104 °F |

The shape-memory property helps catheters and other devices get their shape back. This makes nitinol a top pick for shape-restoring medical tools.

Biocompatibility

Medical devices need to be safe for people. Nitinol is good for the body, even better than stainless steel and titanium.

Nitinol helps cells grow and lowers the risk of blood clots.

Studies show nitinol helps fibroblasts grow by 108% and osteoblasts by 101%.

Nickel can cause allergies, but surface treatments make nitinol safer.

The amount of ions released and how patients react are important for safety.

Nitinol is trusted for many medical uses because it works well and is safe for patients.

Fatigue Resistance

Medical devices must last a long time. Nitinol is very good at handling repeated use.

Nitinol hypotubes can handle high-cycle fatigue strain limits from 0.4–0.8 percent.

The alloy can go through many cycles of loading and unloading without breaking.

Nitinol lasts longer than other metals in medical devices.

This means nitinol is a good choice for robotic catheter systems and other tools that need to work for a long time.

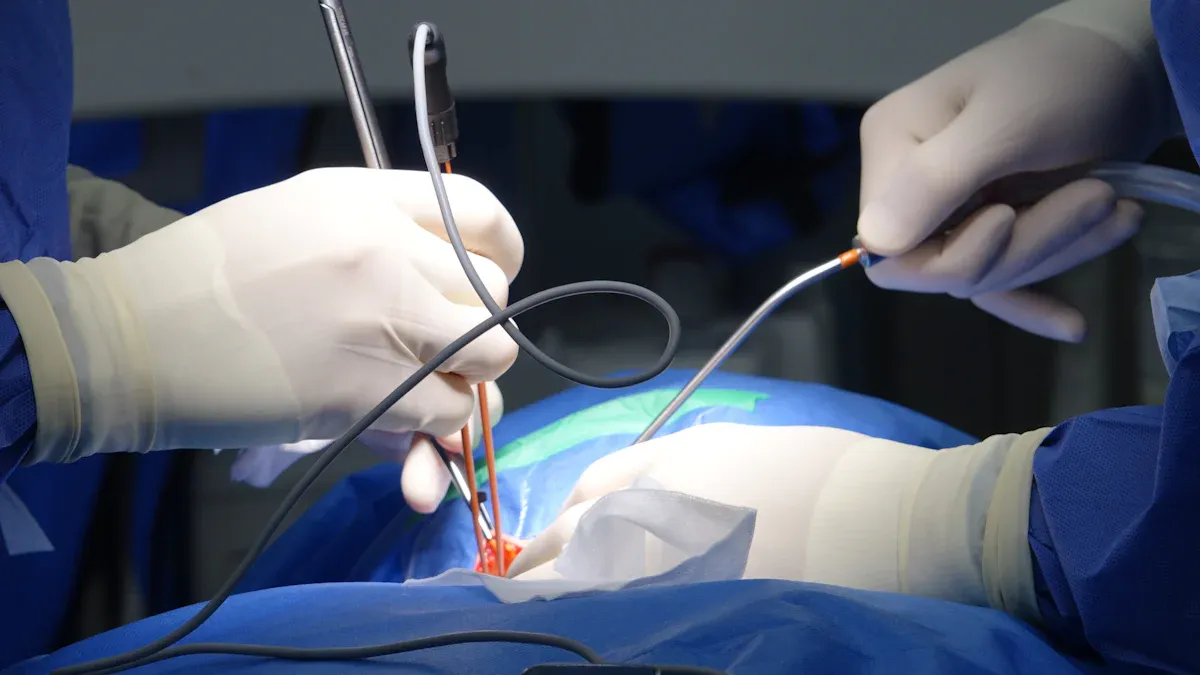

Nitinol Hypotube for Robotic Catheter Applications

Precision and Flexibility

Nitinol tube technology helps robotic catheter systems work better. When you use a nitinol hypotube, the device bends and moves easily. The superelasticity and shape memory let the catheter fit inside the body’s twists and turns. This helps you guide the catheter through tight spots and stay accurate.

Nitinol hypotube lets you move the catheter tip exactly.

The flexible nitinol tube stops kinks, so it stays smooth.

Nitinol tubing can bend a lot and go back to its shape. This helps you reach hard places.

You get more control in surgeries because nitinol tube does not break and keeps its shape.

Using nitinol hypotube makes procedures safer and more exact. The catheter can follow tricky paths, and you can trust it to move how you want.

Catheter Reinforcement

Robotic surgery needs strong and bendy tools. Nitinol tube is a strong part in these systems. When you use nitinol hypotube, you make the cables inside stronger. Nitinol tubing is often joined to stainless steel or tungsten cables. This makes the whole system tough and dependable.

Nitinol tube lets you push and pull the catheter without breaking it. The strong nitinol hypotube means you can use the device many times. Niti hypotube also keeps the catheter flexible, so you can move it in tight or curved spaces. You get a tool that lasts longer and works better in medical jobs.

Safety and Outcomes

Every medical device should be safe and work well. Nitinol hypotube helps you reach this goal. Studies show nitinol tube-based catheters help patients do better. The flexible nitinol tubing lowers problems and helps doctors treat people.

Clinical Trial | Device Description | Recanalization Rate (%) | Symptomatic Intracranial Hemorrhage Rate (%) | Device-Related Complications Rate (%) |

|---|---|---|---|---|

MERCI | Flexible nitinol wire in helical loops | 46 | 8 | N/A |

Multi MERCI | Same device, IV rt-PA refractory patients | 57 | 10 | 4.5 |

Multi MERCI (confirmed) | Merci system alone or with extra therapies | 57.3 / 69.5 | 9.8 | 5.5 |

Nitinol tube helps lower bleeding and device problems. You can trust nitinol hypotube to give better results in medical jobs. Niti hypotube gives you a safer tool for treating people and helps you get higher success rates.

Manufacturing

Laser Cutting

Laser cutting shapes nitinol hypotubes. It uses strong light beams to melt or take away material. The cuts are very exact, sometimes within ±0.01 mm. Computers help make the same design every time. Femtosecond lasers keep things cool. This stops oxide from forming and means less cleaning. The holes or slots you cut change how the tube bends. Engineers pick patterns to make tubes bend more and not kink. Laser cutting gives you strong and exact hypotubes for medical tools.

Microfabrication

Microfabrication helps make nitinol hypotubes for special medical needs.

Laser cutting controls the shape and pattern of each tube.

This lets you change how bendy or strong the tube is.

Nitinol’s shape memory and superelasticity help tubes move fast.

Laser-cut hypotubes bend easily and go through tricky paths.

These tubes are used in catheter mandrel assemblies for exact moves.

Joining Techniques

You need good ways to connect nitinol hypotubes to other parts.

You can weld nitinol with lasers or electron beams, but it loses superelasticity.

Joining nitinol to titanium or stainless steel is tough. You might use soft soldering, resistance welding, or diffusion welding.

Many engineers like crimping or shrink-fitting better.

A new way uses puzzle-cut tubes. You cut lobes on both tube ends. Push them together and they lock, like a Chinese finger trap. This makes a quick and safe connection.

Quality Control

You must follow strict rules when making nitinol hypotubes for medical use.

Source | Evidence |

|---|---|

AccuPath Group Co., Ltd. | Uses strong checks and meets top standards for nitinol hypotubes. |

Your supplier should know medical device rules.

You need to meet FDA and ISO safety and quality rules.

Manners Technology checks every hypotube for medical-grade materials. These steps help you trust nitinol hypotubes in medical tools.

Medical Applications

Vascular Interventions

Doctors use nitinol hypotubes in many blood vessel treatments. These tubes help fix blood vessel problems with less danger. Nitinol makes implants both strong and bendy. You can find these implants in stents, guidewires, and tools for aneurysms. The table below lists some main uses in vascular care:

Application | Description |

|---|---|

Peripheral Vascular Stents | Hold leg arteries open when they get too narrow. |

Guidewires and Catheters | Help move through tight blood vessels and place devices right. |

Cerebral Aneurysm Repair | Support weak spots in brain arteries and lower the risk of bursting. |

Treatment of Cerebral Arterial Stenosis | Open up narrow brain vessels to bring back blood flow and lower stroke risk. |

Aneurysm Embolization | Block blood flow in aneurysms to stop them from bursting. |

Nitinol vascular implants help give better results and safer care.

Interventional Devices

Nitinol hypotubes are used in many medical tools for special treatments. These tubes make catheters and guidewires work better. Nitinol’s bendiness helps move through tricky blood vessels. Shape memory lets the device go back to its shape after bending. The table below shows important features and their good points:

Feature | Benefit |

|---|---|

Flexibility | Makes it easier to move through twisty blood vessels. |

Shape Memory | Lets the device snap back to its shape during use. |

Reduced RF Heating | Keeps you safe in MRI scans by stopping the device from getting too hot. |

Stiffness Matching | Helps the device bend evenly and not break when stressed. |

Passive Visualization | Lets you see the device better in surgery with special markers. |

You get safer and better medical tools for many uses.

Future Trends

You will see more nitinol hypotubes in new medical tools and surgical robots. Laser-cut hypotubes now bend better and do not kink as much. These features help reach hard places with less harm. In AI-assisted endoscopy, nitinol hypotubes give control and steadiness for clear pictures. As more people want nitinol, you will see better vascular implants and guidewires in less invasive surgery. These changes show nitinol will keep making patient care better and bring new ideas to medicine.

Challenges

Material Handling

It is hard to work with nitinol hypotubes. Nitinol is tough to shape. You need special tools for this job. The titanium oxide surface wears out tools fast. Carbide grinding wheels help your tools last longer. Grinding makes heat that can change nitinol’s shape. You need coolants to keep nitinol cool. The shape-setting process needs extra room. You must plan for more space and equipment.

Challenge | Description |

|---|---|

Nitinol is hard to machine. You need special methods to cut and shape it. | |

Tool Wear | The surface wears down tools fast. Carbide wheels help you handle this problem. |

Temperature Management | Grinding creates heat. You use coolants to keep nitinol from changing shape. |

Logistical Space Requirements | Shape-setting needs extra space for storage and equipment. |

Cost and Scalability

Nitinol hypotubes cost more than other materials. Nitinol bends well and remembers its shape. These features are great for robotic catheter systems. You pay more because nitinol needs special ways to make it. Stainless steel costs less and works for simple designs. If you want advanced features, you pick nitinol but must plan for higher costs.

Nitinol gives special flexibility and shape memory for advanced uses.

Making nitinol costs more because of special techniques.

Stainless steel is cheaper and fits basic designs.

Solutions

You can solve these problems with new technology and smart steps. Laser cutting shapes nitinol hypotubes very exactly. Heat treating and shape setting make nitinol strong and bendy. Careful checks make sure each tube is safe and works well. These steps help you trust nitinol hypotubes in robotic catheters.

Laser cutting gives exact sizes for nitinol hypotubes.

Heat treating and shape setting make nitinol strong and flexible.

Inspection checks every tube for quality and safety.

Tip: Using these solutions makes nitinol hypotubes safer and more reliable for robotic catheter systems.

Nitinol hypotubes help doctors do better in surgeries. These tubes make devices more flexible and safer. Nitinol can bend and go back to its shape. New coatings and ways to make nitinol tubes make them stronger. They also make them safer for people.

Devices with nitinol help doctors move tools more easily. They also lower risks when doing surgery.

The market for nitinol medical devices is getting bigger. It will be worth billions by 2035.

More scientists are studying how to treat long-term diseases. They also want to make surgeries easier and less painful.

You get better care and heal faster as technology gets better.

FAQ

What makes nitinol hypotubes special for robotic catheters?

Nitinol hypotubes can bend a lot and go back to their shape. They are strong and flexible. Doctors use them to reach hard places in the body. These tubes last a long time and work well inside you.

Can nitinol cause allergies in patients?

Some people worry about nickel allergies. Special coatings on nitinol tubes help lower this risk. Most patients do not have any problems. Doctors pick safe coatings for medical tools.

How do nitinol hypotubes improve surgery safety?

Nitinol tubes help doctors move catheters with better control. You see fewer bends and breaks. This makes surgeries safer and helps you get better results.

Are nitinol hypotubes expensive?

Nitinol costs more than stainless steel. You pay extra for tubes that bend and remember their shape. Hospitals use nitinol for special surgeries where these features are important.

Where do you find nitinol hypotubes in medicine?

You find nitinol hypotubes in catheters, guidewires, and stents. Doctors use them for heart, brain, and blood vessel treatments. These tubes help make surgeries easier and less painful.

See Also

Nitinol Tubing's Impact on Healthcare Device Innovations

Nitinol Tubing's Contribution to Modern Medical Technologies

The Importance of Nitinol Tubing in Medical Advancements

Transforming Medical Devices Through Nitinol Tubing Innovations

Nitinol Tubing: A Key Component in Minimally Invasive Surgery