How to Improve the Surface Finish of NiTi Tubing

You can achieve a smooth finish on NiTi tubing surface finish improvement by selecting the best surface finishing methods. Electropolishing, mechanical polishing, and special treatments create a smooth and robust oxide layer. This layer protects the tubing from rust and enhances its longevity within the body.

Surface finishing improvement enhances safety by preventing nickel ions from leaching out. It also reduces the risk of allergies and promotes the growth of healthy cells.

Surface Treatment | Thrombogenicity (TAT III marker) | Platelet Adhesion | Endothelial Cell Proliferation |

|---|---|---|---|

Electropolished/Blue Oxide | Much lower | Less | More |

Native Nitinol Surface | Higher | More | Less |

You should focus on proper material preparation and quality checks to enhance NiTi tubing surface finish improvement.

Key Takeaways

Pick the best way to finish the surface, like electropolishing, to make NiTi tubing smooth and strong.

Prepare and clean the material well to make the surface better and stop contamination.

Use checks to measure how rough the surface is and make sure it meets medical rules.

Use passivation treatments to help stop corrosion and lower nickel ion release, making it safer for medical use.

Think about using special coatings to protect NiTi tubing from rust and help lower the chance of blood clots.

NiTi Tubing Surface Finish Improvement

You must be careful with every step when you work on NiTi tubing surface finish improvement. A good surface finish is important for medical and industrial uses. Smooth surfaces stop corrosion and help the tubing work well in the body. You also lower the chance of nickel ions getting out, which keeps people and machines safe.

Material Preparation

You begin by getting the material ready. This step is key for NiTi tubing surface finish improvement.

Finishing and polishing make nitinol tubes last longer and work better.

Electropolishing is the best way to get a smooth and clean surface.

These steps help you meet strict rules for medical devices, like better biocompatibility and stopping corrosion.

You often add cold work to the annealed tube, usually about 30%. You use mandrels in the last drawing step to control tube size and surface quality. Centerless grinding helps you match the exact size customers want, which affects the final finish.

Alloy Purity

You need to pick nitinol alloy that is very pure for the best NiTi tubing surface finish improvement. Bad stuff in the alloy can make the surface worse and lower corrosion resistance. You should always check the alloy before you start finishing. Pure alloy makes polishing and cleaning work better.

Initial Cleaning

You must clean the tubing before you do any surface finishing. This step gets rid of oils, dirt, and other things that can mess up the process.

Here is a table that shows common cleaning methods and what is good about each:

Cleaning Method | Advantages |

|---|---|

Vapor Degreasing | Cleans fast, removes oils and dirt well, works with metals |

Aqueous and Semi-Aqueous Cleaning | Takes away dirt and things that mix with water, helps the environment |

Modified Alcohol and Hydrocarbon | Better for the environment, cleans well in special conditions |

Mechanical and Physical Cleaning | Works with chemical cleaning, good for taking off scale and dirt |

You should pick the cleaning method that fits your tubing and your goals for helping the environment. Clean tubing helps you get the best NiTi tubing surface finish improvement.

You will face many problems in NiTi tubing surface finish improvement. Advanced treatments, hard manufacturing steps, and strict quality rules all matter. You must meet tough requirements, like inside surface roughness of Ra ≤ 1.2μm and outside surface roughness of Ra ≤ 0.6μm. Careful polishing stops damage and helps the tubing work its best.

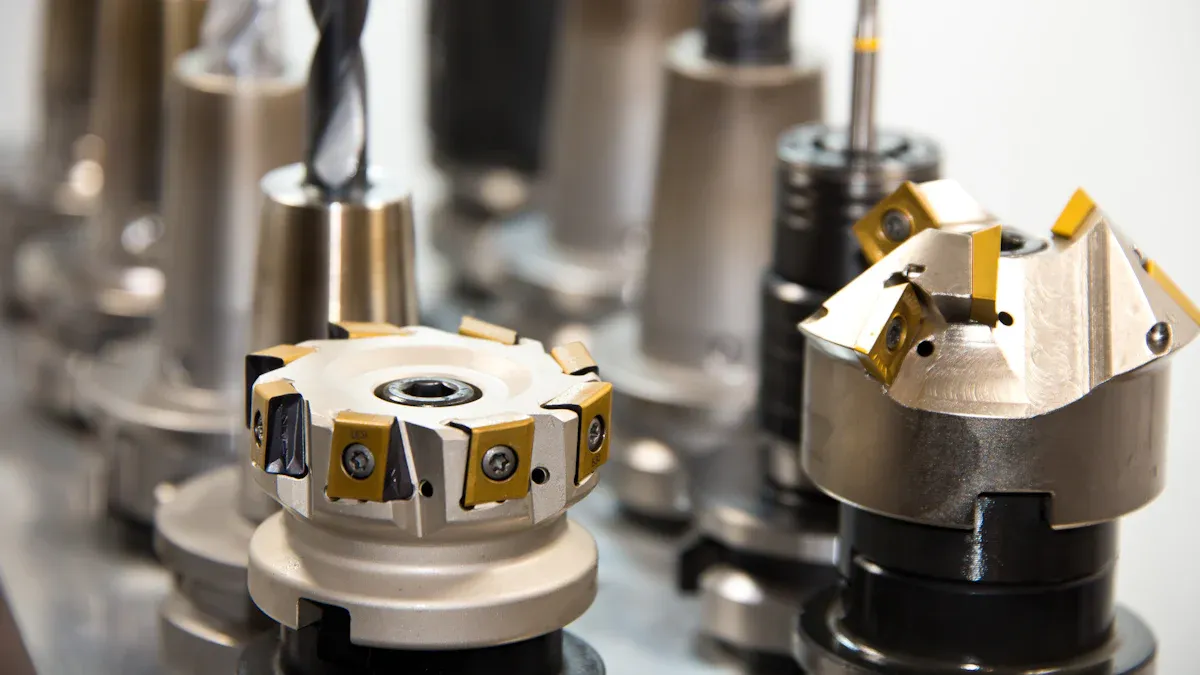

Surface Finishing Methods

There are many ways to make NiTi tubing smoother. Each way helps you get a better finish. It also makes the tubing safer for people and machines. Picking the right method gives you a smooth surface. It also helps stop rust and makes the tubing work well in the body.

Here are the main types of surface finishing methods for NiTi tubing:

Electropolishing

Passivation

Grit or media blasting

Vibratory tumbling

Chemical etching

Ultrasonic cleaning

Ultrasonic vapor degreasing

Choosing the best method lets you control how rough or smooth the tubing is. You can see in the chart how polishing time and speed change the finish.

Rotational Speed (rpm) | Polishing Time (s) | Surface Roughness (Ra) (nm) |

|---|---|---|

600 | 120 | 170 |

1200 | 120 | 30 |

1800 | 120 | 80 |

600 | 150 | Not reduced further |

1200 | 150 | Not reduced further |

1800 | 150 | Not reduced further |

Tip: Always pick the method that fits your tubing. This helps you get a smooth finish and keeps your product safe.

Electropolishing and Mechanical Polishing

Electropolishing and mechanical polishing both make NiTi tubing smooth. Electropolishing uses electricity and a special liquid to take away tiny bumps. This makes the tubing shiny and smooth. Mechanical polishing uses tools and rough materials to rub the tubing smooth.

Electropolishing works best with 12.5% H2SO4, 20 volts, and 2 minutes. If you change these, the tubing might get rough or have problems. Electropolishing makes the tubing easy to clean and safe to use. Mechanical polishing can mess up the crystal structure and push dirt into the surface.

Surface Treatment | Surface Quality | Contaminant Removal |

|---|---|---|

Mechanical Polishing | Distorted crystal structure | Surface impurities embedded |

Electropolishing | Smooth finish | Optimal cleanability and sterility |

Magnetic Abrasive Finishing (MAF)

Magnetic abrasive finishing helps make NiTi tubing smoother. This method uses a magnetic brush to cut and shape the surface. The brush takes away bumps and makes the surface very smooth. MAF is good for inside surfaces and tricky shapes.

MAF makes the surface better and less rough.

It works well for inside parts of NiTi tubing.

Many industries use MAF for a smooth finish.

The magnetic brush can reach hard-to-finish shapes.

Surface Roughness (Ra) | Description |

|---|---|

0.104 µm | Minimum predicted surface roughness after optimization |

0.122 µm | Measured surface roughness after magnetic finishing process |

Ultrasonic Nano-Crystal Surface Modification (UNSM)

Ultrasonic nano-crystal surface modification makes NiTi tubing stronger and smoother. UNSM builds a tiny layer with lots of small grains. This layer helps nitrogen go into the surface and makes a thick, even coat. The new layer sticks well and does not crack easily.

Enhancement Type | Description |

|---|---|

Surface Integrity | UNSM gives better surface layers. |

Mechanical Properties | UNSM makes the tubing stronger. |

Wear Resistance | UNSM helps the tubing last longer. |

Corrosion Resistance | UNSM stops rust and makes tubing last. |

Fatigue Resistance | UNSM lowers the chance of breaking from stress. |

Alkaline Electrolytic Polishing

Alkaline electrolytic polishing helps NiTi tubing get a smooth finish and stops rust. This method takes off scratches, burrs, and tough spots. You must wash off grease and glue, clean welds, and check that welds are tight. You can pick how smooth you want the tubing and add drain holes if needed.

Take off scratches and marks from making the tubing.

Remove big burrs with tumbling or vibratory finishing.

Wash off all soap-based grease.

Take off glue or coatings.

Pick the smoothness (Ra value).

Make sure welds are tight and even.

Clean weld spots.

Remove tough scale from heat treating.

Add drain holes to welded parts.

Make sure blasted parts look even.

Use good electropolishing wire for wire parts.

Ask for a 2B finish on sheet metal for a shiny look.

Alkaline electrolytic polishing changes the oxide layer on NiTi tubing. You get a thick, smooth surface with no tiny cracks or holes. This helps the tubing fight rust.

Chemical Etching

Chemical etching changes the surface of NiTi tubing. This method uses special liquids to make new shapes on the surface. HCl/H2SO4 gives the tubing a special shape. NH4OH/H2O2 makes deep cracks that help cells stick and grow. H2SO4/H2O2 makes new compounds that help the finish.

HCl/H2SO4: Makes a special surface shape and feel.

NH4OH/H2O2: Makes deep cracks for cells to stick and grow.

H2SO4/H2O2: Makes compounds that help the finish.

Always pick the finishing method that fits your tubing. The right method gives you a smooth finish, keeps people safe, and helps your product last longer.

Achieving High Surface Finish and Biocompatibility

Passivation Treatments

Passivation treatments help NiTi tubing look better and work safely. These treatments make a strong titanium oxide layer on the tubing. This layer keeps the tubing safe and stops rust. Nitric acid or citric acid are used to clean away free iron. They help make a passivation film. The film lowers rust and stops nickel from leaking out.

Passivation treatments make NiTi tubing safer for people. The tubing gets better at fighting rust. Less nickel stays on the surface. Fewer nickel ions get out, so patients are safer.

Here is a table that shows how passivation treatments help biocompatibility:

Evidence Description | Impact on Biocompatibility |

|---|---|

Surface passivation techniques increase corrosion resistance of nitinol. | Higher corrosion resistance correlates with reduced nickel leaching, enhancing biocompatibility. |

Passivation treatments decrease NiO2 and NiO concentrations, increasing stable TiO2. | Lower nickel concentration in the surface layer improves corrosion resistance. |

Potentiodynamic tests show higher breakdown potentials after passivation. | Enhanced breakdown potentials indicate better corrosion resistance, improving biocompatibility. |

You can use mechanical polishing, electropolishing, or chemical treatments to make the tubing stronger. Magnetoelectropolishing helps by making the surface smoother. It also builds a stable oxide layer. These steps make the tubing last longer and safer for people.

Special Coatings

Special coatings help NiTi tubing work better and safer. You can pick coatings like parylene or blue oxide. These coatings stop rust and lower blood clot risk. They also keep proteins from sticking. Blue oxide coatings make the surface smoother and safer for medical tools.

Coating Type | Benefits |

|---|---|

Parylene | Prevents rust, reduces blood clot risk, and minimizes protein adhesion. |

Blue Oxide | Enhances surface finish and biocompatibility. |

You can use coatings with molecules like phosphorylcholine. These help lower blood clot risk. These treatments help meet tough medical rules. They also make devices safer and last longer.

Preventing Ni Ion Release

You need to stop nickel ions from leaving the tubing. This keeps patients safe. Treatments can make the oxide layer thicker. Salt-like deposits block tiny cracks and help stop nickel from getting out. Surface treatments build thick TiO2-x films that act as shields.

TiN coatings slow down rust and cut nickel leaking by 35% in fake blood.

PPy coating, silicon carbide coating, and laser treatment lower nickel release.

Chemical treatments and anodization also help lower nickel in the surface layer.

Here is a table that shows how different treatments lower nickel release:

Method | Effectiveness in Reducing Nickel Release |

|---|---|

PPy Coating | Reduced nickel release by half |

Silicon Carbide Coating | Reduced nickel release by more than 90% |

Laser Surface Treatment | Significant reduction in nickel release |

Surface Treatment Techniques | Decreased nickel concentration in surface layer |

You must follow strict rules for nickel ion release. The U.S. Pharmacopeia says the limit is 50 μg/day. ICH-Q3D says the limit is 20 μg/day for medical devices. These treatments help you stay safe and protect people.

Quality Control for NiTi Tubing

Quality control makes sure NiTi tubing is safe and strong. You need to check the surface and look for problems. Every step must work well. Good quality control keeps tubing ready for medical jobs. It also helps stop rust and meets medical rules.

Surface Roughness Measurement

You have to check how rough the tubing is. Smooth tubing is safer for the body. It also lasts longer. There are many ways to measure roughness. Each way gives you useful details about the surface.

Technique | Description |

|---|---|

Optical Scattering | Uses sound waves to check roughness by looking at data. |

Microscopy Techniques | Lets you see tiny bumps for good results on any surface. |

In-Process Surface Assessment | Watches the surface while the tubing is being made. |

Inductance Measurement | Uses magnets to check roughness on magnetic surfaces. |

Machine-Based Measurement | Digital tools look at the surface and compare it to charts. |

Ultrasound Measurement | Uses sensors to send sound and check roughness very well. |

Pick the best way for your tubing and needs. Good measuring helps stop rust and keeps tubing safe for medical use.

Visual and Microscopic Inspection

You need to look at the tubing to find cracks or marks. Looking with your eyes helps you find problems fast. If you see something wrong, you can do more tests. This is important because small problems can cause big trouble in medical tubing.

Inspection Method | Advantages | Limitations |

|---|---|---|

Direct visual inspection | Simple, no tools needed | Depends on who checks |

Industrial microscopes | Finds tiny problems without hurting tubing | Tubing might not fit |

Automated cameras | Fewer mistakes, better quality | Can be expensive |

Borescopes | Lets you see inside hard places | Must choose the right one |

Looking at tubing helps you find cracks and marks.

It is important for checking NiTi tubing.

If you find a problem, you might need more tests.

Note: Looking at tubing gives you a quick idea of quality. It helps you know if tubing is ready or needs fixing.

Process Validation

You must check each step to get good tubing every time. Process validation helps you stop rust and follow medical rules. You need to check things like laser cutting and oxidation. You also need to follow rules like ISO 25539 and ASTM F86.

Use good finishing steps like chemical etching and electropolishing.

Set goals for smoothness (outer Ra≤ 0.4μm, inner Ra≤ 0.6μm).

Fix problems and help stop rust with each step.

Make sure every batch meets medical rules for rust and smoothness.

Keep records of your steps and test results. This helps you show your tubing is safe and will not rust in the body.

You can make NiTi tubing look and work better with electropolishing and passivation. Electropolishing gives the tubing a smooth and shiny surface. It also lowers the amount of nickel, which makes it safer for medical use. You should pick the right process and use good polishing methods. Strong quality checks are important too. Always check your steps and try new ideas to keep tubing safe and strong.

Surface Finish | Breakdown Potential (mV) | Surface Nickel Concentration (%) |

|---|---|---|

Electropolished (EP) | Up to 1000 | Reduced from 11.5 to 1 |

Oxidized Tubing | -117 | N/A |

Electropolishing makes the tubing less rough and stops rust.

Passivation builds a safe oxide layer on the tubing.

FAQ

What is the best way to clean NiTi tubing before finishing?

You can clean NiTi tubing with vapor degreasing or aqueous cleaning. These cleaning methods take away oil and dirt. Clean tubing helps you get a smooth finish. It also helps stop rust.

How does electropolishing improve NiTi tubing?

Electropolishing takes off tiny bumps from the tubing. It makes the tubing shiny and smooth. This helps stop rust and lowers nickel release. Electropolishing makes tubing safer for medical use.

Can you measure surface roughness easily?

You can use optical tools or digital machines to check roughness. These tools give fast results. Smooth tubing lasts longer and works better in the body.

Why do you need special coatings on NiTi tubing?

Special coatings like parylene or blue oxide help stop rust. They lower the chance of blood clots. These coatings help meet medical rules. They keep patients safer.

Does surface finish affect biocompatibility?

Yes. A smooth finish keeps nickel ions from leaking out. This lowers allergy risk. It helps healthy cells grow. Good surface finish makes tubing safer for people.

See Also

A Comprehensive Approach to Choosing Nitinol Tubing

Finding the Ideal Nitinol Tubing Supplier for You

The Influence of NiTi Tubing Testing on Longevity

The Process of Producing Nitinol Tubing for Healthcare

Identifying the Most Cost-Effective 2mm Nitinol Tubing Supplier