How NiTi Medical Guidewires Are Designed and Manufactured

NiTi medical guidewires are transforming healthcare with their exceptional properties and advanced engineering. You might find it fascinating that the demand for these guidewires is steadily increasing. For instance:

The Nitinol-based guide wire market is projected to grow at a remarkable CAGR of 8.1% from 2021 to 2028.

In the Middle East and Africa, countries like Turkey and South Africa are seeing guidewire market growth rates of 6.2% and 7.7%, respectively.

These trends highlight the growing preference for minimally invasive procedures. NiTi alloys, known for their biocompatibility, play a crucial role in meeting this demand, ensuring safer and more effective medical solutions.

Key Takeaways

NiTi medical guidewires are important for less invasive surgeries. They help patients by making treatments safer and more accurate.

NiTi has special features like bending easily and keeping its shape. These features help guidewires move through tricky body pathways.

Special ways of making them, like heating and careful shaping, make sure the guidewires are high-quality and work well.

Coatings, like slippery layers, make guidewires slide easily and safe for the body. This helps make surgeries safer.

Strict rules and careful testing make sure NiTi guidewires are safe and dependable for doctors to use.

What Are NiTi Medical Guidewires?

Importance of NiTi medical guidewires in healthcare

NiTi medical guidewires play a vital role in modern healthcare. Their unique properties make them indispensable in minimally invasive procedures. These guidewires improve patient outcomes by enabling safer and more precise interventions. For example, their biocompatibility ensures they interact safely with human tissue, reducing the risk of adverse reactions. Additionally, their resistance to corrosion allows them to perform reliably in the challenging environment of the human body.

NiTi guidewires are especially valuable in procedures requiring flexibility and strength. They navigate complex anatomical pathways while maintaining the stiffness needed to push through blockages. This combination of features leads to quicker recovery times and fewer complications for patients.

Here’s a breakdown of their advantages:

Advantage | Description |

|---|---|

Biocompatibility | Ensures safe interaction with human tissue, minimizing risks of adverse reactions. |

Resistance to corrosion | Provides durability when exposed to bodily fluids, ensuring long-lasting performance of devices. |

Flexibility and strength | Allows for effective navigation in minimally invasive surgeries, leading to quicker recovery times. |

Navigational capabilities | Offers stiffness for pushing through blockages and flexibility for navigating anatomical curves. |

These benefits highlight why medical guidewires are essential tools in healthcare today.

Key properties and benefits of NiTi medical guidewires

NiTi medical guidewires owe their effectiveness to the remarkable properties of the nickel-titanium alloy. One of the most notable features is superelasticity. This property allows the guidewires to bend and return to their original shape without permanent deformation. It ensures they can handle the stresses of navigating through the body’s intricate pathways.

Another critical property is shape memory. This means the guidewires can return to a pre-set shape when exposed to specific temperatures. This feature is particularly useful in self-expanding stents and other medical devices. Furthermore, NiTi guidewires exhibit excellent fatigue resistance, making them durable even under repeated use.

Studies have shown that these properties enhance the performance of medical devices. For instance:

Nitinol’s superelasticity allows for minimally invasive insertion of devices.

Its corrosion resistance and biocompatibility make it suitable for long-term implantation.

It provides temperature-dependent stiffness, crucial for self-expanding stents.

These features make NiTi guidewires a cornerstone of modern medical technology. They ensure safety, reliability, and effectiveness in a wide range of applications.

Materials Used in Medical Guidewires

Nickel-titanium (NiTi) alloy and its properties

Nickel-titanium, or NiTi, is the backbone of many medical guidewires. Its unique properties make it ideal for navigating the human body during minimally invasive procedures. One standout feature of NiTi is its shape memory. This means the material can return to its original shape after being bent or deformed. For you, this translates to a guidewire that adapts to the body’s curves without losing its functionality.

Another remarkable property is superelasticity. NiTi guidewires can stretch and bend significantly without breaking. This flexibility allows them to move through complex anatomical pathways with ease. Additionally, NiTi is highly resistant to corrosion, ensuring durability even in the challenging environment of the human body. These properties not only improve the performance of guidewires but also enhance patient safety by reducing the risk of complications.

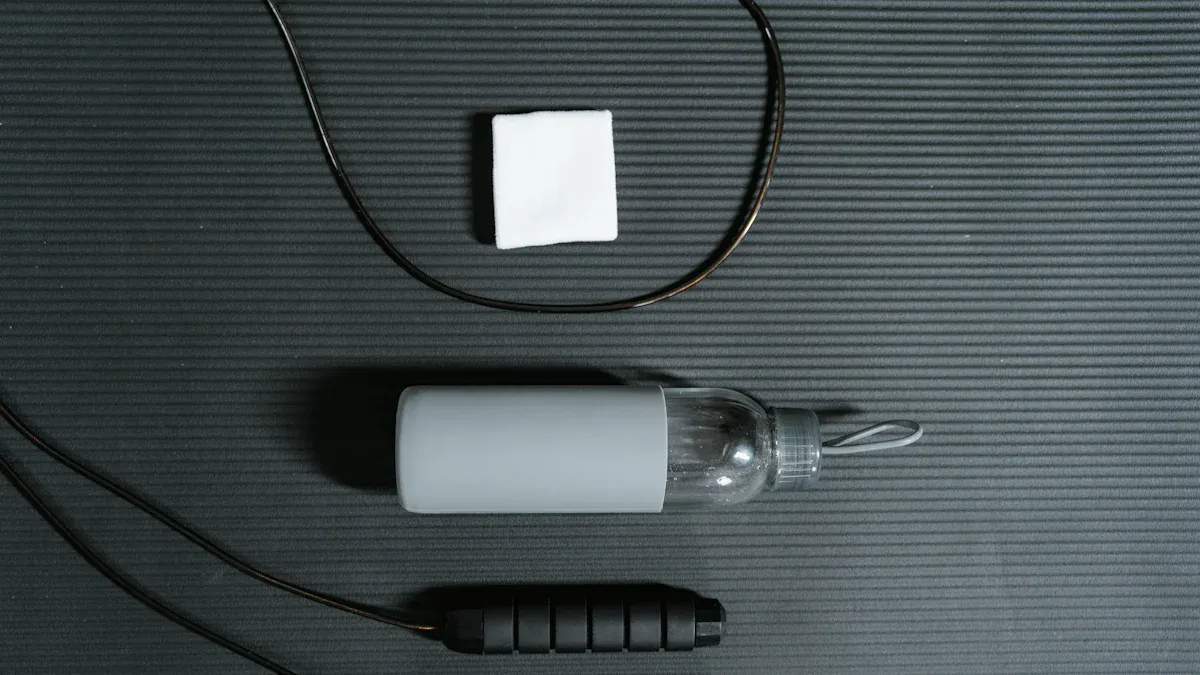

Additional materials and coatings in guidewire design

While NiTi is a key material, other materials and coatings play a crucial role in optimizing medical guidewires. Stainless steel, for example, provides stability and strength. Hybrid designs often combine a stainless steel core with a NiTi outer layer, offering both rigidity and flexibility. Polymers and composites are also common. They reduce friction and improve biocompatibility, ensuring smoother navigation and safer interactions with tissues.

Coatings further enhance the performance of guidewires. Hydrophilic coatings, for instance, reduce friction, making it easier to maneuver the guidewire through blood vessels. A study comparing hydrophilic-coated guidewires to conventional ones found that the coated versions had higher success rates and fewer complications. This highlights how coatings can improve clinical outcomes and patient safety.

The materials used in medical guidewires, along with advanced coatings, ensure these tools meet the demands of modern medicine. By combining strength, flexibility, and biocompatibility, they provide reliable solutions for complex procedures.

Guidewire Manufacturing Process

Material preparation and alloying

The journey of creating NiTi medical guidewires begins with material preparation and alloying. This step ensures the nickel-titanium alloy achieves the desired properties for medical applications. Advanced techniques like laser powder bed fusion (L-PBF) play a crucial role in this process. L-PBF allows you to produce complex metallic structures with high precision, which is essential for the performance of guidewires. By adjusting parameters such as laser power and scanning speed, manufacturers can tailor the phase transformation temperatures of the alloy. This customization ensures the guidewires exhibit the required shape memory and superelasticity.

Vacuum casting is another critical method used during alloying. It prevents impurities from contaminating the material, which could lead to harmful secondary phases. This step enhances the corrosion resistance of the guidewires, ensuring their durability in the human body. These precision manufacturing solutions ensure the alloy meets the high standards required for medical guidewire manufacturing processes.

Wire drawing and shaping techniques

Once the alloy is prepared, the next step involves wire drawing and shaping. This process transforms the raw material into thin, flexible wires suitable for medical use. During wire drawing, the alloy is pulled through a series of dies to achieve the desired diameter. This technique requires extreme precision to ensure the wires maintain uniform thickness and strength.

Shaping techniques further refine the guidewires. These methods allow you to create specific designs that enhance the navigational capabilities of the wires. For example, tapering the ends of the wires improves their ability to move through narrow or curved pathways. The combination of wire drawing and shaping ensures the guidewires are both strong and flexible, meeting the demands of modern medical procedures.

Micro-grinding and surface finishing

The final steps in the guidewire manufacturing process involve micro-grinding and surface finishing. These techniques enhance the performance and safety of the guidewires. Micro-grinding removes excess material, ensuring the wires achieve the precise dimensions required for medical applications. Surface finishing smooths the wires, reducing friction and improving their interaction with human tissue.

Key metrics like material removal rate (MRR), surface roughness, and dimensional accuracy determine the success of these techniques. Factors such as pulse current and the number of passes during grinding significantly impact the surface quality. By optimizing these parameters, manufacturers can produce guidewires with superior performance and reliability. These steps ensure the guidewires meet the highest standards of quality and precision, making them indispensable tools in healthcare.

Heat treatment for shape memory and superelasticity

Heat treatment plays a critical role in the guidewire manufacturing process. It ensures that NiTi medical guidewires achieve their unique properties of shape memory and superelasticity. During this step, manufacturers expose the nickel-titanium alloy to carefully controlled temperatures, typically ranging from 400° to 500°C. This thermal process sets the final shape of the guidewires and enhances their ability to return to their original form after deformation.

The heat treatment process also involves balancing residual cold work. This step prevents permanent deformation while maintaining the flexibility and strength required for medical applications. For instance, after approximately 30% or more of cold work, the alloy undergoes heat treatment to optimize its mechanical properties. This ensures the guidewires can handle the stresses of navigating through complex anatomical pathways without losing their structural integrity.

By fine-tuning the thermal profile, manufacturers achieve the precision needed to produce high-quality guidewires. This step not only enhances the performance of the guidewires but also ensures their reliability in critical medical procedures.

Coating and sterilization processes

The final stages of the guidewire manufacturing process involve coating and sterilization. Coatings are essential for improving the performance and safety of medical guidewires. Hydrophilic coatings, for example, reduce friction, allowing the guidewires to glide smoothly through blood vessels. This minimizes the risk of tissue damage and enhances the overall success rate of medical procedures. Additionally, some coatings improve biocompatibility, ensuring the guidewires interact safely with human tissue.

Sterilization is the last step before the guidewires are ready for use. This process eliminates any potential contaminants, ensuring the guidewires meet strict medical safety standards. Common sterilization methods include ethylene oxide gas and gamma radiation. These techniques effectively kill bacteria and other microorganisms without compromising the structural integrity of the guidewires.

Together, coating and sterilization ensure that medical guidewires are not only functional but also safe for use in healthcare settings. These steps highlight the precision and care involved in the guidewire manufacturing process, ensuring these tools meet the highest standards of quality and reliability.

Challenges in the Medical Guidewire Manufacturing Process

Managing the unique properties of NiTi

Working with nickel-titanium (NiTi) presents unique challenges due to its specialized properties. Its superelasticity and shape memory, while beneficial in medical applications, require careful handling during manufacturing. For example, achieving the right balance between flexibility and stiffness demands precise control over the alloy's composition and heat treatment. Without this balance, the guidewires may fail to perform as intended.

Performance testing validates strategies for managing these properties. For instance, composite wires with a NiTi core undergo rigorous tests like tensile and torque control testing. These tests ensure the wires maintain strength and flexibility under stress. The table below highlights key performance data:

Aspect | Details |

|---|---|

Composite Wire Type | 35Co-35Ni-20Cr-10Mo outer shell with a NiTi core |

Diameter | 0.34 mm (0.0135 in.) |

Production Method | Drawn filled tube (DFT) |

Cold-Reduction Ratios | 20 to 60% reduction of area |

Key Properties | Strong, stiff, superelastic; improved crossing of chronic total occlusions (CTOs) |

These efforts ensure that NiTi guidewires meet the high standards required for medical use.

Precision and scalability in production

Precision is critical in guidewire manufacturing. Achieving sub-micron tolerances ensures the wires meet exact specifications, which is essential for their reliability in medical procedures. Advanced grinding systems, such as those using dual-carriage linear motors, enhance precision and efficiency. These systems adapt to varying technical requirements, ensuring consistent results across production batches.

Scalability adds another layer of complexity. High throughput and precision must coexist to meet growing global demand. Cleanroom environments, like ISO 14644 Class 8, maintain product quality during mass production. Additionally, state-of-the-art technology minimizes downtime and ensures consistent output. This combination of precision and scalability supports the production of high-quality guidewires on a large scale.

Feature | Description |

|---|---|

Sub-micron tolerances | Achieves tolerances as tight as +/- .0001” in diameter, ensuring accuracy and reliability. |

Rapid Production | Capable of meeting project deadlines without compromising on quality. |

ISO 14644 Class 8 Cleanroom | Maintains a controlled environment for consistent product quality. |

Cost considerations in manufacturing

Manufacturing NiTi guidewires involves higher costs compared to alternatives like stainless steel. The complex processes required to handle NiTi, along with the cost of raw materials, contribute to this expense. However, the benefits often outweigh the costs. NiTi's superior flexibility and control reduce complications during procedures, leading to better patient outcomes.

Economic studies highlight how these advantages justify the investment. For example:

Nitinol guidewires, while more expensive, perform better in specialized procedures.

Their durability and biocompatibility reduce the need for replacements, saving costs in the long term.

By focusing on efficiency and innovation, manufacturers can manage costs while maintaining the quality of these essential medical tools.

Quality Control in Medical Guidewire Manufacturing Process

Testing for mechanical properties and biocompatibility

Testing ensures that medical guidewires meet the highest standards of safety and performance. Mechanical property tests evaluate the strength, flexibility, and durability of the guidewires. These tests simulate real-world conditions to confirm that the guidewires can handle the stresses of medical procedures. For example, load testing identifies performance bottlenecks, while stress testing ensures the guidewires remain functional under extreme conditions. Advanced analytics monitor trends and performance metrics, ensuring compliance with service level agreements.

Biocompatibility testing is equally important. It ensures that the materials used in the guidewires interact safely with human tissue. This process involves rigorous evaluations to confirm that the guidewires do not cause adverse reactions or toxicity. By combining mechanical and biocompatibility testing, manufacturers guarantee that the guidewires are both effective and safe for medical use.

Regulatory compliance and certifications

Regulatory compliance plays a critical role in the manufacturing process. You must ensure that guidewires meet the stringent requirements set by organizations like the FDA and ISO. These regulations cover every aspect of production, from material selection to final testing. Certifications such as ISO 13485 demonstrate that the manufacturing process adheres to international quality standards.

Achieving compliance involves thorough documentation and regular audits. Manufacturers must maintain detailed records of every step in the production process. This transparency ensures that the guidewires meet all regulatory requirements. By prioritizing compliance, you can trust that the guidewires are safe, reliable, and ready for use in medical procedures.

Ensuring consistency and reliability

Consistency and reliability are essential in guidewire production. Automated systems enhance the precision of testing processes, reducing errors and improving operational efficiency. These systems create a stable testing environment by following predefined instructions. Reusable test cases further improve test management and profitability.

Manufacturers also focus on maintaining uniformity across production batches. Advanced technologies ensure that every guidewire meets the same high standards. This consistency builds trust in the reliability of the guidewires, making them indispensable tools in healthcare. By prioritizing precision and quality, manufacturers deliver guidewires that perform flawlessly in critical medical applications.

NiTi medical guidewires represent a breakthrough in modern healthcare. Their advanced materials and precision engineering make them essential for minimally invasive procedures. You can trust that the manufacturing process ensures these tools meet the highest standards of safety and performance. As innovation continues, these guidewires will play an even greater role in improving medical outcomes. Their unique properties, like shape memory and superelasticity, will keep driving advancements in healthcare, making procedures safer and more effective for patients worldwide.

FAQ

What makes NiTi guidewires different from other materials?

NiTi guidewires stand out due to their shape memory and superelasticity. These properties let them bend and return to their original shape, making them ideal for navigating complex anatomical pathways. Their corrosion resistance and biocompatibility also ensure safety and durability during medical procedures.

How are NiTi guidewires sterilized before use?

Manufacturers sterilize NiTi guidewires using methods like ethylene oxide gas or gamma radiation. These processes eliminate harmful microorganisms while preserving the guidewire's structural integrity. This ensures the guidewires are safe and ready for medical applications.

Why is heat treatment important in NiTi guidewire production?

Heat treatment enhances the shape memory and superelasticity of NiTi guidewires. By exposing the alloy to controlled temperatures, manufacturers set the guidewire's final shape and improve its flexibility. This step ensures the guidewires perform reliably in demanding medical procedures.

Are NiTi guidewires suitable for long-term use in the body?

Yes, NiTi guidewires are highly biocompatible and resistant to corrosion. These properties make them suitable for long-term use in the human body. Their durability ensures they maintain performance without causing adverse reactions or degradation over time.

What coatings improve the performance of NiTi guidewires?

Hydrophilic coatings reduce friction, allowing smoother navigation through blood vessels. Some coatings also enhance biocompatibility, ensuring safe interaction with tissues. These improvements make the guidewires more effective and safer for minimally invasive procedures.

See Also

The Process Behind Manufacturing Nitinol Tubing for Medicine

Nitinol Tubing's Impact on the Future of Medical Devices

The Importance of Nitinol Tubing in Modern Medical Uses

Nitinol Tubing's Contribution to Progress in Medical Technology