What is NiTi Alloy Tubing and Why is it Unique

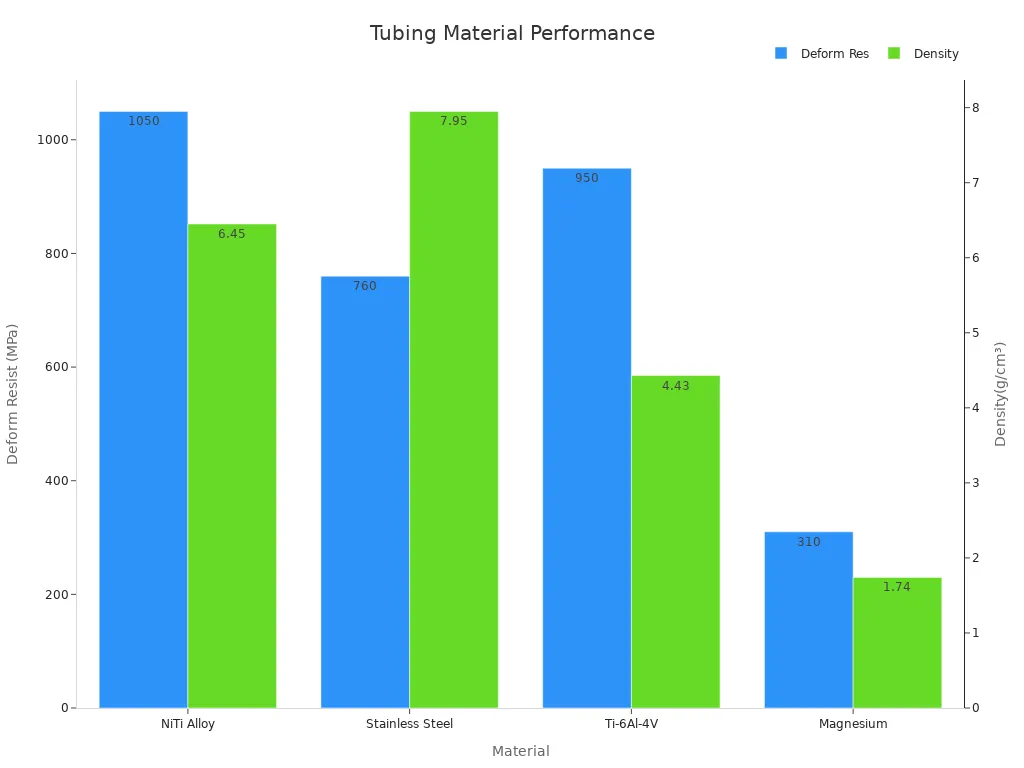

NiTi alloy tubing, also known as nitinol, combines nickel and titanium to form a nickel-titanium alloy with remarkable properties. This tubing stands out from stainless steel and other metals because of its superelasticity and shape memory. The chart below shows that nitinol offers higher deformation resistance and a lower density than stainless steel, making it ideal for medical implants that require both strength and flexibility.

Niti alloy tubing absorbs more energy and matches the flexibility of bone better than most metals. These unique characteristics allow nitinol to support advanced medical and high-performance applications where traditional materials fall short.

Key Takeaways

NiTi alloy tubing, also called nitinol, can bend and return to its original shape thanks to its shape memory and superelasticity.

This tubing is safe for medical use because it resists corrosion and does not harm body tissues.

NiTi tubing is flexible and strong, making it ideal for medical devices like stents and catheters, as well as aerospace and robotic parts.

Manufacturing NiTi tubing requires precise control and advanced technology to keep its special properties consistent.

Despite higher costs, NiTi tubing offers unmatched durability and performance in demanding medical and industrial applications.

What is NiTi Alloy Tubing?

Nitinol Composition

Nitinol stands out because of its unique atomic structure. Scientists define nitinol by its nearly equal mix of nickel and titanium atoms. Most nitinol tubing contains about 50% nickel and 50% titanium by atomic percentage. This balance gives the alloy its special properties. For example, a 1.0 mm nitinol wire often shows 50.6% nickel and 49.4% titanium. Some commercial products, like nitinol 55, have 55.8% nickel by weight. The exact nickel-titanium ratio determines the tube’s behavior. Manufacturers use advanced tools, such as Energy Dispersive X-ray Spectroscopy, to confirm these percentages. This careful control ensures that every piece of niti alloy tubing performs as expected.

Tubing Sizes and Forms

Niti alloy tubing comes in many sizes and forms to meet different needs. Industry standards, such as ASTM F2633-07, set strict rules for medical nitinol tubing. Tubing can have outside diameters up to 10 mm and wall thicknesses up to 2 mm. Tolerances are tight, with inner and outer diameters within ±20 µm and wall thickness within ±15 µm. Most tubing is seamless and superelastic. Thin-wall tubes work well for microcatheters and other small devices. Manufacturers use processes like extrusion and heat treatment to make sure each tube keeps its shape memory. Surface finishing creates a smooth, biocompatible surface, which is important for medical uses.

Tip: Niti tubing’s precise dimensions and smooth finish make it ideal for delicate medical procedures.

Comparison to Other Materials

Nitinol offers several advantages over traditional metals. The table below compares key performance metrics for different types of niti:

Performance Metric | Heat-Activated NiTi | Superelastic NiTi | Conventional Metals |

|---|---|---|---|

Alignment Efficiency | High | High | Lower |

Force Exerted | Lower | Moderate | Higher |

Clinical Handling | Easier | Good | More Difficult |

Niti tubing, especially in superelastic and heat-activated forms, matches or outperforms conventional materials in many ways. For example, nitinol tubing can bend and return to its original shape, while stainless steel tubes may kink or deform. Niti’s microstructure, when made by copper boat induction melting, stays uniform and free of unwanted particles. This consistency helps the tube perform reliably in demanding settings.

NiTi Alloy Tubing Properties

Shape Memory Alloy Effect

Nitinol stands out because of its remarkable shape memory effect. This property allows nitinol tubing to return to its original shape after being bent or deformed. When heated above a certain temperature, the atoms inside the shape memory alloy move back into their original positions. This change happens because nitinol belongs to a group called shape memory alloys. These materials can "remember" their shape even after twisting or stretching.

Researchers have measured the shape memory effect in nitinol tubing using advanced tests. For example, studies show that nitinol tubes can recover up to 2.95% of their original shape after 600 heating and cooling cycles under high stress. Even after many cycles, the shape memory alloy keeps its ability to return to its starting form. The wall thickness and stress levels do not change this effect much within normal ranges. Scientists also found that heating nitinol tubing at 400 °C for 30 minutes keeps the shape memory effect stable. These results prove that nitinol tubing can handle repeated use in medical devices and other demanding applications.

Shape memory alloys like nitinol can be tuned by changing the nickel and titanium ratio or by using special heat treatments. This control lets engineers design tubing for specific tasks, such as a catheter that must bend inside the body and then return to its straight shape. The shape memory effect makes nitinol tubing a top choice for many advanced uses.

Superelasticity

Superelasticity is another key property of nitinol. This means the tubing can stretch or bend much more than regular metals and still snap back to its original shape. The superelastic effect happens at room and body temperatures, making it perfect for medical devices that need to move with the body.

Scientists test superelastic nitinol by pulling and twisting the tubing. They measure how much it stretches and how well it returns to its shape. Nitinol tubing shows a strain recovery of about 5.2% and a tensile strength near 500 MPa. Even after many cycles of bending and straightening, the tubing does not stay bent or lose its strength. Special machines and microscopes confirm that the shape memory alloy changes its structure during these tests, which explains the superelastic behavior.

Biaxial tension and torsion tests on nitinol tubes show that the tubing can handle forces from different directions. The tubing's microstructure changes during these tests, but it always returns to its original form. This property helps nitinol tubing resist kinks and damage, which is important for catheters and other flexible medical devices. Superelastic nitinol also matches the flexibility of bone, making it useful for implants that must move with the body.

Biocompatibility

Biocompatibility means that a material works safely inside the human body. Nitinol has excellent biocompatibility, which is why doctors use it in many medical devices. The surface of nitinol forms a thin layer of titanium oxide. This layer protects the shape memory alloy from releasing too much nickel, which could cause problems in the body.

Tests show that nitinol tubing does not cause allergic reactions or harm nearby tissues. In animal studies, nitinol implants did not show signs of corrosion or release of harmful metals. New bone formed normally around nitinol implants, and the bone contact was similar to other safe materials. Cytotoxicity tests with cells also showed that nitinol supports healthy cell growth.

Note: Long-term use of nitinol in medical devices, such as stents and orthopedic implants, proves its safety and reliability. Doctors have used nitinol for over 40 years in the body with good results.

Researchers also tested nitinol in fluids that mimic the human body, such as synovial fluid and saline. The tubing showed only mild corrosion and did not lose its main properties. The protective oxide layer stayed stable, especially when the tubing was processed correctly. This makes nitinol tubing a trusted choice for catheters and other devices that stay inside the body for a long time.

Corrosion Resistance

Corrosion resistance is a vital property for materials used in medical devices. Nitinol tubing resists corrosion better than many other metals. The titanium oxide layer on the surface acts as a shield, stopping harmful reactions with body fluids.

Laboratories test corrosion resistance by soaking nitinol tubing in solutions that copy human body fluids. They use special machines to measure how much metal dissolves and how the surface changes. Results show that electropolished nitinol tubing does not break down even at high voltages, while tubing with a rougher surface can corrode more easily. Aging the tubing at 450°C improves the stability of the oxide layer and reduces corrosion by up to 87%. However, aging at higher temperatures, like 650°C, lowers corrosion resistance.

Test Condition | Result/Description |

|---|---|

0.9% NaCl at 37°C | Simulates body fluids; nitinol tubing remains stable |

Electropolished Surface | No breakdown up to 1000 mV |

Oxidized Surface | Breakdown at around -117 mV |

450°C Aging | Reduces corrosion current density by ~87%, improves oxide layer |

650°C Aging | Reduces corrosion resistance, less stable oxide layer |

ASTM F2129 Standard | Ensures repeatable and reliable corrosion testing |

Surface finish and heat treatment play a big role in how well nitinol tubing resists corrosion. Damage to the oxide layer, such as from bending or rubbing, can make the tubing more likely to corrode. Careful processing and finishing help keep the tubing safe and long-lasting in medical devices.

Nitinol's corrosion resistance, combined with its shape memory effect, superelasticity, and biocompatibility, makes it one of the best choices for advanced medical and industrial uses.

How NiTi Works

Phase Transformations

Nitinol stands out because of its unique phase transformations. These changes at the atomic level give nitinol its famous shape memory effect and superelasticity. When nitinol cools, it shifts from a stiff austenite phase to a softer martensite phase. This transformation lets nitinol bend or stretch without breaking. When heated, nitinol returns to its original austenite phase, snapping back to its first shape. This is the core of the shape memory effect.

Scientists have found that small changes in nickel content can shift the temperatures where these phase changes happen. By controlling the nickel and titanium mix, they can tune the shape memory effect for different uses. Heat treatments also play a big role. For example, aging nitinol forms tiny Ni4Ti3 particles. These particles create stresses that help the martensite phase form more easily. This makes the shape memory effect stronger and more reliable.

Nitinol’s austenite phase is rigid and strong.

The martensite phase is flexible and resists cracks.

The balance between these phases controls how nitinol bends and returns to shape.

Tests like differential scanning calorimetry and X-ray diffraction help scientists measure these phase changes. They show that the shape memory effect and superelasticity come from these reversible transformations. Nitinol can handle repeated bending and stretching because of this special behavior.

Temperature and Stress Response

Nitinol’s response to temperature and stress sets it apart from other metals. When nitinol tubing faces stress, it can change from austenite to martensite even without cooling. This stress-induced transformation is key to the shape memory effect and superelasticity. When the stress is removed, nitinol returns to its original phase and shape.

Research shows that nitinol tubing can handle large temperature swings. For example, when compressed or stretched, nitinol can heat up by as much as 21 K and cool down by 11 K. These temperature changes happen because of the energy used in the phase transformation. The shape memory effect allows nitinol to recover its shape after these cycles, even under repeated loading.

Nitinol’s melting point is about 1,310°C, and its density is around 6.45 g/cm³. These values help nitinol keep its shape memory effect and superelasticity in tough environments. Scientists use digital image correlation and advanced models to study how nitinol behaves under stress. They find that the martensite phase slows crack growth, making nitinol tubing safer for repeated use.

Tip: The shape memory effect in nitinol can be tuned by changing the nickel content or using special heat treatments. This lets engineers design tubing for specific temperatures and stress levels.

Nitinol’s ability to switch phases under heat or stress explains why it works so well in medical and high-performance devices. The shape memory effect and superelasticity come directly from these phase transformations, making nitinol tubing a top choice for demanding applications.

Medical and Industrial Applications

Medical Uses

Nitinol has changed the way doctors use medical devices. Its shape memory and superelasticity make it perfect for advanced medical tools. Many medical applications rely on nitinol tubing for flexibility and strength. Doctors use nitinol in stents, guidewires, and catheter systems. These devices help treat cardiovascular diseases and reach hard-to-access areas in the body. For example, Medtronic’s Harmony transcatheter pulmonary valve and Edwards Lifesciences Sapien M3 mitral valve system use nitinol for reliable catheter delivery and performance. Nitinol medical devices can bend and return to their original shape, which helps with safe delivery through small blood vessels.

Medical-grade nitinol tubing supports implants such as self-expanding stents and orthopedic devices. These implants match the flexibility of bone and resist kinking. Nitinol’s biocompatibility means it works safely inside the body. FDA guidance highlights nitinol’s mechanical behavior as better than traditional alloys for medical device design. Over 50 million nitinol tubes go into medical devices each year. The medical sector makes up 58% of the global nitinol tube market. Doctors choose nitinol for its durability, safe delivery, and ability to support minimally invasive procedures. As the population ages, demand for nitinol medical devices continues to grow.

Aerospace and Technology

Nitinol also plays a key role in aerospace and technology applications. Engineers use nitinol tubing in aircraft hydraulic and fuel systems. These tubes weigh less than steel but handle high pressure, which improves fuel efficiency. Nitinol’s superelasticity helps absorb vibrations, protecting sensitive equipment during flight. The alloy’s fatigue resistance ensures reliability through many takeoff and landing cycles.

In robotics, nitinol tubing creates flexible arms and grippers. These components perform complex tasks in tight spaces. Nitinol actuators work in spacecraft, where they survive extreme temperatures and stress. Military and defense systems use nitinol for impact-resistant structures and advanced weapon systems. The shape memory effect allows for compact actuators that replace heavier systems. Each year, aerospace uses about 15 million nitinol tubes, while industrial actuators use around 10 million. The global nitinol tube market reached $1.2 billion in 2023, with a forecasted growth rate of 6-7% per year.

Application Segment | Annual NiTi Tube Usage (Units) | Key Drivers / Notes |

|---|---|---|

Medical Device Manufacturing | >50 million | Largest segment; driven by minimally invasive procedures |

Aerospace & Defense | ~15 million | Lightweight, corrosion-resistant components |

Industrial Actuators | ~10 million | Shape memory effect and durability |

Nitinol’s unique properties—flexibility, durability, and biocompatibility—make it essential for both medical and industrial applications.

Challenges and Limitations

Manufacturing

Manufacturing NiTi alloy tubing presents unique challenges. The process requires precise control over composition and temperature. Small changes in nickel or titanium content can affect the tubing’s properties. Advanced techniques, such as Selective Laser Melting (SLM) and Laser Engineered Net Shaping (LENS), help create strong and reliable tubes. However, these methods demand careful adjustment of scanning strategies, oxygen levels, and heat treatments.

Mechanical Property | Manufacturing Technique / Strategy | Key Findings / Impact on Mechanical Properties | Reference |

|---|---|---|---|

Hardness | Additive manufacturing (SLM, LENS), alloy composition control | Rapid cooling in AM leads to grain refinement and increased hardness; SLM-NiTi microhardness (540–735 HV) is higher than LENS-NiTi (380 HV); increasing Ti content raises hardness (Ni45Ti: 525 HV) | Shiva et al. [[107]] |

Hardness | Repetitive scanning strategy in SLM | Produces functionally graded microstructure with increased martensite B19’ phase, resulting in excellent strain hardening effect (>300 MPa) | Yang et al. [[108]] |

Compressive Strength | SLM with different porosity structures (dense, SC, BCC) | Dense NiTi withstands 30.2% compression at 1620 MPa; porous structures show reduced strength and deformation capacity | Andani et al. [[113]] |

Tensile Strength | Stripe rotation scanning strategy in SLM | Defect-free parts with tensile strain up to 15.6%, over twice previous reports; 99% shape memory recovery after 50% compression | Xiong et al. [[115]] |

Tensile Strength | Process parameter optimization and oxygen control | High oxygen (>25 ppm) degrades grain boundaries and ductility; reducing oxygen more critical than laser parameters for ductility improvement | Wang et al. [[119]] |

Tensile Strength | Laser scanning length and direction control | Proper scanning length reduces pores/cracks; scanning direction changes heat dissipation, inhibiting columnar grain growth and improving tensile properties | Zhou et al. [[118]] |

Manufacturing NiTi tubing requires advanced equipment and skilled operators. Even small errors can reduce the tubing’s strength or flexibility.

Cost

NiTi alloy tubing costs more than many traditional metals. The price comes from the need for high-purity raw materials and complex manufacturing steps. Specialized machines and strict quality checks add to the expense. Companies must invest in research and skilled workers to produce reliable tubing. These factors make NiTi tubing less common in low-cost or disposable products. However, its unique properties often justify the higher price in critical applications.

Environmental Factors

Environmental conditions can affect the performance and durability of NiTi alloy tubing. Researchers have studied how different factors impact its lifespan, especially in medical settings:

Surface finish changes the quality of the protective oxide layer, which affects corrosion resistance and fatigue life.

Chemical environments, such as body fluids, can speed up corrosion and reduce fatigue strength.

Cyclic mechanical loading and temperature shifts can cause early fatigue failure.

Electrochemical effects, like pitting corrosion, may drastically shorten the tubing’s life.

Microstructural changes during phase transformations also influence durability.

Surface engineering, such as heat treatment or electropolishing, can improve resistance to environmental damage. Still, NiTi tubing may face challenges in harsh or unpredictable environments.

Note: Engineers must consider these factors when choosing NiTi tubing for demanding applications. Proper design and processing help reduce risks and extend the tubing’s service life.

Nitinol tubing offers unique advantages for advanced engineering and medical applications.

Superelasticity and shape memory allow nitinol to recover its shape and provide up to ten times more flexibility than other metals.

Medical devices benefit from this flexibility, enabling compact insertion and safe expansion inside the body.

Engineers value nitinol for its ability to meet strict fatigue and durability standards.

Nitinol stands out as a smart choice for anyone seeking reliable solutions in demanding medical or high-performance environments.

FAQ

What makes NiTi alloy tubing different from stainless steel tubing?

NiTi alloy tubing bends and returns to its original shape. Stainless steel tubing can bend but may stay deformed. NiTi tubing also resists kinks and matches the flexibility of bone. Doctors and engineers choose NiTi for its unique shape memory and superelasticity.

Is NiTi alloy tubing safe for use inside the human body?

Yes, NiTi alloy tubing is safe for medical use. The tubing forms a thin titanium oxide layer that protects the body from nickel. Studies show that NiTi does not cause allergic reactions or harm tissues. Doctors use it in stents, implants, and other devices.

Can NiTi alloy tubing rust or corrode?

NiTi alloy tubing resists rust and corrosion very well. The titanium oxide layer on the surface acts as a shield. Proper heat treatment and surface finishing improve this protection. NiTi tubing stays strong and safe in body fluids and harsh environments.

How do engineers shape NiTi alloy tubing for special uses?

Engineers use heat treatment and precise control of nickel and titanium content. They can set the tubing to remember a certain shape. Special machines and careful processing help create tubing for catheters, stents, and robotic parts.

What are some common uses for NiTi alloy tubing?

Doctors use NiTi tubing in stents, guidewires, and orthopedic implants. Engineers use it in aircraft, robots, and industrial machines. NiTi tubing works well in places that need flexibility, strength, and resistance to damage.

See Also

The Process Behind Manufacturing Nitinol Tubing For Healthcare

The Importance Of Nitinol Tubing In Modern Medical Use

Ways Nitinol Tubing Is Transforming Medical Device Technology

Tips For Choosing The Ideal Nitinol Tubing Supplier Today

Finding The Most Cost-Effective Supplier For 2mm Nitinol Tubing