Breakthrough Innovations in Nickel Titanium Alloy Tube Manufacturing

Recent changes in nickel titanium alloy tube technology have changed how things are made and used.

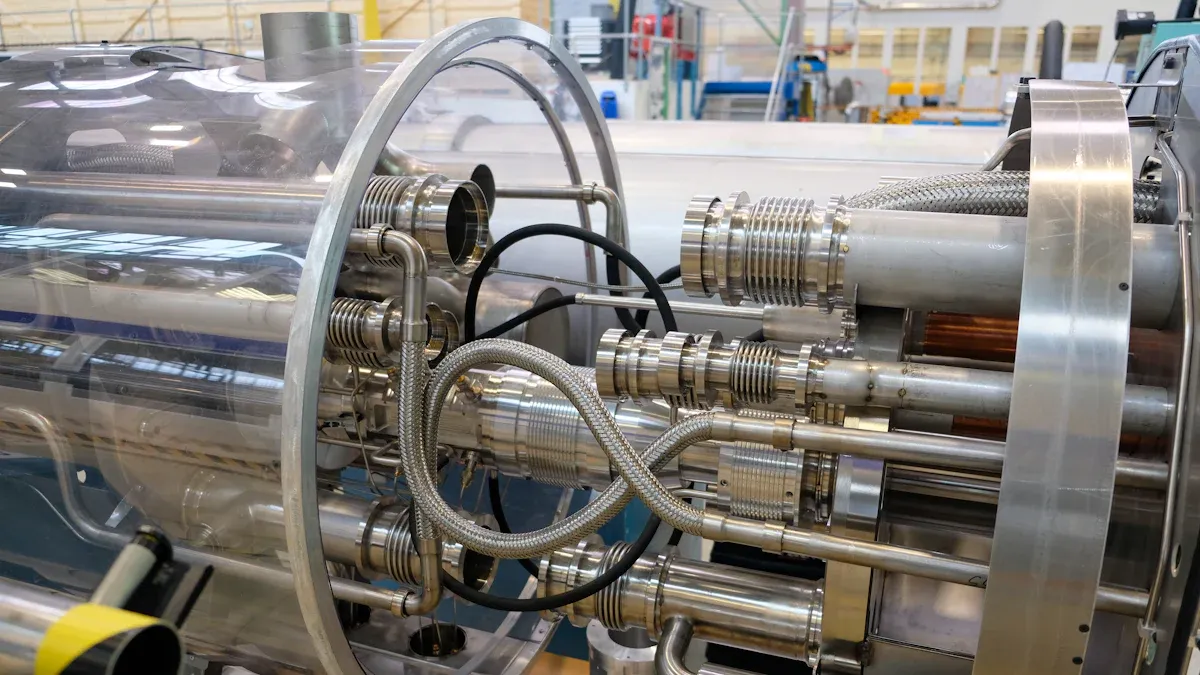

Additive manufacturing and 3D printing help make very exact cuts. They also help create special parts for medical and airplane uses.

Selective laser melting and new cutting ways make tubes stronger. They also help tubes last longer and stay the same each time.

Surface treatments and coatings help tubes work better in the body. They also stop rust and help with cutting, which is important for medical tools.

4D printing and smart manufacturing make tubes that can change and move. These tubes are used in new medical and factory jobs.

Metric | Value/Description |

|---|---|

Market Size (2023) | USD 1.2 billion |

Projected Market (2032) | USD 2.5 billion |

CAGR | 8.3% (2023-2032) |

Medical Sector Share | 78% |

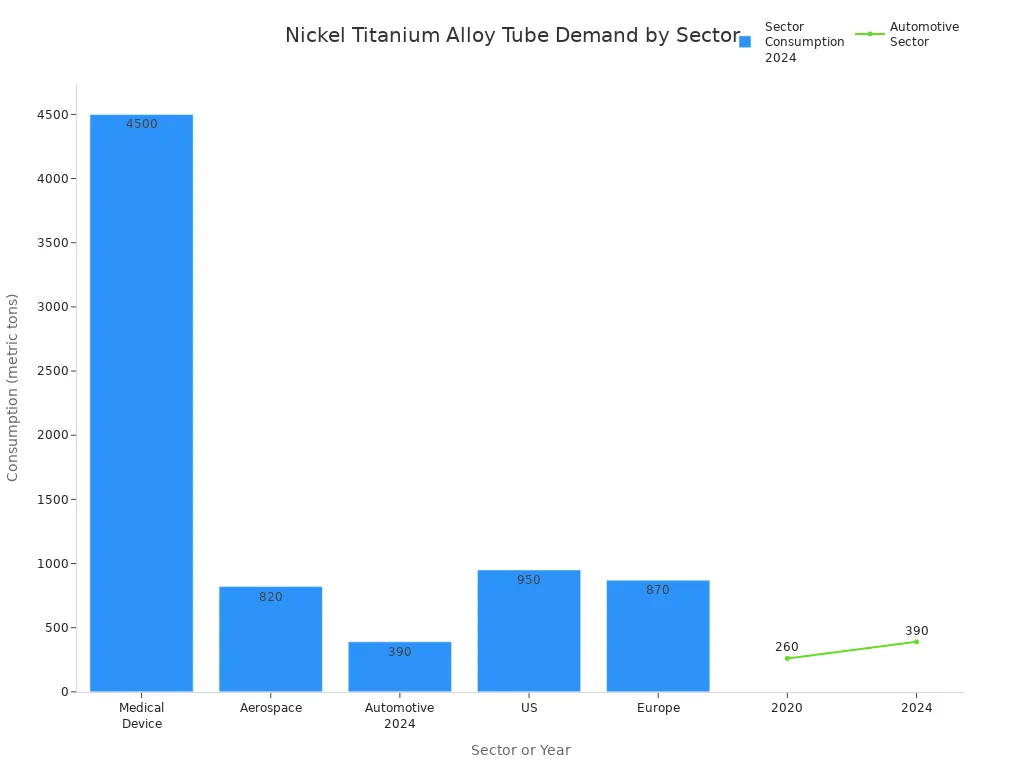

Annual Production | Over 6,800 metric tons; 4,500+ metric tons for medical devices |

Industries now use better cutting and new technology. These changes make tubes more reliable and open up new ways to use nickel titanium alloy tubes.

Key Takeaways

New tools like 3D printing and laser cutting help make nickel titanium alloy tubes stronger. They also make the tubes more exact and quicker to make.

These tubes have special features like superelasticity and shape memory. This helps them bend and go back to their old shape. These features make them great for medical, aerospace, and car uses.

Surface coatings and treatments make the tubes safer and last longer. This is very important for medical devices that go inside the body.

Automation and digital tools help companies make good tubes quickly. They also help use less material and save energy.

The market for nickel titanium alloy tubes is growing fast. Medical and high-tech companies need them more and more. But companies have problems like high prices, strict rules, and needing skilled workers.

Manufacturing Advances

3D Printing of Nickel Titanium Alloys

Additive manufacturing has changed how companies make nickel titanium alloys. 3D printing lets workers create very detailed and special shapes. Old ways cannot make these shapes.

3D printing helps make medical devices that fit each patient. These devices, like nitinol stents, help people heal better.

The process is faster because it uses robots and machines. This makes work quicker and easier.

Less material is wasted, which is good since nickel titanium alloys cost a lot.

Quality checks are better with help from AI systems.

3D printing makes things more exact, special, and better for the environment.

Additive manufacturing also helps engineers test new ideas fast. They can change designs quickly without spending too much money. This helps companies make better products and keep up with what people want.

Nickel-Titanium Tube Laser Cutting

Nickel-titanium tube laser cutting is very important today. New laser tools use femtosecond lasers for very exact cuts. These lasers work so fast that they do not heat the metal too much. This is important for medical and airplane parts. Even small mistakes can cause big problems.

Micro-cutting lets workers make tiny and tricky shapes. This is needed for robots, electronics, and medical tools.

AI and machines watch the cutting and fix problems right away. This makes the work better and faster.

AI can look at machine data to stop breakdowns and help machines last longer.

New laser systems use less power, saving up to 70% energy. This helps the planet.

Hybrid manufacturing mixes 3D printing and laser cutting. This lets companies make hard parts and different batch sizes.

Special software and thin cuts save material. This is good because the material is expensive.

Laser cutting changes the inside and strength of nickel titanium alloys. Using oxygen gas makes the metal hotter near the cut. This can change the grains in the metal. Long laser pulses can make the metal weaker and lower its special stress. Changing laser power can change how the metal remembers its shape. It is important to control the laser and gases to keep the metal working right.

Tip: Using the right laser power, pulse time, and gas keeps the shape memory and special stretch of nickel titanium alloys.

Laser micromachining is liked because it is very exact and can make hard shapes. But, heat from lasers can change the metal’s grains and leave stress inside. This can make the metal weaker and less able to bend many times. Makers must control the process to make sure the tubes are strong and safe.

Automation and Digitalization

Automation and digital tools are now very important for making nickel titanium alloy tubes. The COVID-19 pandemic made companies use more machines and computers. This helped them work better and faster. New digital tools make work easier, clearer, and can be done from far away.

Trends show that using IoT, AI, and cloud systems helps make work better. Automation lets companies record data and track products in real time. Easy-to-use screens help workers do their jobs with fewer mistakes. Connecting to quality systems means checks happen on time and results are checked by computers.

Note: Digital tools like ORBIS MES with SAP S/4HANA help move materials and handle orders. This means less paper and the same process at many places.

Automation lets one worker run many machines. It also helps save energy and cut waste. These changes help companies make more nickel titanium alloys while keeping costs low and quality high.

Material Innovations

Enhanced Nickel Titanium Alloys

Engineers are making nickel titanium alloys better. They mix new elements to make the alloys stronger and more reliable. These new materials work better than old metals in many ways. The table below shows how enhanced nickel titanium alloys compare to older metals:

Property / Feature | Enhanced Nickel-Titanium Alloys (Nitinol) | Traditional Compositions (Stainless Steel, Copper, Titanium Alloys) |

|---|---|---|

Elastic Strain Tolerance | Up to 8% strain with full recovery (superelasticity) | Permanent deformation at 0.2-0.3% strain |

Mechanism | Reversible solid-state phase transformation (martensite ↔ austenite) | Plastic deformation via dislocation movement |

Fatigue Resistance | Withstands millions of loading cycles without failure | Microcracks develop after thousands of cycles |

Temperature Range | Functional from -100°C to 300°C | Fixed properties, fail outside typical ranges |

Corrosion Resistance | Excellent, biocompatible | Generally lower, may require coatings |

Applications | Medical implants, aerospace adaptive structures, automotive actuators, seismic dampers | Conventional structural, automotive, and medical devices |

Requires precise composition control, vacuum/inert atmosphere processing, advanced heat treatments | Standard metal forming and processing | |

Cost | Higher initial cost but lower total lifecycle cost due to durability and multifunctionality | Lower initial cost but higher maintenance and replacement |

Strength | Tensile strength up to 1500 MPa | Typically lower tensile strength |

Density | ~6.45 g/cm³ (lighter than stainless steel, slightly heavier than titanium) | Varies, stainless steel heavier, titanium lighter |

These new materials use special heat and mixing steps. This gives them high strength and flexibility. Sometimes, engineers swap out some nickel for copper. This helps the alloy keep its shape and work better. It also makes the material more stable. These changes help the alloy stretch and bounce back to its shape. Additive manufacturing, like selective laser melting, makes the tubes even more exact. These improvements help the tubes last longer and work better in medicine, planes, and cars.

Note: Making these alloys needs careful steps. This keeps the right mix of strength, flexibility, and rust protection for each job.

Biocompatible Coatings

Surface technology helps nickel titanium alloys work in more places, especially in medicine. Tiny coatings, like tantalum oxide, are put on using special methods. These coatings stop rust and keep the metal’s good features. They also lower the chance of allergies and too much tissue growth. The coatings make the metal safer for the body.

Nano-coatings make the tube’s surface smoother and more exact. This helps cells grow and stops swelling. That is why these alloys are good for heart implants and other medical tools. Other surface treatments, like electropolishing and chemical etching, clean the tubes even more. These steps help the tubes meet strict medical rules and work the same every time.

Nano-coatings help stop rust and make tubes last longer.

Surface treatments make tubes more exact and safer.

Biocompatible coatings let these alloys be used in more medical ways.

Superelasticity and Shape Memory

Superelasticity and shape memory make nickel titanium alloys special. These features come from changes inside the metal when it is stretched or heated. When you pull the metal, it stretches but does not stay bent. When you let go, it goes back to its old shape. This lets the metal handle big stretches and still recover.

Shape memory means the metal “remembers” its shape. When you heat it, it goes back to how it was made. This is important for things like stents, braces, and robot parts. Changing the nickel and titanium mix lets engineers pick how the metal acts.

New science has made these features even better. Special heat steps and adding copper help the metal change shape at the right temperature. Additive manufacturing makes the tubes more even and exact. These changes help the tubes bend many times, stay flexible, and work well.

Superelasticity and shape memory help nickel titanium alloy tubes work in medicine, planes, and robots. These features make the tubes strong, long-lasting, and dependable in tough places.

Applications

Medical Devices

Nickel titanium alloys are used more in medicine now. These alloys have special features that help doctors. They are good for surgeries that do not need big cuts. The superelasticity and shape memory of nickel titanium alloy tube are important. These features help tools move through the body with less harm.

Stents made from nickel titanium alloys can be squeezed small. They get bigger at body temperature. This shape memory means no balloon is needed.

Guide catheters and delivery systems use the superelasticity. They bend and go back to their shape. This helps doctors reach hard places.

The titanium oxide layer makes these tubes safe for the body. It helps stop allergies and swelling.

Kink resistance and fatigue resistance help the tubes last long. They work well even with blood moving all the time.

Custom cutting and laser tools make exact shapes for each blood vessel.

Medical device makers follow ISO13485:2016 rules. This keeps all devices safe and working well.

New ways to make these tubes, like laser cutting and heat steps, help them last longer. These changes make the tubes stronger and stop rust. This means better results for patients and less pain.

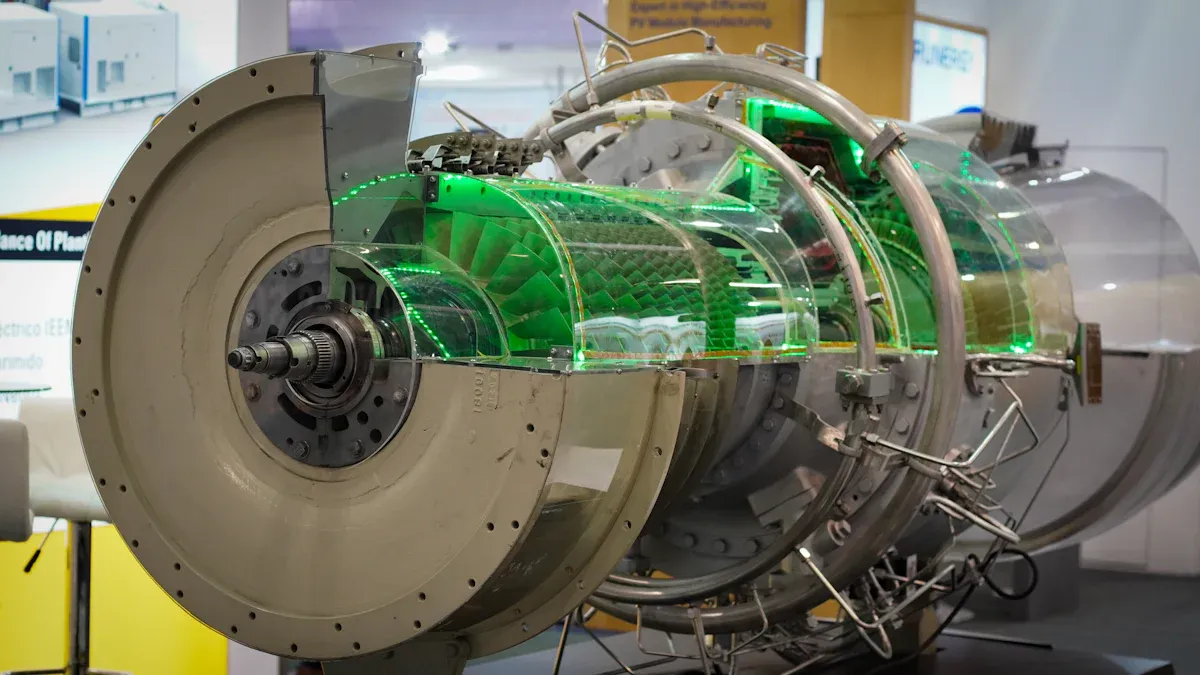

Aerospace Uses

Aerospace jobs need strong and safe parts. Nickel titanium alloys are light and strong. This makes them good for planes. Engineers use these alloys in actuators, landing gear, and engines. Lighter parts help planes use less fuel and work better.

Nickel titanium alloy tube does not rust or break easily. It works well even in tough places.

Laser cutting and careful making help each part meet plane rules.

These alloys last a long time and need less fixing.

Planes are safer and work better because of nickel titanium alloys.

Automotive and Emerging Tech

Cars and new energy vehicles use nickel titanium alloys too. These alloys help with parts that change how stiff the car feels. Shape memory lets these parts adjust for a smoother ride. The alloys are light and strong, so cars weigh less and use less gas.

Niti tube parts in actuators and sensors work well in safety systems.

Laser and new cutting ways make strong, exact parts.

These alloys do not rust, so they last longer in tough places.

New uses include green energy systems. Actuators made from these alloys help save energy. Nickel titanium alloys keep finding new uses in cars and other tech.

Market Trends

Growth Forecast

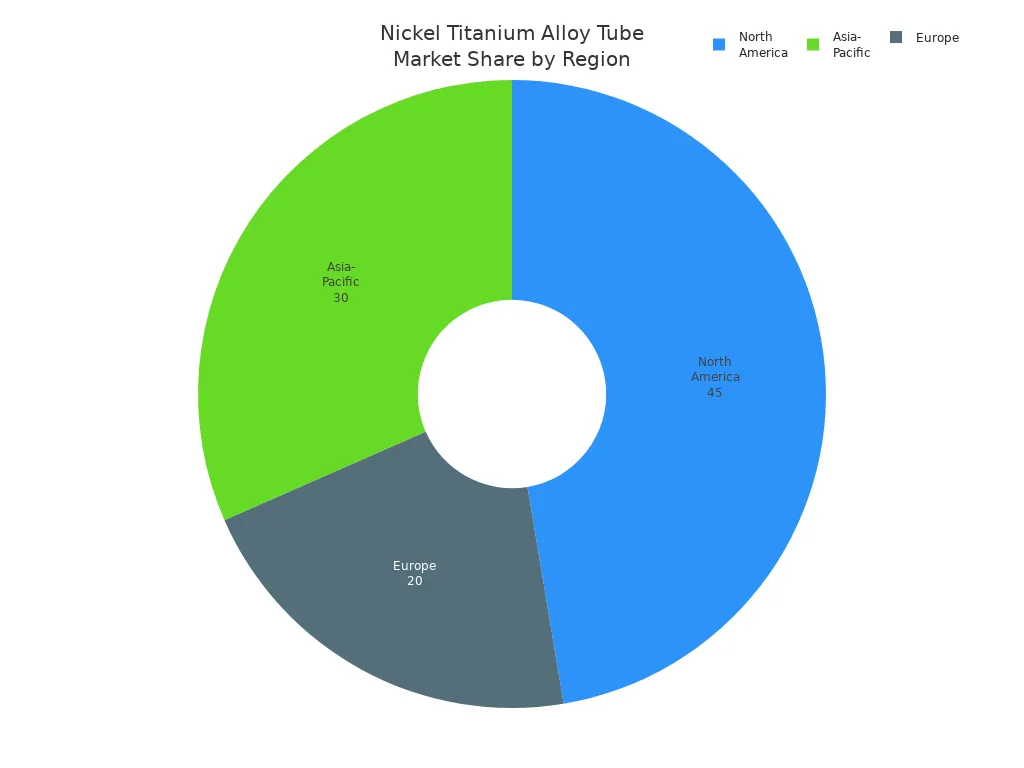

The nickel titanium alloy tube market is growing fast. In 2022, the market was about USD 1.72 billion. By 2033, it may reach USD 2.8 billion. This is because more people want tubes for medical, airplane, and car uses. Companies use new ways to make and cut tubes. This helps lower costs and makes better products. Asia-Pacific will likely give over 35% of the new money. North America is the biggest market. Asia-Pacific is next, then Europe.

Region | Market Share (%) | Key Application Sectors Driving Demand |

|---|---|---|

North America | 45 | Medical, Aircraft, Automotive |

Asia-Pacific | 30 | Medical, Aircraft, Automotive |

Europe | 20 | Medical, Aircraft, Automotive |

New 3D printing and casting help make new things. These changes also help with more medical and high-tech uses.

Sustainability

Factories now care more about the environment. Many use cryogenic machining with cold liquids. This keeps tools cool and saves power. It also lowers costs and cuts pollution. Cryogenic machining can save 27% on costs. It can cut carbon by up to 9%. Tools last longer, almost 39% more than before. Power use drops by over 19%. These steps help meet strict green rules.

Recycling is also important. Factories sort scrap to get nickel and titanium back. Recycling saves energy and keeps the metal good. Digital tools help track what is used. This stops waste and saves energy. These steps help the planet and make less trash.

Note: Recycling special metals saves resources and cuts waste. It also lowers greenhouse gases. This makes making nickel titanium alloy tubes better for the earth.

Future Opportunities

There are new chances for these tubes in many fields. The medical field is growing fast. This is because more people are getting older and need surgery. Devices like stents and guidewires use these tubes. They are strong and bend easily. Car and airplane makers want light and strong tubes. Electronics use these alloys in small, tough parts.

Additive manufacturing lets companies make tricky shapes. This helps in robots, defense, and machines. Asia-Pacific will grow the most because of new factories and hospitals.

Rules and tests are very important for the future. The FDA and MDR have strict rules for safety and strength. These rules make things safer but take more time and money.

Challenges

Production Scalability

Making more nickel titanium alloy tubes is hard for companies. New machines and buildings cost a lot of money. This makes it tough for small companies to grow. Different places have strict rules. These rules make it hard to expand and keep things the same. Companies need skilled workers, but there are not enough. This slows down work and new ideas. Getting raw materials and moving them can be a problem. This can stop or slow down making and sending out tubes. In some places, too many tubes are sold. This makes prices go down and profits smaller.

It is hard to make tubes the right size and quality. This is extra hard for medical and factory jobs.

Rules for medical tools in the U.S. and Europe slow down sales.

Other materials, like shape memory polymers, are strong rivals.

Money problems and world events make prices change a lot.

Too many tubes in the medical field means less money and the need for new ideas.

Quality Assurance

Making sure nickel titanium alloy tubes are good is very important. Companies use vacuum melting to keep the nickel-titanium mix right. They follow ASTM rules for nickel and other properties. Heating the tubes at 440°C for 30 minutes helps them bend and change shape better. Special tools check if the tubes are the right size.

Tests check how strong, stretchy, and tough the tubes are. Another test checks the temperature for the shape memory effect. Looking at the surface finds any problems that could hurt how the tube works or if it is safe for the body. Rust tests show if the tube will last a long time. Tests for the body make sure the tubes are safe for people. Companies also follow ISO13485:2016 rules to keep quality the same and track every tube.

Other checks include X-rays to find inside problems, tests to make sure the metal is right, dye tests for surface cracks, and water pressure tests for leaks and strength. These steps help companies work better and waste less.

Regulatory Barriers

Companies face many rules before they can sell nickel titanium alloy tubes. The table below shows the main problems and how companies fix them:

Regulatory Barrier Category | Specific Barriers and Impacts | How Manufacturers Address Them |

|---|---|---|

Medical Device Regulations | FDA Class II/III approvals need expensive tests and take a long time. Europe MDR makes following rules cost more and takes longer. | Companies join groups like IMDRF. Using IMDRF rules helps get approvals faster. |

Environmental and Material Compliance | EU REACH limits nickel, which costs a lot each year. California Proposition 65 makes companies more responsible. Tracking systems are needed. | Companies buy better tracking and quality tools. They use greener ways to make tubes. |

Trade Policies and Tariffs | U.S. tariffs on Chinese materials make things cost more. Export rules make getting supplies harder. Trade deals help some places more than others. | Companies use more suppliers. They use shipping hubs. They store extra supplies to avoid problems. |

Regional Certification Divergences | China’s GB/T rules mean new and costly tests. India’s BIS rules slow down sales. Australia’s ISO rules make things faster. | Companies change their tests. They plan when to enter new markets to deal with delays. |

IP and Patent Landscape | Patent fights slow down new companies. Weak rules let others copy products and lower prices. | Companies work together or buy others. They use the law to protect their ideas in big markets. |

Companies must keep up with new rules and buy new tools to follow them. Doing this helps them work better, waste less, and grow with new ways to cut and make tubes.

Nickel titanium alloy tube technology is important in many industries. New cutting methods help companies use these tubes in more ways. Cutting tools shape tubes for medicine, planes, and cars. These tools help engineers test ideas faster. Cutting makes tubes strong and flexible for special jobs. It helps doctors use tubes safely in the body. Cutting lets robots and electronics use these tubes too. Energy systems also work better with these tubes. These new ways to cut tubes will help the market grow.

Companies think there will be even more uses as cutting gets better.

FAQ

What makes nickel titanium alloy tubes unique?

Nickel titanium alloy tubes can bend and then go back to their shape. This is because they have superelasticity and shape memory. These features help in medicine, airplanes, and cars.

How does 3D printing improve tube manufacturing?

3D printing makes shapes that old ways cannot make. It uses less material and works faster. Companies can also make tubes for special jobs.

Are nickel titanium alloy tubes safe for medical use?

Doctors trust these tubes because they work well in the body. Special coatings help stop allergies and rust inside people.

What challenges do manufacturers face with these tubes?

Making these tubes costs a lot and has many rules. Factories need skilled workers and good materials. These problems can slow work and make it cost more.

Can these tubes be recycled?

Yes, companies recycle these tubes to save energy and materials. Recycling also helps cut waste and protect the earth.

See Also

Recent Advances In Laser Cutting For Nickel-Titanium Tubes

Ways Nickel-Titanium Tubes Improve Catheter And Implant Efficiency

Why NiTi Tubes Are Transforming Medical And Aerospace Fields

NiTi Tubes' Impact On Advancing Modern Medical Devices

Current Developments In Nickel Titanium Alloy Applications And Tech