What Is Memory Metal Tubing and How Does It Work

You use memory metal tubing when you need a material that can return to its original shape after bending or twisting. This tubing uses shape memory alloys, such as Nitinol, which react to heat by transforming back to their set form. Smart metal like this offers high durability and superelastic performance, even under repeated stress. Researchers have found that memory metal tubing resists cracking and remains stable through many cycles, thanks to its unique shape memory effect and strong phase transformation abilities.

Key Takeaways

Memory metal tubing can return to its original shape after bending or twisting by using special alloys like Nitinol.

Nitinol tubing offers superelasticity and high durability, making it ideal for medical devices, aerospace, and industrial uses.

The shape memory effect works through a reversible phase change triggered by temperature, allowing the tubing to recover its shape repeatedly.

Nitinol tubing is safe for use inside the human body due to its excellent biocompatibility and corrosion resistance.

Memory metal tubing improves product flexibility and lifespan, helping reduce medical procedure times and enhancing performance in many applications.

Memory Metal Tubing

What It Is

You can think of memory metal tubing as a special kind of tube that remembers its original shape. When you bend or twist it, the tube can return to its set form if you heat it. This happens because the tubing is made from a shape memory alloy. These alloys have a unique ability to change their structure when the temperature changes. You often see memory metal tubing used in places where flexibility and strength matter most.

Many engineers and doctors choose memory metal tubing because it can handle repeated bending without breaking. Studies in civil engineering show that shape memory alloy tubing can help buildings stay strong during earthquakes or blasts. The tubing’s superelasticity and shape memory effect help structures recover from damage. You also find this tubing in medical devices, where it needs to bend and move inside the body but still return to its original shape. Fatigue tests on Nitinol tubing show that it can survive millions of cycles without failing. This makes it a reliable choice for both medical and industrial uses.

Tip: If you need a tube that can recover its shape after being deformed, memory metal tubing made from a shape memory alloy is a smart solution.

Common Alloys

You will find that most memory metal tubing uses a shape memory alloy called Nitinol. Nitinol is a mix of nickel and titanium. This memory alloy stands out because it can return to its original shape after being bent or stretched. Nitinol also shows superelasticity, which means it can stretch much more than regular metals and still snap back to its starting form.

Other shape memory alloys include copper-aluminum-nickel and copper-zinc-aluminum. However, Nitinol remains the most popular choice for memory metal tubing. You see Nitinol used in stents, bone plates, dental wires, and even in temperature-sensitive valves. Researchers have tested Nitinol tubing in many ways. For example, they have shown that it can recover its shape after being heated, even after heavy use. In buildings, Nitinol memory alloy tubing helps control vibrations and adds strength. In medical devices, it allows for safe, flexible movement inside the body.

Here is a quick comparison of common shape memory alloys used in memory metal tubing:

Shape Memory Alloy | Main Elements | Key Features | Typical Uses |

|---|---|---|---|

Nitinol | Nickel, Titanium | Superelasticity, biocompatibility | Medical, aerospace, safety |

Cu-Al-Ni | Copper, Aluminum, Nickel | High temperature resistance | Industrial, actuators |

Cu-Zn-Al | Copper, Zinc, Aluminum | Good shape memory, cost-effective | Consumer, robotics |

You can rely on Nitinol memory alloy tubing for its proven fatigue resistance, corrosion resistance, and ability to perform in demanding environments. Empirical research confirms that Nitinol tubing works well in both medical and structural settings, making it a trusted material for many critical applications.

Shape Memory Effect

How It Works

You see the shape memory effect when a shape memory alloy, like nitinol, returns to its original form after you bend or stretch it. This happens because the metal can "remember" its set shape. When you deform nitinol tubing at a low temperature, it stays in the new shape. If you heat it above a certain point, the tubing snaps back to its original form. This is the core of the shape memory effect.

Superelasticity is another special property you find in nitinol. When you stretch nitinol at a higher temperature, it can bend much more than regular metals. Once you let go, it springs back without any heat. This makes nitinol tubing very useful in places where you need both flexibility and strength. For example, doctors use nitinol stents in blood vessels because the stents can bend and move with the body but always return to their original shape.

You can see the shape memory effect in action during experiments. When you cool a shape memory alloy like nitinol, it forms a structure called martensite. If you bend the tubing in this state, it holds the new shape. When you heat the tubing, the structure changes to austenite, and the tubing returns to its original form. This process does not depend on time but only on temperature and stress. You can repeat this cycle many times, and nitinol tubing will keep working. Researchers have shown that nitinol can survive millions of cycles without breaking, which proves its reliability.

Note: You can use nitinol tubing in many ways because it combines the shape memory effect and superelasticity. This makes it perfect for medical devices, robotics, and even earthquake-resistant buildings.

Phase Transformation

The shape memory effect in nitinol comes from a reversible phase transformation between two crystal structures: martensite and austenite. When you cool nitinol, it changes from austenite (a cubic structure) to martensite (a more flexible structure). This change happens without atoms moving far, so the process is quick and does not damage the metal.

When you bend nitinol tubing in the martensite phase, the structure forms tiny twins to reduce stress. If you heat the tubing, the martensite turns back into austenite, and the tubing returns to its original shape. This transformation is reversible and depends on temperature. You can see this in experiments with nitinol and other shape memory alloys. For example, scientists have tested shape memory ceramics inside aluminum. They found that cycling the temperature above and below certain points triggers the phase change, and the material can recover its shape many times without breaking.

The transformation between martensite and austenite also shows something called hysteresis. This means the temperature at which nitinol changes back to austenite is higher than the temperature where it becomes martensite. Heat treatment can make this difference smaller, which helps the tubing work better in repeated cycles.

Here is a table that shows how temperature and other factors affect the phase transformation in shape memory alloys like nitinol:

Parameter/Measurement | Description/Observation |

|---|---|

Transformation Temperatures | Martensitic start (Ms) ~225 K, Austenite finish (Af) ~291 K; these can shift with heat treatment |

Thermal Hysteresis | Reduced from 19 K to 16 K after heat treatment, improving reversibility |

Magnetization Levels | Austenite phase shows magnetization; martensite phase does not; magnetization recovers upon heating |

Stress-Temperature Phase Diagrams | More stress is needed for transformation as temperature rises; magnetic fields can also affect transformation |

Clausius-Clapeyron Slope | Slope ~2.2 MPa/K; entropy change shows the energy needed for transformation |

Magnetic Field Influence | Complete transformation can happen under low magnetic fields with less hysteresis |

Microstructural Effects | Atomic order and structure affect transformation temperatures and how well the process repeats |

You can see that nitinol and other memory alloys rely on this phase transformation to create the shape memory effect and superelasticity. The tubing can change shape and recover many times because the transformation is both reversible and stable. This makes nitinol tubing a smart choice for many demanding uses.

Key Properties

Biocompatibility

You want a material that works safely inside the human body. Nitinol tubing meets this need because it passes strict medical tests. Medical-grade nitinol tubing passes ISO 10993 biocompatibility tests, including checks for cytotoxicity, sensitization, irritation, systemic toxicity, and genotoxicity. Doctors use nitinol in stents and other implants because it rarely causes bad reactions. Clinical studies show that nitinol devices have minimal adverse effects, even after more than 10 years in the body. In neurovascular procedures, nitinol stents reach a 97% technical success rate. This high rate means you can trust nitinol for safe and reliable medical use.

Property / Aspect | Quantified Evidence / Description |

|---|---|

Nickel Ion Release | Reduced to 75 ppb after water-boiling passivation, enhancing biocompatibility and corrosion resistance |

Clinical Technical Success Rate | 97% in neurovascular procedures, supporting biocompatibility and device reliability |

Aneurysm Occlusion Rate | Up to 89% complete occlusion within 18 months, indicating effective vessel remodeling and biocompatibility |

Corrosion Resistance

You need tubing that stands up to harsh environments. Nitinol resists corrosion better than many other metals. After special surface treatments, nitinol tubing releases very little nickel—only about 75 parts per billion. This low release keeps the tubing safe for long-term use in the body. Surface finishing, like electropolishing, makes the tubing even smoother. The surface roughness drops to 0.1 micrometers or less, which helps prevent corrosion. Nitinol tubing also contains very few non-metallic inclusions, with a maximum size of 5.4 micrometers and only 0.5% area ratio. This makes the alloy more reliable and less likely to fail.

Tip: Nitinol tubing keeps its strength and shape, even after millions of cycles in wet or salty conditions.

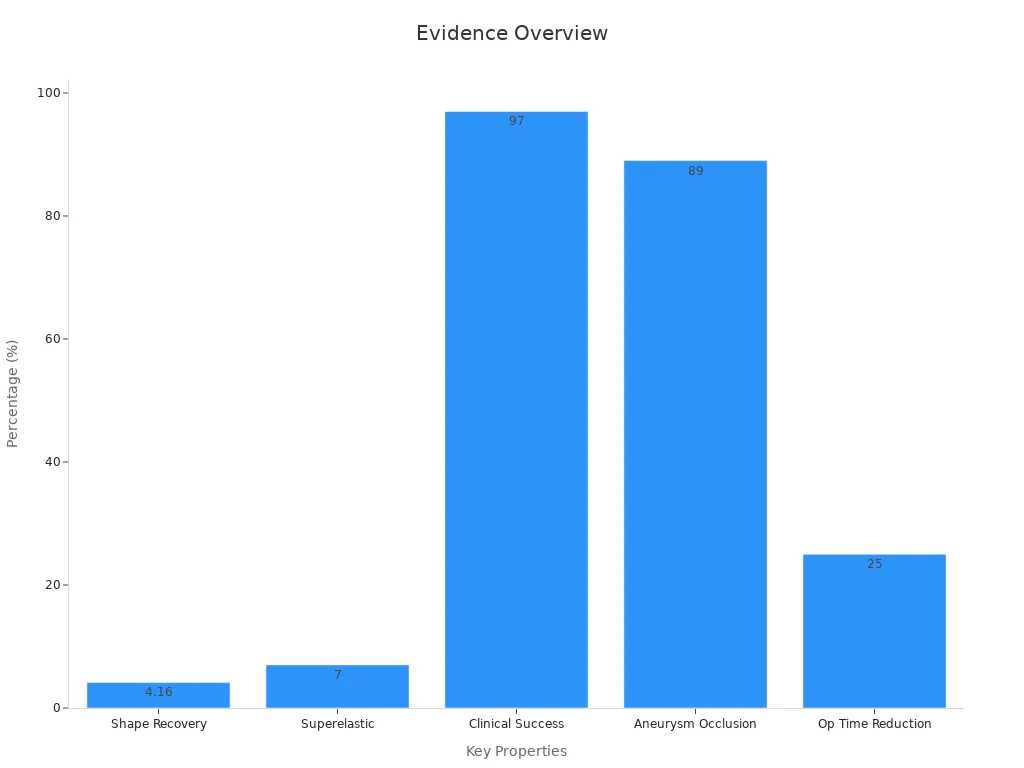

Flexibility

You often need tubing that bends without breaking. Nitinol stands out for its flexibility and shape memory. Shape recovery strain reaches 4.16%, and superelastic strain goes up to 7%. This means you can bend nitinol tubing a lot, and it will return to its original shape. Fatigue life testing shows nitinol tubing can last through over 600 million cardiac cycles without failing. In real medical procedures, this flexibility helps doctors work faster and safer. Operating times drop by up to 25% when using nitinol devices. Complication rates also go down, making procedures safer for patients.

Medical-grade nitinol tubing passes all major safety and performance tests.

Clinical results show up to 89% aneurysm occlusion and a 97% technical success rate.

Flexibility in nitinol tubing helps reduce procedure times and complications by up to 25%.

Applications

Medical Devices

You see memory metal tubing used in many medical devices. Doctors rely on it for stents, guidewires, and bone implants. The tubing’s shape memory effect helps doctors perform minimally invasive procedures. For example, a stent made from nitinol can compress into a small size, travel through a blood vessel, and then expand to support the vessel wall. This makes surgeries safer and recovery faster.

You can trust these devices because they meet strict performance standards. Here is a table that shows why memory metal tubing works so well in medical devices:

Performance Metric | Explanation and Relevance |

|---|---|

Material Composition | Nickel-titanium alloy provides shape memory and mechanical strength for stents and devices |

Dimensional Accuracy | Ensures precise fit and function, which is critical for safety and effectiveness |

Surface Quality | Smooth surfaces lower infection risk and improve biocompatibility in implants |

You benefit from these features because they make medical treatments safer and more effective. Superelasticity allows the tubing to bend and move with your body, reducing the risk of damage.

Industrial Uses

You find memory metal tubing in robotics, aerospace, and even in smart building systems. In robotics, the tubing acts like artificial muscles, moving parts with precision. Aerospace engineers use it for components that must withstand high stress and temperature changes. The tubing’s fatigue resistance and heat tolerance help machines last longer and work better.

Superelasticity and shape memory let robots perform delicate tasks.

Aerospace parts made from nitinol resist extreme heat and stress.

Market growth comes from new research and better technology.

You may also hear about muscle wire, which uses the same shape memory effect to create movement in small machines and robots.

Consumer Products

You use memory metal tubing in everyday items, too. Eyeglass frames made from this tubing bend without breaking, so they last longer. Some toys and gadgets use the tubing to create moving parts that return to their original shape. You might find it in temperature-sensitive valves or smart home devices.

Tip: Products with memory metal tubing often last longer and work better because they recover from bending or twisting.

The popularity of memory metal tubing keeps growing. North America leads in using these materials, but Asia-Pacific is catching up fast. You see more products using this smart material every year.

You now know that memory metal tubing uses shape memory alloys to return to its original shape when heated. This smart material gives you superelasticity, flexibility, and strength. Recent research shows that nickel-titanium alloys work well in medical, aerospace, and everyday products. You benefit from new manufacturing methods that improve accuracy and performance. As technology advances, you will see even more intelligent and reliable uses for memory metal tubing. Smart materials like this help shape the future of modern life.

FAQ

What makes memory metal tubing different from regular metal tubing?

You can bend memory metal tubing, and it will return to its original shape when heated. Regular metal tubing stays bent or breaks. Memory metal tubing uses special alloys that "remember" their shape.

Can you use memory metal tubing in the human body?

Yes, you can use it in the body. Doctors use it for stents and implants. Nitinol tubing is safe and passes strict medical tests for biocompatibility.

How do you trigger the shape memory effect?

You heat the tubing above a certain temperature. The metal then changes back to its original shape. This process works every time you repeat it.

Where can you find memory metal tubing in everyday life?

You see it in eyeglass frames, toys, and some smart home devices. Many products use memory metal tubing because it bends and returns to shape, making them last longer.

See Also

Understanding The Mechanisms Of Nitinol's Unique Properties

Nitinol Tubing Transforming The Future Of Medical Equipment

The Production Process Of Nitinol Tubing For Healthcare Use