What to Know About Nitinol Tubing for Orthopedic Implants in 2025

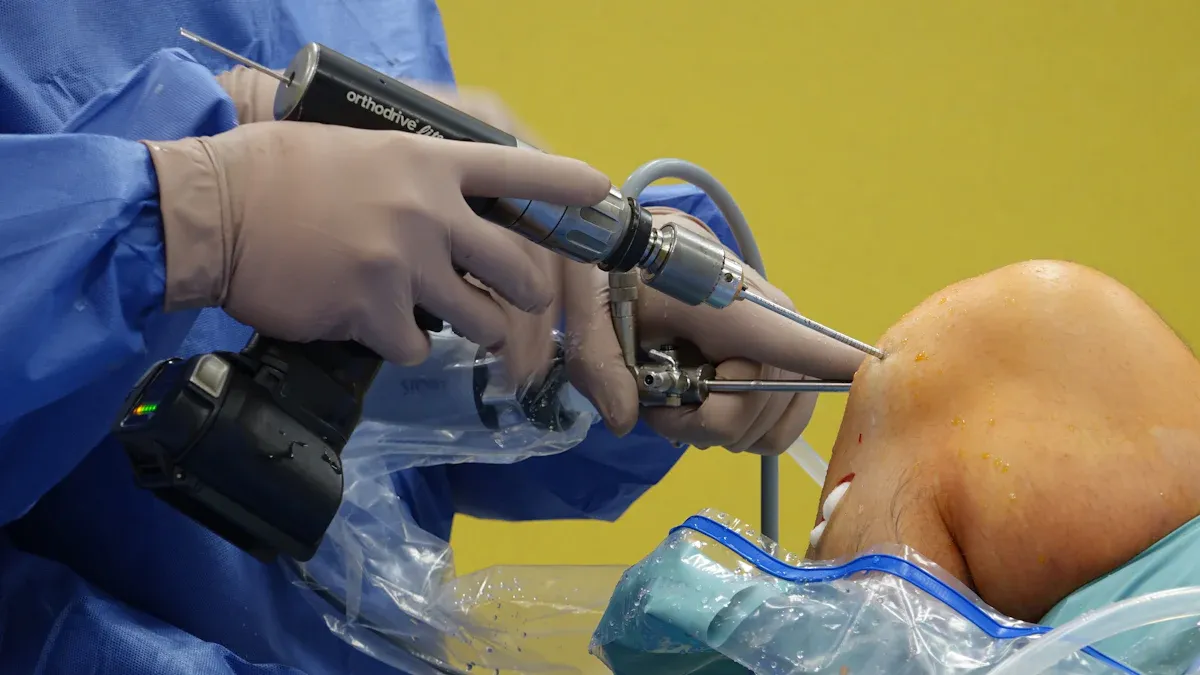

The demand for medical grade nitinol tubing for orthopedic implants continues to rise in 2025 due to its unparalleled benefits. Nitinol, a unique alloy of nickel and titanium, stands out for its exceptional superelasticity and shape memory. These unique properties of nitinol allow it to adapt to the body's movements, making it ideal for orthopedic applications.

High-quality nitinol tubing offers the precision and durability required for medical devices like guidewires and nitinol wires. Its biocompatibility and resistance to corrosion ensure long-term safety and reliability in healthcare. Selecting the right tubing directly impacts the performance of implants, enhancing patient outcomes and supporting innovation in medical applications.

Key Takeaways

Nitinol tubing has special traits like bending back and shape memory. This makes it great for bone implants.

Nitinol is safe for the body and does not rust. This makes it last long in medical use.

Making nitinol tubing with exact sizes is very important. It helps it work well with medical tools.

Smooth surfaces and special coatings make nitinol stronger and safer. This helps patients heal better.

Learning about new nitinol ideas helps doctors care for patients better.

Key Properties of Nitinol Tubing

Nitinol tubing stands out in the field of medical devices due to its remarkable properties. These characteristics make it an essential material for orthopedic implants and other healthcare applications. Understanding these key properties helps in appreciating the advantages of nitinol in medical devices and its role in improving patient outcomes.

Superelasticity and Shape Memory

Superelasticity is one of the most defining features of nitinol tubing. This property allows the material to undergo significant deformation and return to its original shape without permanent damage. For example:

Nitinol guidewires leverage superelasticity to navigate complex anatomical pathways without kinking.

Self-expanding stents utilize this capability to adapt to the body's natural movements, ensuring reliability and adaptability.

The shape memory capability of nitinol tubing further enhances its utility. When exposed to specific temperatures, nitinol can "remember" and revert to its pre-set shape. This unique behavior is critical for applications of nitinol in orthopedic implants, where precision and adaptability are paramount. The impact of superelasticity on medical implants cannot be overstated, as it ensures both durability and flexibility under high-stress conditions.

Additionally, nitinol tubing exhibits exceptional fatigue resistance. Studies show that it can endure millions of stress cycles, with some tests indicating survival up to 10⁷ cycles under specific strain amplitudes. This level of durability makes nitinol tubing a reliable choice for high-stress medical environments.

Biocompatibility and Corrosion Resistance

Biocompatibility and corrosion resistance are vital for any material used in medical applications. Nitinol tubing excels in both areas, making it a preferred choice for healthcare professionals. Its biocompatibility ensures that the material does not trigger adverse reactions when implanted in the human body. This property is crucial for long-term use in orthopedic implants and other medical devices.

Corrosion resistance further enhances the performance of nitinol tubing. The material's ability to withstand harsh bodily environments, including exposure to fluids and varying pH levels, ensures its longevity. This resistance reduces the risk of implant degradation, contributing to better patient outcomes and minimizing the need for replacement procedures.

The combination of biocompatibility and corrosion resistance makes nitinol tubing an ideal material for medical applications. It ensures safety, reliability, and durability, which are essential for improving healthcare standards.

Flexibility and Strength for Orthopedic Applications

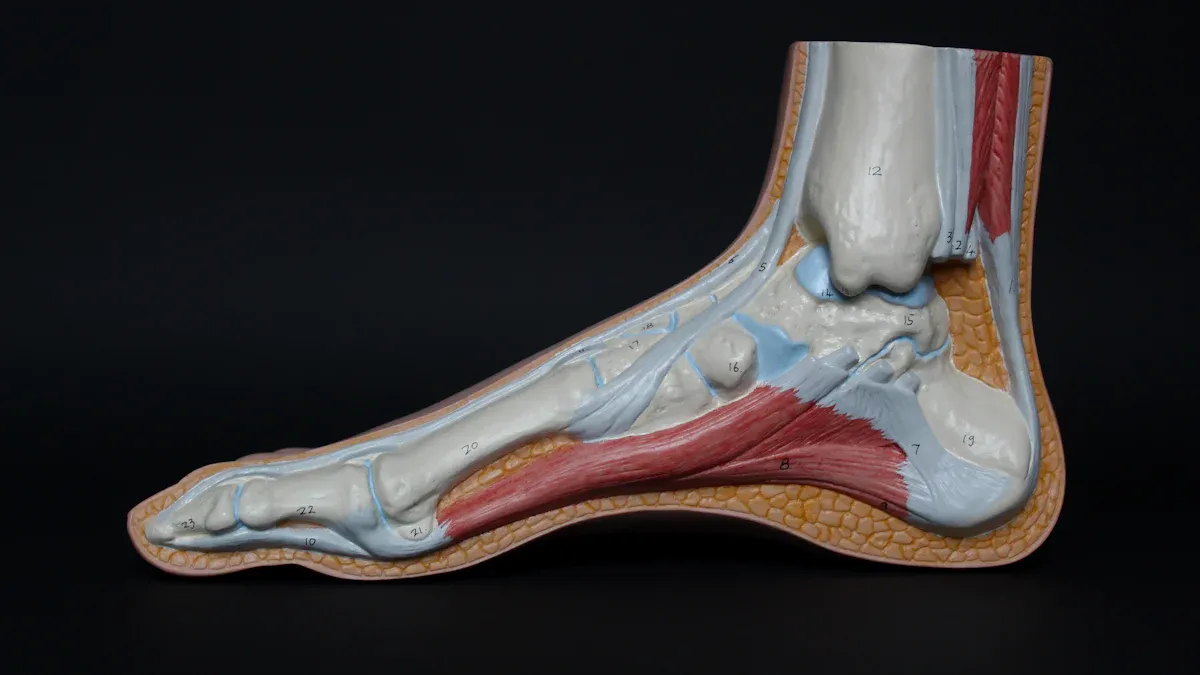

Flexibility and durability are critical for the success of nitinol tubing in orthopedic applications. The material's ability to bend and adapt without losing its structural integrity makes it invaluable for minimally invasive procedures. For instance:

Evidence Description | Key Contribution to Reliability |

|---|---|

Nitinol's durability and precision are critical for the success of minimally invasive procedures. | Exceptional resistance to fatigue ensures structural integrity under repeated use, vital for guidewires and catheters. |

Nitinol enhances the precision and flexibility of medical devices. | Superelasticity and shape memory properties allow navigation through complex pathways, reducing procedural errors. |

Exceptional flexibility improves device performance. | Allows bending through tight spaces while maintaining stability, crucial for precision in delicate interventions. |

The strength of nitinol tubing ensures that it can withstand the mechanical stresses encountered during orthopedic procedures. Its ability to maintain stability while navigating tight spaces enhances the performance of medical devices. This combination of flexibility and strength underscores the importance of nitinol tubing in modern healthcare.

Importance of Dimensional Precision

Dimensional precision plays a critical role in the manufacturing of nitinol tubing for medical devices. The exact dimensions of nitinol wires and tubing directly influence their performance, reliability, and compatibility with orthopedic implants. Ensuring precise measurements is essential for maintaining the integrity of medical applications and achieving optimal patient outcomes.

Diameter and Wall Thickness Considerations

The diameter and wall thickness of nitinol tubing are key factors that determine its functionality in medical devices. These parameters must align with the specific requirements of each application. For instance, thinner tubing is often used in minimally invasive procedures, where flexibility and precision are paramount. Conversely, thicker tubing provides the strength needed for load-bearing implants.

Manufacturers must carefully balance these dimensions to ensure the tubing meets the demands of healthcare applications. Even minor deviations can compromise the performance of nitinol wires, leading to potential risks in medical procedures. Therefore, strict control over diameter and wall thickness is essential for producing high-quality nitinol tubing.

Manufacturing Tolerances in Medical Grade Nitinol Tubing

Adhering to tight manufacturing tolerances is crucial for producing medical-grade nitinol tubing. These tolerances ensure that the tubing meets the stringent standards required for healthcare applications. For example:

Parameter | Tolerance |

|---|---|

Outer Diameter (OD) ≤ 0.3 mm | ±0.005 mm |

0.3 mm ≤ OD ≤ 0.5 mm | ±0.007 mm |

0.5 mm ≤ OD ≤ 1.5 mm | ±0.015 mm |

Compliance with ISO 13485 | Yes |

Manufacturers must also conduct dimensional accuracy testing and functional property verification to ensure the tubing meets these tolerances. Compliance with ISO 13485 certification further guarantees the safety and reliability of nitinol tubing in medical devices.

Ensuring Consistency for Orthopedic Implants

Consistency in the production of nitinol tubing is vital for its use in orthopedic implants. Uniform dimensions and properties ensure that the tubing performs reliably under various conditions. This consistency minimizes the risk of device failure and enhances the overall performance of medical applications.

To achieve this, manufacturers implement rigorous quality control processes. These include advanced testing methods to verify the dimensional precision of nitinol wires and tubing. By maintaining high standards, manufacturers contribute to the success of healthcare procedures and improve patient outcomes.

Surface Quality and Coating Options

Role of Surface Quality in Medical Applications

Surface quality plays a critical role in the performance and reliability of nitinol tubing used in medical applications. Smooth and defect-free surfaces enhance the tubing's fatigue resistance, ensuring durability under repeated stress. Research highlights that surface imperfections, such as voids or irregularities, can act as stress concentrators. These imperfections significantly reduce the fatigue life of nitinol tubing, especially in high-stress regions. For example, fatigue testing on 177 nitinol samples revealed that fractures often occurred in areas with poor surface quality. By minimizing void sizes during material processing, manufacturers can improve the tubing's fatigue resistance, which is essential for reliable medical devices.

In addition to fatigue resistance, surface quality impacts the tubing's interaction with human tissue. A smooth surface reduces the risk of protein adhesion and thrombus formation, enhancing biocompatibility. This is particularly important for nitinol wires and tubing used in orthopedic implants and other healthcare applications.

Common Coatings for Nitinol Tubing

Coatings further enhance the functionality of nitinol tubing in medical applications. Several types of coatings are commonly used to improve the tubing's performance and durability:

Electropolishing creates a smooth, corrosion-resistant surface by removing microscopic imperfections.

Hydrophilic coatings increase lubricity, allowing smoother insertion during medical procedures.

Biocompatible coatings ensure safe interaction with human tissue, reducing the risk of adverse reactions.

Controlled electropolishing processes are especially effective in creating atomically smooth surfaces. These surfaces minimize protein adhesion and thrombus formation, making them ideal for medical devices. Additionally, specialized polymer coatings like PTFE or parylene provide extra corrosion protection. These coatings maintain their adherence even during significant deformations, ensuring long-term durability in clinical settings.

Enhancing Biocompatibility and Durability

Biocompatibility and durability are essential for nitinol tubing used in healthcare. Surface finishing and coatings play a vital role in achieving these qualities. Accelerated aging tests validate the long-term stability of coated nitinol tubing. Simulated use testing ensures that the tubing performs reliably under realistic conditions. Comprehensive chemical analysis confirms the integrity of coatings, ensuring they meet the stringent requirements of medical devices.

For example, hydrophilic coatings improve the tubing's lubricity, reducing friction during insertion. This enhances the performance of nitinol wires and tubing in minimally invasive procedures. Biocompatible coatings, on the other hand, ensure safe interaction with human tissue. These coatings reduce the risk of inflammation or rejection, improving patient outcomes. By combining advanced surface finishing techniques with high-quality coatings, manufacturers can produce nitinol tubing that meets the demanding standards of modern healthcare.

Application-Specific Requirements

Customization for Orthopedic Implants

Customization is essential for nitinol tubing used in orthopedic implants. Each application demands specific properties to ensure optimal performance and patient safety. Nitinol tubing offers unique advantages, such as superelasticity and shape memory, which allow it to adapt to the body's movements. These features are critical for implants that need to be crimped and expanded without permanent deformation.

Several performance metrics support the customization of nitinol tubing for specialized medical devices:

Superelasticity ensures flexibility and adaptability during use.

Biocompatibility guarantees safe interaction with human tissue.

Corrosion resistance enhances longevity in environments exposed to bodily fluids.

Dimensional precision ensures compatibility with specific implant designs.

Fatigue resistance allows the tubing to endure millions of stress cycles without failure.

By tailoring these properties, manufacturers can produce nitinol tubing that meets the exacting demands of guidewires and retrieval devices, stents and stent delivery systems, and other medical applications.

Regulatory Compliance for Medical Grade Nitinol Tubing

Regulatory compliance is a cornerstone of manufacturing medical-grade nitinol tubing. Adhering to stringent standards ensures the safety and reliability of medical devices. Key certifications and standards include:

Certification/Standard | Description |

|---|---|

ISO 13485 | Quality management systems for medical devices |

FDA Registered | Compliance with Quality System Regulation |

ISO 14971:2007 | Risk management for medical devices |

EN ISO 14971:2012 | European risk management standard |

Class I, II, III devices | Includes Premarket Approval (PMA) products |

ISO 8 Certified | Cleanroom-controlled environments |

These certifications validate the quality and safety of nitinol wires and tubing, ensuring they meet the rigorous demands of healthcare applications.

Meeting Performance and Longevity Standards

Performance and longevity are critical for nitinol tubing used in medical devices. High fatigue resistance ensures the tubing can withstand repetitive stress cycles, which is vital for guidewires and retrieval devices. Dimensional precision also plays a significant role in device performance, as even minor variations can affect mechanical reliability.

Manufacturers conduct extensive testing to validate the durability and functionality of nitinol tubing. Simulated use tests and accelerated aging studies confirm that the tubing maintains its integrity under real-world conditions. These efforts ensure that nitinol tubing meets the high standards required for stents and stent delivery systems, orthopedic implants, and other healthcare applications.

Selecting a Reliable Supplier

Selecting a reliable supplier for nitinol tubing is crucial for ensuring the quality and performance of medical devices. A dependable supplier not only meets industry standards but also demonstrates expertise in manufacturing and rigorous quality assurance processes. These factors directly impact the reliability of nitinol wires and tubing used in healthcare applications.

Certifications and Industry Standards

Certifications and adherence to industry standards are key indicators of a supplier's commitment to quality. Suppliers must comply with internationally recognized certifications to ensure their nitinol tubing meets the stringent requirements of medical applications.

ISO 13485 certification guarantees that the manufacturing processes align with global quality management standards for medical devices.

FDA compliance confirms that nitinol tubing is safe and effective for use in healthcare.

ASTM F2063 defines the material properties and testing protocols necessary for medical-grade nitinol, ensuring consistency and reliability.

Other certifications, such as AS9100 for aerospace applications, further demonstrate a supplier's ability to meet high-quality benchmarks. These certifications validate the supplier's dedication to producing nitinol tubing that meets the demands of guidewires, stents, and other critical medical devices.

Certification/Standard | Description |

|---|---|

ISO 13485 | Quality rules for making medical devices. |

AS9100 | Quality management systems for aerospace. |

ASTM F2063 | Standards for nitinol used in medical devices. |

Expertise in Manufacturing Nitinol Tubing

A supplier's expertise in manufacturing nitinol tubing plays a vital role in ensuring the durability and performance of medical devices. Advanced manufacturing techniques enhance the material's resistance to fatigue and corrosion, which is essential for biomedical implants, including orthopedic devices.

Precision manufacturing ensures that nitinol wires and tubing achieve the required dimensional accuracy and surface quality. These factors are critical for high-quality tubing used in healthcare. For example:

Advanced extrusion and drawing processes control wall thickness tolerances within 0.01 mm.

Heat treatments optimize the tubing's shape memory properties and load-bearing capacities, exceeding 1400 N.

Surface finishing techniques achieve roughness (Ra) ≤0.1 μm, enhancing corrosion resistance and biocompatibility.

By leveraging these advanced techniques, suppliers can produce nitinol tubing that meets the exacting standards of modern medical applications.

Quality Assurance and Testing Processes

Rigorous quality assurance and testing processes are essential for delivering reliable nitinol tubing. Suppliers must implement comprehensive testing protocols to validate the tubing's performance and ensure its suitability for medical devices.

Performance Metric | Description |

|---|---|

Microstructure of Raw Materials | Maximum size of porosity and non-metallic inclusion particles controlled within 5.4 μm, area ratio of 0.5%. |

Mechanical Stability | Outstanding stability after 20 cycles of 6% strain recovery testing. |

Wall Thickness Tolerance | Controlled within 0.01 mm using precise extrusion or drawing processes. |

Surface Roughness | Achieved roughness (Ra) ≤0.1 μm enhancing corrosion resistance and biocompatibility. |

Heat Treatment | Full recovery and load-bearing capacities exceeding 1400 N after specific heat treatments. |

Additional testing methods include:

Ultrasonic testing to ensure even wall thickness for structural integrity.

Strength tests to measure tensile strength and elasticity.

Heat tests to confirm shape memory properties.

X-ray tests to assess material purity and detect internal defects.

These quality assurance measures ensure that nitinol tubing performs reliably under real-world conditions. Suppliers who prioritize these processes contribute to the success of healthcare procedures and improve patient outcomes.

Advancements in Nitinol Tubing Technology

Innovations in Nitinol for Orthopedic Implants

Recent advancements in nitinol tubing manufacturing have revolutionized its application in orthopedic implants. Innovative data-driven methodologies now enhance the design and simulation of nitinol-based medical devices. These approaches combine data from multiple sources to predict material deformation, fatigue life, and strength distributions. This three-tiered strategy allows researchers to better understand how nitinol behaves under stress, ensuring its reliability in orthopedic applications.

Additionally, advanced processing techniques, such as laser shock peening, have significantly improved the fatigue resistance of nitinol tubing. This innovation enables the material to endure up to 400 million cycles of arterial pressure, making it ideal for high-stress medical devices like guidewires. These breakthroughs ensure that nitinol tubing continues to meet the rigorous demands of modern healthcare.

Impact on Implant Design and Performance

The unique properties of nitinol tubing have a profound impact on the design and performance of orthopedic implants. Its flexibility allows medical devices to navigate intricate pathways during minimally invasive procedures. Shape memory ensures accurate deployment, while durability maintains structural integrity under repeated use.

Attribute | Impact on Surgery |

|---|---|

Flexibility | Enables navigation through intricate pathways |

Shape Memory | Ensures accurate deployment of devices |

Durability | Maintains structural integrity under repeated use |

Adaptability | Enhances efficacy of procedures, leading to better outcomes |

Clinical evaluations further highlight the benefits of nitinol tubing. Minimal tissue reactions and negligible inflammatory responses have been observed post-implantation. These findings confirm the material's biocompatibility and reliability, making it a preferred choice for medical applications.

Future Trends in Medical Applications

The future of nitinol tubing in medical applications looks promising. The market for nitinol titanium tubing is experiencing rapid growth, driven by innovations in medical technology and the increasing demand for minimally invasive surgical techniques. North America, in particular, is emerging as a key growth area due to its robust healthcare system and the rising prevalence of chronic illnesses.

Research and development efforts in cardiovascular and orthopedic fields are accelerating the adoption of nitinol tubing. Its superelasticity and shape memory make it indispensable for applications like stents, guidewires, and other medical devices. As technology advances, nitinol tubing is expected to play an even greater role in improving patient outcomes and expanding the possibilities of modern healthcare.

Understanding the properties and selection criteria of nitinol tubing is essential for improving the performance of orthopedic implants. Prioritizing quality and reliability ensures that medical devices meet the highest standards of safety and functionality. Advancements in nitinol technology continue to shape the future of healthcare, offering innovative solutions for patient care. Staying informed about emerging trends in orthopedic implants empowers professionals to make better decisions and drive progress in the field.

FAQ

What makes nitinol tubing unique for orthopedic implants?

Nitinol tubing offers superelasticity, shape memory, and biocompatibility. These properties allow it to adapt to body movements, resist corrosion, and maintain durability under stress. Its ability to "remember" shapes ensures precise deployment in implants, making it indispensable for modern medical applications.

How does surface quality impact nitinol tubing performance?

Surface quality directly affects fatigue resistance and biocompatibility. Smooth surfaces reduce stress concentrations, enhancing durability. They also minimize protein adhesion, lowering the risk of complications like thrombus formation. High-quality finishes ensure reliable performance in medical devices.

Why is dimensional precision critical in nitinol tubing?

Dimensional precision ensures compatibility with medical devices and implant designs. Accurate diameter and wall thickness measurements prevent performance issues. Strict tolerances guarantee reliability, especially in minimally invasive procedures where precision is vital for success.

What certifications should a nitinol tubing supplier have?

Suppliers should hold ISO 13485 certification for medical device quality management. FDA compliance and adherence to ASTM F2063 standards ensure safety and reliability. These certifications validate the tubing's suitability for healthcare applications.

What advancements are shaping the future of nitinol tubing?

Innovations like laser shock peening and data-driven design simulations improve fatigue resistance and performance. These advancements enhance the tubing's reliability in high-stress applications, such as guidewires and stents. Future trends focus on expanding its role in minimally invasive surgeries and orthopedic implants.

See Also

Nitinol Tubing: Shaping the Future of Medical Devices

Nitinol Tubing Applications Transforming Healthcare Technology Today

Nitinol Tubing's Impact on the Advancement of Medical Tech

Revolutionizing Medical Devices Through Innovative Nitinol Tubing

The Importance of Nitinol Tubing in Modern Medical Applications