Medical Grade Nitinol Tube Quote Made Simple for You

You can get a medical grade nitinol tube quote quickly if you know what you need. Nitinol is special because of its unique properties, so you must give clear details before you talk to suppliers. Many suppliers use nitinol for medical things, and most want your specs ready before they give a quote. Suppliers want you to say the nitinol grade, size, and any special needs. A medical grade nitinol tube quote lets you compare what suppliers offer. If you want samples, some suppliers can give them. You make things easy by getting your nitinol details ready, so suppliers can answer with a medical grade nitinol tube quote. This saves time and helps suppliers know your nitinol needs. Suppliers like clear requests for a medical grade nitinol tube quote. Most suppliers give fast answers about nitinol options.

Key Takeaways

Get all nitinol tube details ready, like size and finish, before you ask for a quote. Make sure you know what you need for the tube to work right. Pick suppliers who have the right medical certificates and good reviews. This helps you get nitinol tubes that are high quality. Use online RFQ tools or send clear messages with all the info needed. This helps you get quick and correct quotes and samples. Order small batches or samples first. Test them to see if they are good and fit well before you buy a lot. Look at all the quotes closely. Check the price, quality, delivery time, and what services come with it before you choose.

Requirements for a Medical Grade Nitinol Tube Quote

When you ask for a medical grade nitinol tube quote, you need to get some details ready. This helps suppliers answer you fast and give the right information. You should think about tube size, how strong it needs to be, what you will use it for, and how many you want. If you want samples or extra services, say so. This way, your quote will match what you need for your medical device.

Tube Specifications

You have to give clear tube details when you ask for a quote. Suppliers want to know the outer diameter, inner diameter, wall thickness, and length. It is important to be exact with these numbers, especially for medical use. Most suppliers keep the outer diameter between ±0.005 mm and ±0.015 mm. Wall thickness is kept within 0.01 mm. The surface of the tube matters too. You should say if you need a surface roughness (Ra) of 0.1 μm or better. This helps stop rust and keeps the tube safe for medical use.

Specification Category | Key Details and Requirements |

|---|---|

Dimensional Tolerances | Outer diameter: ±0.005–0.015 mm; Wall thickness: within 0.01 mm |

Surface Quality | Surface roughness (Ra) ≤ 0.1 μm for biocompatibility and corrosion resistance |

Manufacturing Techniques | Advanced extrusion, drawing, heat treatments, electropolishing, biocompatible coatings |

Quality Assurance Testing | Ultrasonic thickness, tensile strength, heat treatment verification, X-ray defect detection |

Biocompatibility and Coatings | Electropolishing, hydrophilic or polymer coatings for tissue compatibility |

You can ask for special options like a different wall thickness, diameter, or shape memory. Suppliers use special tools like laser cutting and careful machines to make custom tubes. If you want to test a sample, tell the supplier. Samples help you check if the nitinol is right before you buy more.

Tip: Always tell the supplier what tolerances and surface finish you need. This helps you get good nitinol tubing for your medical device.

Mechanical Properties

Mechanical properties show how nitinol works in your device. You should say if you need superelasticity, shape memory effect, or high fatigue resistance. These features help nitinol bend and go back to its shape. They also help it last a long time. Flexibility and strength are important for medical tools that go inside the body. Being exact with size helps your device work well.

Superelasticity gives flexibility and helps the tube bend.

Shape memory effect helps the tube fit the body.

Fatigue resistance makes the tube last longer.

Flexibility and strength help you move the tube easily.

Exact size helps your device work every time.

Suppliers use heat treatment, annealing, and electropolishing to make nitinol better. They follow rules like ASTM F2063 and ISO 13485 to keep things safe. You should always ask for papers that show the nitinol meets these rules.

Application and Compliance

You need to tell the supplier what you will use the nitinol tube for. This helps them suggest the best tube for your project. Nitinol tubes are used in things like bone implants, guidewires, stents, and other medical tools. You should also say what rules the tube must follow, like ASTM F2063, ISO 13485, FDA, or ISO 14971.

Suppliers check these rules in a few steps:

Labs test each batch for chemical makeup, strength, temperature, and rust.

Makers keep careful records and watch the process.

Each batch gets a certificate from another company.

Suppliers give proof that the tube meets ISO 10993, ISO 13485, FDA, and cleanroom rules.

Papers include design files and records for checks.

Note: Always ask for the newest certificates and proof that the nitinol meets the rules. This keeps your medical device safe and high quality.

Quantity and Small Batch Orders

How many tubes you order changes the price and how fast you get them. You should say if you want a small batch, a sample, or a big order. Some suppliers like Tegramedical and DLX Alloy let you order as few as 15 tubes or just a few meters for testing. This helps you try new ideas and get samples for new devices.

Supplier | Minimum Order Quantity | Maximum Order Quantity |

|---|---|---|

Tegramedical | Minimum order value of $250 | Up to 10 products or 100 pieces |

DLX Alloy | Minimum order quantity of 15 units | Not specified |

Small batch custom medical nitinol tubing costs more for each tube because it is harder to make and there are fewer tubes. Custom tubes take two to four weeks to make, but standard tubes may ship in a few days. Sometimes, problems with supplies or materials can slow things down, so plan ahead and tell the supplier what you need.

You can also ask for samples, faster shipping, or special boxes in your quote. Normal shipping is often free, but overnight or special shipping costs more. These extra services make the quote higher, but they can help if you need the tubes fast.

Small batch custom medical nitinol tubing helps you test ideas and order just what you need.

Samples let you check the quality before you buy more.

You can add special options like packaging or fast shipping to your quote.

Tip: Always say if you need samples, small batch custom medical nitinol tubing, or custom tubes for testing. This helps suppliers give you the right price and delivery time.

Finding the Right Supplier

Picking the best nitinol supplier is very important for your project. You need a supplier who knows medical nitinol rules. They must give you good tubes every time.

Supplier Research

First, check what people say about each nitinol supplier. Read reviews from other companies that use medical devices. Good suppliers show their certificates and focus on medical uses. Make sure they use new ways to make nitinol, like seamless extrusion. This helps the tubes stay strong and the size stay correct. It is also good if they let you pick custom tube sizes and features. You can talk to suppliers to see if they know a lot and answer fast. If you can, visit their factory to watch how they check quality.

Tip: A good nitinol supplier gives clear answers and helps with your questions.

Medical Certifications

Hospitals and device makers want strict certificates from nitinol suppliers. Look for ISO 13485 and ASTM F2516 certificates. These show the tubes are safe and high quality for medical use. ISO 13485 means the supplier follows tough quality rules. ASTM F2063 and ASTM F2516 are rules for medical nitinol parts. Some suppliers have FDA registration, which is needed for special devices like stents or implants. Ask for papers like Device Master Records, Device History Records, and test reports. These papers show the tubes are safe and you can track them.

Integrated Services

Many top suppliers help you from design to making the tubes. This means you get help with design, making, and testing all in one place. These services include design help, laser cutting, surface work, and testing for bending. Some suppliers use their own tools to change things like transformation temperature. You get faster samples, better custom tubes, and on-time delivery. Big suppliers with many workers and machines can do hard projects. They also control the supply chain, so you get your tubes when you need them.

Integrated services save time and lower risk.

You get custom nitinol tubes that fit your medical device.

Fast answers and online quote tools make things simple.

Note: Always pick suppliers with online quote tools and quick answers. This helps you get your nitinol tubes fast and keeps your project moving.

Requesting Quotes and Samples

When you ask for quotes or samples for medical grade nitinol tubes, you must give suppliers all the important information. This helps you get the right price, quick answers, and the correct tubes for your project. You can make things easier by using a checklist and picking the best way to contact suppliers.

Information to Include

Suppliers need exact details to give you a good quote. If you forget something, you might wait longer or get the wrong tube. Use this checklist to help you remember everything:

Tubing size: inner diameter, outer diameter, wall thickness, and length with tight limits

Special features: superelasticity, shape memory, or a certain transformation temperature (like 20 ± 3 °C)

Surface finish: electropolishing, passivation, or other treatments to make the tube last longer and lower nickel ion release

Compliance: needed certificates and standards like ISO 13485, ASTM F2063, and FDA

Medical use: explain how you will use the nitinol tube (like for stents, guidewires, or implants)

Documents: ask for quality test reports, batch records, and audit papers

Biocompatibility and corrosion resistance: say if you need proof for these

Mechanical strength: tell if you want high fatigue resistance or other strength needs

Quantity: say how many tubes or meters you want, and if you need a small batch or a big order

Samples: say if you want samples to test before buying more

Customization: list any special needs, like packaging or fast shipping

Contact info: add your name, company, email, and phone number

Tip: Giving more details helps suppliers send you a better quote and the right samples faster.

You can use a simple message like this when you talk to suppliers:

Hello,

I want a quote for medical grade nitinol tubing with these details:

- Inner diameter (ID): ___ mm

- Outer diameter (OD): ___ mm

- Wall thickness: ___ mm

- Length: ___ mm

- Quantity: ___

- Special features: (superelasticity, transformation temperature, etc.)

- Surface finish: (electropolishing, passivation, etc.)

- Compliance: (ISO 13485, ASTM F2063, FDA, etc.)

- Medical use: (stent, guidewire, etc.)

- Documents needed: (test reports, batch records, etc.)

- Samples: (yes/no)

- Custom needs: (special packaging, fast shipping, etc.)

- Contact info: (name, company, email, phone)

Thank you.

Using Online RFQ Tools

Many suppliers have online RFQ tools now. These tools make it much easier and faster to ask for quotes and samples. You fill out a form on the supplier’s website, type in your nitinol tube details, and upload any drawings or papers. The system sends your request straight to the sales team.

Online RFQ tools have many good points:

You save time by putting all your info in one place.

You can add files, like drawings or certificates.

You get an email to show your request was sent.

Suppliers often answer faster because the system keeps your request organized.

Some suppliers let you check your quote status or see delivery times. If you need custom tubes or special things, you can write notes in the form. Online RFQ tools help you avoid mistakes and make sure suppliers get all the info they need.

Note: Always check your info before you send the RFQ. This helps you avoid delays and makes sure you get the right nitinol tubes and samples.

Contact Methods

You have a few ways to talk to suppliers when you want quotes or samples. Each way has its own good points:

Contact Method | Best For | Advantages | Tips |

|---|---|---|---|

Online RFQ Tool | Most requests | Fast, organized, easy to add files | Use for detailed specs and custom needs |

Hard or custom tube orders | Good for sending drawings and long lists | Be clear and use a checklist | |

Phone | Urgent questions or delivery updates | Fast answers, talk directly | Get your specs ready before calling |

Live Chat | Quick questions | Instant help, easy to ask about options | Use for simple requests or follow-ups |

If you use email or phone, always give your full contact info and all the details from the checklist. For urgent orders or special samples, call the supplier right away. Some suppliers have live chat on their websites for quick help with nitinol choices or custom questions.

Tip: Clear talking helps suppliers know what you need. Always ask for a reply to show they got your request.

If you follow these steps, asking for quotes and samples for medical grade nitinol tubes is easy. You get the right price, fast shipping, and the best custom options for your project.

After You Submit Your Request

Response Times

When you send your request for medical grade nitinol tubes, most suppliers reply in about three days. Some suppliers answer even faster if you ask for quick delivery or samples. Check your email and phone often for replies from suppliers. If you do not hear back in three days, reach out to the supplier again. Following up quickly helps you avoid waiting too long for your project. Good suppliers will update you about prices, nitinol stock, and when they can deliver.

Tip: Always keep a copy of your request details. This helps you see which suppliers answer and how fast they give prices and delivery choices.

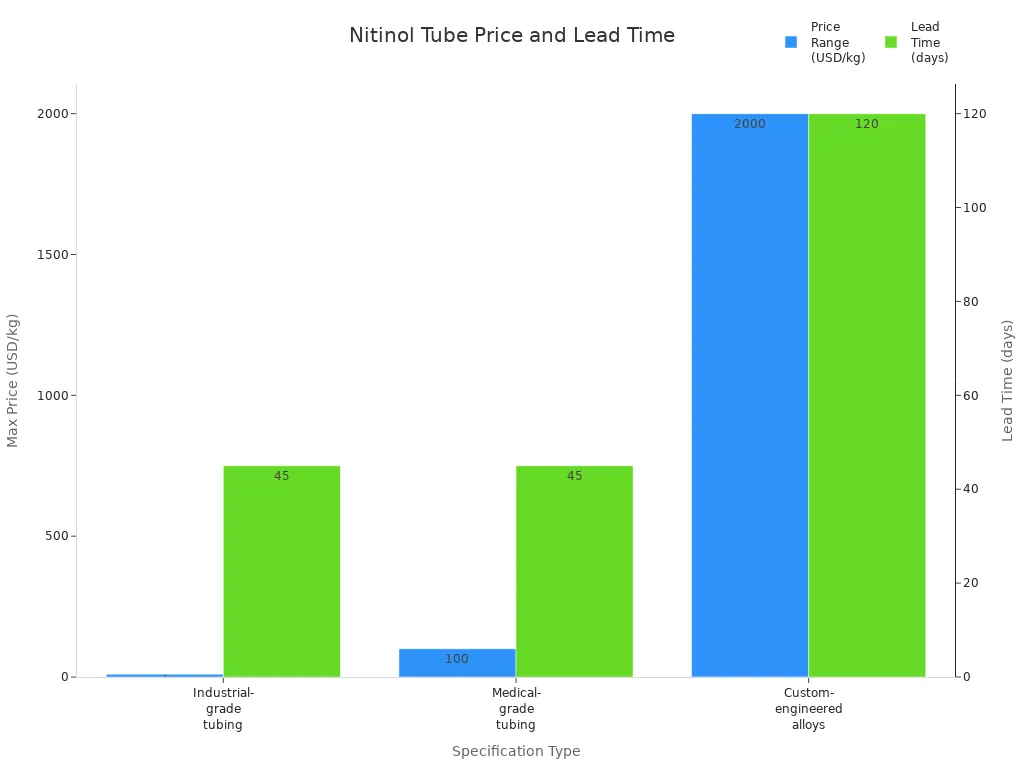

Comparing Quotes

When you get quotes from different suppliers, do not just look at the price. Check the whole offer, like nitinol quality, delivery time, and what comes with the samples. Make a table to compare the offers and see the differences:

Key Factor | Explanation | Impact on Quote Evaluation |

|---|---|---|

Raw Material Costs | Titanium and nickel prices change a lot. Suppliers may change prices if the market changes. | This changes the base price; check if it matches the market. |

Nitinol Form & Manufacturing Complexity | Tubing needs to be very exact. Suppliers may charge more for tight sizes and special shapes. | Complex tubes cost more; compare what each supplier offers. |

Precision Processing & Finishing | Steps like laser cutting, heat treatment, and electropolishing add value. | Each step adds cost; make sure all steps are listed. |

Heat Sensitivity & Handling | Nitinol needs careful handling and special boxes for fast shipping. | Handling adds to the price; check if shipping keeps it safe. |

Also, check if the quote includes samples, certificates, and fast shipping. Some suppliers give better prices if you order more or buy from them again.

Next Steps

After you look at all the quotes, pick the supplier who gives you what you need, has a fair price, and can deliver on time. Make sure you confirm your order, the number of samples, nitinol grade, and when it will arrive. Ask for tracking numbers and updates about your order. If you need your order fast, remind the supplier before you pay. Keep all records of prices, nitinol details, and delivery promises. This helps you fix problems if something goes wrong.

If you do not get a reply or your order is late, contact other suppliers. Good suppliers want your business and will try hard to meet your nitinol tube needs.

You can get a medical grade nitinol tube quote easily if you follow some steps. First, get your needs ready and check if the supplier is good. Use online tools like Chamfr to get answers fast. Many new buyers have trouble because they do not talk clearly, do not have the right papers, or wait too long for replies. You can stop these problems by asking for samples, reading what others say about the supplier, and using safe websites. Getting quotes and samples is easy when you know what to do. Start your project now and work with suppliers you trust.

FAQ

What is medical grade nitinol tubing?

Medical grade nitinol tubing is made from a nickel-titanium alloy. This tubing bends easily and goes back to its shape. It is safe for use in the body. People use it in stents, guidewires, and other medical tools. Suppliers check the tubing to make sure it meets strict medical rules.

How fast can I get a quote for nitinol tubes?

Most suppliers answer in about three days. You get answers faster if you give all the details. Using online RFQ tools helps you get a quote the quickest.

Can I order small quantities or samples?

Yes, you can ask for small batches or samples. Many suppliers let you order just a few tubes. You can test the samples before you buy more.

What certifications should I look for in a supplier?

You should look for ISO 13485, ASTM F2063, and FDA approval. These show the supplier follows medical device safety and quality rules.

See Also

The Process Behind Manufacturing Nitinol Tubing For Medicine

Ways Nitinol Tubing Is Transforming Modern Medical Devices

Finding The Most Cost-Effective Nitinol Tubing Supplier 2mm