How to Manufacture Precision Drawn Nitinol Tubing

Precision drawn Nitinol tubing with tight tolerance and exact measurements is very important. It is used in medical and aerospace fields for reliable tools. Examples include stents and guidewires that save lives. Nitinol bends easily and remembers its shape, making it great for flexible and strong devices. It can bend and go back to its original form, working well every time. Accurate sizes, such as precision drawn Nitinol tubing with tight tolerance, make it even more dependable, cutting waste by 30% compared to regular metals. By making tools safer and more effective, nitinol tubing leads to new ideas in important industries.

Key Takeaways

Nitinol tubing is important in medicine and aerospace because it can return to its shape and stretch easily.

Picking the right mix of metals and using heat can make Nitinol work better for certain jobs.

Exact measurements and special tools make sure Nitinol tubing is the right size and high quality.

Careful steps like shaping and pulling are needed to make strong and useful Nitinol tubing.

Regular checks and approvals keep Nitinol tubing safe and dependable for important uses.

Material Selection

Properties of Nitinol

Nitinol is special because of its unique abilities. It can stretch a lot and still go back to its original shape. This makes it great for flexible tools like stents and guidewires. These tools work well even under pressure. Nitinol also resists rust, which helps it last longer in tough conditions. It is safe for the body, so it’s perfect for medical tubing, including tiny systems like microfluidics.

Another cool feature is its ability to "remember" shapes. When heated to certain temperatures, it returns to a pre-set shape. This happens because of changes between two phases called austenite and martensite. This shape memory helps Nitinol work reliably in precise manufacturing.

Alloy Composition and Customization

Nitinol is made from nickel and titanium, usually half of each. Changing this mix can adjust how it reacts to heat, making it fit different uses. Adding other metals like chromium or cobalt can make it resist rust better or change its strength.

Customization isn’t just about the mix. Special heat treatments can make Nitinol stronger and more flexible. Manufacturers can also change the size, length, and surface of the tubing to match exact needs. This level of detail ensures Nitinol tubing works perfectly for important industries.

Customization Aspect | Description |

|---|---|

Composition Adjustments | Changing the nickel-titanium mix changes how it reacts to heat. Adding other metals can improve rust resistance or strength. |

Thermomechanical Processing | Using heat and cold treatments improves strength and flexibility. |

Dimensional Specifications | Tubing size, length, and surface can be adjusted for specific designs, especially for medical tools. |

Why Nitinol is Ideal for Tight Tolerances

Nitinol’s special features make it great for precise manufacturing. Its flexibility lets it handle repeated bending without breaking. This means fewer replacements, saving money for manufacturers.

Nitinol can be shaped into exact sizes without losing strength. This is important for making tubing with consistent measurements, especially for medical tools. Advanced methods, like computer simulations, help improve Nitinol’s performance for demanding uses.

Specification/Advantage | Description |

|---|---|

Superelasticity | Nitinol stretches and returns to its shape, useful for bending tools. |

Tight Tolerances | Exact sizes are key for medical tools to work properly. |

Precision Manufacturing | High-tech equipment ensures tubing stays uniform for later steps. |

Manufacturing Process

Extrusion of Nitinol

Extrusion is the first step to make nitinol tubing. The nitinol alloy is pushed through a mold to form a long tube shape. This process makes sure the tubing has the same thickness everywhere. It also improves nitinol’s special abilities, like bending and remembering shapes.

Studies show extrusion-based methods create high-quality nitinol tubing. For example, 3D-printed nitinol can bend and return to its shape under stress. It showed a memory strain of 1.9% and a stretch strain of 1.3%. These results prove extrusion helps make tubing with reliable features.

To get the best results, you must control extrusion settings. Things like heat, pressure, and mold design affect the tubing’s size and strength.

Drawing Techniques for Precision Tubing

Drawing is the next step to make nitinol tubing smaller. The tubing is pulled through smaller molds to get the right size and thickness. This step also makes the surface smoother for tools that need exact measurements.

Single-pass or multi-pass drawing methods can be used. Multi-pass drawing is better for nitinol because it reduces size slowly, avoiding damage. Advanced machines with computer controls help keep the process accurate. They check speed, tension, and lubrication during drawing.

Drawing is very important for medical tools like stents and guidewires. These tools need smooth surfaces and exact sizes to work well. Using modern machines and careful methods ensures nitinol tubing meets strict standards.

Annealing and Heat Treatment

Annealing and heat treatment improve nitinol tubing’s properties. These steps involve heating the tubing and cooling it carefully. Annealing removes stress, makes it more flexible, and improves its ability to remember shapes.

The heat level affects the tubing’s final features. For example, heating at 350–550°C for different times changes how it reacts to temperature and pressure. Tubes heated at 450–550°C for 1–10 minutes show special changes useful for certain tools.

Temperature Range (°C) | Heat Treatment Times (min) | Effects on Tubing Properties |

|---|---|---|

350 - 550 | 3, 5, 10, 20, 60, 120 | Changes in bending and memory abilities |

250 - 400 | 1, 2, 4, 8, 32, 64 | Heat treatment in controlled salt baths |

450 - 550 | 1 - 10 | Creates two-step changes in tubing |

Heat treatment also adds a peak phase to nitinol tubing. This makes it easier to adjust the tubing for specific uses, like medical or aerospace tools.

By carefully managing these heating steps, the tubing becomes strong and dependable. These processes are key to making nitinol tubing that lasts and performs well.

Precision Calibration

Precision calibration is key to making nitinol tubing the right size. Advanced tools and methods help meet strict standards and improve reliability.

Tools for Measuring Dimensional Accuracy

Measuring tools are important for keeping tubing sizes consistent. They check inner and outer diameters, wall thickness, and ovality accurately.

Laser Micrometer Systems: Systems like BenchLinc use lasers to measure tubing sizes precisely. They ensure products meet industry rules by giving reliable data.

Diffraction-Based Instruments: Tools like Cersa use diffraction to measure with 5µm accuracy. They are great for applications needing tight tolerances.

Advanced Optical Technologies: Non-contact tools like PAI, FVM, and CSI measure quickly and accurately. These reduce mistakes during inspections.

Coordinate Measuring Machines (CMM): CMMs use video probes and optical tech to inspect tubing sizes. They work well even in tough conditions.

Tip: Modern measuring tools improve accuracy, cut waste, and boost efficiency.

Techniques for Achieving Tight Tolerances

Making nitinol tubing with tight tolerances needs careful methods. Statistical tools and real-time checks help improve precision.

Evidence Type | Description |

|---|---|

CMM Inspection | Statistical checks and size analysis improve quality control. |

Crosstalk Coefficient Calibration | Better crosstalk estimates make measurements more accurate and efficient. |

Multi-pass drawing slowly reduces tubing size to avoid damage. Real-Time Error Compensation (RTEC) systems adjust measurements for consistent results.

New tools like optical comparators and digital calipers make measurements better. They send data automatically, reducing mistakes and speeding up inspections.

Addressing Manufacturing Challenges

Making nitinol tubing comes with challenges. You need to manage supply chains, material properties, and certifications.

Supplier Selection: Choose suppliers with ISO 13485 and AS9100 certifications. These ensure products meet medical and aerospace standards.

Advanced Manufacturing Technologies: New techniques improve nitinol’s features for important uses.

Strategic Partnerships: Work with trusted suppliers to keep production stable and access new technologies.

By focusing on these areas, you can solve problems and make tubing that meets high standards.

Note: Solving challenges early helps avoid delays and keeps production quality steady.

Quality Control

Testing for Dimensional Accuracy

Checking the size of Nitinol tubing is very important. It ensures the tubing works well in medical tools. Special tests check the outer diameter (OD), inner diameter (ID), and wall thickness. Tools like laser micrometers measure these sizes very accurately. Ultrasonic systems also help find problems inside the tubing. Non-destructive testing (NDT) finds flaws without harming the tubing.

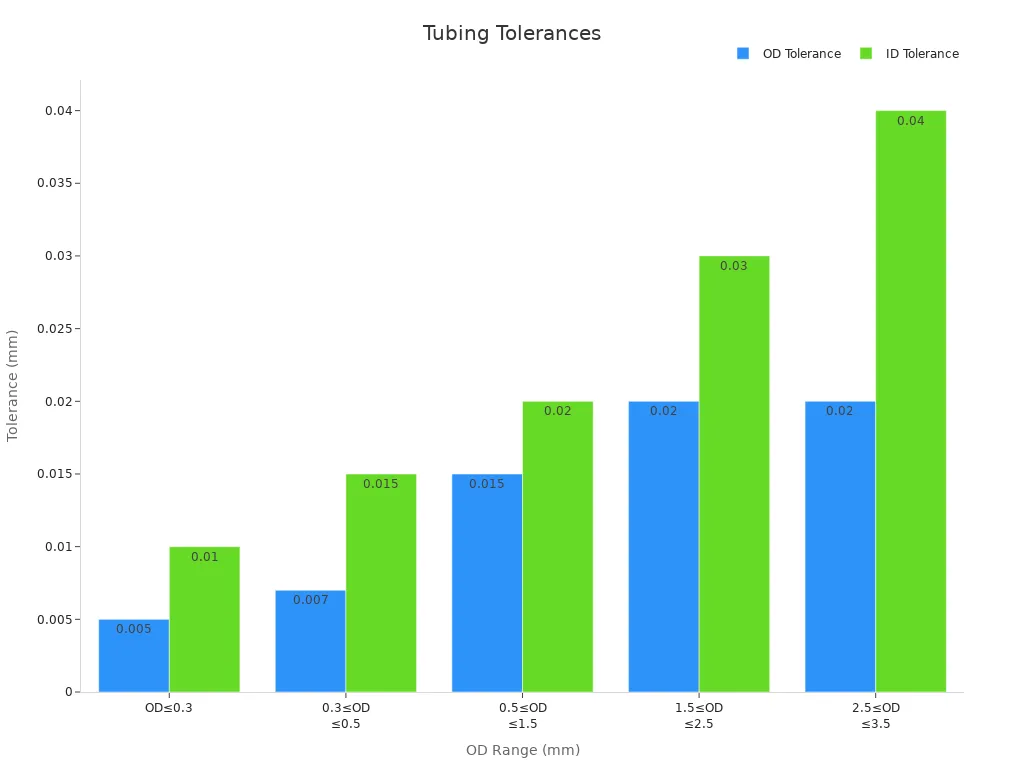

Here’s a table showing size tolerances for different tubing:

Outer Diameter (OD) (mm) | OD Tolerance (mm) | ID Tolerance (mm) |

|---|---|---|

OD ≤ 0.3 | ±0.005 | ±0.010 |

0.3 ≤ OD ≤ 0.5 | ±0.007 | ±0.015 |

0.5 ≤ OD ≤ 1.5 | ±0.015 | ±0.020 |

1.5 ≤ OD ≤ 2.5 | ±0.020 | ±0.030 |

2.5 ≤ OD ≤ 3.5 | ±0.020 | ±0.040 |

Electropolishing makes the tubing’s surface smoother and more accurate. These tests make sure the tubing meets strict medical standards.

Standards and Certifications for Nitinol Tubing

Following rules and certifications keeps Nitinol tubing safe and high-quality. Look for certifications like ASTM F2063, which checks if the material is good for medical use. ISO 9001 shows the supplier cares about quality. ISO 13485 proves the tubing meets medical device rules.

Certification Type | Importance in Quality Assurance |

|---|---|

ASTM F2063 | Checks material standards for medical-grade Nitinol. |

ISO 9001 | Shows the supplier follows quality rules. |

ISO 13485 | Proves the tubing meets medical device regulations. |

These certifications make sure the tubing is reliable. They also build trust for important uses like stents and guidewires.

Inspection Protocols for Consistency

Keeping Nitinol tubing consistent needs strong inspection methods. Statistical Process Control (SPC) helps track and improve production. Tools like charts and diagrams find problems and fix them.

SPC Techniques: Use data to spot and fix issues.

Control Charts: Watch production steps in real-time.

Cause-and-Effect Diagrams: Find reasons for problems.

Pareto Charts: Focus on big issues affecting quality.

Regular checks of materials and finished tubing ensure it meets standards. These methods help make tubing that works well every time.

Tip: Catching problems early saves time and reduces waste.

Making precision-drawn Nitinol tubing needs careful steps. First, pick the right material. Make sure the alloy mix fits the job. Special methods like extrusion, drawing, and heat treatment shape the tubing. These steps help it meet exact size needs. Precision tools and strict checks ensure it works for important uses.

Choosing materials, using good methods, and checking quality are key. These steps make tubing that works well in tough fields like medical and aerospace. Precision is not just important—it’s the base for safety and new ideas.

Tip: Pay attention to every detail to create top-quality tubing.

FAQ

What makes Nitinol tubing special compared to other materials?

Nitinol tubing is unique because of its shape memory and superelasticity. It bends easily and goes back to its original shape. These features make it great for medical and aerospace tools needing flexibility and strength.

How do you keep tight tolerances during manufacturing?

Tight tolerances are achieved using advanced tools like laser micrometers. Precision drawing and real-time monitoring systems help keep sizes consistent. Multi-pass drawing also ensures smooth surfaces and accurate dimensions.

Is Nitinol tubing safe for medical use?

Yes, Nitinol tubing is safe for medical tools. It resists rust and works well inside the body. Certifications like ASTM F2063 and ISO 13485 prove it meets strict medical rules for stents and guidewires.

Can Nitinol tubing be made for specific uses?

Yes, Nitinol tubing can be customized for different needs. You can change its size, surface, and alloy mix. Heat treatments and special processes improve its features for specific jobs.

What problems might happen during Nitinol tubing production?

Making Nitinol tubing can be tricky. Problems include keeping material quality, meeting size rules, and passing certifications. Working with certified suppliers and using new technologies can solve these issues.

Tip: Fixing problems early helps make better tubing and avoids delays.

See Also

Comprehensive Overview of Nitinol Parts and Production Methods

Finding the Most Cost-Effective 2mm Nitinol Tubing Supplier

Evaluating Nitinol Tubing Strength Against Stainless Steel Options

The Importance of Nitinol Tubing in Minimally Invasive Surgery