Essential Tips for Maintaining Nickel-Iron Alloy Tubes in High-Pressure Settings

Nickel-iron tubes are crucial in environments with high pressure, making the Best Nickel-Iron Alloy Tubes for High Pressure essential for ensuring strength and performance under tough conditions. Proper maintenance is vital to help them withstand heat and pressure fluctuations. Neglecting maintenance can lead to machine failures, causing delays or even posing safety risks.

Regular care makes the Best Nickel-Iron Alloy Tubes for High Pressure last longer and operate more efficiently.

Minor issues, such as cracks or rust, can escalate if left unaddressed. Early intervention in fixing these problems keeps machines safe and protects workers in demanding jobs.

Key Takeaways

Check the tubes often. Look for cracks, rust, or damage to fix problems early and stay safe.

Use proper cleaners. Pick products made for nickel tubes to avoid harm.

Stick to a care plan. Clean, oil, and check tubes regularly to save money and make them last longer.

Teach workers how to handle tubes safely. Training helps prevent damage and ensures good care.

Have experts check tubes every year. They can spot hidden problems and give helpful tips for care.

Challenges in High-Pressure Environments

Stress and Fatigue on Nickel Alloy Tubes

Nickel-iron tubes face a lot of pressure in tough settings. Constant high pressure can slowly weaken the material. This weakening causes small cracks or bends to appear over time. These small problems can grow into big ones if ignored.

Checking the tubes often helps find early damage and keeps them safe.

Workers should look for any visible damage on the tubes. Special tools can find hidden weak spots inside the tubes. Fixing these problems early saves money and keeps the system running well.

Corrosion Risks in High-Pressure Systems

Corrosion is a big problem for nickel-iron tubes in high-pressure systems. Moisture, heat, and chemicals make corrosion happen faster. Over time, this makes the tubes weaker and more likely to break.

To stop corrosion, workers can use anti-rust coatings on the tubes. Cleaning the tubes often removes harmful buildup. Keeping the area dry and controlling humidity also helps prevent rust.

Tip: Use cleaners made for nickel-iron tubes to avoid damage.

Temperature Fluctuations and Their Effects

High-pressure systems often have big temperature changes. These changes make the tubes expand and shrink again and again. Over time, this can cause cracks or leaks in the tubes.

To reduce this problem, keep the system at a steady temperature. Adding insulation around the tubes helps control temperature swings. Watching the system closely can catch problems early.

Keeping conditions steady helps nickel-iron tubes last longer.

Best Practices for Maintaining Nickel Alloy Tubes

Inspection Steps for High-Pressure Use

Regular checks are key to keeping nickel alloy tubes safe. These checks find early problems like cracks, rust, or bends. Such issues can weaken the tubes over time. Following set rules ensures these checks are done right. For example, standards like ASTM B161-25 and B407-22 give clear steps for inspecting tubes in high-pressure systems.

Standard | What It Covers |

|---|---|

Rules for Nickel Seamless Pipes and Tubes | |

Rules for Nickel-Iron-Chromium Alloy Seamless Pipes | |

Rules for Nickel-Iron-Chromium-Molybdenum-Copper Alloy Pipes | |

Rules for Welded Nickel-Iron-Chromium Alloy Tubes | |

Rules for Seamless Nickel Alloy Tubes |

Special tools, like ultrasonic testers, find hidden damage inside tubes. Workers should also look for surface damage during regular checks. Setting up a schedule for inspections keeps the system working well and avoids sudden breakdowns.

Tip: Follow the maker's rules when checking tubes to avoid damage or losing warranties.

Cleaning Nickel Alloy Tubes

Cleaning is important to keep nickel alloy tubes working well. Over time, dirt, chemicals, and water can build up on the tubes. This can cause rust and make them less effective. Using cleaners made for nickel alloys removes dirt without harming the tubes.

For example, anti-rust sprays and special cleaners protect the tubes from rust. Workers should not use rough tools or strong chemicals that might scratch the tubes. Instead, soft brushes and gentle cleaners work best.

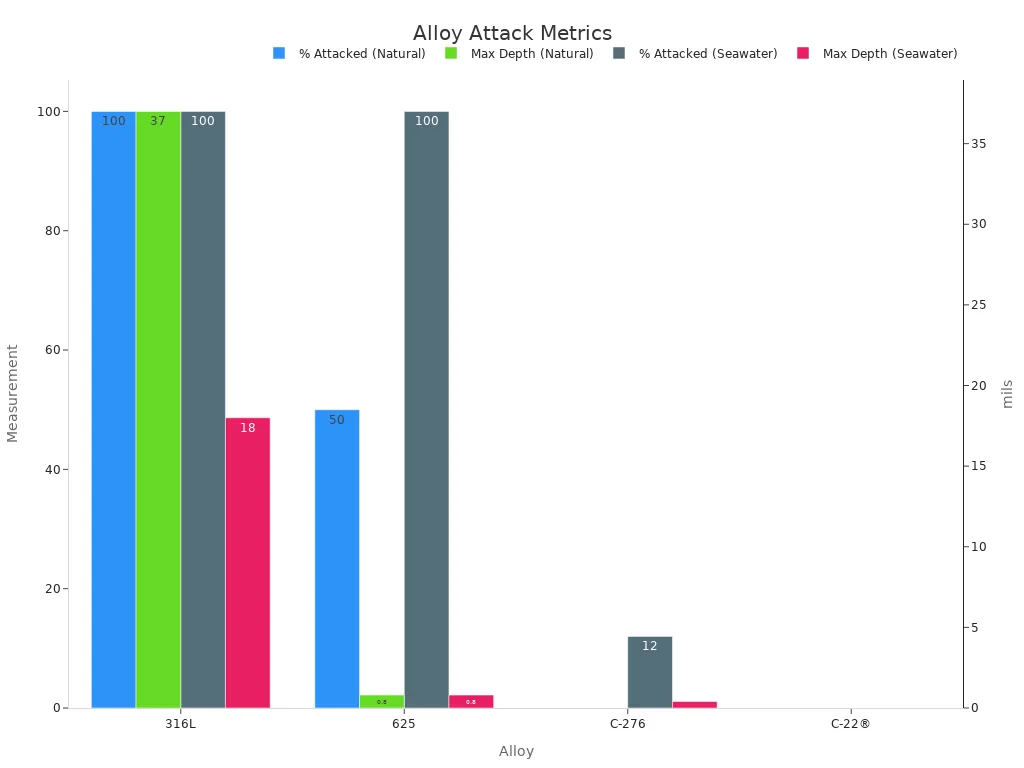

The chart above shows how well different alloys resist rust in various conditions. Nickel alloy tubes, like C-22®, resist rust better, making them great for high-pressure jobs. Cleaning often helps keep this rust resistance strong and ensures the tubes work well.

Note: Always dry the tubes completely after cleaning to stop rust caused by leftover water.

Watching for Wear and Tear

Watching for wear helps catch problems before they get worse. Signs like thinner walls, small cracks, or color changes mean the tubes might need fixing or replacing. Tools like calipers and thickness gauges help measure the tubes and find problems.

Checking the tubes when they are first installed gives a starting point. Later checks can compare to this starting point to spot changes. Fixing problems early stops more damage. Systems with sensors can also track the tubes' condition and help with quick repairs.

Callout: Finding wear early saves money and avoids system failures.

Using Lubrication and Coatings

Lubrication and coatings help protect nickel alloy tubes. They lower friction, stop wear, and guard against damage. These steps make the system last longer and work better.

Why Lubrication Helps

Lubrication reduces stress from movement or shaking in systems. It keeps things running smoothly and prevents cracks or surface harm. Workers should pick lubricants made for nickel alloy tubes. This avoids harmful chemical reactions.

Tip: Spread lubrication evenly to avoid uneven wear and ensure protection.

How Coatings Protect

Coatings keep tubes safe from rust, heat changes, and chemicals. Anti-rust coatings, like epoxy or ceramic, block moisture and harmful substances. Heating before and after coating helps it stick better and last longer.

Workers should check coated areas often for peeling or damage. Fixing or reapplying coatings when needed stops further harm and keeps tubes strong.

How to Apply Them

Applying coatings and lubrication needs care. Clean the tubes first to remove dirt or residue. This ensures the protection works well. Use sprays or brushes to cover the tubes evenly.

Note: Follow the maker's rules for coating thickness and drying times for best results.

Planning Preventive Maintenance

Preventive maintenance keeps nickel alloy tubes reliable in tough conditions. A good plan finds problems early, saving time and repair costs.

Why Regular Maintenance Matters

High-pressure systems put stress on tubes. Regular checks find early signs of wear, rust, or damage. Cleaning and inspections keep tubes in top shape.

Callout: Preventive maintenance saves money by avoiding big repairs.

Making a Maintenance Plan

A good plan includes inspections, cleaning, lubrication, and heat treatments. Focus on risky spots like joints and bends where damage happens more often.

Maintenance Task | How Often | Tools Needed |

|---|---|---|

Visual Inspection | Weekly | Flashlight, magnifier |

Cleaning | Monthly | Nickel-safe cleaners |

Lubrication Application | Every 3 months | Lubricants, applicators |

Coating Reapplication | Yearly | Brushes, spray equipment |

Training and Keeping Records

Training workers ensures maintenance is done right. Write down each task, noting tube condition and repairs. This helps track how the system performs over time.

Tip: Use digital tools to plan and record maintenance for better results.

Common Maintenance Mistakes to Avoid

Overlooking Small Cracks or Flaws

Ignoring small cracks in nickel alloy tubes can cause big issues. These tiny flaws grow under high pressure, leading to leaks or tube failure. Regular checks help find these problems early. Workers should use tools like magnifiers or ultrasonic testers to spot hidden cracks.

Tip: Fix small cracks quickly to avoid expensive repairs or delays.

Leaving these cracks untreated weakens the tubes and creates safety risks. High-pressure systems need strong parts to work safely. Even a tiny crack can stop operations and put workers in danger. Regular maintenance keeps the system safe and reliable.

Using the Wrong Cleaning Products

Using bad cleaning products can harm nickel alloy tubes. Strong chemicals or rough tools can damage the surface or thin the walls. This makes the tubes weaker and shortens their life. Always use cleaners made for nickel alloys.

For example, neutral pH cleaners remove dirt without hurting the material. Avoid acidic or alkaline cleaners unless the maker says they are safe. Use soft brushes or cloths instead of rough tools that can scratch the surface.

Do | Don’t |

|---|---|

Use nickel-safe cleaners | Use strong chemicals |

Clean with soft brushes | Use rough tools |

Rinse well after cleaning | Leave residue on the tubes |

Note: Test a small spot before using a new cleaner on the whole tube.

Good cleaning keeps the tubes looking nice and working well. This helps them last longer in tough, high-pressure conditions.

Ignoring Manufacturer Instructions

Not following the maker's instructions can damage nickel alloy tubes. These instructions explain how to install, clean, and maintain the tubes. Ignoring them can lead to mistakes or using the wrong materials.

Manufacturers give these rules to make the tubes last longer and work better. For example, they may suggest certain coatings or lubricants and how often to maintain the tubes. Following these rules keeps the system running smoothly.

Callout: Manufacturer instructions are important for keeping the system safe and strong.

Skipping these instructions can cancel warranties and raise repair costs. Workers should keep the manual nearby and check it often. Training workers on these rules helps avoid mistakes.

Postponing Scheduled Maintenance

Skipping planned maintenance can cause big problems in high-pressure systems. Nickel-iron alloy tubes need regular care to work well. Delaying maintenance raises the chance of damage, breakdowns, and expensive fixes.

Why Delaying Maintenance is Risky

Increased Wear and Tear

High-pressure systems face tough conditions every day. Over time, this puts stress on nickel-iron alloy tubes. Missing maintenance lets small cracks or thinning walls get worse. These small issues can turn into major failures, stopping operations.Higher Repair Costs

Skipping maintenance often leads to costly repairs. For example, a tiny crack can grow and require replacing the whole tube. Regular care finds these problems early and saves money over time.Safety Hazards

Damaged tubes in high-pressure systems can be dangerous. Leaks or bursts might harm workers or equipment. Sticking to a maintenance plan keeps the system safe and reliable.

Tip: Always follow maintenance schedules to avoid risks and extra costs.

How to Avoid Delays

Set Clear Reminders

Use apps or calendars to track when maintenance is due. Alerts help teams finish tasks on time.Assign Responsibilities

Pick team members to handle maintenance jobs. Clear roles make sure tasks don’t get skipped.Monitor System Performance

Add sensors to check the condition of nickel-iron alloy tubes. These tools give live updates, showing when maintenance is needed.

Action | Frequency | Purpose |

|---|---|---|

Schedule Inspections | Weekly or Monthly | Spot early signs of damage |

Review Maintenance Logs | Quarterly | Confirm tasks are completed |

Conduct Staff Training | Annually | Improve maintenance skills |

The Long-Term Benefits of Staying on Schedule

Regular care helps nickel-iron alloy tubes last longer. It also reduces downtime, keeping the system running smoothly. Teams that stick to schedules face fewer emergencies and lower repair costs.

Callout: Staying on schedule improves safety, saves money, and boosts efficiency.

By avoiding delays, companies can keep high-pressure systems safe and working well.

Preventive Measures for Longevity

Setting Up a Maintenance Plan

A good maintenance plan keeps nickel-iron alloy tubes working well. Regular care stops small problems from becoming expensive repairs. Companies should make a clear schedule for checks, cleaning, lubrication, and coatings.

Tip: Pay extra attention to joints and bends. These areas face the most stress.

Using a calendar or app helps teams stay on track. Giving tasks to specific workers ensures they get done. For example, weekly checks can find surface damage early. Monthly cleanings remove dirt and stop rust. Annual coating updates protect tubes from corrosion.

Task | How Often | Why It’s Important |

|---|---|---|

Visual Inspections | Weekly | Find damage early |

Cleaning | Monthly | Stop rust and remove buildup |

Lubrication Application | Every 3 months | Lower friction and wear |

Coating Reapplication | Yearly | Guard against rust and damage |

Following a plan reduces downtime and helps tubes last longer.

Teaching Workers Safe Handling

Teaching workers how to handle nickel-iron alloy tubes prevents damage. Training shows them how to avoid rough handling or using the wrong tools.

Callout: Trained workers can spot problems early and fix them quickly.

Hands-on lessons and videos are great for teaching safe methods. Workers should also learn to use tools like ultrasonic testers and thickness gauges. Regular training keeps everyone updated on the best ways to care for the tubes.

Using Tools to Monitor Tubes

Monitoring tools are important for keeping nickel-iron alloy tubes in good shape. Ultrasonic testers find hidden cracks, and thickness gauges check for thinning walls. These tools give accurate information to decide on repairs or replacements.

Note: High-quality tools give better results and fewer mistakes.

Digital sensors can watch tube performance all the time. They alert workers to changes in pressure, temperature, or damage. Catching problems early avoids sudden failures and keeps systems running smoothly.

Getting Experts for Regular Checks

Having experts check nickel-iron alloy tubes is very important. They have special skills and tools to find hidden problems. Experts also make sure the tubes follow safety rules.

Why Expert Checks Matter

Experts can find issues that regular checks might miss. They use advanced tools like ultrasonic testers and X-rays to look inside the tubes. This helps them spot wear, rust, or weak spots.

Tip: Plan expert checks at least once a year to avoid surprises.

How Experts Help

Better Safety

Experts make sure tubes are safe to use. They help lower risks like leaks or bursts in high-pressure systems.Saving Money

Fixing problems early costs less than fixing big failures. Replacing one tube is cheaper than fixing the whole system.Longer Tube Life

Experts give advice on how to care for tubes. Their tips help tubes last longer and work better.

Picking the Right Experts

Choose experts who know about high-pressure systems and nickel alloys. Look for certifications from groups like ASME or ASTM. Certified experts follow industry rules and do a good job.

What to Look For | Why It’s Important |

|---|---|

Certifications | Shows skill and knowledge |

Special Tools | Finds hidden problems |

Good Reputation | Means they are trustworthy |

Note: Keep reports from expert checks. These records show how the tubes are doing and help plan future care.

Expert checks improve how systems work and keep them reliable for a long time.

Taking care of nickel-iron alloy tubes in high-pressure systems is important. Regular checks, cleaning, and upkeep help them last longer and stay safe. Fixing problems early stops damage like rust and wear, keeping systems running well.

Key Point | What It Means |

|---|---|

Longer Lifespan | Regular care helps nickel alloy tubes last many years. |

Spotting Problems Early | Inspections find rust or damage before they cause big issues. |

Keeping Systems Efficient | Cleaning removes dirt and keeps everything working smoothly. |

Following Rules | Sticking to standards ensures safety and good performance. |

Better Value | Good care means the tubes work well for a long time, saving money. |

Using smart maintenance practices gives long-lasting results and meets safety rules. Getting experts to check the tubes adds extra protection and keeps them working well. Companies that focus on care protect their equipment and create safer workplaces.

Tip: Regular maintenance saves money, lowers risks, and boosts performance.

FAQ

What shows that nickel-iron alloy tubes need maintenance?

Check for cracks, rust, or color changes on the surface. Use tools like ultrasonic testers to find hidden damage inside. Leaks or thinner walls also mean the tubes are wearing out. Regular checks catch these problems early.

Tip: Fix small issues quickly to avoid expensive repairs later.

Can I use any cleaner for nickel-iron alloy tubes?

No, only use cleaners made for nickel alloys. Strong chemicals or rough tools can harm the surface. Neutral pH cleaners are safest. Rinse well and dry the tubes to stop rust.

Note: Try new cleaners on a small spot before using them everywhere.

How often should you do preventive maintenance?

Inspect the tubes weekly, clean them monthly, and add lubrication every three months. Apply coatings once a year. Follow the maker’s rules for exact schedules.

Task | How Often |

|---|---|

Visual Inspections | Weekly |

Cleaning | Monthly |

Lubrication Application | Every 3 Months |

What tools help check tube condition?

Ultrasonic testers, thickness gauges, and sensors are useful. These tools find cracks, measure wall thickness, and track performance live.

Tip: Use good-quality tools for better results and fewer mistakes.

Why follow the maker’s instructions?

Maker instructions explain how to care for the tubes properly. They list safe cleaners, coatings, and schedules. Ignoring these rules can cancel warranties and shorten tube life.

Callout: Keep the manual nearby and train workers to follow it carefully.

See Also

The Influence of NiTi Tubing Testing on Longevity

Improving Catheter and Implant Function with Nickel-Titanium Tubing

Why NiTi Tubes Are Revolutionary for Medical and Aerospace Fields

Current Developments in Nickel Titanium Alloy Applications and Innovations