Why Nitinol Tubing Is the Material of Choice for Modern Medical Devices

Nitinol tubing is at the forefront of innovation in medical devices in 2025, driven by the latest Nitinol tubing technology in medical devices. Its superelasticity and shape memory allow devices to return to their original shape after bending, making nitinol tubing essential for less invasive surgeries and robot-assisted procedures. Medical devices crafted with nitinol tubing are highly flexible, strong, and biocompatible, promoting faster healing and reducing the risk of complications.

Clinical data highlights the benefits of nitinol tubing:

Performance Metric

2025 Results

Complete vessel recanalization

86.7%

Procedural success rate

88%

Durability (bending cycles)

10 million

Overall clinical success rate

97%

Each year, more physicians adopt nitinol tubing in their medical instruments, thanks to advancements in manufacturing, expanded design options, and the latest Nitinol tubing technology in medical devices. These improvements enhance the performance and reliability of medical devices for both patients and healthcare providers.

Key Takeaways

Nitinol tubing can bend and go back to its shape. This helps medical devices work better in surgeries. It makes surgeries less invasive and safer for patients.

Nitinol tubing works well with the human body. It does not rust easily. This lowers the chance of the body rejecting implants. It also keeps patients safer. Nitinol tubing is good for use in the body for a long time.

New ways of making nitinol tubing make it very pure. These ways also make it very exact. This helps medical devices work better and last longer. It is important for hard medical procedures.

Doctors use nitinol tubing in many devices. These include heart, brain, and bone devices. It helps doctors do better in surgeries. Patients also get better faster.

New ideas like smart features and green ways to make nitinol tubing are important. They help nitinol tubing meet new medical needs. They also help protect the environment.

Nitinol Tubing Properties

Superelasticity

Superelasticity makes nitinol tubing special in medical devices. Devices with superelastic nitinol tubing can bend many times and do not stay bent. Digital Image Correlation shows nitinol spreads out strain when it is loaded again and again. This stops kinking and helps nitinol tubing keep its shape under pressure. Temperature checks help set the right shape, which is important for superelasticity. The stress-strain curve of superelastic nitinol tubing has a flat part. In this part, the tubing gives almost the same force even when stretched a lot. This helps stents and catheters move through tricky blood vessels. Devices get both flexibility and shape memory, so they work well in less invasive surgeries.

Shape Memory

Shape memory is a key feature of nitinol tubing. When you bend nitinol, it goes back to its first shape when heated. Tests show medical grade nitinol tubing can handle stress from 500 MPa to 900 MPa and still keep its shape memory. Heat-treated nitinol gets over 90% recovery by the second try and 96% by the tenth, with steady strain above 6.5%. Devices with nitinol tubing can stretch up to 10%. This is much more than the 1% limit for stainless steel. This means nitinol tubing keeps its shape and works well after many uses. Its flexibility and shape memory help devices stay safe and reliable for patients.

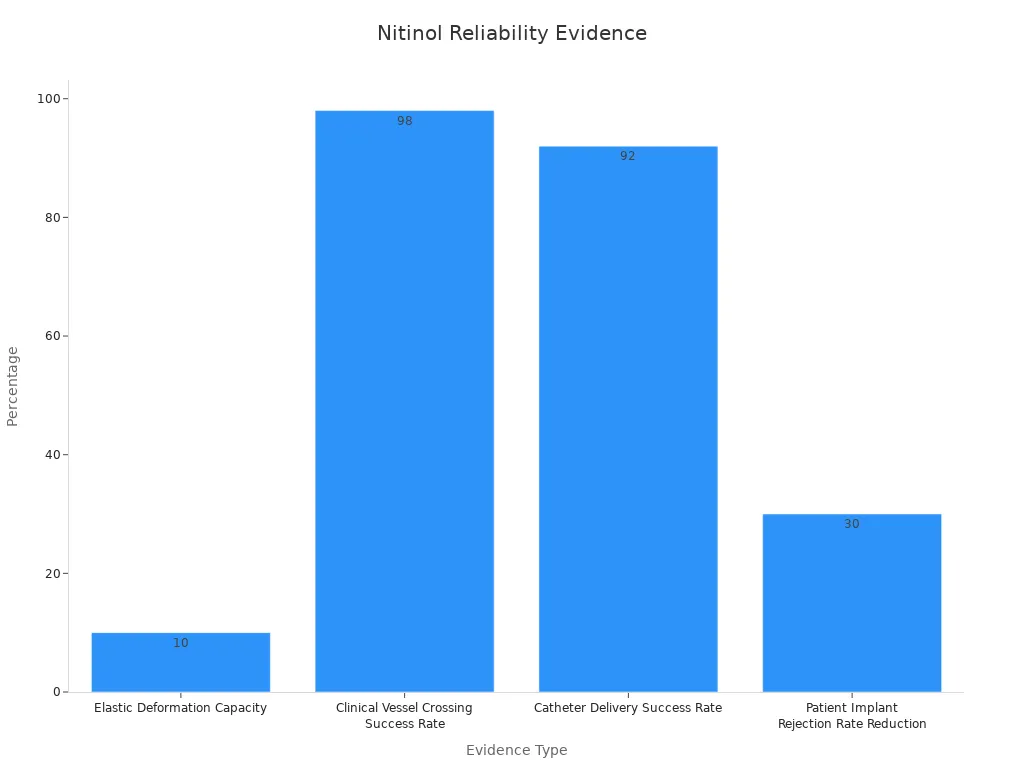

Evidence Type | Metric / Result | Description / Context |

|---|---|---|

Elastic Deformation Capacity | Up to 10% strain | Nitinol tubing can stretch up to 10%, which is much more than 1% for stainless steel, showing great shape memory. |

High-Cycle Fatigue Strain Limit | 0.4% to 0.8% strain | Shows nitinol tubing lasts a long time under repeated stress, making it reliable. |

Clinical Vessel Crossing Success Rate | 98% | The Silverway guidewire works well in blood vessels, showing high reliability. |

Catheter Delivery Success Rate | 92% | Catheters are placed successfully most of the time, so devices work well. |

Patient Implant Rejection Rate Reduction | 30% lower than traditional metals | Nitinol tubing is less likely to be rejected by the body, so it is safer for implants. |

Biocompatibility

Biocompatibility is very important for materials in medical devices. Medical grade nitinol tubing is very biocompatible and does not rust easily, so it lowers the chance of bad reactions. Studies like DAWN and PARTNER 3 show nitinol devices help more people live better and longer than old treatments. For example, the DAWN trial found 49% of people were independent at 90 days with nitinol, but only 13% with standard care. Nitinol tubing also lowers implant rejection by 30% compared to other metals. Trials show nitinol stents hurt vessel walls less and lower the chance of the vessel getting blocked again. These results show nitinol tubing is very safe and does not rust, so it is great for long-term implants.

Clinical trials proved nitinol stents work for tough artery problems.

Tests looked at how much force was needed, how stents opened, and what happened to the tissue.

After treatment, doctors saw less vessel wall damage and fewer blockages.

Corrosion Resistance

Corrosion resistance helps nitinol tubing last longer and stay safe in the body. Lab tests show nickel ions drop to 75 parts per billion after special cleaning. Oxygen and carbon in medical grade nitinol tubing stay below 60 ppm and 20 ppm. After polishing, the surface is very smooth at 0.1 micrometers or less. Tubing smaller than 0.3 mm can be made with a size difference of only ±0.005 mm. Long tests in liquid show nitinol tubing does not get pitted under body-like conditions. It lasts over 600 million heartbeats without breaking, so it is very strong. Studies show better processing makes the surface cleaner, which helps with safety and stops rust. These features make sure nitinol tubing stays safe and works well in medical devices.

Medical Device Performance

Minimally Invasive Solutions

Nitinol tubing helps doctors do less invasive surgeries. It is very flexible and can return to its shape. Surgeons use nitinol devices to move through the body with less harm. Studies show a 97% success rate for these procedures. At 12 months, 96.7% of aneurysms are closed. The DAWN Trial found 49% of patients using nitinol tools could live on their own after 90 days. Only 13% could with regular care. This means nitinol tubing helps save lives. Devices like neurovascular catheters, guidewires, and stents use nitinol tubing. These tools work well and are very precise. Nitinol tubing can stretch 7% and return 4.16%. This helps devices fit the body and lowers the chance of hurting blood vessels.

Metric / Study | Result / Outcome |

|---|---|

Technical success rate | 97% in 72 patients |

Aneurysm occlusion rate | 96.7% at 12 months |

DAWN Trial (functional independence) | 49% with nitinol vs. 13% standard care |

PARTNER 3 Trial (mortality rate) | 1.0% nitinol-assisted vs. 2.5% open-heart surgery |

Device Reliability

Nitinol tubing makes medical devices last a long time. These devices do not break easily, even after many uses. Guidewires cross blood vessels 98% of the time. Catheters are delivered safely 92% of the time. Nitinol tubing bends and returns to shape again and again. This is important for implants and stents. New ways to make nitinol tubing make it even better. Careful checks find problems before devices are used. Only the best tubing goes into medical tools. This means fewer device changes and fewer extra surgeries.

Nitinol tubing still works after millions of uses.

Special processing helps nitinol tubing last longer.

Devices with nitinol tubing work better than old materials.

Performance Metric / Application | Nitinol Tubing | Stainless Steel Tubing |

|---|---|---|

Flexibility and Shape Memory | High | Low |

Fatigue Resistance | Excellent | Moderate to low |

Clinical Success Rates (Stents) | ~97% | N/A |

Patient Safety

Keeping patients safe is very important with nitinol tubing. Companies follow strict rules to make sure devices are safe. They test each batch for strength and safety. Trials show little tissue reaction and a 30% drop in eye pressure for six months. Nitinol tubing does not rust and keeps its size. This helps keep implants safe for a long time. Better cleaning and careful checks protect patients even more.

Note: The MISAGO 1 and ORION studies show nitinol stents keep blood vessels open and flexible, making patients safer.

Safety Metric / Standard | Description / Impact |

|---|---|

ISO 13485 Certification | Reduces defects and recalls by 78% among certified manufacturers |

Testing Protocols | Guarantee device reliability under dynamic conditions |

Clinical Evidence | Minimal tissue reactions and improved patient outcomes |

Latest Nitinol Tubing Technology in Medical Devices

High-Purity Material

High-purity nitinol is very important in new medical devices. Companies like Resonetics and Fort Wayne Metals make special nitinol alloys. One example is Confluent’s SE508 ELI. These alloys are strong and safe for the body. They work well in heart implants and other important devices. Pure nitinol tubing lowers the chance of bad reactions. It also keeps patients safer for a long time. Makers use special cleaning steps to keep oxygen and carbon very low. This helps stop rust and keeps the tubing safe inside the body. Focusing on purity helps new ideas and meets the need for less invasive surgeries.

Note: High-purity nitinol tubing helps devices last longer and work better, even in tough medical situations.

Precision Manufacturing

Precision is key in new nitinol tubing for medical devices. Factories use laser cutting, 3D printing, and special machines. These tools make tubing with very exact sizes and shapes. Companies like Resolution Medical and Fort Wayne Metals check their work all the time. They can make tubing with sizes as close as ±0.0005 inches. This lets them build tiny, detailed devices that fit the body well. They follow rules like ASTM F2063 and ISO 13485 to make sure tubing is safe.

Aspect | Details |

|---|---|

Measurement Standards | ASTM F2063, ISO 13485, ISO 9001 |

Dimensional Tolerances | As tight as ±0.0005 inches (~±12.7 µm) |

Inspection Methods | Visual, ultrasonic, and radiographic testing |

Real-time Monitoring | Detects variations as small as ±5 µm |

Surface Finishing | Electropolishing for smoothness and biocompatibility |

Quality Control | Rigorous protocols for structural integrity and dimensional stability |

Makers also polish and coat the tubing to make it smoother. This helps stop rust and makes the tubing work better in the body. New ways to make nitinol tubing help create new devices and help patients heal faster.

Enhanced Radiopacity

Better radiopacity is a big part of new nitinol tubing. Doctors need to see devices clearly during surgery. Makers add DFT® flat wire and other special materials to nitinol tubing. This lets doctors watch stents, catheters, and guidewires on screens. Better radiopacity makes surgeries safer and more exact.

DFT® flat wire makes devices easier to see but keeps them flexible.

Radiopaque nitinol tubing helps doctors put devices in the right place.

Better images help patients get better results and shorten surgery time.

These new features help both doctors and patients. They also help new medical technology keep getting better.

Smart Integration

Smart integration is a big step forward for nitinol tubing. Makers now add sensors and actuators to nitinol tubing. These smart devices can check vital signs and react to changes fast. For example, nitinol tubing in health sensors can bend and still give good readings. In robot surgery, nitinol parts move like real muscles and help doctors work carefully.

Performance Metric | Description and Benefit |

|---|---|

Shape Memory Effect | Lets nitinol tubing go back to its shape, making devices flexible and easy to use. |

Superelasticity | Tubing can bend a lot and return, so it lasts longer and works better. |

Dimensional Accuracy | Makes sure devices like stents fit just right, which is very important for safety. |

Surface Quality | Smooth tubing lowers infection risk and is safer for the body. |

Fatigue Resistance | Devices last longer even when used many times, which is good for robots and planes too. |

Sensor Integration | Lets devices check things in real time and react fast, making them smarter. |

Smart integration also helps in planes and smart homes, but it is most important in medical devices. Mixing nitinol’s special features with new electronics makes devices safer and more reliable.

Tip: Smart nitinol tubing gives real-time feedback and can change how it works, making medical devices even better.

Meeting Growing Demand Through Innovation

New nitinol tubing technology helps meet the need for less invasive surgeries and better medical care. Bigger factories, like Confluent’s in Costa Rica, help supply more tubing around the world. Having factories in different places and working with partners keeps the tubing supply steady. The market is expected to grow by 8% each year from 2025 to 2033 because of these changes.

Big companies like Confluent Medical, SAES Getters, ATI, and Johnson Matthey lead the way.

Research and new ideas keep making nitinol tubing better.

Spending money on quality and new technology helps the market grow and stay strong.

Using pure nitinol, careful manufacturing, better radiopacity, and smart features makes nitinol tubing the best choice for new medical devices. These changes help patients and doctors get better results and safer care.

Nitinol Tubing in Medical Devices

Cardiovascular

Nitinol tubing is very important in heart devices. Companies use nitinol to make stents, catheters, and guidewires. These tools must work well in tough places. New digital image tools help measure strain on nitinol implants, even when they are very small. This helps prove that stents and catheters last long and stay safe.

The MISAGO 1 trial found nitinol stents work better than angioplasty for certain artery problems.

The first test of nitinol self-expanding everolimus-eluting stents showed patients got much better.

The ORION trial proved the Boston Scientific Epic Stent keeps blood vessels open and flexible.

Nitinol tubing lets catheters and guidewires move through tricky vessels. This helps both patients and doctors get better results.

Neurovascular

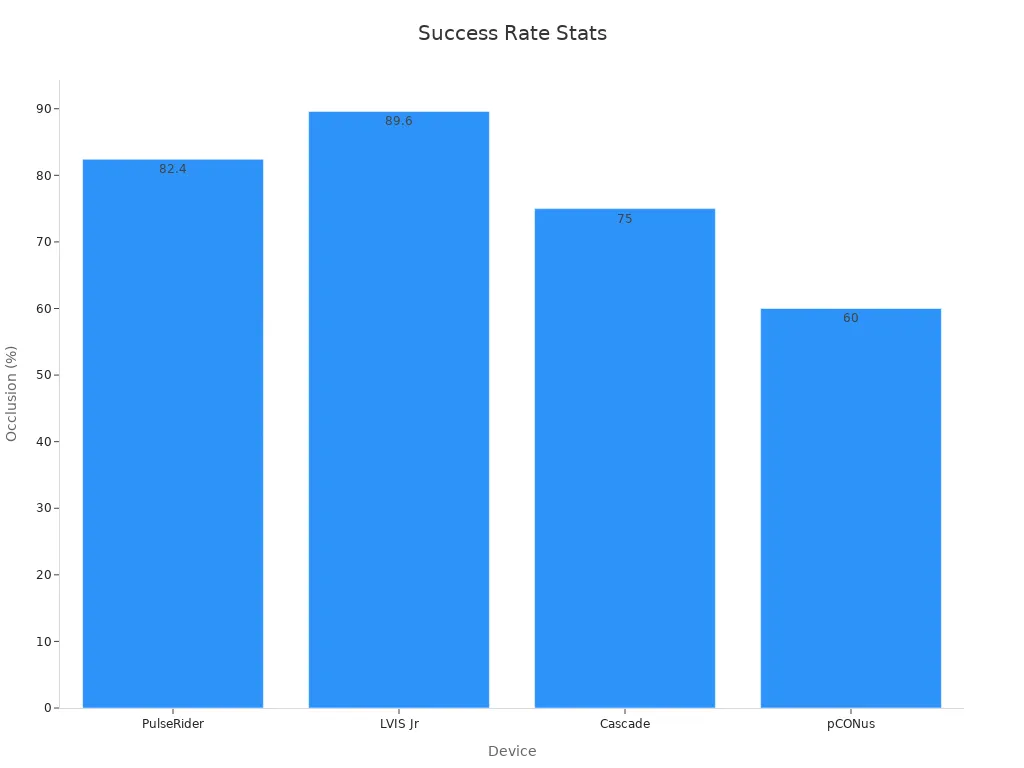

Nitinol tubing is used in brain devices like stents, catheters, and guidewires. These tools must reach tiny brain vessels and stay bendy. Studies show nitinol implants have high success and few problems.

Device | Sample Size | Technical Success Rate | Complication Rate | Occlusion Rate (Immediate / Follow-up) | Notes on Catheter Failure or Complications |

|---|---|---|---|---|---|

PulseRider | 34, 63, 54 aneurysms | 96.2% | 3 major in 54 cases | 82.4% immediate; 87.9% at 6 months | No catheter failure; low complications |

LVIS Jr | 30 patients | N/A | N/A | 89.6% immediate; 96% at 5.2 months | Smaller catheter, easier vessel access |

Cascade | 12 aneurysms | N/A | None reported | 75% complete occlusion | No catheter failure reported |

pCONus | 203 aneurysms | 100% | 0% technical; 7% morbidity; 0% mortality | 60% complete; 14% retreatment | No catheter failure; no hemorrhagic complications |

Nitinol tubing helps guidewires and catheters put implants in the right spot. This leads to high success and few repeat surgeries.

Orthopedic

Orthopedic devices use nitinol tubing and implants. Nitinol staples and spinal implants are easier and faster to put in than screws. Their shape lets doctors make smaller cuts and helps people heal faster. Nitinol acts like real bone, so it lowers stress and helps bones heal strong. Porous nitinol implants got FDA approval and show good healing. Nitinol tubing gives steady pressure and bends well, so orthopedic tools last longer and are safe for the body.

Emerging Applications

Nitinol tubing is now used in new medical areas.

Robot surgeries use nitinol for strong, precise tools.

Sensors and health trackers use nitinol because it is safe for the body.

Regenerative medicine and tissue repair use nitinol’s special features.

The world market for nitinol implants could reach $1.6 billion by 2027.

New markets in Asia-Pacific and Latin America want more advanced devices with nitinol tubing. Companies build local factories and work with doctors to meet this need. Nitinol tubing helps create new ideas, custom tools, and better care for patients everywhere.

Safety and Sustainability

Long-Term Safety

Nitinol tubing is known for being safe for a long time in medical devices. Studies show nitinol tubing lasts longer than other materials. This is important for implants that stay in the body for years. Research proves nitinol is safe for the body and does not cause harm. It also does not rust easily. These features help nitinol tubing stay safe and work well inside people. Companies use new ways to make nitinol tubing last two or three times longer than older materials. They polish the surface to remove tiny flaws that could break. Special coatings, like hydrophilic and biocompatible layers, help stop swelling and lower the chance of blood clots. Fast aging tests show these coatings keep working over time.

Nitinol tubing can bend and twist many times and still keep its shape.

Tests show nitinol tubing does not break after millions of bends.

Rules from the FDA and ISO 10993-1 make sure nitinol tubing is safe for people.

Source/Study | Focus Area | Key Findings |

|---|---|---|

Rahimipour et al. (2020) | Corrosion resistance and biocompatibility | Surface treatments make nitinol tubing resist rust and prove it is safe for long-term use. |

ORION Clinical Trial | Safety and efficacy of nitinol stents | 123 patients over 9 months, showing few big problems and good device results. |

Custom Solutions

Makers design nitinol devices to fit different patients and surgeries. Nitinol tubing can be made in many shapes, sizes, and strengths. Stories from doctors show keeping the right temperature and smooth surface is very important. These things help nitinol tubing work safely in stents and guidewires. New ways to make samples, like using polymer cores, let doctors create special implants for each person, such as atrial occluders.

Performance Metric | Value/Description |

|---|---|

Tensile Strength | 500 MPa to 900 MPa |

Local Strains | Up to 6% |

Cycles to Failure | Up to 10 million cycles |

Strain Amplitudes | 0.5% to 2.9% |

Cold Work Percentage | 20–30% |

Makers check nitinol tubing with many tests for strength, bending, and rust. They follow strict rules like ISO 13485 and FDA standards to keep tubing safe. Using pure nitinol stops early breaks and helps devices last longer.

Eco-Friendly Manufacturing

Eco-friendly ways help make nitinol tubing better for the planet. Life Cycle Assessments look at how making tubing affects the earth from start to finish. Factories use machines that save energy and lower pollution. They use closed-loop recycling to collect and reuse scrap nitinol, which cuts waste and saves raw materials.

Aspect | Description |

|---|---|

Life Cycle Assessment (LCA) | Checks how tubing production affects the environment. |

Energy-Efficient Production | Special heating and furnaces use 15–20% less energy. |

Closed-Loop Recycling Systems | Collecting scrap saves 25–30% on new materials. |

Regulatory Mandates | EU MDR makes companies check the environment for nitinol tubing. |

Market Impact | Green practices help the NiTi alloy market grow by 7.8% each year until 2030. |

Making nitinol tubing in eco-friendly ways helps protect the earth and meets the need for new medical devices. These steps make nitinol tubing a smart and safe choice for the future.

Nitinol tubing is the best material for medical devices in 2025. It can bend and return to its shape. It remembers its shape and is safe for the body. These features help doctors use it in heart, bone, and new medical tools. New ways to make nitinol tubing help it fit patients better. Special coatings make implants safer and last longer. Making nitinol tubing costs less now, so more people can get advanced devices. Nitinol tubing helps doctors find new solutions, helps patients heal, and raises the bar for medical care everywhere.

FAQ

What makes nitinol tubing ideal for minimally invasive procedures?

Nitinol tubing can bend and return to its shape. This helps stents, catheters, and guidewires move easily. Doctors use these tools for less invasive surgeries. The tubing’s flexibility lets doctors work with more care and safety.

How does biocompatibility and corrosion resistance benefit medical devices?

Medical grade nitinol tubing is safe for the body and does not rust. These features help lower the chance of rejection. Devices made from nitinol last longer inside people. This keeps implants and catheters safe for important treatments.

What advancements in nitinol tubing manufacturing support innovation?

New ways to make nitinol tubing use pure alloys and better engineering. These changes help make special devices for tough medical jobs. The latest nitinol tubing technology helps create new and better medical tools.

Why do clinicians prefer superelastic nitinol tubing for stents and guidewires?

Superelastic nitinol tubing bends through tricky blood vessels. It does not kink or break easily. This makes stents and guidewires work well in hard cases. The tubing helps patients get better results with advanced devices.

Can nitinol tubing be customized for specific medical applications?

Yes. Makers can design nitinol tubing for special needs. New technology lets them make custom implants and catheters. This helps devices work better for many different patients.

See Also

Transforming Medical Devices Through Innovative Nitinol Tubing

The Importance Of Nitinol Tubing In Modern Medical Uses

The Process Behind Creating Nitinol Tubing For Medicine