How Laser Cutting Services Shape Superelastic Nitinol Tubing for Medical Devices

Laser cutting services superelastic nitinol tubing to precisely shape it for medical devices. These laser cutting services superelastic nitinol tubing enable manufacturers to create intricate metal tubes with high accuracy and minimal waste. By using laser cutting services superelastic nitinol tubing retains its essential superelastic and shape memory properties, which are critical for medical applications. Many choose laser cutting services superelastic nitinol tubing because this technique reduces heat damage and mechanical stress on the tubing. The table below highlights how laser cutting services superelastic nitinol tubing improve manufacturing speed, quality, and efficiency:

Feature Aspect | Benefit for Medical Devices |

|---|---|

Production Speed | Up to 30% faster throughput |

Material Waste | Less waste, lower costs |

Heat Damage | Preserves superelastic nitinol tubing |

Mechanical Stress | Maintains laser-cut nitinol tubing quality |

Key Takeaways

Laser cutting shapes nitinol tubing very accurately. It keeps its superelastic and shape memory properties safe. This helps make better medical devices.

Nitinol tubing can bend and go back to its first shape. This makes it great for flexible and long-lasting tools like stents and guidewires.

Laser-cut nitinol tubing has smooth edges and fits very well. This lowers waste and makes devices safer and work better.

Special lasers and careful steps protect nitinol tubing from heat harm. This makes sure medical devices stay strong and work well.

Custom laser cutting lets people change designs fast to help patients. This helps doctors give safer and better treatments.

Nitinol Tubing Properties

Superelasticity

Nitinol tubing is special because it is superelastic. This means it can bend, twist, and stretch without breaking. It always goes back to its original shape. Scientists test nitinol tubing by changing its temperature and checking resistance. One study found nitinol tubing with a 2.18 mm outer diameter could handle a lot of strain at body temperature. Even after millions of bends, it returned to its shape. Nitinol tubing is more flexible and lasts longer than stainless steel. Devices made from nitinol tubing can move through tight spaces in the body. They still work well after many uses. Superelasticity helps medical devices last longer and work better.

Nitinol tubing’s superelasticity lets it bend and twist many times.

It has a high fatigue life, so it is reliable for tough jobs.

Shape memory and superelasticity help devices return to their shape.

Shape Memory

Shape memory and superelasticity are why nitinol tubing is used in medical devices. Shape memory means the tubing can go back to its shape after being bent or squeezed. This happens because the metal’s crystal structure changes when it gets hot or cold. Studies show nitinol tubing changes its force and size at different temperatures. For example, the tubing’s force drops by 65% at 20°C and only 6% at 30°C. This helps doctors put devices in the body when they are small. Then, the devices can expand once inside. Shape memory and superelasticity make nitinol tubing great for stents, guidewires, and other tools that need to change shape safely.

Shape memory and superelasticity let nitinol tubing be squeezed for insertion and then expand.

Devices with nitinol tubing help patients do better and lower surgery risks.

Good nitinol makes sure medical devices move the same way every time.

Biocompatibility

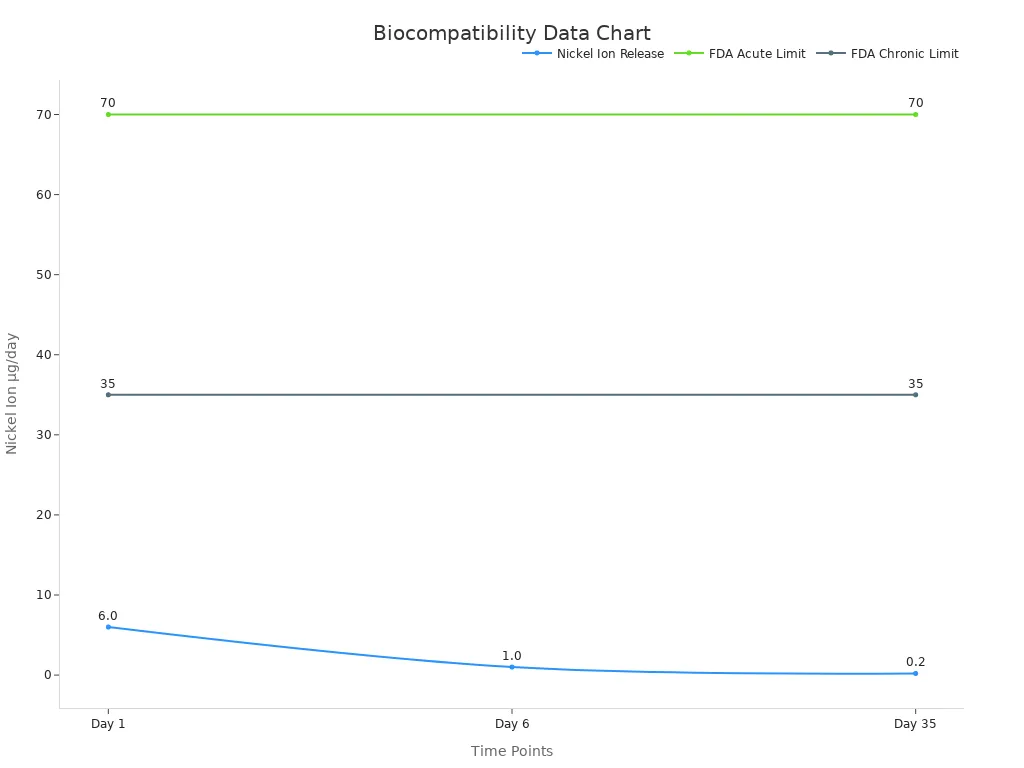

Biocompatibility is very important for materials used in the body. Nitinol tubing meets strict rules like ASTM F2063 and ISO 10993. These rules check for purity and safety. Nitinol tubing gives off very little nickel, much less than FDA limits. The table below shows how safe nitinol tubing is over time:

Parameter | Measurement / Limit |

|---|---|

Nickel Ion Release (Day 1) | About 6.0 µg/day (max 7.6) |

Nickel Ion Release (Day 6) | About 1 µg/day |

Nickel Ion Release (Day 35) | About 0.2 µg/day |

FDA Acute Tolerable Limit | 70 µg/day |

FDA Chronic Tolerable Limit | 35 µg/day |

Nitinol tubing causes little swelling and forms a thin, stable layer in the body.

Surface treatments like electropolishing and passivation make nitinol tubing safer and stop rust.

Tests show nitinol tubing can last through over 600 million heartbeats.

Shape memory, superelasticity, biocompatibility, and corrosion resistance make nitinol tubing safe and strong for long-term use.

Laser Cutting Services Superelastic Nitinol Tubing

Precision Cutting

Laser cutting services superelastic nitinol tubing help engineers make very detailed shapes. These shapes are needed for medical devices that go inside the body. The tubing can have small holes, slots, and patterns. These features help the device work better. Laser cutting has been used for over thirty years in this field.

Some real examples are:

Nitinol stents cut by lasers for bile duct care.

Stents with valves for fixing hearts and veins.

Laser cut hypotubes in catheters and guidewires for better movement.

Laser cutting gives very exact results. The table below shows how accurate laser-cut nitinol tubing is:

Parameter | Value |

|---|---|

Outer Diameter Range | 0.010"–0.065" (0.254–1.65 mm) |

Tolerances Achieved | As low as ±0.0005" (12.7 µm) |

Accuracy for Premium Grade | Over 95% |

Laser-cut nitinol tubing is used in many medical tools. Stents and blood vessel implants need special patterns to open up and support vessels. Catheters and guidewires made from laser cut hypotubes bend well and do not kink. Braces and surgical tools made with laser-cut nitinol tubing help patients heal faster and with less pain.

Femtosecond and Fiber Lasers

Special lasers called femtosecond and fiber lasers are used for cutting. These lasers help keep the superelasticity and shape memory of nitinol tubing. Femtosecond lasers cut with very quick pulses. This means the tubing does not get too hot. The metal keeps its important features. Resonetics uses femtosecond lasers to make tiny shapes in nitinol tubing. Their method keeps the tubing strong and bendy.

Femtosecond lasers take away material without much heat. This is called nonthermal ablation. It leaves a clean surface with almost no heat damage. The cut stays smooth and does not change the tubing’s structure. This helps the tubing keep its superelasticity and shape memory.

Fiber lasers use short bursts of energy to cut the tubing. They can make some heat, but engineers control it. They change the number of passes, the gas used, and the speed. This protects the tubing’s properties. Tests like differential scanning calorimetry and nanoindentation check the tubing after cutting.

Tip: Using gases like argon during laser cutting stops oxidation and keeps the tubing clean.

Clean Cuts and Minimal Waste

Laser cutting services superelastic nitinol tubing make clean cuts with little waste. This is good for making medical devices because it saves material and money. Laser-cut nitinol tubing often does not need extra finishing. The process makes smooth edges and exact shapes, so there is less work after.

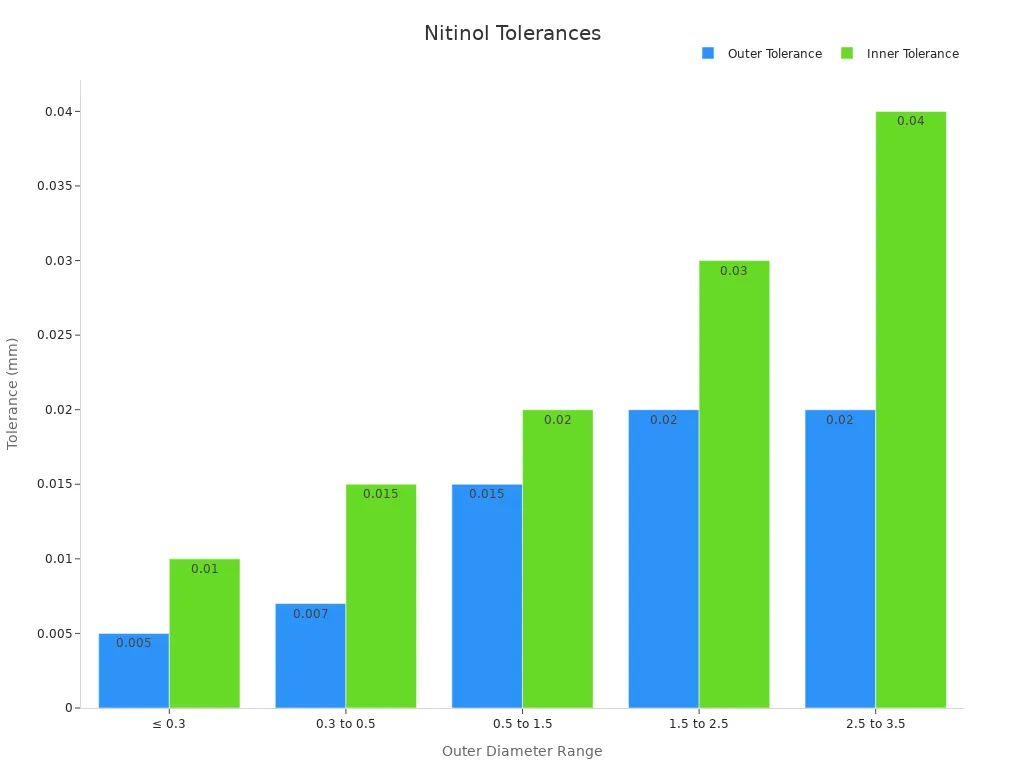

The table below shows the tight tolerances for nitinol tubing:

Outer Diameter Range (mm) | Outer Diameter Tolerance (mm) | Inner Diameter Tolerance (mm) |

|---|---|---|

≤ 0.3 | ±0.005 | ±0.010 |

0.3 to 0.5 | ±0.007 | ±0.015 |

0.5 to 1.5 | ±0.015 | ±0.020 |

1.5 to 2.5 | ±0.020 | ±0.030 |

2.5 to 3.5 | ±0.020 | ±0.040 |

Premium-grade laser-cut nitinol tubing can be as exact as ±0.0005 inches. This is very important for laser cut hypotubes in implants and other medical tools. Quality checks use laser micrometry and ultrasonic testing for every piece. Surface finishing, like electropolishing, makes the tubing even smoother.

Laser cutting services superelastic nitinol tubing also use tests that do not harm the tubing. Engineers measure the outer diameter, wall thickness, and roundness to make sure each piece is right. Mechanical tests check strength, elasticity, and how long it lasts. All tubing must meet ASTM and ISO safety rules.

Laser-cut nitinol tubing helps save material and makes clean, safe medical devices. Advanced laser cutting lets engineers make complex and strong devices with little waste.

Laser-Cut Nitinol Tubing Benefits

Complex Geometries

Laser-cut nitinol tubing lets engineers make very detailed shapes. This helps design medical devices with tiny holes and patterns. Laser cutting gives very high accuracy for stents and implants. It also helps engineers make new designs fast. They can test these designs for each patient’s needs.

Metric / Feature | Description / Value |

|---|---|

Dimensional accuracy | Less than 5% change in nitinol spring diameters from 0.7 to 1.9 mm |

Turnaround time and cost | Costs less by using 3D-printed plastic fixtures instead of metal or ceramic |

Customization capability | Microlaser-welding lets engineers make custom nitinol stent backbones with exact shapes |

Fabrication flexibility | Using small wire bending machines means less hand work and fewer fixtures |

Application examples | Used for custom implants, heart valves, and mesh tires for planes |

Laser-cut nitinol tubing makes it easy to create complex shapes. It also lets engineers add more than one function to a device. Tests show the tubing is strong and bends well. Laser micrometers check the size is right, as close as ±0.005 mm for small tubes. This accuracy helps medical devices work well inside the body.

Laser micromachining gives very exact cuts for metal and plastic parts.

Smooth edges and repeatable shapes mean less extra work is needed.

The process keeps the tubing strong and stops it from bending out of shape.

Engineers can make just one or many tubes, all with the same quality.

Device Performance

Laser-cut nitinol tubing helps medical devices work better in many ways. Tests show these tubes are strong and flexible. This helps stents and hypotubes work well in the body. Laser cutting also makes it easier for doctors to put devices in during surgery.

Performance/Outcome Measure | Result/Statistic | Significance |

|---|---|---|

Recanalization success rate (TICI 2b/3) | Up to 94.8% | Works well for removing clots during stroke treatment |

Mortality within 90 days (successful recanalization) | 8.6% | Fewer deaths compared to when recanalization does not work |

Favorable neurological outcome (mRS 0–2) at mid-term follow-up | 41.9% | As good or better than other studies, showing better patient recovery |

Radial force (N) | 4.10 ± 0.07 (laser-cut nitinol) vs 3.77 ± 0.01 (Solitaire) | Higher force helps hold open blood vessels |

Flexibility (N) | 0.59 ± 0.05 (laser-cut nitinol) vs 0.38 ± 0.11 (Solitaire) | More flexible tubes move better in small vessels |

Deployment force (N) | 0.32 ± 0.02 (laser-cut nitinol) vs 0.37 ± 0.02 (Solitaire) | Lower force makes it easier to place devices |

PROST clinical trial (pRESET vs Solitaire) | Functional independence at 90 days: 54.9% vs 57.5% | Shows both devices are safe and work well |

Complication rates | Low and similar to other devices | Proves laser-cut nitinol stents are safe |

Laser-cut nitinol tubing lets medical devices do hard jobs. Stents made from this tubing can open blocked vessels and stay in place. Hypotubes can bend and move through tiny blood vessels without folding. Laser cutting also helps engineers test and improve new designs quickly.

Note: Laser-cut nitinol tubing lets doctors make stents for each patient, which helps people get better results.

Safety and Reliability

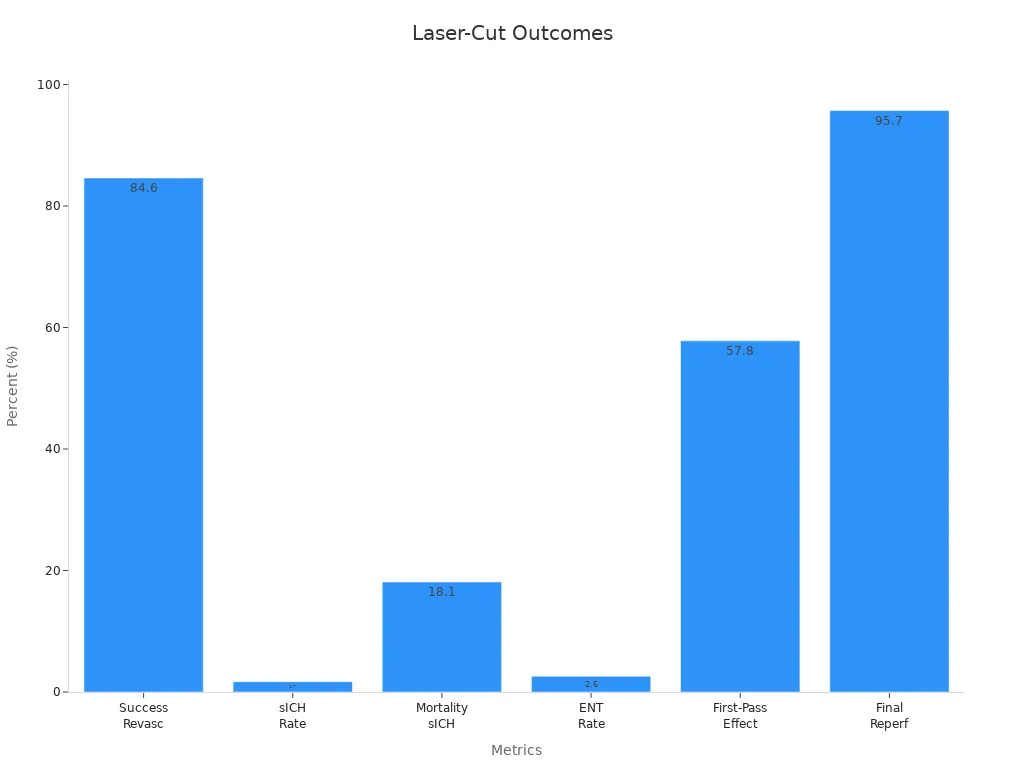

Laser-cut nitinol tubing is very safe and reliable for medical devices. The process makes smooth surfaces and exact shapes, which lowers the chance of blood clots. Extra steps like electropolishing make the tubing even smoother and safer by lowering nickel release. Studies show laser-cut nitinol devices have few problems and work well.

Performance Metric | Laser-Cut Nitinol Device Result | Comparator / Historical Data | Significance / Notes |

|---|---|---|---|

Successful Revascularization (mTICI 2b-3) | 84.6% | 73.4% (historical) | Much better results (p < 0.01) |

Symptomatic Intracranial Hemorrhage (sICH) Rate | 1.7% | N/A | Very low rate of this problem |

Mortality and sICH Composite Endpoint | 18.1% | 20.4% (historical) | About the same safety as before |

Embolization to New Territory (ENT) Rate | 2.6% (95% CI 0.5%–7.4%) | 7.4% (pooled comparator trials) | Much better results (p = 0.0403) |

First-Pass Effect | 57.8% | N/A | Shows the device works well on the first try |

Final Successful Reperfusion (mTICI 2b-3) | 95.7% | N/A | Very high success rate |

Median Groin-to-Revascularization Time | 24 minutes | 25 minutes (fastest reported) | Fast procedure time |

Studies over time show nitinol tubing with laser cutting keeps blood vessels open and safe. Animal tests show a 100% success rate with no device problems. Science tests check the tubing’s strength and safety. Quality systems like ISO 9001 make sure every tube meets strict rules.

Laser cutting makes strong, clean welds with little heat damage.

Special machines help join parts together with great accuracy.

These things make medical devices last longer and keep patients safe.

Tip: Biocompatibility and corrosion resistance are very important for making sure laser-cut nitinol tubing is safe to use in the body for a long time.

Nitinol Laser Cut Hypotubes in Medical Devices

Stents and Guidewires

Nitinol laser cut hypotubes are important for stents and guidewires. Engineers use them to make special patterns. These patterns help stents open up and hold blood vessels. The nitinol tubes can bend and go back to their shape. This is needed for stents and blood vessel implants. Doctors use these tubes to treat blocked arteries and veins. Making nitinol laser cut hypotubes takes eight careful steps. First, the tube is welded or drawn. Then, it is laser cut. Next, workers remove sharp edges. The tube is heat treated and cleaned. After that, it is checked, sterilized, and packed. These steps make sure each device is safe and works well.

Catheters and Implants

Catheters and implants use nitinol laser cut hypotubes for strength and flexibility. Scientists have looked at different ways to make these tubes. Tubes made with careful drawing last longer and are stronger. They can bend many times without breaking. This is very important for medical devices. Catheters made from these tubes move through small, twisty blood vessels. They do not kink or fold. Implants made from nitinol last a long time and do not break easily. The smooth surface and even structure help stop device problems. Medical teams pick nitinol because it is safe for the body and works well in tough jobs.

Miniaturization

Laser cutting lets engineers make nitinol laser cut hypotubes with tiny details. This helps make new medical devices with small, complex parts. Special laser controls help make tight fits and detailed shapes. Old ways could not do this. Small nitinol laser cut hypotubes are now used in surgery tools, testing devices, and implants. These small tools can reach places in the body that were hard to get to before. As technology gets better, engineers will make even smaller and more exact nitinol tubes for new medical uses.

Note: Making small laser cut hypotubes helps doctors do less invasive surgeries and helps patients heal faster.

Challenges and Solutions

Heat Management

Heat can change how nitinol tubing works. Engineers must control heat when cutting nitinol. This keeps the tubing superelastic and strong. Femtosecond lasers use very quick pulses. These pulses cut the tubing with almost no heat. This stops burrs and keeps shape memory. Argon gas helps by blowing away melted metal. It also stops oxidation from happening. The recast layer is a thin, hard edge. It stays under 0.0005 inch thick. This keeps the tubing smooth and means less cleaning is needed.

Surface Quality

Medical devices need smooth surfaces to work well. Rough edges or burrs can cause trouble in the body. After cutting, engineers use electropolishing. This removes small burrs and slag left behind. It also makes a thin, safe oxide layer on the tubing. Sensors and cameras watch the cutting as it happens. They check the laser’s power and focus. Femtosecond lasers make very clean cuts. They can keep tolerances as tight as +/- 2.5 micrometers. Keeping the room at the right temperature and humidity helps stop microcracks.

Experts check the tubing’s surface with special tools.

Statistical process control keeps the process steady and safe.

Quality Control

Quality control checks every nitinol tube meets strict rules. Engineers use control charts to watch for changes. If they see a problem, they stop and fix it. They measure melt pool width and depth to find defects. Design of Experiments helps pick the best machine settings. Machine learning can help find what causes problems. These steps help make sure each tube is safe for the body.

Metric | Description and Relevance |

|---|---|

Melt pool width (W) | Shows how wide the melted area is |

Melt pool depth (D) | Checks how deep the cut goes |

Melt pool area | Helps define safe process windows |

Length-to-depth ratio (L/D) | Finds zones where defects may form |

Tip: Careful checks and process control help keep nitinol tubing safe and reliable for medical devices.

Laser-cut nitinol tubing helps make medical devices with exact shapes. The surfaces are smooth and the devices work well. This way, tools are safer and more dependable. Laser cutting lets engineers make detailed designs and tight fits.

Devices can be smaller and bend easier, so doctors can help patients with less danger.

Experts think the market will keep growing as lasers and miniaturization get better.

Experts believe laser-cut nitinol tubing will help make safer and newer medical devices in the future.

FAQ

What is superelastic nitinol tubing used for in medical devices?

Superelastic nitinol tubing is used to make stents, guidewires, and catheters. These tools need to bend and then go back to their shape. Doctors use them to open blocked blood vessels. They also help doctors reach places in the body that are hard to get to.

How does laser cutting protect nitinol’s special properties?

Laser cutting uses fast, focused energy to cut the tubing. This keeps the tubing cool and stops it from getting damaged. The tubing stays strong and can bend easily. Engineers use special lasers and gases to keep the tubing’s superelastic and shape memory features safe.

Why do doctors prefer laser-cut nitinol tubing?

Doctors like laser-cut nitinol tubing because it is very exact and safe. The tubing has smooth edges and the right shapes. This lowers the chance of blood clots. It also helps the devices work better inside the body.

Can laser-cut nitinol tubing be customized for each patient?

Yes, engineers can make nitinol tubing to fit each patient. Laser cutting lets them change the shape and size quickly. This helps doctors pick the best device for every person.

See Also

The Process Behind Manufacturing Nitinol Tubing For Medicine

Nitinol Tubing Transforming The Future Of Medical Devices

A Deep Dive Into Nitinol Tubing Uses In Healthcare