Comprehensive Review of Laser Cut Nitinol Tubing Products for Stents and Catheters

Laser cut nitinol tubing is the top pick for stents and catheters. Nitinol has superelasticity, shape memory, and flexibility. This makes it great for tricky blood vessel shapes. Devices with this tubing last longer and bend without breaking. They also have less chance of folding or kinking. Studies show nitinol stents, especially interwoven ones, work very well. They stay open and do not break much, even in tough cases. Doctors trust laser cut nitinol tubing for its strong features. It is safe for the body and made with care. These things help new medical devices get better. They also help patients have better results.

Key Takeaways

Laser cut nitinol tubing is great for stents and catheters. It bends without breaking. It remembers its shape. This makes medical devices safer. It also makes them more reliable.

Good manufacturing uses careful laser cutting. It also uses heat treatment and surface finishing. These steps help nitinol tubing fit well. They make it strong. The tubing lasts longer in the body.

Clinical studies show nitinol stents work well. They keep blood vessels open. They have few problems. This helps patients heal faster. It helps them live healthier lives.

New laser technology helps companies make custom nitinol devices fast. This means better care for patients. The tools fit better. They work better too.

Surface treatments like electropolishing protect nitinol tubing. They stop corrosion. They lower nickel release. This makes medical devices safer. It also makes them last longer.

Key Insights

Product Selection

Choosing the right laser cut nitinol tubing is important. You need to think about how it will be used and how it is made. Companies now use better laser cutting to make stents and catheters faster and more exact. This helps them make detailed shapes for hard-to-reach places in the body. Controlling the temperature during making helps mix nickel and titanium better. This makes nitinol work better in medical tools.

Certified ways of making nitinol tubing, like ISO 13485, help keep it safe and high quality. These rules lower the chance of mistakes or recalls. This is very important for stents and other things that go inside the body. Doctors trust these products because they work well every time.

Now, companies use 3D printing with laser cutting to make stents and catheters with special shapes. This makes building them faster and lets them be used in more ways. These new ideas help fix problems with getting supplies and meet the need for more stents and catheters.

Tests show that how the tubing is made changes its quality. For example, using single-draw with special tools makes tubing more even and smooth. This helps stents last longer and work better. But, using continuous drawing with other tools can cause stress and small problems on the surface. This can make stents not work as well.

Evaluation Criteria

Doctors and engineers look at a few main things when picking laser cut nitinol tubing. They check how strong it is, if it is safe for the body, and how exact it is made.

The table below shows important numbers for how strong and exact nitinol tubing is for stents and other uses:

Grade | OD Range (in/mm) | OD/ID Ratio | OD Tolerance (in/µm) | Concentricity Tolerance | Alloy/Ingot Type |

|---|---|---|---|---|---|

Standard | 0.010 - 0.065 (0.254-1.65) | 1.11 - 2.67 | +0.0003 to +0.001 (10.2 - 25.4) | N/A (Specified OD/ID) | Standard |

Precision | 0.065 - 0.197 (1.65 - 5) | >1.08 | ±0.0005 (12.7) for smaller OD group; ±0.0008 to ±0.001 (20.3 - 25.4) for larger OD group | >90% | Standard |

Premium | 0.065 - >0.198 (1.65 - >5) | >1.08 or <1.08 (thin wall) | ±0.0005 (12.7) to ±0.0008 (20.3), dependent on OD and wall thickness | >95% | Standard & Enduro |

These numbers are very important for stents and catheters. The size and shape must be just right so stents fit well in blood vessels and work safely.

Doctors also look at how well the tubing works in real life. The next table shows important facts for how well it works in the body:

Clinical Performance Indicator | Description | Quantitative Benchmark / Value | Clinical Insight |

|---|---|---|---|

Cut Depth | Depth of incision in soft tissue | Up to 214 μm ± 31 μm at ≤1 W; max 820 μm at 445 nm (visible range) at >2 W | Visible wavelengths (e.g., 445 nm) produce deeper cuts than near-infrared (e.g., 810 nm, 344 μm) |

Cut Width | Width of incision relative to fiber core diameter | Average 125 μm ± 24 μm, below fiber core diameter (280 μm) | Narrow cuts attributed to Gaussian beam distribution and tissue properties |

Thermal Tissue Damage | Extent of thermal effect zone around incision | Thermal damage zones vary by wavelength; visible wavelengths show narrower thermal zones compared to NIR | Thermal effects increase with wavelength; visible lasers cause less collateral thermal damage |

Efficiency Factor (γz) | Ratio of incision depth to total thermal interaction depth | Clinical orientation threshold set at γz = 0.6; values range from 0.51 to 0.74 in practice | γz ≥ 0.6 indicates acceptable cutting efficiency; used as a clinical benchmark for laser settings |

These facts help doctors and engineers pick the best laser settings for stents and catheters. They want to cut well but not hurt the tissue too much. For example, cutting faster makes the cut smaller and causes less heat and stress. This helps stop problems like cracks, which is important for stents to last a long time.

Tip: Always check that the nitinol tubing you pick meets both strength and safety rules before using it in stents or other medical tools. This keeps patients safe and helps the tools work their best.

Nitinol Overview

Properties of Nitinol

Nitinol is a very important shape memory alloy for medicine. It has special features like shape memory and superelasticity. These features make it great for medical devices. Shape memory means nitinol can go back to its old shape after being bent when it gets warm. Superelasticity lets nitinol stretch a lot and snap back fast. This is needed for stents and catheters that must bend inside the body.

Nitinol is made from nickel and titanium mixed together. How much nickel or titanium is in it changes how it acts and at what temperature it changes shape. More titanium makes it better at shape memory at room temperature. More nickel helps it be more superelastic. In labs, thin nitinol tubes with exact sizes acted differently when pulled in different ways. This makes it easier to design new medical devices.

Nitinol is also safe for the body. It does not rust and does not cause strong immune reactions. This means it is safe to use in people for a long time. Hospitals trust nitinol because it works well and keeps patients safe.

Role in Medical Devices

Nitinol is very important in today’s medical tools. Its superelasticity and shape memory help doctors do less invasive surgeries. This means patients heal faster. Doctors use nitinol in stents, catheters, heart valves, and guidewires. These tools need to bend, squeeze, and stretch without breaking.

The world market for nitinol medical tools is growing fast. By 2025, it could be worth $2.5 billion. It is growing about 7% each year until 2033. This is because more people need advanced medical care, more people are getting older, and more have long-term illnesses. Hospitals use the most nitinol tools, but clinics and other centers are using them more too.

Most nitinol is used in heart and blood vessel surgeries.

Bone and dental doctors use more nitinol now because it helps fix bones and teeth.

Nitinol is also used in brain, stomach, and urinary treatments for less invasive care.

Region / Category | Statistic / Data Point | Year(s) |

|---|---|---|

North America | Over 60% of peripheral vascular surgeries in the U.S. used nitinol stents | 2023 |

Europe | Over 4.5 million nitinol-based procedures performed | 2023 |

Asia-Pacific | 9,000+ hospitals in China using nitinol devices; 2 million dental procedures in Japan | 2023-2024 |

Middle East & Africa | 500,000+ nitinol devices used; 120+ hospitals in Africa adopting nitinol devices | 2023-2024 |

Boston Scientific | Supplied over 3 million nitinol-based vascular devices globally | 2023 |

Medtronic | Produced more than 4.5 million nitinol-based stents and embolic coils | 2023 |

Venture Capital Investment | 70+ deals worth USD 1.2 billion focused on nitinol device startups | 2023 |

New Product Introductions | Over 150 new nitinol-based products launched globally | 2023-2024 |

Manufacturing Plants | 120+ nitinol-processing plants operational globally | Early 2024 |

Emerging Markets Investment | USD 500 million+ foreign direct investment in nitinol tech integration | 2023 |

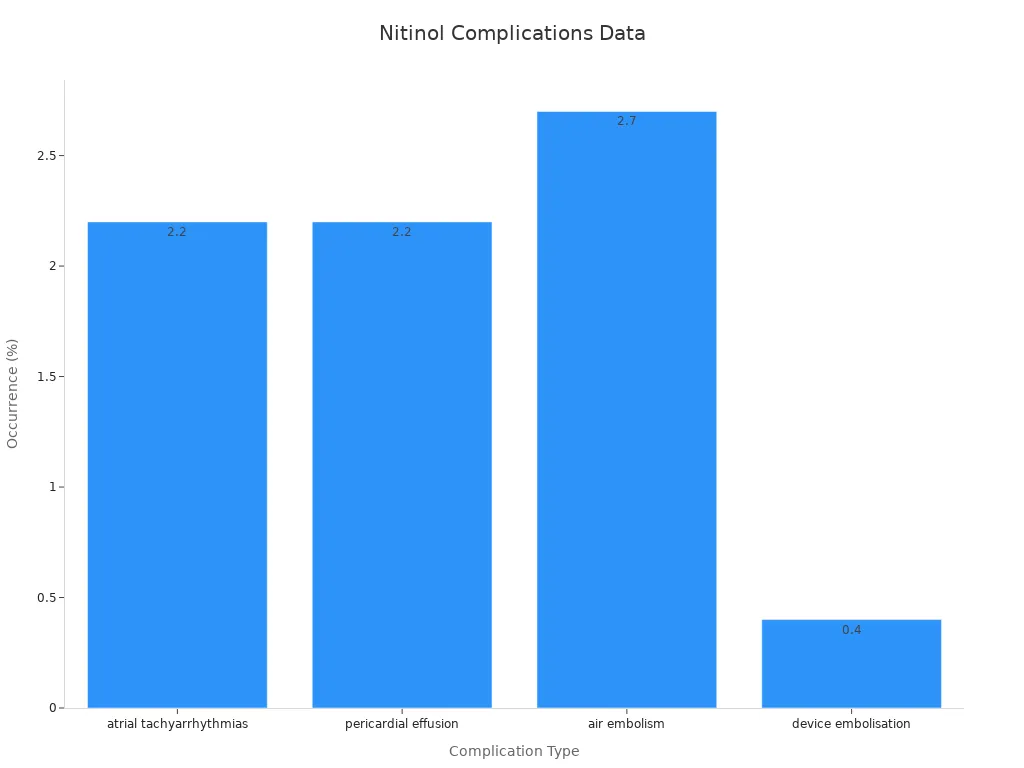

Nitinol medical devices help lower problems for patients. In a study with 450 patients using three nitinol occluder devices, there were no big problems and almost all surgeries worked. Small problems were rare, and the chance of the device moving was lower than before.

Because nitinol is safe, stretchy, and can remember its shape, it is a top pick for medical tools. As technology gets better, nitinol devices will help more patients and be used in new ways.

Vascular Stents and Catheters

Stent Requirements

Vascular stents are very important in medicine. They need to be flexible and strong. Stents must open up inside blood vessels and not break. They should keep their shape after being placed. The tube has to handle many bends and movements in the body. Nitinol stents use special nitinol features to do this job. Superelasticity and shape memory help the tube bounce back after bending. This lets stents stay open and keep blood moving.

Doctors test stents in many ways to make sure they work. The table below lists important test numbers:

Parameter | Numerical Threshold / Value | Description / Context |

|---|---|---|

Fatigue limit stress amplitude | 59 ksi at 10^7 cycles | Fatigue limit for wire specimens in saline at 37°C under tension. |

Deformation magnitudes tested | 0.7%, 1.05%, 1.3% | 0.7% predicts survival, 1.3% predicts fracture at 10^7 cycles. |

Wire diameter | 0.005 in | Similar to stent tubing wall thickness. |

Radial stiffness | Change in stent diameter | Measured for each stent size and target site. |

Radial strength | Pressure causing deformation | Indicates resistance to collapse under load. |

Radial outward force | Minimum and maximum values | Assessed across vessel size range and length. |

Mechanical properties | UTS, yield strength, elongation | Physical tests for nitinol, including stress-strain curves. |

Torque strength | Rotations to failure | Delivery system tested by rotating until failure. |

Accelerated durability | Equivalent to 10 years of use | Tested under pulsatile flow and cyclic loads. |

Drug-eluting stents need even more careful control. The tube must give out medicine evenly and keep its shape. Nitinol tubing is very exact and round, which is needed for these uses.

Catheter Applications

Catheters are used for many medical jobs. They have to bend through small blood vessels. They also need to deliver treatments exactly where needed. Nitinol tubing is great for catheters because it is flexible and strong. It is also safe for the body. The tube can go back to its shape after bending. This is important for tools that are used again and again.

When you compare materials, nitinol is often the best for catheters:

Material | Tensile Strength (MPa) | Key Advantages | Limitations |

|---|---|---|---|

Nitinol Tubing | ~500 (room temp), up to 900 | Superelasticity, shape memory, flexibility, biocompatibility, corrosion resistance, fatigue resistance | Higher cost, limited machinability, reduced high-cycle fatigue limit |

Stainless Steel | ~550 and higher | High strength, corrosion resistance, cost-effective | Heavier, less flexible |

Titanium Alloys | Up to 1200 | High strength-to-weight, biocompatible, lightweight | Expensive, less flexible |

Nitinol tubing comes in many sizes. The smallest tubes are 0.010" wide. The biggest are 0.065" wide. Some tubes are made with very tight size limits, as close as 10.2 μm. Premium nitinol tubes are over 95% accurate in shape. These things make nitinol tubing perfect for guidewires, stents, and implants. Drug-eluting catheters use nitinol tubes to give medicine right where it is needed. Nitinol devices can be used for a short time or left in the body. They last a long time and keep patients safe.

Note: Nitinol tubing is special because it is stretchy, remembers its shape, and is safe for the body. That is why it is the best choice for stents and catheters in today’s medicine.

Laser Cut Nitinol Tubing Technology

Laser Systems

Modern laser systems help shape nitinol for medical devices. Companies use special lasers, like ytterbium fiber lasers, to cut tubes very exactly. These lasers shine energy on a tiny spot, about 16.5 to 32.5 micrometers wide. This lets them make detailed shapes and smooth edges. Laser cutting works well because nitinol keeps its shape memory and superelasticity. Most factories use some manual work since nitinol does not like too much heat or stress. Machines do not do everything, but laser welding can join nitinol parts if needed. Welds do not keep superelasticity, so engineers put them in safe spots.

Process Parameters

How good the laser cut nitinol tubing is depends on many things. Important parts are laser power, pulse frequency, cutting speed, and how many times the laser goes over the tube. Femtosecond lasers are used a lot because they make less heat, which keeps the tube’s special features safe. Cutting underwater can help stop heat damage even more. Shielding gas and pressure also change how the tube turns out. For example, using 55 W power and oxygen cooling keeps the tube cool and stops burrs. Changing these settings helps the tube stay strong and bendy. After cutting, steps like chemical etching and high-vacuum annealing make the tube’s surface and strength better.

Metric Category / Aspect | Details / Values |

|---|---|

Dimensional Tolerances | ±0.005 mm for tubing diameters ≤ 0.3 mm |

Laser Cutting Parameters | 55 W power, 16.5 µm pulse, oxygen cooling |

Post-Processing Steps | Chemical etching, annealing, polishing |

Surface Quality | Burr-free, fine finish, minimal thermal damage |

Mechanical Properties | Enhanced by cold work and heat treatment |

Cut Quality

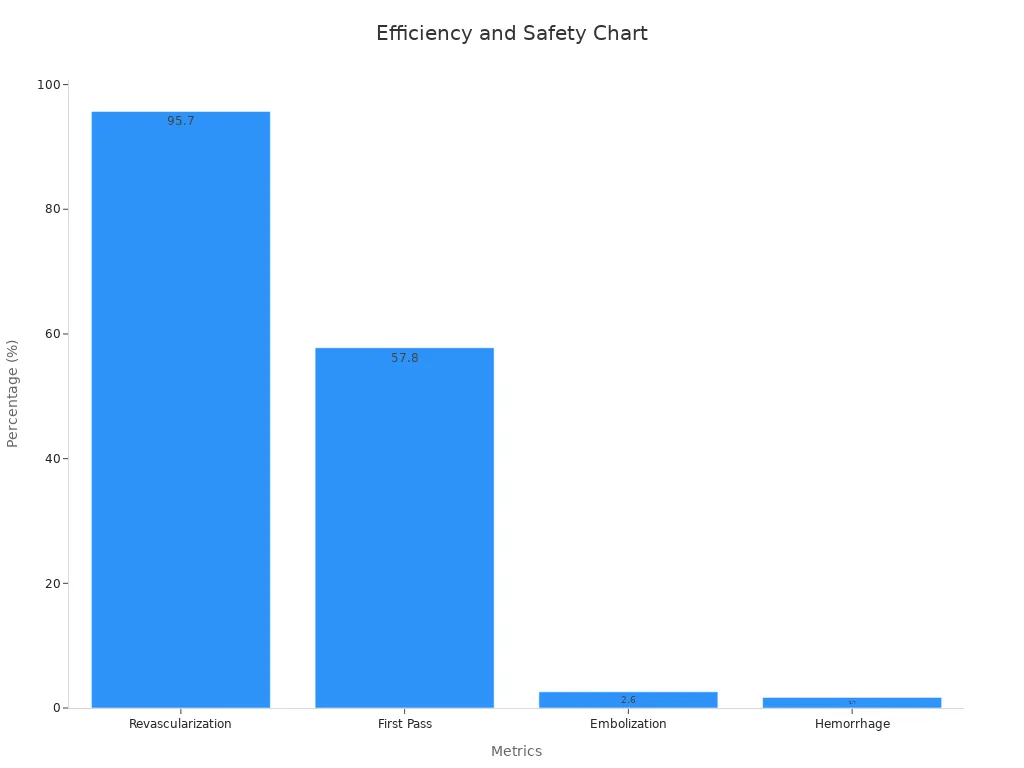

Cut quality is very important for nitinol tubes in stents and catheters. Checks include looking at the inside structure, wall thickness, and surface roughness. Engineers test each tube to see if it bounces back and lasts long. Surface finishing, like electropolishing, takes away sharp edges and lowers nickel ion release, making the tube safer. Special checks, like X-ray and CT scans, help find any problems. Controlled heat treatment helps the tube get its shape back and stay strong under stress. These steps help doctors get good results, with up to 95.7% success and few problems.

Note: Good laser cut nitinol tubing bends without kinking, pushes easily, and has smooth ends, so it works well for hard blood vessel procedures.

Manufacturing and Post-Processing

Laser Cutting vs. Other Methods

Laser cutting is the main way to shape nitinol for medical tools. Femtosecond lasers use very short bursts of light to cut. These lasers make tiny cuts and do not heat up the metal much. This helps nitinol keep its shape memory and superelasticity. Companies use AI and machines to set laser settings quickly. This means fewer mistakes and up to 30% more products made. Laser beams can be shaped to make detailed designs. The laser does not touch the metal, so less fixing is needed later. Laser cutting wastes less material than old cutting ways. It also puts less stress on the nitinol. This keeps nitinol’s special features safe.

Aspect/Feature | Industrial Benchmark / Performance Data |

|---|---|

Femtosecond Lasers | Precise cutting, minimal heat-affected zones |

AI and Automation | Real-time optimization, higher throughput |

Energy Efficiency | Low-energy lasers, reduced power use |

Material Waste Reduction | Less waste, better cost-effectiveness |

Laser Beam Shaping | Intricate designs, less thermal damage |

Efficiency Gains | Up to 30% faster production |

Mechanical Stress Reduction | Non-contact, preserves nitinol’s properties |

Customization & Prototyping | Rapid, accurate patient-specific devices |

Laser cutting must be very exact for stents and catheters. Factories control the air and temperature to stop tiny cracks. They also check and clean the lasers often to keep cuts perfect.

Shape-Setting and Heat Treatment

Shape-setting and heat treatment are important for making nitinol devices. Workers heat the tubes on special holders to lock in the right shape. They use strand annealing, box furnaces, salt baths, or fluidized beds. These ways heat the tube evenly and let workers control time and temperature. Joule heating is a fast way to set shapes. To stop the surface from turning brown, companies use vacuum or special gases. Cooling the tubes quickly in water helps keep nitinol strong.

The heat is usually between 400 °C and 500 °C. This comes after the tube is squeezed or stretched by about 30%. Good heat treatment gives the tube its final shape and strength. It also sets the temperature where nitinol changes shape. This makes sure nitinol keeps its shape memory and superelasticity and does not bend forever.

Surface Finishing

Surface finishing makes nitinol devices last longer and work better in the body. Workers use polishing, electropolishing, and magnetoelectropolishing. These steps make a thin, strong titanium dioxide layer on the tube. This layer stops nickel from leaking out and keeps rust away. Electropolishing and magnetoelectropolishing work best. They make a smooth layer with no cracks. This lowers the chance of nickel getting into the body and helps the device last longer.

Study / Surface Treatment | Key Findings | Implications for Biocompatibility and Durability |

|---|---|---|

Electropolishing (EP) and Magnetoelectropolishing (MEP) | Nickel-free oxide layer | Better corrosion resistance, improved cellular adhesion |

Chu et al. | TiO2 layer from EP | Improved corrosion resistance and biocompatibility |

Zhang et al. | TiN coating | 50% lower corrosion rate, coating integrity important |

Dharam et al. | MEP | Enhanced tissue integration, longer implant life |

Haider et al. | MEP | High resistance to pitting corrosion |

Electropolished/Blue Oxide | Lower thrombogenicity, more cell growth | Statistically significant biocompatibility gains |

Electropolishing and magnetoelectropolishing make nitinol safer and stronger. These steps help nitinol devices work well and last a long time in the body. A smooth tube surface helps make safe and steady medical implants.

Product Comparison

Leading Manufacturers

Some companies are the main leaders in making laser cut nitinol tubing for stents and catheters. These companies make sure their medical products are safe and work well. They follow strict rules to keep patients safe. Here are some of the top companies:

Boston Scientific: This company makes advanced vascular stents and drug-eluting stents. They use laser cut nitinol tubing to help stents work better and help patients feel better.

Medtronic: Medtronic makes many medical devices, like drug-eluting and bare-metal stents. They work hard to make stents that work the same way every time.

Cook Medical: Cook Medical makes drug-eluting stents and catheters. Their products use laser cut nitinol tubing to stay flexible and strong in tough blood vessels.

Abbott: Abbott’s vascular stents and drug-eluting stents are used by many doctors. They spend money on research to make their medical implants safer and better.

Bard (now part of BD): Bard’s laser cut nitinol stents are trusted for blood vessel treatments. Their stents work well and do not break easily.

Top companies spend money on research to make stents safer and better for patients. They use special laser cutting, heat, and surface finishing to make medical devices that help doctors and patients.

Performance Data

Doctors and engineers look at how well different stents made from laser cut nitinol tubing work. The table below shows important numbers for braided and laser-cut nitinol stents in the common femoral vein. These numbers show how long stents stay open and how often they break.

Performance Indicator | Braided Nitinol Stents | Laser-Cut Nitinol Stents | Statistical Significance (p-value) |

|---|---|---|---|

Primary Patency Rate at 12 months | 86.7% (95% CI 75–98.1%) | 67.3% (95% CI 58–76.6%) | 0.016 (logrank) |

Secondary Patency Rate at 12 months | 100% | 93.9% (95% CI 89.2–98.6%) | 0.1 (logrank) |

Stent Fracture Incidence | 0% | 4% | N/A |

Median Improvement in Villalta Score | 4 points (IQR 2–6) | 4 points (IQR 2–6) | No difference |

Laser cut nitinol stents keep working well and help patients feel better. But braided nitinol stents stay open longer and do not break at all. Both types use special materials and steps like laser cutting, chemical etching, and electro-polishing to work their best.

Tests show that heat treatment changes how strong laser cut nitinol tubing is. If you lower the heat to 400 °C, the tubing gets up to 25.4% less crush resistance, and wire-braided stents lose 47.5%. Radial strength also drops by 87.0% for laser-cut and 40.5% for wire-braided stents. The austenite finish temperature (Af) is important for superelasticity. If the heat is too high, Af can get too close to body temperature and change how the stent works. Companies try to keep Af between 15–25 °C so the stent stays superelastic in the body.

Tip: Doing the same steps every time, like laser cutting, shape-setting, and surface finishing, helps stents keep the right strength and heat properties.

Clinical Outcomes

Clinical trials give doctors important facts about how safe and helpful laser cut nitinol tubing is in stents and catheters. The table below shows how often stents stay open after one year in big studies.

Clinical Trial / Device (Company) | 12-Month Primary Patency Rate (%) | Year |

|---|---|---|

FAST (Luminexx, Bard) | 68.3 | 2007 |

ASSESS (Absolute, Abbott) | 90.7 (at 1 month) | 2007 |

Zilver PTX (Cook Medical) | 77.6 – 86.2 | 2011, 2013 |

RESILIENT (LifeStent, Bard) | 81 – 81.5 | 2012, 2015 |

DEBATE SFA (Maris, Medtronic) | 57.7 | 2013 |

The DURABILITY II trial had 287 patients with artery problems in their legs. After one year, 67.7% of stents stayed open by ultrasound. Another way of checking showed 77.2% stayed open, 86.9% needed some help, and 87.3% stayed open after more help. Most patients could walk better, had less pain, and had better blood flow. Only 0.4% of stents broke. Over 83% of patients got better in their Rutherford score, showing that laser cut nitinol stents work well in real life.

Drug-eluting stents made with laser cut nitinol tubing also work well. These stents give out medicine to stop blood vessels from closing again. Studies show that drug-eluting stents lower the chance of the vessel closing and mean fewer repeat treatments. Using superelastic nitinol and careful drug delivery helps keep patients safe and healthy.

Note: Clinical studies show that laser cut nitinol tubing helps stents work well, stay open, and have few problems. These results show that using new stent designs and making steps helps patients get better.

Challenges and Solutions

Fatigue and Durability

Fatigue and durability are big worries for nitinol vascular stents. These stents move a lot inside the body. They must last through millions of bends without breaking. Companies test nitinol tubing by bending it many times, sometimes up to 400 million times. They use two ways to test: one checks if the stent stays whole, and the other finds when it breaks. The first way is used more because doctors want stents that never break in the body. Blood vessels are tricky places, so companies use computers and real tests to make sure stents are safe. Making nitinol stronger with cold work and heat helps it last longer. Smoothing the surface with electropolishing takes away tiny cracks and makes stents tougher. These steps help stents work well and keep patients safe for a long time.

Keeping nitinol cool during laser cutting is very important. Special cooling and freezing methods help nitinol stay strong.

Better drilling and laser settings stop tiny cracks and heat damage.

Smoothing the surface with electropolishing makes it slick and stops blood from sticking.

Corrosion Resistance

Corrosion resistance is very important for nitinol stents and catheters. Laser cutting can leave small flaws on the tube’s surface. How smooth the tube is matters for safety. Electropolished tubes can handle much higher voltages, sometimes up to 1000 mV, and do not break down. Tubes with oxidized surfaces break down at lower voltages, around -117 mV. Special tests at body temperature check how well the tube fights rust. Smaller stent surfaces can handle more voltage, which means they resist rust better. Sometimes, things like Ti2NiOx can start tiny rust spots. Adding coatings puts a shield on the tube and makes it safer for blood. These steps help stents last longer and keep patients safe.

Radiopacity

Radiopacity lets doctors see stents and catheters during surgery. Scientists use fake body parts and different people to check how well stents show up on X-rays. They use special scales to rate how clear the images are, how well they can see layers, and if there are any problems with the pictures.

Assessment Aspect | Scale Type | Description |

|---|---|---|

Image clarity ranking | Visual Analogue Scale (VAS) | Readers rate how clear the vessel and plaque look in the picture |

Layered structure differentiation | 1 to 4 scale | 1 means all vessel wall layers are easy to see; 4 means none are clear |

Non-layered structure (plaque presence) | 1 to 5 scale | 1 means the image looks like a real tissue sample; 5 means it is very hard to see |

Calcification (abnormal physiology) | 1 to 5 scale | 1 means the image is very clear; 5 means it is too blurry |

Artifact effect on image reading | 1 to 3 scale | 1 means no problems in the picture; 3 means big problems that make it hard to read |

Companies want stents that show up well on X-rays and do not cause problems in the pictures. This helps doctors put nitinol stents in the right place safely.

Innovations in Medical Device Manufacturing

Advanced Laser Techniques

New laser technology has changed how nitinol tubing is made. Engineers use femtosecond and fiber lasers for very exact cuts. These lasers make tiny patterns and smooth edges for advanced devices. After cutting, electropolishing makes the surface super smooth, down to nanometers. This keeps the nitinol’s inside structure safe and stops heat damage near the cut. Tests show these steps keep nitinol strong and bendy. For example, actuation force is half as much as stainless steel. The inside of bending parts gets about 10% bigger. This gives more room for other parts in the device.

Innovation Aspect | Evidence / Metric | Impact on Medical Device Manufacturing and Patient Outcomes |

|---|---|---|

Precision Manufacturing | Dimensional tolerances as tight as ±0.0005 inches (±12.7 µm) | Makes very exact, custom devices that fit the body well and work safely |

Fatigue Resistance and Durability | Devices withstand millions of cycles without failure; high-cycle fatigue strain limit between 0.4% to 0.8% strain | Means devices last a long time and keep working even after lots of use |

Radiopacity Enhancements | Use of DFT® flat wire and special materials to improve visibility during surgery | Helps doctors see devices better, making surgery safer and faster |

Rapid Prototyping

Rapid prototyping is now a big part of making nitinol devices. Engineers use computer design and 3D printing to make test models fast. This lets teams try new ideas and change designs in just days. Custom devices for special patient needs are easier to make. Hospitals get these special devices faster. The market for nitinol medical devices grows by 8% each year. This shows more people want these new devices. Clinical trials like DAWN and PARTNER 3 show nitinol devices help more patients live on their own and lower death rates compared to old treatments.

Note: Rapid prototyping helps make nitinol devices faster, so doctors can get the tools they need for today’s medicine.

Joining Technologies

Joining technologies are very important for putting nitinol devices together. Laser welding, micro-joining, and special glues connect nitinol parts without losing their special features. These ways keep shape memory and superelasticity safe. Now, smart sensors and actuators can be built into nitinol tubing. This lets devices give feedback and change during medical work. Better joining also lowers the chance of implant rejection by 30% compared to old metals. The devices stay safe for the body and do not let out much nickel. Smooth surfaces help too. These new joining methods make devices safer and last longer for many uses.

Laser cut nitinol tubing is the best for stents. Nitinol makes stents strong and flexible. It also keeps them safe for patients. Stents with nitinol last a long time. They fit well inside blood vessels. Big companies use nitinol to help patients heal quickly. Nitinol stops stents from bending or breaking. Engineers must check the size, shape, and finish of the tubing. Nitinol will keep making stents better. New nitinol ideas will make stents safer and work better. Nitinol will be important for stents in the future.

FAQ

What makes laser cut nitinol tubing ideal for stents and catheters?

Laser cut nitinol tubing can bend a lot and snap back. It remembers its shape after being bent. This helps stents and catheters move through twisty blood vessels. The tubing does not fold or break easily. This keeps patients safer and helps the device work better.

How does surface finishing improve nitinol tubing?

Surface finishing, like electropolishing, makes the tube smooth. It takes away sharp edges and rough spots. This stops nickel from leaking out. It also helps the tube fight rust. A smooth tube lasts longer in the body.

Are there any risks with using nitinol in medical devices?

Nitinol is safe for most people. Some people may be sensitive to nickel, but this is rare. Companies add coatings and use special treatments. These steps help keep nickel from touching the body and make the device safer.

How do manufacturers ensure the quality of laser cut nitinol tubing?

Manufacturers follow strict rules like ISO 13485. They use tests like X-rays and CT scans to check the tubes. These tests make sure the tubes are the right size and shape. Quality checks help every tube meet safety and work well.

Can nitinol tubing be customized for specific patient needs?

Yes. Companies use fast design and special lasers to make custom tubes. They can change the shape and size for each patient. This helps the device fit better and work best for each person.

See Also

Understanding Nitinol Tubing Uses Within Medical Equipment

The Process Behind Producing Nitinol Tubing For Medicine

Nitinol Tubing Transforming The Future Of Medical Tools

Nitinol Tubing’s Impact On Progressing Healthcare Innovations