How Laser Cutting Improves Nitinol Tubing for Medical Use

Laser cut Nitinol tubing for medical devices has revolutionized the way Nitinol tubing is utilized in the medical field. This technology enables extremely precise cuts, which are essential for intricate designs in medical tools. Unlike traditional methods, laser cutting minimizes material waste and preserves Nitinol's unique properties. It also facilitates the creation of components that are safe for the human body. By using laser cut Nitinol tubing for medical devices, manufacturers can produce tools that function effectively and contribute to patient recovery.

Key Takeaways

Laser cutting makes exact cuts in Nitinol tubing. This helps medical tools fit well and work properly.

It reduces wasted material and keeps Nitinol's special features. This makes devices safer for patients to use.

Laser cutting creates detailed designs for specific medical needs. This improves tools like stents and catheters.

It lowers the chance of overheating, which can harm Nitinol's memory and flexibility.

This method makes Nitinol devices stronger and more dependable for long-term use in the body.

The Unique Properties of Nitinol

Shape Memory and Superelasticity

Nitinol is special because it can "remember" its shape. When heated, it goes back to its original form. For example, a nitinol stent can be squeezed small to fit inside the body. Once inside, it expands to the right size. Nitinol is also super stretchy and can bend a lot without breaking. This makes it great for tools like stents and guidewires that need to move with the body.

Mechanism | Description |

|---|---|

Shape Memory Effect | Nitinol changes shape when heated and returns to normal after bending. |

Superelasticity | Nitinol stretches and bends but snaps back to its shape when stress is gone. |

Composition Sensitivity | The mix of nickel and titanium affects how nitinol works and can be adjusted during production. |

Biocompatibility and Corrosion Resistance

Nitinol is safe for the body and doesn’t rust easily. A special layer on its surface stops it from corroding. Treatments like polishing make it even safer by lowering the risk of blood clots. Studies show nitinol doesn’t release harmful materials into the body, so it’s great for implants.

A protective layer on nitinol stops it from rusting.

Polishing reduces nickel exposure, making it safer for the body.

Research proves nitinol is safe and doesn’t cause harm inside the body.

Applications in Medical Devices

Nitinol is used in many medical tools because of its unique abilities. Its shape memory and flexibility are perfect for stents, which need to fit inside blood vessels. It’s also used in guidewires and catheters because they need to bend and last a long time. In surgeries, nitinol staples help hold bones together and adjust to their shape.

Nitinol staples are used in surgeries for feet, ankles, and spines.

Stents made of nitinol expand properly inside the body.

Guidewires and catheters use nitinol to move through tricky body paths.

Nitinol is a key material in modern medical tools. It helps devices work well while keeping patients safe.

Challenges in Making Nitinol Stents and Other Tools

Hard to Work With Due to Material Traits

Nitinol is tricky to shape because of its special traits. Its ability to change phases and harden makes cutting tough. Careful shaping is needed to keep it safe and useful. Smooth surfaces, around 1-2 μm, help it stay in place, like in dental implants. But bad shaping can cause wear or nickel leaks, which are unsafe.

A TiO2 layer on nitinol stops rust and helps healing.

It cracks more easily than some materials, so shaping needs care.

Surface texture affects how bacteria stick, which can cause infections.

These problems need advanced tools and strict checks to make safe stents.

Keeping It Safe for the Body

Making nitinol stents safe for the body is very important. Nickel release must be checked for devices used for a long time. Polishing and rust tests help meet safety rules. New tests are being made to check risks for each device instead of using general methods.

Checking nickel release keeps patients safe.

Polishing lowers nickel exposure and makes it safer.

Rust tests check how strong nitinol devices are.

Focusing on safety makes devices that work well and are safe for people.

Making Complex Designs Perfect

Nitinol stents often need detailed designs and exact sizes. Engineers face problems like soft wires that are hard to handle. New ideas, like separating straight and curved parts, make wires stronger but still flexible. This makes stents work better and cuts costs by 40%.

Making complex designs needs skill and accuracy.

Following safety rules makes the process harder.

Saving materials and cutting costs helps production.

Fixing these issues helps make nitinol tools that meet modern medical needs.

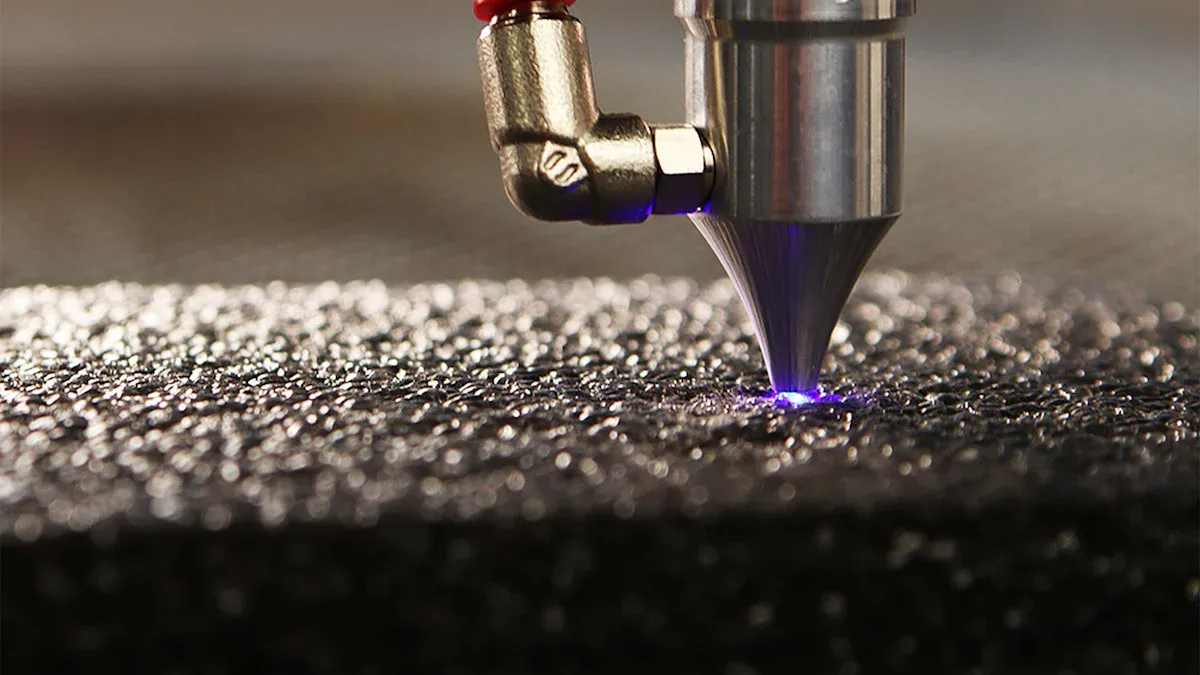

How Laser Cutting Helps Nitinol Tubing for Medical Devices

Making Accurate Cuts and Tight Fits

Laser cutting is key for making nitinol tubing precise. Nitinol's special traits, like bending and shape memory, need careful handling. Lasers make exact cuts, which is crucial for medical tools.

This method allows for very tight fits, even on tiny parts. For example, stents need perfect sizes to work inside blood vessels. Laser cutting can achieve tolerances as small as ±0.0005 inches (12.7 µm). The table below shows how precise laser cutting can be:

Specification | Value |

|---|---|

Outer Diameter Range | 0.010"–0.065" (0.254–1.65 mm) |

Tolerances | Down to 10.2 μm |

OD/ID Ratios | 1.11–2.67 |

Precision for Stent Applications | ±0.0005" (12.7 µm) |

Precision for Larger Diameters | ±0.0008"–0.001" (20.3–25.4 µm) |

Accuracy | Over 90% |

Premium Grade Tolerances | ±0.0005" |

Accuracy for Premium Grade | Over 95% |

This level of accuracy helps medical tools work well and safely.

Protecting Material and Avoiding Heat Damage

Nitinol’s special features must stay intact during cutting. Laser cutting avoids overheating, which can harm its bending and shape memory abilities. Other methods can cause cracks or weaken the material.

Lasers use controlled energy to cut without damaging nitinol. This keeps its surface smooth and its structure strong. It also ensures nitinol stays safe for the body and resists rust. This is vital for tools like stents and guidewires that touch the body.

Laser cutting also reduces extra steps like polishing or heat fixing. This saves time and keeps nitinol’s original qualities intact.

Allowing Unique Designs and Shapes

Laser cutting makes it easy to create custom designs for medical tools. It can make detailed shapes that other methods can’t. This helps create tools that work better for specific medical needs.

For instance, laser cut nitinol tubing can have special shapes to fit the body. Stents can have openings to improve blood flow. Catheters can be made in different sizes for various uses.

Laser cutting isn’t just for medical tools. Other industries, like jewelry and furniture, use it too. Examples include:

Names or messages engraved on jewelry for a personal touch.

Detailed 3D sculptures made with fiber lasers.

Custom furniture with unique patterns and shapes.

In medical devices, this customization ensures tools meet patient and doctor needs. It also inspires new ideas for nitinol products in the future.

Real-World Uses of Laser-Cut Nitinol Tubing

Stents and Blood Vessel Implants

Laser-cut Nitinol tubing is important for making stents and implants. These tools help treat blocked or weak blood vessels. They are precise and work well inside the body.

The process starts with a metal tube. Lasers cut it into patterns to make a stent. This design helps the stent expand and support vessel walls. Before use, the stent is compressed into a delivery system. It is made 10% to 40% larger to fit securely when placed. Stretching it after placement improves how it works over time.

Material Type | Benefits | Drawbacks |

|---|---|---|

BMS | Strong support | Harmful breakdown products |

DES | Less vessel narrowing | Hard to make |

BDS | More flexible | Few material choices |

Nitinol stents are flexible, safe for the body, and move with it. These features make them a trusted choice for implants. This technology has changed heart treatments, making them safer and better.

Catheters and Guidewires

Catheters and guidewires made from laser-cut Nitinol tubing perform better than older designs. These tools are used to move through the body during medical procedures. They are precise and strong, helping doctors get better results.

Laser-cut catheters are better in many ways:

Performance Metric | Laser-Cut Catheters (LCT) | Traditional Catheters |

|---|---|---|

Torque Control | Better | Worse |

Kink Resistance | Higher | Normal |

Pull Strength | Similar | Similar |

Bending Ability | Equal | Equal |

Laser-cut catheters twist better and don’t kink easily. This makes it simpler to move through tricky body areas. Laser-cut guidewires are both flexible and strong, giving doctors more control during delicate tasks.

Braces and Surgery Tools

Laser-cut Nitinol tubing is also used in braces and surgery tools. These tools offer special benefits that help patients and doctors. For example, Nitinol braces adjust to your teeth, gently moving them into place.

In surgeries, laser-cut tools are precise and safe. Studies show their benefits:

Study Topic | Results |

|---|---|

Laser vs. regular surgery for soft tissue | Same results, but lasers reduced bleeding and pain. |

Laser for delayed tooth eruption | Faster tooth growth and healthy gums. |

Laser gum surgery vs. non-surgical methods | Better gum health early on with lasers. |

General laser benefits in surgery | Stops bleeding, cleans area, reduces pain, and lowers need for painkillers. |

These studies show how laser-cut tools improve surgery accuracy and reduce pain. This technology keeps advancing, giving doctors better tools to care for patients.

Laser cutting changes how Nitinol tubing is made for medical tools. It fixes cutting problems and keeps the material safe for the body. This method protects Nitinol from rust, making it better for implants. Research shows laser cutting improves how long Nitinol lasts. For instance, tubes made with TM-1 methods handle stress 2-3 times better than TM-2 after 10 million uses. These upgrades make devices stronger and more dependable. Using laser cutting helps create new designs that help both makers and patients.

FAQ

Why is laser cutting better than older methods for Nitinol?

Laser cutting is very precise and keeps Nitinol’s special traits. It avoids overheating, which can harm the material. Older methods struggle with tricky designs and tight fits. Lasers handle detailed patterns and keep Nitinol safe for medical use.

Does laser cutting change Nitinol’s shape memory or flexibility?

No, laser cutting keeps Nitinol’s shape memory and flexibility safe. It uses controlled energy to avoid heat damage. This helps Nitinol bend, stretch, and return to its shape, which is important for tools like stents and guidewires.

Is laser cutting safe for tools used inside the body?

Yes, laser cutting makes smooth surfaces and lowers nickel exposure. It keeps Nitinol safe for the body and stops it from rusting. This makes it great for implants like stents that touch blood and tissues safely.

How does laser cutting help make custom medical tools?

Laser cutting makes detailed shapes and patterns for special needs. For example, stents can have holes to help blood flow. Catheters can be made in different sizes. This improves how tools work and helps patients recover better.

Do other industries use laser-cut Nitinol tubing?

Yes, other industries like jewelry and aerospace use it too. Jewelry makers create fancy designs, and aerospace uses it for light, bendable parts. Its many uses make it helpful in different fields.

See Also

The Process Behind Nitinol Tubing Production for Healthcare

Nitinol Tubing's Impact on the Future of Medical Devices

The Importance of Nitinol Tubing in Modern Medical Solutions

Nitinol Tubing's Contribution to Progress in Medical Technology