Exploring the Role of Laser-Cut Nitinol Tubing in Stroke Treatment Devices

Laser-cut nitinol tubing has transformed the field of mechanical thrombectomy by providing unmatched precision and flexibility. Devices crafted from nitinol tubing demonstrate adjustable stent lengths, ranging from 9 to 13 cm, and promote rapid tissue coverage, as shown in the table below.

Time after implantation | Average neointimal thickness (μm) | Stent length (cm) |

|---|---|---|

1 month | 476 (9 cm), 190 (11 cm), 247 (13 cm) | 9, 11, 13 |

6 months | 900 (9 cm), 1050 (11 cm), 786 (13 cm) | 9, 11, 13 |

Advancements in laser cutting and nitinol tubing properties allow safe, reliable devices for minimally invasive procedures. Laser-Cut Nitinol Tubing for Mechanical Thrombectomy Devices supports better outcomes for both patients and clinicians.

Key Takeaways

Laser-cut nitinol tubing offers unique shape memory and superelasticity, allowing stroke devices to flex and return to their original shape for safe navigation through blood vessels.

Advanced laser cutting creates precise, smooth, and complex device designs that improve flexibility, durability, and clot removal success in mechanical thrombectomy.

Nitinol tubing is highly biocompatible and corrosion-resistant, reducing risks and ensuring long-term safety for patients during stroke treatments.

Devices made with laser-cut nitinol tubing deliver better clinical outcomes by enabling faster, safer, and more effective clot retrieval with fewer complications.

Future innovations like AI-driven laser cutting and smart sensors promise even more precise, customized, and efficient stroke treatment devices.

Nitinol Tubing in Stroke Devices

Shape Memory and Superelasticity

Nitinol tubing stands out in stroke devices due to its remarkable shape memory and superelasticity. These properties allow the tubing to recover its original shape after deformation, which is essential for devices that must navigate complex vascular pathways. Tensile testing, stress-strain analysis, and advanced imaging techniques such as scanning electron microscopy confirm the superelastic behavior and shape memory characteristics of nitinol tubing. Standardized tests, including differential scanning calorimetry and bend-free recovery assessments, provide quantitative data on transformation temperatures and shape recovery. Biaxial tension–torsion experiments further reveal how nitinol tubing responds to real-world loading conditions, highlighting its ability to undergo stress-induced phase transformations. This unique combination of properties enables superelasticity for flexibility, allowing stent retrievers to adapt to tortuous vessels and maintain their effectiveness during clot retrieval. Compared to conventional materials like stainless steel, nitinol tubing delivers superior flexibility and durability, which translates to improved clinical performance in mechanical thrombectomy. Microfabricated nitinol stent retrievers with patterned surfaces have demonstrated enhanced clot retrieval efficacy in laboratory settings, underscoring the value of superelasticity for enhanced flexibility in stroke treatment devices.

Biocompatibility and Safety

Biocompatibility and corrosion resistance play a critical role in the success of nitinol tubing for neurovascular applications. Clinical studies have shown that nitinol stents maintain vessel patency and deliver long-term safety in vascular interventions. For example, research by Lichtenberg et al. (2014), Sakamoto et al. (2013), and Scheinert et al. (2013) demonstrated positive outcomes and durability in complex vascular cases, supporting the use of nitinol tubing in stroke devices.

Study (Author, Year) | Key Findings Supporting Biocompatibility and Safety of Nitinol Tubing in Stroke Devices |

|---|---|

Lichtenberg et al. (2014) | Improved vessel patency and long-term safety in femoral and popliteal arteries |

Sakamoto et al. (2013) | Positive long-term outcomes in chronic total occlusion cases |

Scheinert et al. (2013) | Effectiveness and safety in complex vascular cases |

Material science advancements, such as electropolishing and plasma coating, further enhance biocompatibility and corrosion resistance by reducing nickel ion release and promoting endothelialization. The Stentrode self-expanding nitinol stent, tested in neurovascular clinical trials, has demonstrated both safety and efficacy for patients. These findings confirm that nitinol tubing offers reliable biocompatibility and corrosion resistance, making it a preferred choice for modern stroke treatment devices.

Laser-Cut Nitinol Tubing for Mechanical Thrombectomy Devices

High-Precision Nitinol Tubing

High-precision nitinol tubing forms the backbone of modern thrombectomy devices. Manufacturers select nitinol tubing for its unique combination of shape memory, superelasticity, and biocompatibility. These properties allow thrombectomy stent designs to achieve the flexibility and durability required for safe navigation through delicate cerebral vessels. Dimensional accuracy remains critical in this context. Laser-cut nitinol tubing for mechanical thrombectomy devices achieves outer and inner diameter tolerances as tight as ±0.005 mm for diameters below 0.3 mm. This level of precision ensures that custom nitinol stents fit exactly within the vascular anatomy, reducing the risk of complications.

The manufacturing process for high-precision nitinol tubing involves careful control of material composition. Adjusting the nickel-titanium ratio optimizes both shape memory and superelastic properties. Cold working and heat treatment further enhance the tubing’s ability to flex and recover its original shape, which is essential for repeated deployment and retrieval during thrombectomy procedures.

Smooth surface finishes on nitinol tubing improve biocompatibility and reduce infection risk, which is vital for implantable thrombectomy stent devices.

Laser-cut nitinol tubing enables the creation of intricate patterns, including slots, holes, and curves. These features allow for precise control over device flexibility and radial force. Custom nitinol stents can transition smoothly from a stiffer proximal end to a more flexible distal tip, improving navigation and clot retrieval. The ability to produce complex geometries with minimal thermal damage preserves the unique properties of nitinol tubing, ensuring reliable performance in mechanical thrombectomy.

Metric Category | Supporting Details |

|---|---|

Material Composition | Nickel-titanium ratio tailored for optimal shape memory and superelasticity |

Dimensional Accuracy | OD/ID tolerances: ±0.005 mm for OD ≤ 0.3 mm |

Surface Quality | Smooth finishes reduce infection risk and improve biocompatibility |

Manufacturing | Laser cutting enables complex geometries with minimal thermal damage |

Mechanical Properties | Cold working and heat treatment enhance superelasticity and durability |

Advanced Laser Cutting Techniques

Advanced laser cutting techniques have revolutionized the production of laser-cut nitinol tubing for mechanical thrombectomy devices. Photolithography-based laser machining systems, such as the Starcut tube fiber, deliver the precision needed for intricate thrombectomy stent designs. These systems operate at a power output of 55 W and use a 16.5 µm pulse wavelength. Oxygen cooling systems help manage heat during the cutting process, reducing the risk of thermal damage.

Laser-cut nitinol tubing benefits from the use of ultrafast lasers, which minimize the heat-affected zone and preserve the material’s superelasticity. Inert gases, such as nitrogen, create a controlled atmosphere during fabrication. This environment reduces oxidation and improves the quality of the cut edges. Post-processing steps play a crucial role in ensuring the final quality of nitinol tubing. Chemical etching removes oxides and organic residues, while high-vacuum annealing at 450–600 °C for 10–30 minutes relieves residual stresses and forms a stable oxide layer.

Mechanical machining, blasting, and vibratory polishing further reduce surface roughness and residual stresses.

These steps enhance fatigue strength and durability, which are essential for thrombectomy stent performance.

Polishing and surface treatments also decrease porosity near the tubing edges, improving overall part density and reliability.

Aspect | Details |

|---|---|

Laser Cutting System | Photolithography-based laser machining (Starcut tube fiber) |

Power Output | 55 W |

Laser Wavelength | 16.5 µm pulse |

Cooling System | Oxygen cooling |

Post-processing Steps | Chemical etching, heat treatment, mechanical polishing |

Heat Treatment Parameters | 450–600 °C for 10–30 min in high-vacuum furnace |

Performance Metrics | Burr-free edges, fine surface finish, tight tolerances, complex shapes |

Device Functional Benefits | Kink resistance, pushability, torque handling, trackability, transition performance |

Laser-cut nitinol tubing for mechanical thrombectomy devices stands out for its ability to produce burr-free edges and fine surface finishes, minimizing the need for secondary processing. The process enables the creation of custom nitinol stents with precise geometry changes, supporting optimal transition performance from the proximal to distal ends. Fatigue and durability tests, including finite element analysis and three-point bending, confirm the tubing’s ability to withstand physiological conditions encountered during thrombectomy.

Note: While laser cutting offers unmatched precision, it can introduce thermal damage and microcracks if not properly controlled. Post-processing and the use of inert gases help mitigate these risks, ensuring that high-precision nitinol tubing maintains its mechanical integrity and performance.

Laser-cut nitinol tubing for mechanical thrombectomy devices continues to set the standard for innovation in stroke treatment. The combination of advanced laser cutting, careful material selection, and rigorous post-processing enables the production of custom nitinol stents that deliver superior kink resistance, pushability, and trackability. These qualities directly translate to safer, more effective thrombectomy procedures and improved patient outcomes.

Mechanical Thrombectomy Device Performance

Flexibility and Navigation

Mechanical thrombectomy devices built with laser-cut nitinol tubing deliver exceptional flexibility and navigation. These devices must travel through complex, winding blood vessels to reach the site of a clot. The flexible nature of nitinol tubing allows for smooth passage, reducing the risk of vessel injury during minimally invasive procedures. Devices like the Toro 88 catheter use advanced micro-wire designs to enhance control and maneuverability. Clinical feedback highlights how these features improve navigation through challenging neurovascular pathways, making clot removal more efficient.

A comparison of device navigation and maneuverability shows that design plays a crucial role in performance:

Device Type | Navigation/Maneuverability Aspect | Performance Metric | Outcome/Impact on Stroke Treatment Maneuverability |

|---|---|---|---|

Proximal Aspiration | Fast repeated application, low thromboembolic risk | Embolic event rate: 3% vs 26% (distal device) | Lower embolic risk, lower clot removal success (39.4%) |

Distal Basketlike Device | Higher clot removal success, more complex navigation | Success rate: 82.6% vs 39.4% (proximal device) | Higher success, increased embolic events, mitigated by balloon occlusion |

Merci Retriever | Flexible nitinol wire, coil loops, microcatheter delivery | Improved deliverability with 4.3F distal access catheter | Enhanced navigation and simultaneous clot removal capability |

These results demonstrate that flexibility and navigation directly impact the success of clot removal during minimally invasive procedures.

Clot Retrieval and Safety

Effective clot removal remains the primary goal of mechanical thrombectomy. Devices such as the Tigertriever and Jrecan stent retrievers use laser-cut nitinol tubing to optimize radial force and clot fixation. The closed-ended distal capture basket design helps minimize distal embolization, improving safety during minimally invasive procedures. A soft, atraumatic tip ensures safe deployment and reduces the risk of vessel injury.

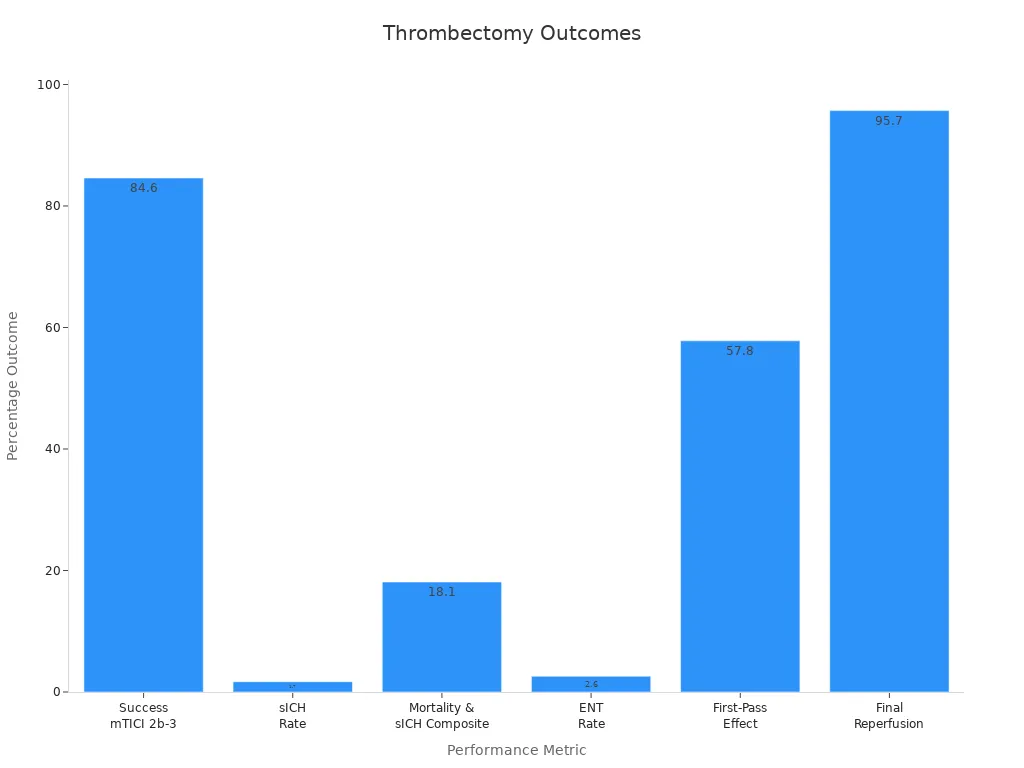

Clinical trials, including STAR, SWIFT, and EXTEND-IA, confirm that modern thrombectomy devices achieve high rates of successful clot removal and vessel reopening. The following table summarizes key performance metrics:

Performance Metric | Tigertriever Result | Comparator / Historical Data | Significance / Notes |

|---|---|---|---|

Successful Revascularization (mTICI 2b-3) | 84.6% | 73.4% (historical) | p < 0.01, indicating superior efficacy |

Symptomatic Intracranial Hemorrhage (sICH) Rate | 1.7% | N/A | Very low safety event rate |

Mortality and sICH Composite Endpoint | 18.1% | 20.4% (historical) | Comparable safety profile |

Embolization to New Territory (ENT) Rate | 2.6% (95% CI 0.5%–7.4%) | 7.4% (pooled comparator trials) | Statistically superior (p = 0.0403) |

First-Pass Effect | 57.8% | N/A | Indicates efficiency in clot removal on first attempt |

Final Successful Reperfusion (mTICI 2b-3) | 95.7% | N/A | High overall reperfusion success |

Median Groin-to-Revascularization Time | 24 minutes | 25 minutes (fastest reported) | Favorable procedural time |

These results highlight the efficiency and safety of clot removal using laser-cut nitinol tubing in minimally invasive procedures. The combination of advanced design and material properties ensures that thrombectomy devices deliver reliable outcomes for patients.

Clinical Impact of Laser-Cut Nitinol Tubing

Improved Outcomes

Laser-cut nitinol tubing has reshaped stroke intervention by delivering safer and more effective treatments. Devices made from this material show remarkable shape memory, superelasticity, and biocompatibility. These features allow clinicians to navigate complex blood vessels with precision, reducing procedure times and minimizing vessel trauma. Clinical data confirm that nitinol-based catheters and stents maintain their structural integrity during minimally invasive stroke procedures. For example, the WATCHMAN FLX™ device from Boston Scientific uses laser-cut nitinol tubing to prevent strokes in patients with atrial fibrillation, demonstrating reliable performance in critical settings.

Comparative studies highlight the benefits of modern thrombectomy devices over older technologies. Both the Solitaire AB/FR stent and the Aperio clot-removal device, which use laser-cut nitinol tubing, achieved a 100% recanalization rate in animal models without device-related complications. Clinical trials report recanalization rates up to 90% and good outcomes in more than half of treated patients, surpassing results from traditional thrombolysis. Quality control measures, such as athermal laser cutting and strict adherence to ISO 13485:2012 standards, ensure device reliability and safety. Testing methods like metallography and corrosion resistance assessments confirm the tubing’s durability and biocompatibility, supporting improved patient recovery.

Devices with laser-cut nitinol tubing show minimal tissue reactions and a significant reduction in device recalls, reflecting their safety and reliability in advanced medical applications.

Future Directions

The future of laser-cut nitinol tubing in advanced medical applications looks promising. Technological trends point to the adoption of ultrahigh-power fiber lasers and all-silicon lasers, which enable faster and more precise cutting. Integration of AI, Big Data, and IoT in laser cutting systems allows real-time data analysis and predictive maintenance, reducing operational costs and energy use. The rise of 3D laser cutting technology supports the creation of complex device geometries and customized solutions for patient-specific needs.

Industry projections show that AI-powered laser cutting systems will represent over 25% of the market by 2025. Fiber laser machines are expected to account for nearly 60% of the market by 2024, driven by efficiency and lower costs. Investments in green laser-cutting technologies aim to reduce environmental impact, aligning with sustainability goals. Medical device manufacturers are also exploring the integration of smart sensors and electronics into interventional devices, enabling real-time monitoring and telemedicine capabilities. These innovations will continue to enhance device performance, reliability, and patient outcomes in the years ahead.

Laser-cut nitinol tubing has advanced stroke care by enabling flexible, durable, and precise stent retrievers. These devices adapt to vascular anatomy and maintain structural integrity during interventions, which improves clinical outcomes.

Advanced stent retriever designs, including closed-cell and multi-layered configurations, enhance clot retrieval.

Radio-opaque markers and longer stent retrievers increase visibility and first-pass success rates.

Ongoing research explores new geometric configurations and smart device integration, promising even safer and more effective treatments.

FAQ

What makes nitinol tubing ideal for stroke treatment devices?

Nitinol tubing offers shape memory and superelasticity. These properties allow devices to flex and return to their original shape. Clinicians can navigate complex blood vessels safely and efficiently.

How does laser cutting improve thrombectomy device performance?

Laser cutting enables precise, intricate designs. This process preserves nitinol’s unique properties. Devices achieve better flexibility, kink resistance, and reliable clot retrieval.

Are laser-cut nitinol devices safe for patients?

Clinical studies confirm high biocompatibility and corrosion resistance. Post-processing steps, such as electropolishing, further reduce risks. Patients experience fewer complications and improved outcomes.

Can these devices be customized for individual patients?

Manufacturers can tailor device dimensions and geometries using advanced laser cutting. Customization supports better fit and performance for unique vascular anatomies.

What future innovations are expected in this field?

Industry experts anticipate AI-driven laser systems, smart sensors, and 3D laser cutting. These advances will enable more precise, efficient, and patient-specific stroke treatment devices.