Laparoscopic tool shaft insulation PET sleeve keeps surgery safe

You use laparoscopic tool shaft insulation PET sleeve for safe surgeries. This sleeve keeps you safe from electrical problems and physical harm. Insulation is important for patient safety because it stops dangerous leaks. You need to check and test the sleeve often to make sure it works right.

Checking and testing often helps you keep safety high in every surgery.

Key Takeaways

Laparoscopic tool shaft insulation PET sleeves stop electrical leaks. They help keep patients safe during surgery.

Always check PET sleeves for cracks or damage. This helps keep everyone safe and stops serious injuries.

Pick PET sleeves because they last long and resist heat and chemicals. This helps surgical tools work longer.

Use a checklist to clean and check tools. This keeps safety high in the operating room.

Take out any damaged tools right away. This lowers risks and keeps patients safe.

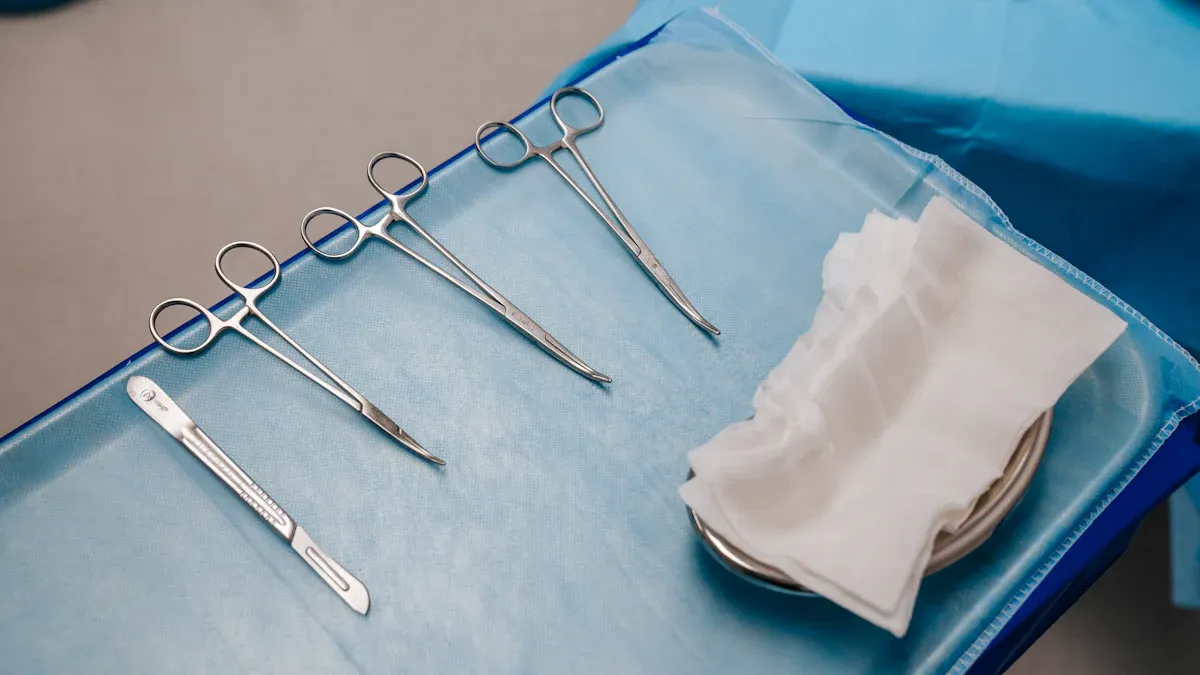

PET sleeve overview

PET material properties

You use PET sleeves to protect laparoscopic tools. PET means polyethylene terephthalate. This material has many good qualities:

PET tubing is tough and lasts a long time, even in hard surgeries.

It has strong dielectric strength, over 4,000 V/mil, so it insulates well.

PET melts at 235°C, so it can handle high heat and stay strong.

PET does not get ruined by medicines, so it works well in hospitals.

It follows ISO 17665-1:2023 rules for hot sterilization.

New changes make PET less likely to wear out, so you can clean it many times.

PET is safe for the body, so it helps stop germs from spreading.

You find PET in insulin pumps, wearable injectors, and robot surgery tools.

PET heat shrink tubing is very strong and stays bendy after cleaning.

PET does not get damaged by chemicals, which is important for safety.

The material stops germs, so patients stay safe.

Tip: Pick PET sleeves because they last long and keep people safe.

Insulation sheath function

The insulation sheath keeps electrical current inside the tool tip. This safety layer stops the current from escaping and causing burns or other harm. If the insulation breaks, current can leak out. This can hurt patients badly. You need to check the insulation often to keep surgeries safe.

Insulation integrity and patient safety

Electrical leakage prevention

It is important to keep insulation strong. This stops electrical leaks during laparoscopic electrosurgery. Using a laparoscopic tool shaft insulation PET sleeve adds a barrier. The barrier keeps electrical current inside the tool. It helps prevent dangerous leaks that can cause burns or injuries.

You can test insulation in different ways before surgery:

Use insulator testers to find tears or cracks in the sleeve.

Look at the sleeve, but some problems are hard to see.

Use electrosurgical test equipment to check for defects.

Teach your staff how to use testing devices the right way.

Take care of your testing equipment to keep patients safe.

Follow ANSI/AAMI ST79 rules for checking insulated tools.

Record problems using the FDA MAUDE reporting system.

Start a quality inspection program in your sterile processing area.

Tip: Always test insulated tools before every surgery to keep everyone safe.

Role in patient safety

You help keep patients safe by stopping insulation failure. If you miss a defect, electrical current can escape. This can cause serious harm. Insulation failure is a big reason for problems in minimally invasive surgery. You may see thermal bowel injuries in 1 to 5 out of every 1,000 surgeries. Studies show insulation failure happens in 27% of all laparoscopic tools. It happens even more in monopolar tools.

The distal third of the tool is where failure happens most. Reusable tools fail more often than disposable ones. Using a damaged tool raises the risk of burns, fires, or death.

Mechanism | Description |

|---|---|

Capacitive Coupling | Insulation failure lets current pass through, causing skin burns. |

Direct Electrical Contact | Insulation failure can touch organs and cause burns or holes. |

You may not notice 67% of stray burns during surgery. About 5.4% of laparoscopic surgeries in the U.S. cause accidental tissue burns. These burns hurt over 162,000 patients each year. One out of four patients with internal burns may die.

Using a laparoscopic tool shaft insulation PET sleeve lowers the chance of electrical and thermal injury. Studies show these sleeves increase electric resistance and help stop burns. Checking and testing often helps you avoid problems and keeps patients safe.

PET sleeve safety benefits

Reduced risk of burns

When you use a laparoscopic tool shaft insulation PET sleeve, you help stop burns. The sleeve covers the shaft of the tool and keeps electrical current inside. This strong layer blocks stray energy from getting out during surgery. It lowers the chance of burns on tissue or organs. Many surgeons see fewer injuries when they use PET sleeves. You help keep every patient safer in each surgery.

Tip: Always look at the sleeve for cracks or damage before surgery. This easy check helps you stop dangerous burns.

You also lower the chance of fires in the operating room. PET sleeves can handle heat and chemicals, so they do not break down fast. You can trust the insulation to work, even in long surgeries.

Instrument durability

You want your laparoscopic tools to last a long time. PET sleeves make tools stronger and help them last longer. The insulation keeps the shaft safe from scratches, dents, and chemical harm. You clean and sterilize your tools many times, but PET sleeves stay strong and bendy. This means you do not need to buy new tools as often.

Benefit | How PET Sleeve Helps |

|---|---|

Longer tool life | Protects against wear and tear |

Fewer replacements | Reduces costs for new instruments |

Reliable performance | Maintains insulation over time |

Using strong sleeves is also good for the environment. But making PET sleeves does create carbon emissions. Synthetic fibers like PET make about two-thirds of carbon emissions from textiles. PET does not break down in nature, so it stays in landfills for a long time. You can help by picking reusable sleeves and recycling when you can.

You keep patients safe when you use PET sleeves. You also help your tools last longer and lower risks in every surgery.

Maintenance and quality assurance

Inspection protocols

You need to check your laparoscopic tools often. Always look at the PET sleeve for cracks or tiny breaks. Use a lighted magnifier to spot small problems. Test the insulation every time, and follow what the maker says. If you see any damage, stop using the tool right away. This keeps your safety rules strong and helps protect patients.

Here is a table to help you remember the main steps for checking PET sleeve insulation on laparoscopic tools:

Inspection Protocols for PET Sleeve Insulation on Laparoscopic Tools |

|---|

Test tools for strength each time you clean them. |

Look at insulation with a lighted magnifier. |

Make sure the insulation does not have any damage. |

Follow the maker’s steps for testing insulation. |

Check insulation at all the right spots. |

Look at cables and cords to make sure they work. |

Take out broken tools right away. |

Use an insulation integrity tester to find hidden problems. This tool helps you see issues your eyes can miss. Always follow the IEC 60601-1 rule for medical device insulation. This rule helps you stop electrical dangers and keeps tools safe.

Cleaning and testing

Clean your tools after every use. Use cleaning solutions that are approved and follow the maker’s steps. After cleaning, check the PET sleeve for new damage. Test the insulation before and after each surgery. Also test during regular checks. If a tool fails the test, stop using it and send it to get fixed.

Regular cleaning and checking help you find problems early. You keep your tools working well and keep patients safe. These steps also help you follow safety rules and keep your hospital ready for surgery.

Tip: Make a checklist for cleaning and checking. This helps you remember each step and keeps your tools safe.

Common issues and solutions

Sleeve damage detection

You need to find damage on sleeves before using tools. Small cracks or tears can cause big trouble. Look at the sleeve with a magnifier to spot problems. Check for broken fibers or rough spots on the sleeve. Use special devices to find insulation failure you cannot see. These devices help you find problems early.

Here is an easy checklist for finding sleeve damage:

Look for cracks, tears, or worn spots on the sleeve.

Use a lighted magnifier to see tiny breaks.

Test the insulation with a device before each use.

Check for broken fibers along the cable.

Do not squeeze, stretch, or bend the cable sharply.

Wipe the cable gently after surgery to clean it.

Tip: Always check the insulation before every surgery. Finding problems early helps keep patients safe.

Managing insulation failure

Act quickly if you find insulation failure. Take the damaged tool out of the surgery area right away. Do not use it again until it is fixed or replaced. Check for insulation failure often, especially with reusable tools. Use detection devices often because failures can happen during surgery and may not be noticed.

Here is a table with steps to handle insulation failure:

Step | Action |

|---|---|

Detection | Use devices to find insulation failure |

Removal | Take damaged tools out of use right away |

Reporting | Write down the failure for tracking |

Replacement/Repair | Fix or replace the tool before next use |

Staff Training | Teach your team how to spot and fix issues |

You keep patients safe by following these steps. Regular checks and quick action lower the risk of burns and injuries. You help your team work better and keep every surgery safe.

You use the laparoscopic tool shaft insulation PET sleeve to keep insulation strong. This helps make every laparoscopic electrosurgery safer. You need to check, clean, and test your tools often. These steps help protect patients from harm. New insulation technology gives you better tools. It also helps make surgeries safer for everyone.

Always look at your sleeves before each surgery.

Learn about new products to get better protection.

Paying close attention helps keep every patient safe.

FAQ

What is a PET sleeve?

A PET sleeve covers the shaft of laparoscopic tools. PET means polyethylene terephthalate. The sleeve helps stop electrical leaks. It protects patients during surgery.

How do you check for sleeve damage?

You look at the sleeve using a lighted magnifier. You test the insulation with a special device. If you see cracks or tears, take the tool out right away.

Can you reuse PET sleeves?

You can reuse PET sleeves if they are strong and clean. You need to check and test them after each cleaning. If you find any damage, you must replace the sleeve.

Why is insulation important in laparoscopic surgery?

Insulation keeps electrical current inside the tool. It helps stop burns and injuries. Good insulation keeps every patient safe.

See Also

Leading Providers of FEP Insulation for Laparoscopic Surgery

Key Uses of Ultrathin PET Heat Shrink Tubing in Medicine

FEP vs. Polyolefins: Heat Shrink Tubing for Electrosurgery