How to Choose the Best Shape Memory Alloy Tubing for Your Project

To pick the best shape memory alloy tubing, look at these things:

Factor | Numerical Criteria / Percentages | Notes / Explanation |

|---|---|---|

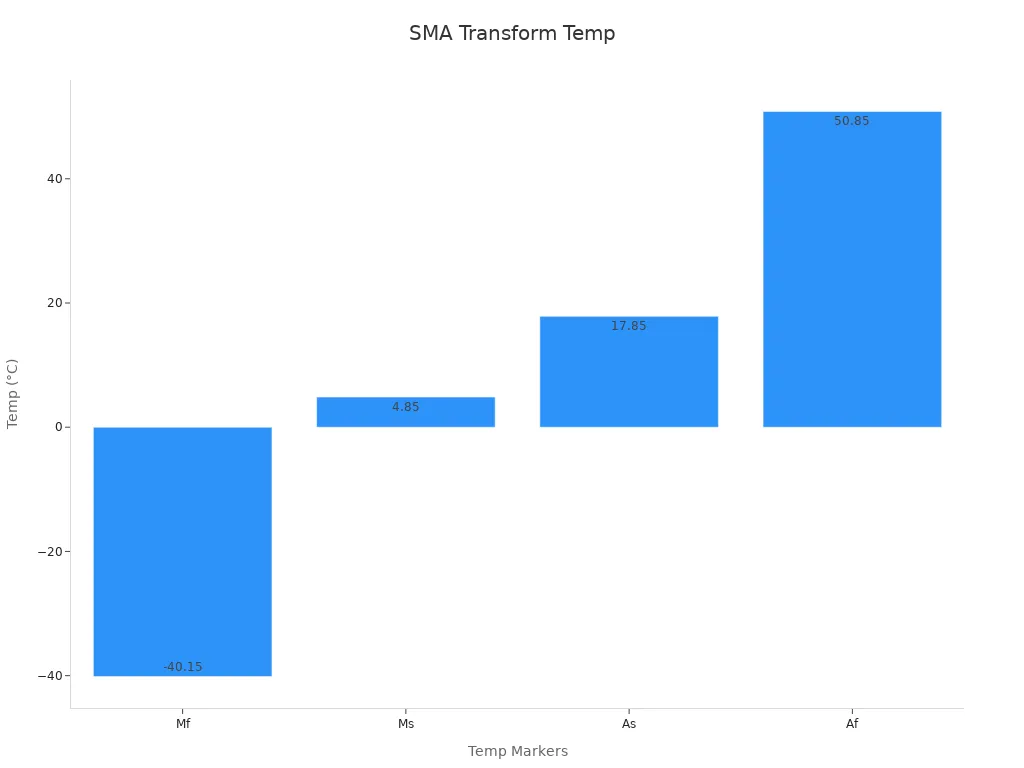

Transformation Temperature | Mf = -40.15°C, Ms = 4.85°C, As = 17.85°C, Af = 50.85°C | Shows the temperature range where the phase changes. This is very important for how the Ni-Ti alloy works. |

Shape Memory Effect | Complete shape recovery; better with 500°C heat treatment | How well it goes back to its shape and how stiff it is depends on how it is treated. |

Mechanical Strength | Elastic modulus and stress depend on heat treatment | Treating at 500°C makes it stiffer. |

Size | Wire diameter = 2.08 mm | The diameter changes how the tubing acts. |

Corrosion Resistance | N/A | This matters if the tubing will be in tough places. |

Supplier Reliability | N/A | Pick suppliers you can trust for good tubing. |

You need shape memory alloy tubing that fits your project. Pick tubing with the right transformation temperature. Make sure it has the shape memory effect you want. Check if it is strong enough. Look at the tubing size and make sure it is good quality. Good suppliers help you avoid problems that can make the tubing wear out faster. The chart below shows the transformation temperatures. Use it to help you choose your tubing.

Key Takeaways

Pick tubing that has the right transformation temperature and size for your project. Nitinol tubing is strong and flexible. It can return to its original shape and stretch without breaking. Choose medical grade tubing that has the right safety certificates. This helps make sure it is safe and lasts a long time. Buy tubing from suppliers you trust. They should give you quality tests and certificates. Make sure the tubing can handle bending many times. Check if it has the right heat treatment for good performance.

Shape Memory Alloy Tubing Basics

What Is Shape Memory Alloy Tubing

Shape memory alloy tubing is special because it can change shape and go back to how it was. This tubing is made from a mix of nickel and titanium called nitinol. The tubing "remembers" its shape. If you bend or twist it when it is cold, it stays bent. When you heat it up, it goes back to its old shape. This happens because the inside of the alloy changes. The tubing can also stretch and snap back without breaking. This is called superelasticity. These features make shape memory alloy tubing useful in many areas.

Key Properties and Benefits

Shape memory alloy tubing has some important features. The biggest ones are the shape memory effect and superelasticity. Nitinol tubing can be soft and bendy or hard and stiff. It changes between these at certain temperatures. You can see the main features of nitinol tubing in the table below:

Property | Value/Range | Description |

|---|---|---|

Atomic Composition | ~50-51% Nickel, 49-50% Titanium | The right mix is key for shape memory and superelasticity |

Young's Modulus (Martensitic) | 20–50 GPa | Shows flexibility |

Young's Modulus (Austenitic) | 40–90 GPa | Shows rigidity |

Transformation Temperatures | −20°C to +110°C | Controls when the tubing changes shape |

Mean Strain Limit | 2.0% - 4.0% | How much you can stretch the tubing |

Fatigue Safety Limit | ~1.75% (sputtered Nitinol) | Safe strain for repeated use |

Maximum Local Strain | >4% (sputtered), up to 6% (optimized tubing) | Shows durability under repeated bending |

Nitinol tubing is safe for the body and does not rust. You can use it in medical tools, planes, and robots. The tubing lasts a long time, even in hard places. It gives you a safe and strong choice for tough jobs.

Nitinol Tubing Overview

Nitinol tubing is the most common shape memory alloy tubing. You see nitinol tubing in stents and medical tools because it is safe and does not rust. Nitinol tubing is also good for planes and robots. The tubing can bend and stretch many times. You can use nitinol tubing in machines that need to move a lot. Knowing about the shape memory effect helps you pick the right tubing. Nitinol tubing is stretchy, lasts long, and works well. You can trust nitinol tubing for smart gadgets and soft robots. The tubing's superelasticity and shape memory effect make it special. When you choose nitinol tubing, you get strength, bendiness, and toughness that most other alloys do not have.

Project Requirements

Application and Function

Think about how you will use the tubing. Each project needs different tubing features. Nitinol tubing is special because it can change shape and go back. You find nitinol tubing in many things. It is used in medical devices, planes, cars, and robots. Each use has its own needs.

Medical devices need tubing that is safe for people. It must handle body heat and stay strong. Nitinol tubing is good for stents and implants. It works well inside the body.

In planes, you want tubing that is light and strong. It must work in tough places. Nitinol tubing is great for moving parts and wings that change shape.

Cars use nitinol tubing for seats and safety parts. The tubing must work fast and be reliable.

Robots and electronics need tubing that bends and goes back. Nitinol tubing helps make parts that move and flex.

Shape memory alloys come in many types. NiTi-based alloys, like nitinol, work better than Cu-based or Fe-based ones. This makes nitinol tubing best for hard jobs. Pick tubing that matches your project for the best results.

Environment and Corrosion Resistance

Think about where you will use the tubing. The place affects how long it lasts and how well it works. Nitinol tubing does not rust or corrode. This is important for medical devices in the body or in wet places.

Tip: Check if your tubing will touch chemicals, saltwater, or body fluids. Nitinol tubing keeps working even in tough spots.

Medical grade nitinol tubing fights rust and keeps its shape. This makes it safe for medical tools and other careful uses. In planes and cars, you also need tubing that does not wear out. Nitinol tubing keeps working after many uses.

Mechanical and Dimensional Needs

You need to know how strong and what size tubing you want. Nitinol tubing comes in many sizes and thicknesses. Pick the right one for how much force and bending you need.

For medical tools, you want tubing that is thin and strong. Medical grade nitinol tubing gives you both.

In robots, you may need tubing that bends a lot. Nitinol memory wire inside helps with moving again and again.

Planes and cars need tubing that can take stress and shaking. Nitinol tubing is tough and keeps working over time.

Check the size limits for your tubing. Small changes can affect how it fits. Good nitinol tubing has tight size limits and works well.

Application Area | Key Mechanical Needs | Typical Tubing Features |

|---|---|---|

Medical Devices | Flexibility, strength, biocompatibility | Thin walls, smooth surface, precise size |

Aerospace | Fatigue resistance, lightweight | Strong, corrosion-resistant, custom sizes |

Robotics | High flexibility, repeatability | Superelastic, durable, small diameter |

Automotive | Quick actuation, safety | Reliable, strong, adaptable |

Medical Devices Applications

Medical devices need the best quality and safety. Always pick medical grade nitinol tubing for these jobs. This tubing is made to strict rules and tested for the body. Nitinol tubing gives you shape memory and superelasticity for stents and implants.

Studies show that good nitinol tubing helps patients do better. For example, top nitinol tubing in eye implants lowers eye pressure for months. Nitinol stents work better and have fewer problems when made with good tubing. Certified makers have fewer recalls, so quality is very important.

Medical grade nitinol tubing is strong, safe, and lasts long.

Devices with nitinol tubing work better and last longer.

You get fewer problems and better results for people.

When you use nitinol in your projects, check that the tubing meets medical rules. Quality is most important for medical uses. Work with suppliers who know medical needs and can give you the right tubing.

Alloy and Specification Selection

Nitinol vs Other Alloys

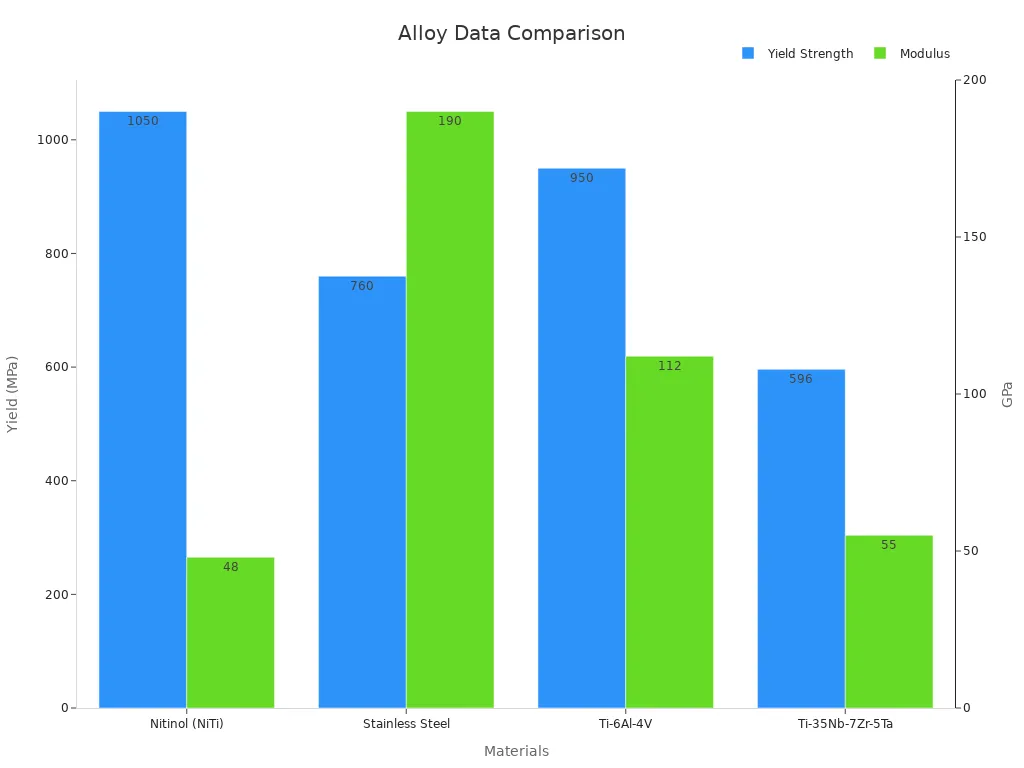

When you pick tubing, you should compare nitinol tubing with other alloys. Nitinol nickel titanium is special because it is strong and flexible. You can see this in the table below:

Material | Yield Strength (MPa) | Modulus of Elasticity (GPa) |

|---|---|---|

Nitinol (NiTi) | 1050 | 48 |

Stainless Steel | 760 | ~190 |

Co-based Alloy | N/A | ~210 |

CP-Titanium | 240–550 | 100 |

Ti-6Al-4V | 950 | 112 |

Ti-35Nb-7Zr-5Ta | 596 | 55 |

Nitinol tubing is stronger than most other alloys. It also bends more before breaking because its modulus of elasticity is lower. This makes nitinol tubing great for jobs that need both strength and flexibility. Stainless steel and titanium alloys are strong, but they do not have the shape memory effect or superelasticity like nitinol tubing.

You can see these differences in the chart below:

Nitinol tubing can stretch up to 6–8% and go back to its shape. Stainless steel and titanium alloys cannot do this. Nitinol nickel titanium tubing is also more bendy, which helps in medical and robotic uses.

Note: Nitinol tubing is hard to machine and needs careful handling. You should work with suppliers who know how to deal with these problems.

How you make the tubing changes its hardness and strength. For example, dense selective laser melted nitinol is strong and can handle big forces. Porous nitinol tubing is lighter but not as strong. If there is too much oxygen when making the tubing, it gets weaker. Always check the tubing quality.

Nitinol Memory Wire and Actuation

Nitinol memory wire is a special kind of nitinol tubing. You use nitinol memory wire to make things move or change shape. When you heat the wire, it moves or changes shape. This makes nitinol memory wire good for smart gadgets, robots, and medical tools.

You can use nitinol memory wire to make things move in small spaces. In medical devices, nitinol memory wire can open or close a valve. In robots, nitinol memory wire can bend or move a joint. Nitinol memory wire lasts a long time and keeps working after many uses.

You can train nitinol memory wire to remember a shape. When you heat it, the wire goes back to that shape. This is helpful for things that need to move the same way every time.

Tip: Always check how the nitinol is heated and cooled. The way you treat the tubing changes how well it works. Good heat treatment makes the shape memory effect better and helps the tubing last longer.

Tubing Size and Tolerances

Tubing size and tolerances are very important for your project. You need to pick the right inner diameter, outer diameter, and wall thickness. These sizes change how the tubing fits, how much it can hold, and how strong it is.

Tubing specifications tell you the size range you can use. Tight tolerances mean the tubing fits better and works well. For example, medical grade nitinol tubing needs very exact sizes to fit in the body. If the tubing is too big or too small, it might not work or could cause problems.

You should use calipers or size guides to check tubing size. Always match the tubing size to your project. If you need high pressure or tight bends, pick tubing with the right wall thickness and bend radius. Tubing specifications also tell you about pressure and temperature limits. Make sure your tubing can handle the job.

Note: Tighter tolerances make tubing cost more. Only ask for the precision you really need. Work with your supplier to get the best balance of cost and performance.

Fatigue and Performance

Fatigue resistance is very important for nitinol tubing, especially in medical and high-use jobs. Nitinol tubing can last through millions of bends if made well. How long nitinol tubing lasts depends on its inside structure and how it is made.

Aspect | Key Findings |

|---|---|

Fatigue Life Comparison | Tubing made with process TM-1 lasts 2-3 times longer than TM-2 tubing. TM-1 tubing matches the fatigue life of high-purity materials. |

Microstructural Correlation | More and smaller inclusions in TM-1 tubing improve fatigue resistance. |

Probabilistic Fatigue Modeling | New models use microstructure to predict fatigue life, reducing the need for long tests. |

Fatigue Testing Conditions | TM-1 tubing resists breaking after 10 million cycles at body temperature. |

Limitations & Recommendations | Larger samples help improve fatigue predictions, especially for medical devices. |

Having more and smaller inclusions in the tubing helps it last longer. The way you make the tubing matters a lot. TM-1 process gives you tubing that lasts longer when used again and again. This is important for medical grade nitinol tubing in stents and implants.

Nitinol tubing can bend or stretch and then go back to its shape. This makes nitinol tubing great for things that need to move or bend many times.

Tip: Always ask your supplier about how the tubing is made. Better ways of making tubing give you longer-lasting and stronger tubing.

When you pick nitinol tubing, look at the transformation temperature, strength, and fatigue resistance. Nitinol nickel titanium tubing gives you the best mix of bendiness, strength, and long life for tough jobs. Always match the tubing to your needs for the best results.

Supplier and Quality Check

Supplier Evaluation

Pick suppliers who follow strict safety and quality rules. First, check if they have important certifications. Look for ISO 13485, ISO 10993, and ASTM F2063. These show the supplier follows safety and performance rules. Good suppliers also have FDA compliance and EU CE marking. These prove the tubing is safe worldwide.

Ask for certificates of analysis and conformance. These papers show each batch is good quality. Suppliers should give you material test reports and traceability records. You can trust suppliers who have these documents. Do not use suppliers who cannot show proof of quality.

Tip: German suppliers often make nitinol tubing that holds over 400 bar. This shows their tubing is high quality. About 30% of needles from some Eastern European markets do not meet ISO 9626:2016. Always check for certifications.

Quality Assurance

You want tubing that is always high quality. Good suppliers use strict controls and keep impurities low. They test each batch for strength, fatigue life, and corrosion resistance. Certified suppliers follow ASTM F2063 and ISO 13485. These rules need sample testing and lab checks.

Suppliers use tools like laser micrometers and ultrasonic gauges. These tools help keep wall thickness and diameter correct. They check surface roughness to be as low as Ra ≤0.1 μm. Each batch gets a certificate of analysis. This proves the tubing meets all rules and standards.

Quality Control Metric | Description / Validation Evidence |

|---|---|

Chemical Composition | Nickel content controlled for shape memory and superelasticity |

Impurity Limits | Oxygen <60 ppm, Carbon <20 ppm |

Mechanical Properties | Tensile strength, elongation, superelastic strain measured |

Dimensional Tolerances | Wall thickness within ±15 µm, diameter within ±20 µm |

Surface Condition | Electropolishing and chemical etching for corrosion resistance |

Fatigue Testing | High cycle fatigue testing (>10 million cycles) |

Certification and Traceability | Batch testing and certificates per ASTM F2063 and ISO standards |

Fabrication and Joining

Think about how easy it is to work with the tubing. Good tubing lets you weld, join, and shape it safely. Studies show POM and PEEK support up to 3500 N of force. Welded nitinol actuators work well in labs, but cracks can form near welds. You need to check joining methods for your project.

Heat treatment changes the phase transformation temperature. It does not always change how you use the tubing. Actuator lengths change by about 3–4% when heated. This matches what designers want. Suppliers who test these things and give clear papers help you avoid problems.

Note: Always ask for samples before buying a lot. Testing samples lets you check quality and see if the tubing works for you.

You can pick the right nitinol memory wire by using easy steps. First, make sure the tubing fits your medical device or other needs. Use the checklist in this guide to look at quality, size, and strength. Experts say you should work with suppliers who test tubing and follow medical rules. Tests show that medical nitinol memory wire bends better and lasts longer in devices. Always ask for samples and check for quality papers. Learning about new uses for nitinol memory wire helps you find more ways to use it. Knowing how to use nitinol memory wire helps you make safe and strong medical devices.

FAQ

What is the main benefit of using nitinol tubing?

You get both flexibility and strength. Nitinol tubing bends without breaking and returns to its original shape. This makes it great for medical devices, robots, and other smart products.

How do you check if tubing is medical grade?

Look for certifications like ISO 13485 and ASTM F2063. Ask your supplier for test reports and certificates. Medical grade tubing must meet strict safety and quality rules.

Can you cut or shape nitinol tubing at home?

You should not cut or shape nitinol tubing at home. Special tools and skills are needed. Cutting it the wrong way can damage the tubing or change its properties.

What should you do if you need a custom size?

Tip: Contact your supplier with your exact size and tolerance needs. Many suppliers offer custom tubing. Always ask for a sample to test before you order a large amount.

See Also

Choosing The Ideal Nitinol Tubing Supplier For You

A Detailed Approach To Selecting Proper Nitinol Tubing

Selecting The Perfect Ultra-Thin PET Heat Shrink Tubing

Understanding Nitinol’s Shape Memory And Superelastic Properties

Finding The Most Cost-Effective Nitinol Tubing OD 2mm Supplier