How Nitinol Tubing is Manufactured for Medical Applications

Nitinol has changed medical devices with its special abilities. You may ask why this material is unique. It can "remember" shapes and return to them after bending. This is called shape memory and is very useful. It is also superelastic, meaning it can handle stress without breaking. These features make nitinol tubing important for devices like stents and catheters.

The need for nitinol tubes is growing fast. In 2023, the medical tubing market was worth $3.5 billion. By 2032, it may grow to $6.2 billion, with a yearly growth of 6.5%. This shows how much nitinol is used in modern medicine. To meet this need, companies like AccuPath make sure every step of production is precise and high-quality.

Key Takeaways

Nitinol tubing has special traits like shape memory and flexibility. These make it great for medical tools like stents and catheters.

To make it strong and long-lasting, pure nickel and titanium are used. The materials must meet strict quality rules.

Special melting methods, like vacuum arc melting (VAR) and vacuum induction melting (VIM), mix the metals evenly. This helps the tubing work better.

Surface treatments, such as electropolishing and passivation, make the tubing safer. These treatments also help it work well inside the human body.

Careful checks, like ultrasonic testing and following ASTM rules, make sure nitinol tubing is safe and works perfectly.

Raw Material Selection and Alloying

Pure Nickel and Titanium

Good nitinol starts with very pure materials. Makers use clean nickel and titanium to make strong tubing. Dirt or tiny holes can weaken the material. For medical nitinol, holes must be smaller than 39 microns. The total hole area must stay under 2.8% when magnified. These rules make the tubing last longer and work better.

To meet these rules, makers pick nickel and titanium that follow ASTM standards. This keeps nickel in the alloy between 54.5% and 57%. This balance gives nitinol its special bending and shape memory abilities. AccuPath, a top maker, follows these strict steps to make safe tubing for medical tools.

Why Ni–Ti Ratio Matters in Nitinol Tubing

The nickel-to-titanium mix is very important. A small change can affect how nitinol bends back or handles stress. Keeping the right titanium amount also makes it safe for the body, perfect for implants.

Makers test the nickel-titanium mix carefully. They check sizes, strength, and structure to ensure it’s correct. These tests make sure nitinol tubing works well in tools like stents and catheters.

How Nitinol Alloying Works

Making nitinol starts by melting pure nickel and titanium in a clean space. This stops dirt from getting in, which could cause weak spots. Weak spots can make the tubing break, so they must be avoided.

During melting, advanced methods mix nickel and titanium evenly. One method is vacuum arc melting, which creates a smooth blend. The alloy is then processed more to improve its structure and strength. AccuPath uses the best methods to make nitinol tubing that is strong and reliable.

Melting and Initial Shaping

Vacuum Arc Melting for Nitinol Tubes

Nitinol tubes start with vacuum arc melting (VAR). This process makes sure the alloy is mixed evenly. During VAR, large nitinol ingots are melted in a vacuum. The vacuum removes dirt and keeps the material clean. Clean materials last longer and make better nitinol tubes.

Sometimes, VAR is paired with vacuum induction melting (VIM). VIM sets the first mix, and VAR evens it out. Using both methods creates high-quality medical nitinol. The table below shows how these methods work:

Process Type | Key Metrics | Description |

|---|---|---|

Vacuum Induction Melting (VIM) | First melt for even mix | Best for small nitinol amounts. |

Vacuum Arc Remelting (VAR) | Evens mix with many cycles | Great for big batches, combines VIM results. |

Double-Melt Process | Uses both VIM and VAR | VIM sets mix, VAR evens it out. |

AccuPath uses these methods to make top-quality nitinol tubing for medical tools.

Ingot Processing and Hot Working

After melting, nitinol ingots are cleaned and shaped. Special diamond tools are used to process them. Heating between steps keeps the material strong. Cleaning the surface removes any dirt or flaws.

Hot working, like extrusion or swaging, improves the material's strength. These steps happen at high heat to make nitinol flexible and strong. Cold working, like rolling or drawing, follows to make the tubing the right size and stronger.

Extrusion into Tubular Form

Extrusion turns nitinol ingots into tube shapes. This step adds about 30% cold work to the material. Cold work helps nitinol get its special bending abilities for medical devices.

The final drawing step reduces the tubing size in stages. Each stage is carefully done to meet medical standards. AccuPath ensures every step makes tubing with the best properties for medical use.

Heat Treatment and Shaping

Annealing for Shape Memory and Superelasticity

Heat treatment is key to nitinol's special abilities. During annealing, the tubing is heated and cooled in cycles. This process arranges the material's structure, helping it "remember" its shape after bending. For superelastic tubing, annealing also makes it handle stress without staying bent.

The settings during annealing are very important. The heat is usually between 450°C and 550°C. The tubing is shaped on special tools during this process. This helps it get the right strength and flexibility. The table below shows key details about heat treatment:

Parameter | Details |

|---|---|

Effect on Dislocation Density | Changes material's density and structure |

Impact on Transformation Temperature | Higher Ti2(Ni,Cu)3 levels raise transformation temperatures |

Temperature Range | 450°C to 550°C |

Process | Shaped on special tools |

Impact | Aligns structure for memory and flexibility |

AccuPath uses advanced controls to make sure every batch of tubing is high quality.

Cold Working for Precision in Nitinol Tubing

Cold working makes nitinol tubing the right size and stronger. Processes like rolling and drawing make the tubing thinner and harder. These steps also smooth the surface, which is important for medical tools.

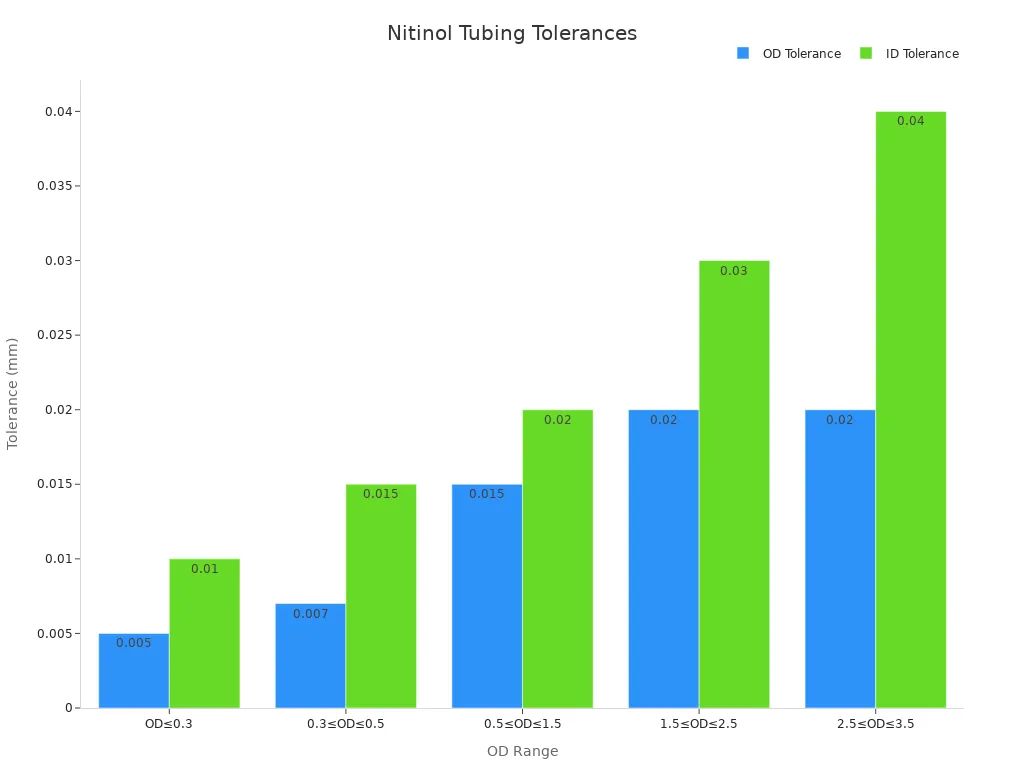

Getting the size exactly right is very important. The table below shows how precise the tubing sizes are:

Outer Diameter (OD) Range (mm) | OD Tolerance (mm) | ID Tolerance (mm) |

|---|---|---|

OD≤0.3 | ±0.005 | ±0.010 |

0.3≤OD≤0.5 | ±0.007 | ±0.015 |

0.5≤OD≤1.5 | ±0.015 | ±0.020 |

1.5≤OD≤2.5 | ±0.020 | ±0.030 |

2.5≤OD≤3.5 | ±0.020 | ±0.040 |

Heating during cold working removes stress inside the tubing. This keeps the tubing's size accurate. AccuPath's cold working methods ensure their tubing meets strict medical standards.

Tube Drawing for Desired Dimensions

Tube drawing is the last step in shaping nitinol tubing. The tubing is pulled through dies to get the right size and thickness. Each pull makes the tubing stronger. Heating between pulls stops cracks and keeps the tubing flexible.

Tube drawing ensures the tubing is very round and even. Keeping the right ratio of outer diameter to wall thickness is important. AccuPath uses special tools to make tubing with exact sizes. The chart below shows how outer diameter and wall thickness tolerances compare:

AccuPath's tube drawing methods make tubing perfect for medical tools like stents and catheters.

Surface Treatment

Electropolishing for Superelastic Nitinol Tubing

Electropolishing is important for making nitinol tubing better. It smooths the surface by removing tiny flaws. This helps the tubing work well and stay safe for the body. A smooth surface keeps the tubing superelastic. This means it can bend and return to its shape without breaking.

Tests show how useful electropolishing is. For example, shape setting takes just 15 seconds. Using cold electrolytes also improves the tubing's strength. These changes make the tubing reliable for medical tools. The table below shows key results:

Laboratory Results | Surface Finish Metrics | Observations |

|---|---|---|

Shape setting achieved in 15 seconds | Enhanced surface finish due to electropolishing | Superior results compared to conventional methods |

Low electrolyte temperature used | Improved mechanical properties | Correlation with superelasticity observed |

AccuPath uses advanced electropolishing to make strong and smooth nitinol tubing. This ensures it works well in medical devices.

Passivation for Enhanced Biocompatibility

Passivation is another step to improve nitinol tubing. This process adds a protective layer to stop rust and make it safer for the body. This makes nitinol great for implants like stents and bone tools.

Nitinol already resists rust, but passivation makes it even better. It cleans the tubing and makes it more uniform. This helps it work well inside the body. AccuPath’s passivation methods ensure their tubing is safe and high-quality.

Surface Inspection for Medical-Grade Nitinol Tubes

Checking the surface is very important for medical nitinol tubes. Careful tests are done during production. These include checking sizes, strength, and structure. Any problems are fixed to keep the tubing top quality.

These checks make sure the tubing is safe and reliable. For example, the tubing must be the right size and have a smooth surface. AccuPath follows strict rules to make sure their tubing meets medical needs.

Tip: Surface treatments like electropolishing and passivation improve tubing. They make it safe for the body and perfect for medical use.

Quality Control

Ultrasonic Testing for Even Wall Thickness

Making sure nitinol tubes have even walls is very important. Uneven walls can cause problems in medical tools. Ultrasonic testing helps check wall thickness without damaging the tubes. It uses sound waves to find any uneven spots. Fixing these early stops problems in devices like stents or catheters.

Keeping the right outer diameter-to-wall thickness ratio is key. If this ratio changes, the tube may not be straight or even. This can make the tube less reliable. Tiny non-metal parts in the material can also shorten the tube's life.

AccuPath uses advanced ultrasonic testing to check their nitinol tubes. This ensures the tubes are strong and work well in medical tools.

Testing Tube Sizes for Accuracy

Nitinol tubes need to be the right size to work well. Accurate measurements during making are very important. Strength tests check how much the tube can stretch or hold. Heat tests confirm the tube's shape memory abilities. Other tests, like X-ray checks, make sure the material is pure and strong.

Strength tests for stretching and holding

Heat tests for shape memory

X-ray and sound wave tests for material checks

AccuPath uses these tests to make sure their tubes meet strict size rules. This makes the tubes safe for use in medical devices approved by the FDA.

Following ASTM Rules for Medical Tubes

Following ASTM rules is needed to make safe nitinol tubes. These rules ensure the tubes are safe for the body and last long. Cleaner materials help the tubes stay strong and meet ASTM standards.

Proof of Quality | What It Ensures |

|---|---|

Cleaner materials | Longer-lasting tubes that meet ASTM standards |

AccuPath follows ASTM and FDA rules to make high-quality nitinol tubes. Their careful checks ensure the tubes are safe and ready for life-saving medical tools.

Tip: Pick nitinol tubes from trusted makers like AccuPath. They focus on quality and follow ASTM and FDA rules.

Making nitinol tubing needs careful steps to meet medical standards. Pure materials and heat treatments help it gain special traits. These traits, like shape memory and superelasticity, are vital for tools like stents and catheters.

Tests like sound waves and X-rays check the tubing's strength and size.

Using methods like VIM-VAR melting makes the tubing last longer.

Companies like AccuPath test their tubing to ensure it works well.

Advanced methods and strict checks make nitinol tubing key for medical tools. AccuPath ensures their tubing is safe and high-quality for life-saving devices.

FAQ

Why is Nitinol tubing great for medical devices?

Nitinol tubing has shape memory and superelasticity. These features help it work well in medical tools like stents and catheters. It adjusts easily to the human body. AccuPath makes sure their tubing is safe and meets strict medical rules.

How does AccuPath make sure its Nitinol tubing is high quality?

AccuPath uses special methods like ultrasonic testing and electropolishing. These steps make the tubing smooth, accurate, and safe for the body. They follow ASTM and FDA rules to create tubing for life-saving tools.

Can Nitinol tubing be made for specific medical needs?

Yes, Nitinol tubing can be customized for different uses. AccuPath offers options for size, surface finish, and strength. This makes the tubing fit perfectly for many medical tools.

Why is surface treatment important for Nitinol tubing?

Surface treatment improves how the tubing works and keeps it safe. Electropolishing makes the surface smooth, and passivation adds a protective layer. AccuPath uses these treatments to make tubing strong and safe for medical use.

How does AccuPath keep its tubing precise?

AccuPath uses cold working and tube drawing to get exact sizes. These steps make sure the tubing has even walls and the right dimensions. This accuracy makes their tubing perfect for important medical tools.

Tip: Pick AccuPath for top-quality Nitinol tubing. Their skill and care make them a trusted choice for medical device makers.