The History and Breakthroughs of Shape Memory Metals

Shape memory metals exhibit a remarkable ability to return to their original shape after deformation. This unique property arises from their atomic structure, which undergoes reversible transformations. Among these metals, nitinol memory metal stands out for its wide-ranging applications in modern technology.

Its shape memory effect enables the creation of adaptive structures like morphing wings, enhancing aerodynamic efficiency.

Aerospace innovations benefit from lightweight and durable materials that perform under extreme conditions.

These advancements contribute to significant fuel savings and improved performance.

Shape memory alloys hold transformative potential across industries, redefining possibilities in medicine, robotics, and consumer electronics.

Key Takeaways

Shape memory metals, like nitinol, can bend and return to their original shape. This makes them helpful in many technologies.

Nitinol's special features help in medicine, like making stents and surgical tools. These tools make treatments better for patients.

In aerospace, nitinol is used to make light and flexible parts. This improves fuel use and performance of aircraft.

Nitinol is also used in electronics to make bendable devices and smart gadgets.

Scientists are still finding new ways to use nitinol in robots and AI. This will lead to more exciting inventions in the future.

The Origins of Shape Memory Alloys

Early Discoveries in Metallurgy

The journey of shape memory alloys began with early metallurgical research in the 20th century. Scientists observed unusual behaviors in certain metals, which hinted at the potential for reversible transformations. These observations laid the groundwork for the discovery of the shape memory effect.

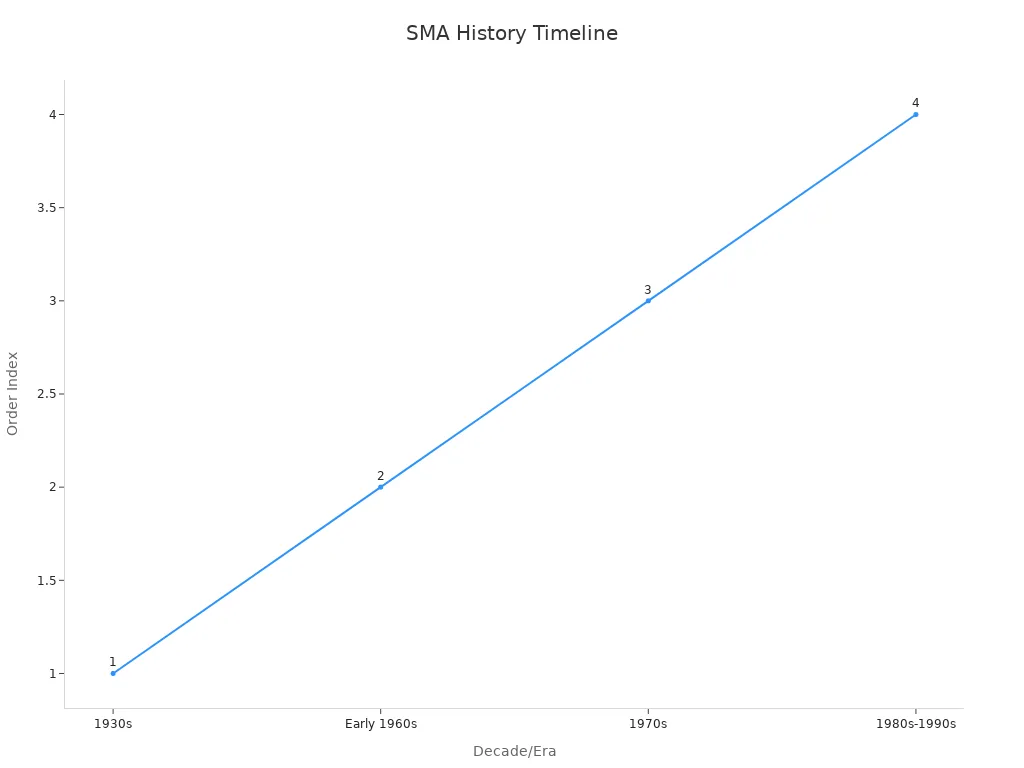

Year/Decade | Event/Discovery |

|---|---|

1930s | Earliest documented observations of shape-memory effects. |

Early 1960s | Significant discovery of nickel-titanium alloys (Nitinol), marking a milestone in SMA research. |

1970s | First commercial application of nickel-titanium alloys in military aircraft hydraulic couplings. |

1980s-1990s | Advancements in understanding martensitic transformations, enhancing fatigue life and stability. |

The 1930s marked the first recorded instances of the shape memory effect, though its practical applications remained unexplored. By the 1960s, researchers began to focus on specific alloys, leading to the discovery of nitinol shape memory alloys. This period also saw the development of techniques to improve the stability and durability of these materials.

The Discovery of Nitinol Shape Memory Alloys

The discovery of nitinol shape memory alloys occurred in 1959 at the Naval Ordnance Laboratory. William J. Buehler and Frederick E. Wang were investigating materials for missile nose cones. They needed alloys that could endure extreme conditions, including heat, fatigue, and impact. During their experiments, they observed a remarkable property in a nickel-titanium alloy.

A 1:1 combination of nickel and titanium demonstrated the ability to return to its original shape when heated.

This discovery was accidental, as a sample contracted back to its initial form after heat was applied.

The alloy was later named "Nitinol," derived from Nickel, Titanium, and Naval Ordnance Laboratory.

This breakthrough revealed the potential of nitinol memory metal for various applications. Its unique properties, including the shape memory effect and superelasticity, made it a revolutionary material in metallurgy.

Key Milestones in the Development of Nitinol

The history of nitinol is marked by several key milestones that highlight its evolution and growing importance. These milestones showcase how nitinol transitioned from a laboratory discovery to a material with widespread applications.

Early 1970s: The first commercial application of nitinol was in fluid fitting couplings for military aircraft. This marked its entry into practical use.

1975: The first symposium on the shape memory effect took place in Toronto, fostering discussions on its potential.

Early 1980s: Chinese researchers pioneered the use of nitinol in human implants, opening doors to medical applications.

1988: Michigan hosted the first conference focused entirely on the engineering aspects of shape memory alloys.

1992: The Society of Shape Memory and Superelastic Technologies (SMST) was established to advance the engineering and applications of these alloys.

These milestones reflect the growing interest in nitinol shape memory alloys and their transformative potential. From aerospace to medicine, nitinol has become a cornerstone in modern technology.

The Science Behind Nitinol and Shape Memory Alloys

How the Shape Memory Effect Works

The shape memory effect in nitinol shape memory alloys is a result of their unique ability to undergo reversible phase transformations. These transformations occur between two distinct crystal structures: martensite and austenite. Martensite forms at lower temperatures and is soft and easily deformed. Austenite, on the other hand, appears at higher temperatures and is stronger with a cubic structure. When nitinol is deformed in its martensitic phase, it retains the new shape. However, heating it above a specific temperature (Af) triggers the transformation back to austenite, restoring the original shape.

This remarkable behavior is driven by temperature changes, typically requiring a shift of about 10 degrees Celsius. The molecular structure of martensite is twinned, allowing it to accommodate significant strains without permanent deformation. This property makes nitinol memory metal ideal for applications requiring precision and adaptability.

Superelasticity in Nitinol

Superelasticity is another extraordinary property of nitinol. Unlike the shape memory effect, superelasticity occurs at temperatures above the austenite finish temperature (Af). When stress is applied, nitinol can undergo large deformations and return to its original shape upon stress removal. This behavior is due to stress-induced phase transformations between austenite and martensite.

Research studies highlight the practical applications of superelastic nitinol. For instance, Sohn et al. demonstrated its use in vibration control systems, while Dolce and Cardone explored its role in seismic protection devices. These findings underscore the versatility of nitinol in engineering and safety-critical applications.

Study | Findings |

|---|---|

Sohn et al. | Utilized SMA pseudo-rubber metals for vibration control. |

Dolce and Cardone | Investigated cyclic tensile behavior of superelastic NiTi wires. |

Vemury and Renfrey | Examined the impact of alloy composition on energy dissipation. |

The Role of Nickel and Titanium in Nitinol Memory Metal

The properties of nitinol stem from its composition, primarily a 50:50 atomic ratio of nickel and titanium. This precise balance is crucial for achieving the desired transformation temperatures and mechanical behavior. Adjusting the nickel content can significantly alter the alloy's properties. For example, increasing the nickel ratio to 51% can lower the transformation temperature by over 100°C.

Nickel contributes to the alloy's strength and corrosion resistance, while titanium enhances its flexibility and biocompatibility. Together, these elements create a material that is not only durable but also adaptable to various environments. This unique combination makes nitinol shape memory alloys indispensable in fields like medicine, aerospace, and robotics.

Breakthroughs and Applications of Shape Memory Alloys

Medical Applications: Stents, Orthodontics, and Surgical Tools

Nitinol shape memory alloys have revolutionized the medical field, offering unparalleled adaptability and biocompatibility. Their unique properties, such as the shape memory effect and superelasticity, make them ideal for innovative medical devices. Stents, for instance, represent one of the fastest-growing applications of nitinol in cardiovascular medicine. These devices expand within blood vessels to restore proper blood flow, addressing limitations of traditional balloon angioplasty. The Simon Inferior Vena Cava filter, another breakthrough, effectively traps blood clots to prevent pulmonary embolism.

Orthodontics has also benefited from nitinol's superelasticity. Archwires made from this material apply consistent pressure to teeth, reducing the need for frequent adjustments. In minimally invasive surgery, nitinol-based surgical tools offer precision and flexibility. The Septal Occlusion System, designed for patients with ventricular septal defects, demonstrates the alloy's potential in complex procedures. Clinical studies confirm nitinol's biocompatibility, with no allergic reactions or corrosion observed in vivo.

AccuPath has played a pivotal role in advancing nitinol tubing for medical devices. Their expertise ensures high-quality materials that meet the stringent demands of biomedical engineering. This commitment to innovation supports the development of cutting-edge solutions in surgery and other medical applications.

Aerospace Innovations: Lightweight and Adaptive Components

The aerospace industry has embraced nitinol shape memory alloys for their lightweight design and resilience in extreme environments. These materials enhance fuel efficiency and performance by reducing the overall weight of aircraft components. Nitinol's ability to withstand high stress and temperature variations makes it invaluable for adaptive structures, such as morphing wings. These wings adjust their shape mid-flight, optimizing aerodynamic efficiency.

The strength-to-weight ratio of nitinol surpasses that of many traditional materials, making it a preferred choice for engineers. Its superelasticity also contributes to vibration damping, improving the safety and stability of aircraft. Research highlights its potential in satellite technology, where weight and durability are critical factors.

AccuPath's contributions to memory alloy technology extend to aerospace applications. Their precision-engineered nitinol tubing supports the creation of components that perform reliably under extreme conditions. This dedication to quality drives advancements in aerospace engineering.

Consumer Electronics: Flexible Devices and Smart Wearables

Shape memory alloys have found their way into consumer electronics, enabling the development of flexible and adaptive devices. Nitinol's superelasticity allows for the creation of foldable smartphones and tablets that can endure repeated bending without damage. Smart wearables, such as fitness trackers and medical monitoring devices, also benefit from nitinol's durability and adaptability.

The alloy's ability to return to its original shape after deformation ensures long-lasting performance in everyday use. Engineers leverage its properties to design compact and lightweight components, enhancing user comfort and convenience. As consumer demand for innovative technology grows, nitinol continues to play a crucial role in shaping the future of electronics.

AccuPath's expertise in nitinol tubing supports the production of high-performance components for consumer electronics. Their commitment to precision and innovation ensures that manufacturers can meet the evolving needs of the market.

Ongoing Research and Future Potential of Shape Memory Alloys

Recent Advancements in Nitinol Shape Memory Alloys

Recent advancements in nitinol technology have expanded its applications across industries. Researchers continue to explore its thermomechanical properties, which enhance its performance in actuators and robotics. Studies at UCLA have focused on thin film nitinol for vascular repair devices, including heart valves and stents. These innovations improve the precision and reliability of medical devices, supporting minimally invasive surgery and complex procedures.

Nitinol’s unique properties, such as superelasticity and biocompatibility, make it indispensable in biomedical engineering. Its use in surgical tools has transformed medical advancements, enabling surgeons to perform delicate operations with greater accuracy. The alloy’s ability to adapt to temperature changes ensures consistent performance in critical applications.

Emerging Applications in Robotics and Artificial Intelligence

Shape memory alloys are revolutionizing robotics and artificial intelligence. Experiments with SMA wires have led to the development of soft robotic hands, which mimic human dexterity. Researchers have tested various wire topologies, including inclined and X-shaped designs, to optimize joint motion and prevent buckling. These prototypes demonstrate the potential of nitinol in creating adaptive systems for robotics.

In artificial intelligence, nitinol supports the development of actuators that respond to environmental changes. Its superelasticity allows for precise movements, making it ideal for applications requiring flexibility and durability. The integration of shape memory alloys into robotics enhances functionality, paving the way for smarter and more efficient machines.

AccuPath’s Role in Advancing Shape Memory Alloy Technology

AccuPath has played a pivotal role in advancing memory alloy technology. Their expertise in microstructure optimization and surface finishes ensures high-quality materials for biomedical applications. Case studies highlight their ability to customize nitinol tubing for complex medical devices, meeting tight deadlines without compromising quality.

Metric | Description |

|---|---|

Dimensional Tolerances | Ultra-tight tolerances critical for precision applications. |

Microstructure Optimization | Enhancements to the microstructure that improve material properties and performance. |

Surface Finishes | Pristine finishes necessary for biocompatibility and functionality in medical devices. |

Concentricity | Achieved >98% concentricity, essential for device performance. |

Fatigue Durability | Demonstrated twofold improvement in durability through microstructural refinement. |

AccuPath’s contributions extend beyond medical devices. Their advancements in nitinol memory metal support applications in aerospace and robotics, driving innovation across industries. By refining the properties of nickel titanium alloys, AccuPath ensures reliable performance in demanding environments.

Shape memory alloys, particularly nitinol, have reshaped industries with their unique properties. Their ability to "remember" shapes has driven breakthroughs in medicine, aerospace, and consumer electronics. These innovations highlight their historical significance and ongoing relevance.

Shape memory alloys hold the potential to revolutionize technology. Their adaptability and durability continue to inspire advancements in robotics, artificial intelligence, and beyond.

AccuPath’s contributions to refining nitinol technology underscore the importance of research in unlocking new possibilities. Readers can explore these developments to stay informed about the future of shape memory alloys.

FAQ

What makes nitinol unique compared to other metals?

Nitinol stands out due to its shape memory effect and superelasticity. These properties allow it to return to its original shape after deformation and endure significant strain without permanent damage. Its biocompatibility and corrosion resistance further enhance its versatility in medical and engineering applications.

How does temperature affect the behavior of nitinol?

Temperature triggers phase transformations in nitinol. At lower temperatures, it exists in the martensitic phase, which is soft and deformable. Heating it above the austenite finish temperature restores its original shape. This temperature-dependent behavior underpins its shape memory effect.

Are shape memory alloys safe for medical use?

Yes, shape memory alloys like nitinol are biocompatible and safe for medical applications. Clinical studies confirm their resistance to corrosion and lack of allergic reactions. These properties make them ideal for stents, surgical tools, and orthodontic devices.

Can nitinol be used in extreme environments?

Nitinol performs exceptionally well in extreme environments. Its ability to withstand high stress, temperature fluctuations, and fatigue makes it suitable for aerospace components, such as morphing wings and satellite parts. Its durability ensures reliable performance under demanding conditions.

What industries benefit most from shape memory alloys?

Shape memory alloys impact industries like medicine, aerospace, robotics, and consumer electronics. They enable innovations such as adaptive medical devices, lightweight aircraft components, soft robotic systems, and flexible consumer gadgets. Their adaptability drives advancements across these fields.

💡 Tip: For more insights into nitinol's applications, explore AccuPath’s contributions to advancing shape memory alloy technology.

See Also

Understanding Nitinol's Unique Properties: Shape Memory And Superelasticity

Current Developments in Nickel Titanium Alloys and Their Applications

Exploring Nickel Titanium's Role in Medical Technology Advancements

Transformative Innovations in PTFE Liners for Healthcare Devices