The Ultimate Guide to High-Performance PET Heat Shrink Tubing

Choosing the right heat shrink tubing ensures reliable performance and long-lasting durability. As industries grow, the market for heat-shrink tubing is projected to reach $3 billion by 2029, driven by the demand for effective insulation and protection. High-performance PET heat shrink tubing stands out due to its exceptional tensile strength, wide diameter range, and precise wall thickness. With shrink ratios up to 3:1, it offers unmatched versatility for applications requiring robust mechanical reinforcement and environmental sealing. Whether you need electrical insulation or specialty solutions, PET tubing delivers superior results compared to traditional materials.

Key Takeaways

PET heat shrink tubing is strong, flexible, and heat-resistant. It works well for many uses.

Picking the right size and shrink ratio is important. Measure parts carefully to make sure it fits tightly.

PET tubing resists chemicals, water, and sunlight. It lasts a long time even in tough conditions.

Many industries use this tubing, like healthcare, airplanes, and cars. It helps with electrical safety and adds strength.

Checking and caring for PET tubing often can make it last longer. This keeps it working well for important jobs.

What Is High-Performance PET Heat Shrink Tubing?

High-performance PET heat shrink tubing is a versatile solution designed to meet the demands of various industries. Its unique properties make it one of the ideal tubing materials for applications requiring durability, flexibility, and thermal stability. Let’s explore its material properties, benefits, and common uses.

PET Material Properties

PET (Polyethylene Terephthalate) is a polymer known for its exceptional performance in challenging environments. High-performance PET heat shrink tubing stands out due to its:

Durability: It offers long-lasting performance, even in harsh conditions.

Chemical Resistance: PET resists exposure to oils, solvents, and other chemicals, making it suitable for diverse applications.

Flexibility: The tubing adapts to various shapes and sizes, ensuring a snug fit.

Thermal Stability: It maintains its properties under extreme temperatures, making it reliable for both high-heat and cold environments.

Customization: PET tubing can be tailored to meet specific needs, especially in sensitive industries like healthcare.

These properties make PET a preferred choice for applications requiring strength and reliability.

Benefits of PET Heat Shrink Tubing

Using PET heat shrink tubing provides several advantages:

Enhanced Protection: It safeguards components from environmental factors like moisture, UV rays, and chemicals.

Improved Insulation: PET tubing ensures electrical insulation, reducing the risk of short circuits.

Mechanical Reinforcement: It adds strength to delicate components, extending their lifespan.

Versatility: Its flexibility and customization options make it suitable for a wide range of industries, including medical, aerospace, and electronics.

By choosing high-performance PET heat shrink tubing, you ensure reliable performance and long-term durability.

Common Uses of Heat Shrink Tubing

PET heat shrink tubing is widely used across industries due to its adaptability. Here are some common applications:

Variable Stiffness Catheters: It enhances stiffness in medical devices without increasing their size.

Protective Covering and Bundling: It securely bundles wires and components, offering protection and organization.

Reinforcement: PET tubing strengthens devices like balloon catheters, ensuring durability.

Tube Marking and Printing: It allows for custom markings, aiding in identification and organization.

Electrical Insulation: It provides excellent insulation for sensitive electronic components.

These applications highlight the versatility and effectiveness of PET heat shrink tubing in meeting diverse needs.

Factors for Selecting the Right Heat Shrink Tubing Material

When selecting the right heat shrink tubing for your application, you need to consider several critical factors. These factors ensure the tubing performs effectively under specific conditions, providing durability, safety, and reliability. Let’s explore the key considerations.

Environmental Conditions (Temperature, UV, Chemicals)

The application environment plays a significant role in determining the type of heat shrink tubing you need. Environmental factors such as temperature extremes, UV exposure, and chemical contact can impact the tubing's performance. Here are some essential criteria to evaluate:

Abrasion Resistance: The tubing should withstand physical wear caused by movement or environmental shifts.

Temperature Extremes: Choose materials that can handle both high and low temperatures without losing their properties.

UV Resistance: If the tubing will be exposed to sunlight, ensure it resists UV degradation to maintain its integrity.

Chemical Resistance: Assess the presence of oils, solvents, or caustic substances in the environment. PET heat shrink tubing, for example, offers excellent resistance to many chemicals.

Moisture Protection: For applications in damp or wet conditions, select tubing that provides a watertight seal.

A study by The Western Company of North America demonstrated the effectiveness of heat shrink tubing in creating watertight joints for sewer pipes. This highlights its ability to endure challenging environmental conditions while maintaining durability.

Mechanical and Electrical Requirements

Understanding the mechanical and electrical demands of your application is crucial for selecting the right heat shrink tubing material. Different applications require tubing with specific properties to ensure optimal performance.

Metric Type | Specific Tests/Requirements |

|---|---|

Electrical Insulation Regulations | UL/CSA 224: Dielectric Voltage Withstand, Breakdown, Volume Resistivity, Secant Modulus |

AMS-DTL-23053: Dielectric Strength, Volume Resistivity, Tensile Strength, Ultimate Elongation | |

Mechanical Load | Tensile Strength, Ultimate Elongation, Cold Impact, Modulus |

Electrical Conductivity | Dielectric Constant, Volume Resistivity, Dielectric Strength |

For electrical applications, the tubing must meet insulation standards like UL/CSA 224 or AMS-DTL-23053. These standards ensure the tubing can handle high voltages and resist electrical breakdown. For mechanical applications, prioritize tensile strength and impact resistance to protect components from physical stress.

Industry Standards and Certifications

Industry standards and certifications validate the quality and performance of heat shrink tubing. When selecting tubing, look for compliance with recognized standards to ensure safety and reliability.

Category Name | Standards | U.S. CCN | Canada CCN |

|---|---|---|---|

Tubing, Extruded Insulating – Component | ANSI/UL 224, CSA C22.2 No. 198.1 | YDPU2 | YDPU8 |

Miscellaneous Tubing, Polymeric – Component | ANSI/UL 224, CSA C22.2 No. 198.1 | YDTU2 | YDTU8 |

Tubing, Flame-Retardant – Component | ANSI/UL 224, CSA C22.2 No. 198.1 | YDQS2 | YDQS8 |

Tubing for Use with Seasonal and Holiday Decorative Products – Component | ANSI/UL 224, UL 588 | DHAK2 | N/A |

These certifications ensure the tubing meets stringent requirements for electrical insulation, flame retardancy, and environmental resistance. For example, ANSI/UL 224 certification guarantees the tubing can withstand high temperatures and provide reliable insulation.

By considering these factors, you can confidently choose high-performance PET heat shrink tubing that meets your specific needs. This ensures your application remains safe, durable, and efficient.

How to Choose Heat Shrink Tubing for Your Needs

Selecting the right heat shrink tubing is essential for ensuring optimal performance and durability in your application. To make the best choice, you need to focus on three critical aspects: measuring for the correct size, understanding shrink ratios, and ensuring a proper fit. Let’s break these down step by step.

Measuring for the Correct Size

Accurate sizing is the foundation of choosing the right heat shrink tubing. If the tubing is too small, it won’t fit over your components. If it’s too large, it won’t shrink tightly enough to provide proper insulation or protection. Follow these steps to measure correctly:

Measure the widest area of the material you want to cover. Add 20-30% to this measurement to determine the minimum inner diameter of the tubing before shrinkage.

Determine the shrink ratio required for your application. Common ratios include 2:1, 2.5:1, and 3:1. For example, a 3:1 ratio means the tubing will shrink to one-third of its original diameter.

Account for length changes during shrinkage. Tubing can lose 5-15% of its length when heated, so ensure you cut enough to cover the entire area.

Consider wall thickness after shrinkage. As the tubing shrinks, its walls thicken, which can impact flexibility and insulation properties.

By following these steps, you can confidently select tubing that fits your components perfectly.

Here’s a quick comparison of sizing variations for different applications:

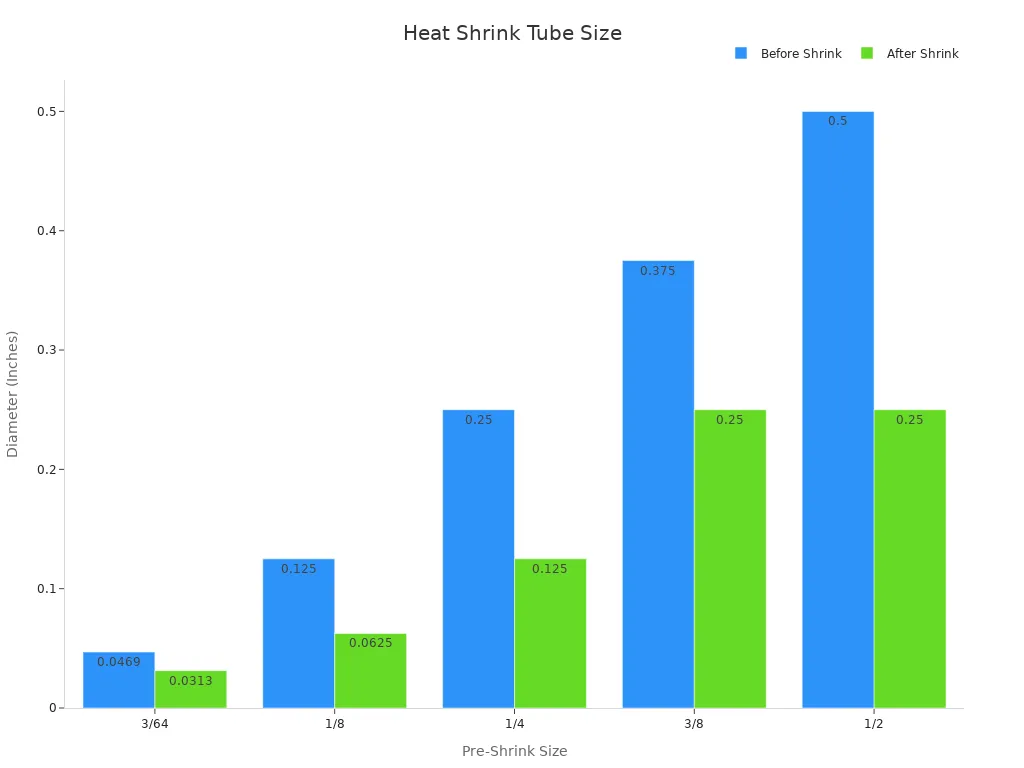

Size (Diameter Before Shrink) | Diameter After Shrink | Common Applications |

|---|---|---|

3/64" | 1/32" | Small electronic components |

1/8" | 1/16" | Connectors and wires in low-voltage projects |

1/4" | 1/8" | Insulation for automotive wiring |

3/8" | 1/4" | Sealing cable splices |

1/2" | 1/4" | Protecting larger wires and connections |

Understanding Shrink Ratios

Shrink ratios are a critical factor when you choose heat shrink tubing. They indicate how much the tubing will reduce in diameter when heated. For example, a 2:1 ratio means the tubing will shrink to half its original diameter, while a 3:1 ratio will shrink to one-third.

Here’s how to determine the right shrink ratio for your needs:

Match the tubing’s expanded diameter to the largest part of your component.

Ensure the recovered diameter is smaller than the smallest part of your component. This ensures a snug fit after shrinking.

For instance, if your component has a maximum diameter of 6 mm and a minimum diameter of 2 mm, a 3:1 shrink ratio would work best. This ratio allows the tubing to fit over the larger section and shrink tightly around the smaller section.

Tips for Ensuring a Proper Fit

To achieve a secure and reliable fit, follow these practical tips:

Preheat the tubing evenly: Use a heat gun or similar tool to apply consistent heat across the tubing. Avoid overheating, as this can damage the material.

Test fit before shrinking: Slide the tubing over your component to ensure it covers the desired area. Adjust as needed before applying heat.

Work in sections: For longer tubing, shrink one section at a time to maintain control and achieve uniform results.

Choose high-quality tubing: Brands like AccuPath offer premium PET heat shrink tubing that ensures durability, flexibility, and precise sizing.

By taking these steps, you can ensure your heat shrink tubing performs effectively, providing insulation, protection, and reinforcement for your components.

Applications of High-Performance PET Heat Shrink Tubing

High-performance PET heat shrink tubing offers versatile solutions across various industries. Its unique properties make it indispensable for applications requiring durability, insulation, and protection. Let’s explore its key uses.

Electrical Insulation and Protection

PET heat shrink tubing excels in providing electrical insulation and protection for sensitive components. It prevents short circuits and safeguards wires and cables from external damage. Industries like healthcare, automotive, and aerospace rely on this tubing for its exceptional performance.

Application Sector | Performance Characteristics |

|---|---|

Healthcare | Provides insulation, protection, and contamination resistance for medical devices and equipment. |

Electrical & Electronics | Requires reliable insulation and protection for wires, cables, and electronic components. |

Automotive | Protects wiring harnesses, connectors, and sensors from mechanical damage, moisture, and chemicals. |

Aerospace | Insulates wiring systems in aircraft, meeting stringent safety and performance requirements under harsh conditions. |

AccuPath’s high-performance PET heat shrink tubing ensures reliable electrical insulation, even in demanding environments. Its abrasion resistance and thermal stability make it a trusted choice for critical applications.

Mechanical Reinforcement

This tubing strengthens delicate components, extending their lifespan. It provides mechanical reinforcement for wiring, connectors, and sensors, protecting them from wear and tear. For example, in automotive applications, it helps protect wiring harnesses from vibration and mechanical stress.

Single-wall heat shrink tubing is particularly effective for lightweight reinforcement needs. Its flexibility allows it to adapt to various shapes, ensuring a snug fit. AccuPath’s tubing offers unmatched durability, making it ideal for industries requiring robust solutions.

Environmental Sealing

PET heat shrink tubing provides excellent protection from moisture, chemicals, and UV exposure. It creates a watertight seal, ensuring components remain safe in harsh conditions. This makes it perfect for waterproofing applications in outdoor and marine environments.

In aerospace, the tubing withstands extreme temperatures and environmental stress, ensuring reliable performance. AccuPath’s products deliver superior environmental sealing, offering peace of mind in critical applications.

By choosing AccuPath’s high-performance PET heat shrink tubing, you gain a reliable solution for electrical insulation, mechanical reinforcement, and environmental sealing. Its versatility and durability make it a top choice for diverse industries.

Specialty Applications (Medical, Aerospace, etc.)

High-performance PET heat shrink tubing plays a critical role in specialty industries like medical and aerospace. These fields demand precision, reliability, and durability, making PET tubing an ideal choice for their unique requirements.

Medical Applications

In the medical field, PET tubing ensures safety and performance in sensitive environments. You’ll find it used in devices like catheters, surgical instruments, and diagnostic equipment. Its biocompatibility and ability to withstand sterilization processes make it indispensable. For example, dual-wall heat shrink tubing provides both insulation and environmental sealing, protecting delicate medical components from contamination.

PET tubing also supports advanced medical technologies. It reinforces variable stiffness catheters, enabling precise control during procedures. Its transparency allows for visual inspection, ensuring quality and reliability in critical applications.

Aerospace Applications

In aerospace, PET tubing excels under extreme conditions. It provides insulation and mechanical protection for wiring systems in aircraft and spacecraft. You can rely on it to withstand high temperatures, UV exposure, and vibration, ensuring long-term performance.

Dual-wall heat shrink tubing is particularly valuable in aerospace applications. It offers a combination of electrical insulation and environmental sealing, protecting components from moisture, chemicals, and mechanical stress. This makes it a trusted solution for mission-critical systems.

By choosing PET tubing for these specialty applications, you gain a reliable and versatile solution that meets the highest industry standards. Its unique properties make it an essential material for advancing technology in medical and aerospace fields.

PET vs. Other Heat Shrink Tubing Materials

PET vs. Polyolefin

Polyolefin is one of the most common materials for heat shrink tubing. It offers flexibility and affordability, making it a popular choice for general-purpose applications. However, PET heat shrink tubing outperforms Polyolefin in several key areas:

Durability: PET tubing provides superior tensile strength, making it more resistant to wear and tear.

Thermal Stability: PET withstands higher temperatures without losing its properties, while Polyolefin may degrade under extreme heat.

Chemical Resistance: PET resists oils, solvents, and other chemicals better than Polyolefin, ensuring long-term reliability.

If your application involves harsh environments or requires high mechanical strength, PET tubing is the better option. Polyolefin works well for basic insulation needs, but PET excels in demanding conditions.

PET vs. PVC

PVC is another widely used material for heat shrink tubing. It is valued for its flame-retardant properties and cost-effectiveness. However, PET tubing offers distinct advantages:

Environmental Impact: PET is more eco-friendly than PVC, which releases harmful chemicals during production and disposal.

UV Resistance: PET tubing resists UV degradation, making it ideal for outdoor applications. PVC tends to yellow and crack under prolonged sunlight exposure.

Flexibility and Strength: PET combines flexibility with high tensile strength, while PVC can become brittle over time.

For applications requiring environmental sealing or outdoor durability, PET tubing provides a more reliable and sustainable solution.

Why Choose PET Heat Shrink Tubing?

PET heat shrink tubing stands out due to its unmatched combination of strength, flexibility, and chemical resistance. It performs exceptionally well in high-temperature environments and offers excellent protection against UV rays and moisture. Industries like aerospace, medical, and automotive rely on PET tubing for its reliability and versatility.

By choosing PET, you ensure your components remain protected and durable, even in the most challenging conditions. Its superior properties make it a worthwhile investment for critical applications.

Tips for Using and Maintaining PET Heat Shrink Tubing

Installation Best Practices

Proper installation ensures the effectiveness of heat shrink tubing in providing electrical insulation and protection. Follow these tips to achieve optimal results:

Prepare the surface: Clean the component thoroughly to remove dirt, grease, or moisture. A clean surface ensures the tubing adheres securely.

Choose the right sizing: Measure the component’s diameter and select tubing with an appropriate shrink ratio. Accurate sizing prevents loose fits or overstretching.

Apply heat evenly: Use a heat gun to shrink the tubing uniformly. Move the heat source in a circular motion to avoid overheating or damaging the material.

Inspect the fit: After shrinking, check for gaps or uneven coverage. Adjust as needed to ensure complete insulation and protection.

These safety tips help you achieve effective cable management while maintaining the tubing’s integrity.

Maintenance for Longevity

Maintaining PET heat shrink tubing extends its lifespan and ensures reliable performance. Regular inspections and proper care prevent premature wear. Here’s how you can maintain your tubing:

Inspect for damage: Periodically check for cracks, discoloration, or signs of wear. Replace damaged tubing to maintain safety and insulation.

Avoid extreme conditions: Protect the tubing from prolonged exposure to temperatures exceeding its short-term limit of 200°C or below -196°C.

Clean gently: Use a soft cloth and mild detergent to clean the tubing. Avoid abrasive materials that could compromise its surface.

Performance evaluation data further supports these strategies:

Property | Details |

|---|---|

Dielectric Strength | > 4,000 V/mil |

Dielectric Constant | 3.3 |

Dissipation Factor | 0.0025 |

Volume Resistivity | 10^18 Ohm-cm |

Surface Resistivity | 10^14 Ohm/square |

Long-term Temperature | -196°C to 135°C |

Short-term Temperature | Up to 200°C |

Melting Point | 235°C |

Biocompatibility | ISO 10993 |

These properties highlight the tubing’s durability and ability to withstand challenging application environments.

Evaluating Your Application Needs

Understanding your application needs ensures you select and maintain the right tubing. Consider these factors:

Environmental conditions: Assess the application environment, including temperature, UV exposure, and chemical contact. PET tubing excels in harsh conditions, offering reliable protection.

Component requirements: Evaluate the mechanical and electrical demands of your wiring or device. PET tubing provides robust insulation and reinforcement for sensitive components.

Industry standards: Ensure the tubing meets relevant certifications for safety and performance. For example, ISO 10993 guarantees biocompatibility for medical applications.

By evaluating these needs, you can choose tubing that aligns with your application and ensures long-term reliability.

Choosing the right heat shrink tubing ensures optimal performance and long-term reliability. High-performance PET heat shrink tubing stands out due to its flexibility, biocompatibility, and ability to conform to various shapes, making it ideal for medical and industrial applications. Its thin profile and heat shrink functionality provide excellent protection and electrical insulation, ensuring safety in critical environments.

Understanding material properties, proper sizing, and specific application needs is essential for achieving the best results. With growing demand for customized tubing and advancements in manufacturing, PET tubing continues to lead the market. By selecting high-performance PET heat shrink tubing, you invest in a durable, versatile solution that meets the highest standards of protection and performance.

FAQ

What is the primary purpose of PET heat shrink tubing?

PET heat shrink tubing provides insulation, protection, and reinforcement for components. It shields against environmental factors like moisture, UV rays, and chemicals while offering mechanical support for delicate parts.

How do you measure the correct size for heat shrink tubing?

Measure the widest part of your component and add 20-30% to determine the tubing’s minimum diameter. Ensure the shrink ratio matches your needs for a snug fit.

Can PET heat shrink tubing be used for outdoor applications?

Yes, PET heat shrink tubing resists UV rays and harsh weather conditions, making it suitable for outdoor use. It ensures long-term durability and protection for exposed components.

Is PET heat shrink tubing suitable for high-temperature environments?

PET heat shrink tubing performs well in high-temperature environments. It maintains its properties under extreme heat, making it ideal for demanding applications like aerospace and automotive wiring.

How do you ensure proper installation of heat shrink tubing?

Clean the surface of your component, select the correct size, and apply heat evenly using a heat gun. Inspect the tubing after shrinking to confirm a secure and uniform fit.

See Also

Selecting The Ideal Ultra-Thin PET Heat Shrink Tubing

Key Insights On PET Heat Shrink Tubing For Electronics

Comprehensive Guide To Selecting The Correct Heat Shrink Size

Important Guidelines For Effectively Using FEP Heat Shrink Tubing