The Hidden Struggles of Laser-Cut Nitinol Tubing

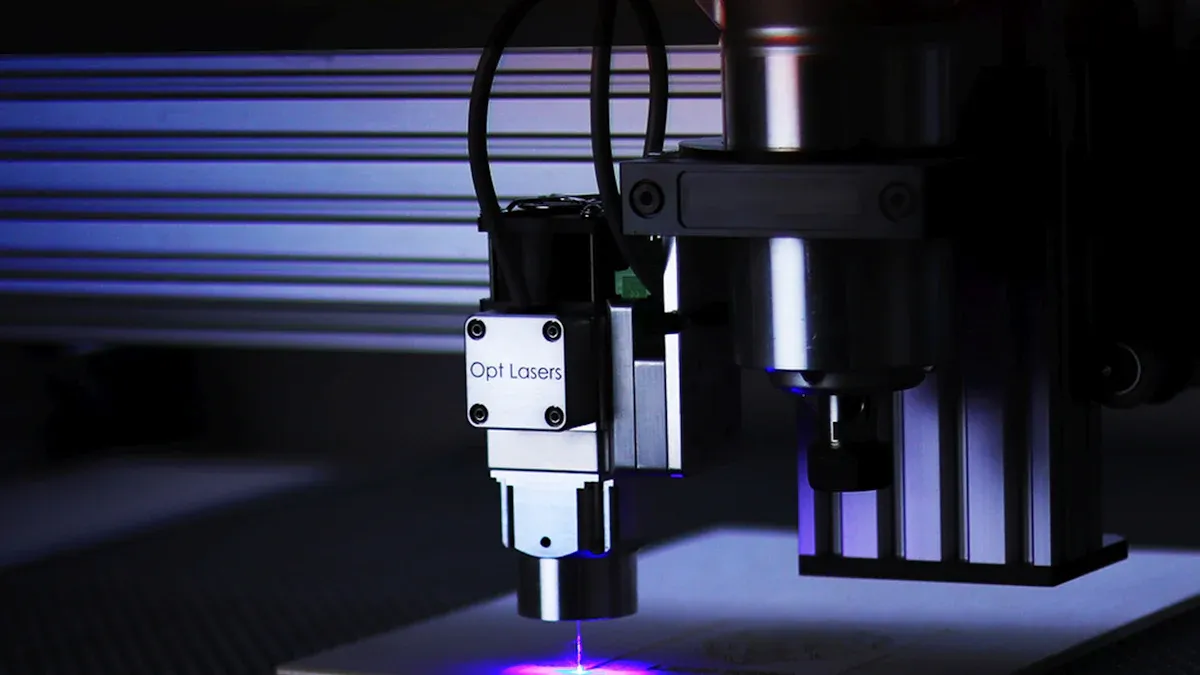

Laser-cut nitinol tubing has special problems during production. Its unique traits, like shape memory and flexibility, are useful in medical devices. But these same traits make cutting harder. Nitinol reacts to heat, which can cause damage and lower quality. Machines used for cutting also have limits, causing waste and higher costs. Only about 70% of the material is usable.

Making tiny springs and expanding frames needs careful cutting. Demand for nitinol tubing is growing fast. Better methods, like femtosecond laser cutting, can improve usable material to 95%. This reduces extra work and makes the product better. Solving these problems helps nitinol tubing work well and stay reliable.

Key Takeaways

Nitinol tubing is super stretchy, making it great for medical tools but hard to cut perfectly.

Heat from lasers can weaken nitinol, so cooling with gas or water keeps it strong.

Keeping laser machines clean and adjusted helps cut better and wastes less material.

Pure gases like nitrogen or argon stop rust and make smoother surfaces, which are safer for medical use.

Teaching workers how to use lasers well makes cutting faster and reduces mistakes, creating better nitinol tubing.

Material Challenges in Nitinol Tubing

Unique Properties of Nitinol

Nitinol tubing is special because of its unique features. It can bend a lot without breaking, which is called superelasticity. This makes it great for things like medical implants that need to be strong and flexible. But this same flexibility makes cutting it very tricky since it resists being shaped exactly.

Another challenge is electropolishing, a process that adds a thin 4 nm oxide layer to the surface. This layer helps stop rust and lowers nickel release, making nitinol safer for medical use. However, it also makes laser cutting harder, so the cutting process needs to be adjusted.

Evidence Description | Impact on Laser Cutting |

|---|---|

Electropolishing creates a 4 nm oxide layer, reducing nickel release and improving rust resistance. | Makes nitinol safer and stronger for medical implants. |

Nitinol’s superelasticity lets it handle big bends without breaking. | Helps keep its shape during cutting but makes shaping harder. |

Electropolished surfaces release less nickel than untreated ones. | Improves safety for medical devices made from nitinol. |

Heat Sensitivity and Thermal Damage

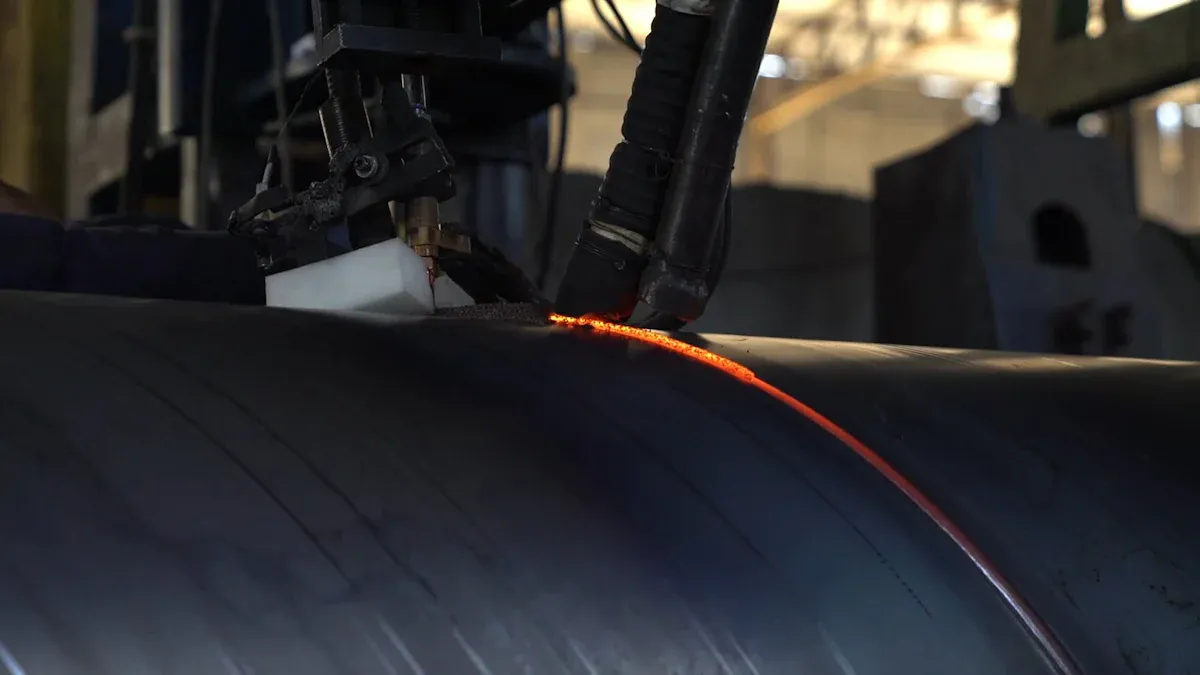

Nitinol is very sensitive to heat, which causes problems when cutting. Lasers create high heat that can change how the material behaves and weaken it. For example, heat can damage the surface by 1.7 μm to 50 μm, which affects its strength.

Even small temperature changes can make a big difference. A tiny drop of ~1.5 ˚C in the finish temperature can happen during laser cutting. Larger shifts of ~15 ˚C in starting temperatures have also been seen, which can hurt performance. Too much heat can lower the material's strength by up to 40%, making it less durable.

Evidence Type | Description |

|---|---|

Thermal Damage | Laser heat can damage the surface by 1.7 μm to 50 μm, changing how nitinol works. |

Temperature Impact | Laser cutting can lower the finish temperature by ~1.5 ˚C. |

Transformation Shifts | Starting temperatures can shift by ~15 ˚C, affecting performance. |

Stress Reduction | More heat during cutting lowers stress strength by 15%. |

Strength Reduction | Laser heat can cut strength by 25% to 40%. |

Work-Hardening and Its Impact on Cutting

Work-hardening happens when nitinol gets harder and more brittle after being bent or shaped. This makes it tougher to cut and can wear out tools faster. If not handled carefully, it raises costs and wastes material.

Work-hardened nitinol fights against cutting, making it less precise. This leads to more tool damage and higher expenses. To fix this, the cutting process must be controlled to avoid extra stress on the material.

Studies show nitinol wires often break under repeated stress. The wires also have a lower fatigue limit compared to diamonds. This means cracks form more easily in nitinol, showing how hard it is to make high-quality tubing.

Technical Challenges in Laser Cutting

Achieving Precision and Consistency

Cutting nitinol tubing with precision is very challenging. Its special traits, like superelasticity and shape memory, make exact cuts hard. Even tiny mistakes can hurt how the product works, especially in medical tools where accuracy is key.

Lasers can cut precisely, but settings like power and speed must be right. If not, the laser might make uneven cuts or harm the material. For instance, bad focus can make cuts wider and less accurate. Thin nitinol walls are also tricky since they can bend or warp during cutting.

Using advanced lasers, like fiber lasers, helps keep cuts consistent. These tools give better control and reduce mistakes. Checking and adjusting the process often can also ensure high-quality results.

Managing Burr Formation and Surface Quality

Burrs are tiny leftover bits on edges after cutting nitinol. They make surfaces rough and need extra work to remove, which takes time and costs more.

Heat from lasers is a big reason burrs form. Too much heat melts the material unevenly, leaving rough edges. Cooling methods, like gas-assisted cutting, can lower the heat. Using pure gases like nitrogen or argon also stops oxidation and keeps surfaces smooth.

Smooth surfaces are very important for things like medical implants. These need to be safe and work well. Post-processing, like electropolishing, can smooth out burrs and make surfaces even. But it’s better to avoid burrs during cutting than to fix them later.

Equipment Limitations and Calibration

Laser cutting machines have limits and need regular care. Over time, they can lose accuracy, making cuts less precise. Maintenance and calibration are needed to keep them working well.

For example, machines should be checked every six months to stay accurate. A tolerance of 0.0002 inches is common, and yearly checks help keep stability. Most measurements are accurate 95% of the time, but for better precision, 99.7% accuracy may be used, needing more frequent checks.

Calibration Tolerance | Check Frequency | Accuracy Evidence |

|---|---|---|

0.0002 inch | Every six months | Yearly checks keep stability. |

If machines aren’t calibrated, cuts can be uneven, with more burrs and less precision. Older machines may lack features for cutting nitinol well. Buying newer, specialized machines can solve these problems and make production faster and better.

Cutting Gas Purity and Pressure

When cutting Nitinol tubing, the gas's purity and pressure are very important. These factors affect how clean and precise the cuts will be. Understanding them helps improve the cutting process.

Why Cutting Gas Purity Matters

Dirty gas can cause oxidation and uneven cuts. For Nitinol, oxidation makes the material weaker and less effective. Using pure gases like nitrogen or argon stops this problem. These gases protect the material during cutting, making edges smooth and reducing burrs.

Tip: Always check gas purity before cutting. Use gas with 99.99% purity or higher for the best results.

The Role of Gas Pressure

Gas pressure affects how well the laser cuts the material. Low pressure can leave cuts unfinished, while too much pressure can bend thin tubing. Finding the right pressure is key to getting accurate cuts.

Pressure Range | Effect on Cutting | Recommendation |

|---|---|---|

Below 10 psi | Cuts are incomplete and edges are rough | Slowly increase pressure |

10–20 psi | Best for thin tubing | Keep pressure steady |

Above 20 psi | Tubing may bend or warp | Lower pressure for delicate cuts |

Practical Tips for Managing Gas Purity and Pressure

Check Gas Quality: Use a tool to measure gas purity regularly.

Test Pressure Settings: Try different pressures on sample pieces to find the best one.

Use Special Nozzles: Buy nozzles made for precise cutting to control gas flow better.

Note: If edges look uneven or discolored, the gas might be dirty, or the pressure could be wrong.

Benefits of Optimizing Gas Parameters

Keeping gas pure and pressure correct improves surface quality. This reduces extra work after cutting, saving time and money. It also makes Nitinol tubing stronger and more reliable for things like medical implants.

🚀 Pro Tip: Work with suppliers who offer certified pure gases and help with pressure settings. This ensures better results and fewer mistakes during production.

Practical Solutions for Laser-Cut Nitinol Tubing

Adjusting Laser Settings

To cut nitinol tubing well, laser settings must be adjusted. Power, speed, and focus are key to good cuts. Too much power overheats the material, causing damage and rough edges. Too little power leaves cuts incomplete.

Laser speed also matters. Slow speeds cut deeper but cause heat buildup. Faster speeds lower heat but may reduce accuracy. Finding the right speed is important for clean cuts.

Focus settings affect the cut's quality too. A blurry laser focus makes cuts uneven and wide. Regularly checking the laser focus keeps cuts sharp and precise.

Tip: Test your laser on scrap nitinol pieces first. This helps avoid mistakes and saves material.

Cooling Methods to Control Heat

Heat is a big problem when cutting nitinol. Too much heat weakens the material and ruins its surface. Using cooling methods during cutting can help manage heat.

Gas cooling works well. Blowing nitrogen or argon gas at the cut cools it fast. These gases also stop oxidation and keep edges smooth.

Water-cooled fixtures are another option. They hold the tubing steady and absorb heat. This is helpful for thin tubes that can warp from heat.

Pro Tip: Use both gas cooling and water-cooled fixtures together. This keeps cuts clean and the material strong.

Improving Surface Quality After Cutting

Even with good cutting, nitinol surfaces may need fixing. Post-processing improves surface quality and ensures high standards.

Electropolishing is a great method. It removes tiny burrs and smooths rough edges. This makes the surface shiny and rust-resistant. Smooth surfaces are safer for medical uses, reducing irritation risks.

You can measure surface roughness to check post-processing results. Tools like optical devices compare surfaces before and after polishing. Material removal rates show how well imperfections are reduced.

Metric | Description |

|---|---|

Surface Roughness Measurements | Use optical tools to compare surfaces before and after polishing. |

Material Removal Rates | Check how much material is removed to improve surface quality. |

Geometrical Accuracy | Measure strut thickness with digital tools for precise results. |

Geometrical accuracy is also important. Digital tools measure tubing thickness to ensure it meets requirements. This is crucial for products like medical stents.

Note: Always check your post-processing methods using these tools. This keeps your nitinol products high-quality and reliable.

Specialized Tools for Cutting Nitinol Tubing

Using special tools made for nitinol improves cutting quality. Regular machines often struggle with nitinol's bending ability and heat issues. Advanced machines are built to handle these problems better.

Ultra-short pulsed lasers are great for cutting nitinol. These lasers use advanced energy methods to cut precisely. They don’t create leftover heat, so the material stays strong. This keeps nitinol’s structure safe, making it perfect for medical implants.

Some machines also have better focus controls. These let you adjust the laser beam for accurate cuts. This is very important for thin nitinol tubes, where small mistakes can ruin the material. Other machines include cooling systems to stop heat damage. These systems help make smooth and clean edges.

When choosing tools, pick ones made for nitinol. These machines often have features like auto-calibration and smart software. These extras reduce mistakes, save time, and lower material waste.

Holding Thin Nitinol Tubes Steady

Thin nitinol tubes are hard to cut because they’re so delicate. Without support, they can bend or shake, causing rough edges and wasted material. Special fixtures are needed to keep the tubes steady for clean cuts.

Fixtures for nitinol hold the tubes firmly without harming them. Many use water-cooled clamps to grip the tubes and cool them at the same time. This stops overheating and keeps the tubes from bending. Some fixtures also have adjustable grips for different tube sizes.

Another helpful tool is vacuum-based fixtures. These use suction to hold the tubes in place. This works well for very thin tubes that regular clamps might damage. Vacuum fixtures spread the force evenly, keeping the tubes stable during cutting.

For the best results, use stabilizing fixtures with advanced cutting tools. This combo reduces mistakes and improves cutting quality. Check and maintain your fixtures often to avoid problems and ensure good results.

Best Practices for Manufacturers

Keeping Machines in Good Shape

Taking care of laser machines is very important. Regular maintenance keeps them working well and cutting nitinol properly. Calibration helps the machines stay precise and avoid damaging nitinol’s special features.

Checking machines often can catch problems early. For example, calibration keeps cuts accurate, and inspections find worn-out parts. Fixing things like coolant leaks stops bigger damage later.

Evidence | Description |

|---|---|

Regular calibration | Keeps machine cuts accurate. |

Calibration records | Tracks how well the machine works over time. |

Regular checks | Finds parts that need fixing or replacing. |

Fixing coolant leaks | Stops serious machine damage. |

By caring for your machines, they last longer and work better. This helps make nitinol tubing smoothly without delays.

Teaching Operators to Use Lasers Well

Training workers is key to making good nitinol tubing. Skilled workers know how to set lasers, control speeds, and adjust gas pressure. Training also helps them learn new laser cutting methods.

Studies show trained workers make fewer mistakes and save money. Certification proves their skills and keeps them up to industry standards. Learning new things helps them handle challenges and cut nitinol precisely.

Evidence Type | Description |

|---|---|

Better Efficiency | Training helps workers do their jobs faster and cheaper. |

Staying Updated | Workers learn new tools and follow industry rules. |

Certification | Proves workers are skilled and meet high standards. |

Teaching workers improves product quality and makes them feel more confident and happy.

Working with Trusted Suppliers

Good suppliers make nitinol tubing production easier. They provide safe, high-quality materials that meet medical standards. They can also customize tubing to fit specific needs.

Experienced suppliers check their materials carefully and follow strict safety rules. Many have ISO 13485 certification, which proves they meet global safety standards. They also offer materials that are traceable, so you know where they came from.

Benefit | Description |

|---|---|

High Quality | Materials meet medical safety rules and work well. |

Custom Options | Tubing can be made to fit exact sizes and needs. |

Reliable and Traceable | Materials are checked for quality and can be traced back to their source. |

Choosing good suppliers lowers risks, improves production, and ensures your nitinol tubing is always top quality.

Material Preparation to Avoid Contamination

Getting nitinol tubing ready before cutting is very important. It helps avoid contamination and keeps the material strong for medical use. Clean tubing makes cutting easier and improves results.

Start by cleaning the tubing well. Dirt, oil, and leftover materials can mess up the laser's accuracy. Use ultrasonic cleaners to remove tiny particles. These cleaners work deeply without harming the tubing. Rinse the tubing with deionized water to wash away chemicals.

Keep the workspace neat and clean. A messy area can cause contamination. Use exhaust systems to clear the air of particles during cutting. Let the system run a few minutes after cutting to improve air quality. This helps protect the tubing from airborne dirt.

Know the dangers of laser-made particles. Cutting lasers create tiny bits that can stick to the tubing. These particles can lower the tubing's quality. Use shields or covers to block particles during cutting. Check the tubing often for dirt before moving to the next step.

Handle tubing carefully to avoid damage. Wear gloves to stop oils or dirt from your hands getting on it. Store tubing in sealed containers to keep it safe from pollutants. Label containers clearly to avoid mix-ups and track materials easily.

Following these steps keeps nitinol tubing clean and ready for cutting. Clean tubing leads to better cuts, fewer mistakes, and stronger finished products.

Tip: Check your workspace and tools often for dirt or contamination. Regular cleaning helps keep production smooth and efficient.

Laser-cut nitinol tubing has special problems that need close care. Its sensitivity to heat, hardening during work, and safety for the body make accuracy very important. Unlike other materials, nitinol needs super-fine precision and smooth surfaces for medical use. Using femtosecond lasers gives better results, but keeping machines in good shape and training workers is key. Solving these issues helps make reliable products that meet strict industry rules.

Metric/Challenge | Nitinol Tubing | Other Materials (e.g., Stainless Steel) |

|---|---|---|

Surface Roughness | Needs very smooth surfaces | Less important |

Biocompatibility | High, but nickel can sometimes migrate | Varies, often lower than Nitinol |

Machining Process | Femtosecond lasers work best | Regular tools often work fine |

Corrosion Resistance | As good or better than stainless steel | Varies, often not as good as Nitinol |

Accuracy Requirement | Needs super-fine precision | Less strict requirements |

Tip: Aim for accuracy and steady results to handle nitinol's challenges and make top-quality products.

FAQ

What makes laser-cut nitinol tubing special?

Laser-cut nitinol tubing is flexible and remembers its shape. These features make it great for medical tools like stents. But it reacts to heat and hardens with use, so careful cutting is needed to keep it strong.

How can you stop heat damage during laser cutting?

You can stop heat damage by cooling the material fast. Use gas cooling or water-cooled clamps to lower the heat. These methods help keep nitinol strong and working well.

Why are burrs a problem when cutting nitinol?

Burrs happen when laser heat melts nitinol unevenly. They leave rough edges that need extra work to fix. Using clean cutting gases and adjusting laser settings can reduce burrs and make smoother edges.

Why is gas purity important for laser cutting?

Clean gas helps make smooth cuts by stopping oxidation. Dirty gas can weaken nitinol and change its color. Using pure gases like nitrogen or argon keeps edges neat and strong.

How do you cut thin nitinol tubes accurately?

To cut thin tubes well, hold them steady with special clamps. These clamps stop bending or shaking. Pair them with advanced lasers for clean cuts and less heat damage.