Why Flexible Nitinol Tubing Is the Top Choice for Minimally Invasive Surgery

Flexible nitinol tubing is the best choice for minimally invasive surgery. It has special benefits that make it stand out. Its shape memory and superelasticity help medical devices work well. Guidewires made from nitinol can cross vessels 98% of the time. Nitinol is very safe for the body. It has a strong titanium oxide layer that stops nickel from leaking. Surgeons trust flexible nitinol tubing because it bends easily and lasts a long time. Implants can handle up to 400 million pressure cycles. They can also stretch up to 5.5% and return to their shape. These qualities make nitinol great for implants in hard surgeries.

Property | Value or Description |

|---|---|

Clinical Success Rate | 98% vessel crossing success with nitinol guidewires |

Fatigue Resistance | Up to 400 million pressure cycles for implants |

Strain Recovery | Up to 5.5% without permanent deformation |

Corrosion Resistance | Stable titanium oxide layer ensures long-term biocompatibility |

Key Takeaways

Flexible nitinol tubing bends without breaking. It goes back to its shape after bending. This makes it great for safe and careful surgeries. Nitinol's superelasticity and shape memory help implants last longer. They also let implants move well with the body. This lowers risks during surgery. The strong titanium oxide layer on nitinol tubing keeps it safe in the body. It helps stop infection and helps patients heal better. Using nitinol tubing lets surgeons make smaller cuts. Smaller cuts mean less pain for patients. Patients heal faster and have less scarring. Making nitinol tubing is hard and costs a lot. But new ideas are making it better to produce. These changes help use nitinol tubing in more medical devices.

Flexible Nitinol Tubing Properties

Shape Memory

Nitinol is a shape-memory alloy. This means it can go back to its original shape after being bent or twisted. Doctors use this in implants that need to fit inside the body and then get bigger to the right size. The shape memory works with temperature changes. When nitinol is cold, it is soft and easy to bend. If you heat it up, it snaps back to its set shape. The table below shows how temperature changes nitinol:

Temperature Range (°C) | Phase | Description |

|---|---|---|

Below ~18°C | Martensitic | Flexible, can be deformed |

~18°C to ~50°C | Transition Zone | Shape recovery starts |

~50°C to 81°C | Austenitic | Rigid, returns to original shape |

This special feature helps nitinol implants work in many surgeries.

Superelasticity

Super elastic nitinol can stretch much more than most metals. Doctors can bend and flex nitinol implants without breaking them. Nitinol tubing can handle strains up to 7% and still go back to its shape. Most metals would break or stay bent at these levels. This superelasticity lets implants move with the body and last longer. The table below shows how nitinol is different from other metals:

Parameter | Nitinol Value | Typical Metal Value |

|---|---|---|

Maximum Strain (before damage) | ~7% | <1% |

Recovery after bending | Complete | Partial or none |

Super elastic nitinol gives doctors more control and keeps patients safer during surgery.

Biocompatibility

Nitinol is very safe for the body. The body accepts nitinol implants and does not react badly. Nitinol has a strong titanium oxide layer on its surface. This layer stops nickel from leaking out and keeps tissues safe. Biocompatibility tests follow strict rules like ISO 10993. Studies show nitinol implants stay safe and stable in the body for many years. Doctors use nitinol for heart stents, bone implants, and other devices because it is proven to be safe.

Flexibility and Durability

Nitinol is very flexible, which is why it is used in medical devices. Nitinol tubing bends easily and fits into small spaces in the body. Implants made from nitinol can move with the body and go back to their shape after bending. This flexibility helps doctors reach hard places during surgery. Nitinol tubing is also very strong. It does not kink and can handle millions of cycles without breaking. Some nitinol implants last through 400 million pressure cycles. The list below shows the main points:

Nitinol tubing does not get tired or kink easily.

Better manufacturing can make nitinol implants last three times longer.

Clinical data shows nitinol guidewires work 98% of the time.

Surface finishing makes nitinol resist rust and last longer.

Flexibility and strength make nitinol the best choice for implants in minimally invasive surgery.

Surgical Benefits in Minimally Invasive Therapy

Precision and Control

Flexible nitinol tubing helps surgeons be very precise. Doctors can steer tools accurately, even in small spaces. Nitinol implants have a special design with flexure hinges and tendons. This lets the tip move up to 100° one way. The tubing keeps its shape after many bends. Doctors trust this control to put implants in the right spot.

The table below shows how flexible nitinol tubing helps with precision and control:

Aspect | Description / Measurement | Relevance to Precision and Control |

|---|---|---|

Device Outer Diameter | 10 mm (matching common laparoscopes) | Ensures practical use and fits with other tools |

Bending Section Length | 64 mm | Shows how far it can bend |

Degrees of Freedom (DOF) | 2 DOF | Lets doctors steer in more ways |

Total Bending Angle | 100° in one direction | Helps place the tip exactly |

Actuation Method | Tendon-based with preloaded Nitinol wires (100 µm diameter) | Gives smooth, repeatable bends with little force |

Axial Deformation | Less than ~1 mm under load | Stays stiff for good steering |

Material Properties | Superelastic Nitinol with Austenite finish temperature ~18°C | Handles many bends without getting weak |

Structural Design | Symmetrical orthogonal flexure hinges in tubular geometry | Balances bending and twisting for better control |

Nitinol implants slide easily and move force well. These features help doctors guide tools smoothly. The tubing does not kink, so it keeps its shape during surgery. This makes surgery safer and helps patients get better results.

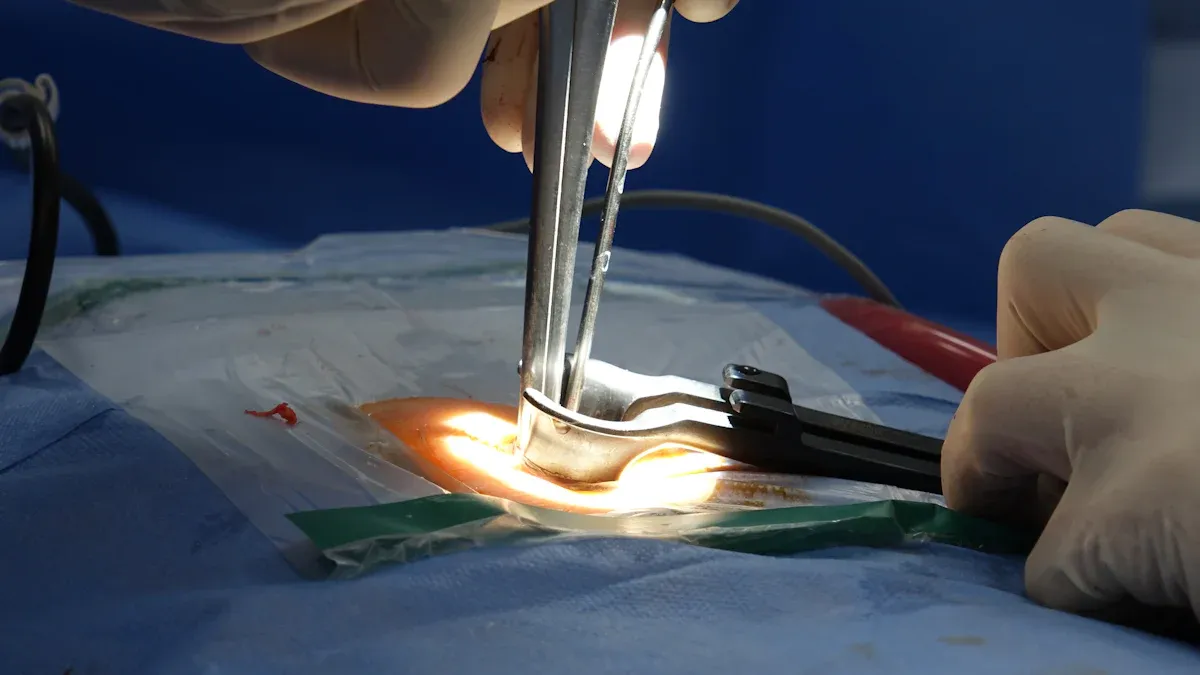

Navigation in Complex Anatomy

Doctors face tough spots inside the body. Flexible nitinol tubing helps them reach deep places and move through tricky paths. The tubing bends easily to follow curves in blood vessels. Nitinol implants fit through small cuts and tight spaces without losing strength.

Nitinol devices can bend a lot, up to 7%, without breaking. The tubing stays steady with less than 1 mm of change under pressure. This helps doctors feel sure when putting implants in hard spots.

Tip: Flexible nitinol tubing lets surgeons move through soft tissues gently, so there is less harm and patients feel better.

Doctors use nitinol implants in bone surgeries and other operations. The tubing’s bendiness and strength help treat problems that once needed big cuts. This means fewer problems and more comfort for patients.

Reduced Scarring and Recovery Time

Minimally invasive therapy uses small cuts to fix health problems. Flexible nitinol tubing makes these small cuts possible. The tubing fits through tiny sheaths and can get bigger inside the body. This lets doctors put in implants without big cuts.

Smaller cuts mean less damage to skin and tissue. Patients feel less pain and are more comfortable after surgery. Nitinol implants also lower the chance of infection and bleeding. The strong titanium oxide layer keeps the implants safe inside the body.

Many studies show patients with nitinol implants heal faster. They spend less time in the hospital and get back to normal life sooner. Fewer problems and more comfort make nitinol the best choice for these surgeries.

Flexible nitinol tubing allows smaller cuts and safer movement.

Nitinol implants do not kink and reach deep spots.

Patients heal faster and have less scarring.

Applications of Nitinol in Surgery

Guidewires and Catheters

Doctors use nitinol guidewires and catheters to reach deep areas. These guidewires bend easily and move through tight blood vessels. Nitinol implants do not kink or break during surgery. The superelasticity and shape memory help doctors steer tools well. Nitinol guidewires are more flexible and last longer than stainless steel or titanium alloys. The table below shows how nitinol is different from other materials:

Material | Tensile Strength (MPa) | Key Advantages | Limitations |

|---|---|---|---|

Nitinol | 500–900 | Superelasticity, shape memory, fatigue resistance, biocompatibility | Higher cost, limited machinability |

Stainless Steel | Up to 1100+ | High strength, rigidity, cost-effective | Less flexible, lacks superelasticity |

Titanium Alloys | Up to 1200 | High strength-to-weight ratio, biocompatible | Expensive, less flexible than nitinol |

Nitinol devices lower problems by about 25% because they do not kink and move smoothly. Doctors trust nitinol implants for safe and good results.

Stents and Valve Frames

Nitinol stents and valve frames keep blood vessels and heart valves open. These implants can last through 400 million cycles in arteries and at least 600 million cycles in heart valves. Shape memory lets the devices expand to fit the vessel just right. Nitinol medical devices move with the body and work for many years. The table below shows important facts:

Metric | Result/Description |

|---|---|

Durability cycles (stents) | Up to 400 million |

Durability cycles (valves) | At least 600 million |

Flexibility (Solitaire FR) | 0.38 ± 0.11 N |

Flexibility (Trevo XP ProVue) | 0.91 ± 0.11 N |

Nitinol implants are safe for the body and do not rust. These features lower risks and help patients heal faster.

Orthopedic Implants

Nitinol medical devices are important in bone surgeries. Doctors use nitinol staples in foot and ankle operations. These implants help bones heal with a fusion rate of about 94.6% and a complication rate of 11.25%. Nitinol gives steady pressure, which helps bones heal quicker. Surgeries are faster with nitinol than with plates and screws. The table below compares nitinol staples to regular implants:

Evidence Aspect | Nitinol Compression Staples | Traditional Implants (Plates and Screws) |

|---|---|---|

Fusion Rate | ~94.6% | Comparable |

Complication Rate | 11.25% | Comparable |

Operation Time | Reduced | Longer |

Biomechanical Properties | Sustained dynamic compression | Static fixation |

Nitinol orthopedic implants help with pain and movement. These implants make surgery easier and help patients get better faster.

Clinical Evidence and Outcomes

Comparative Studies

Researchers have checked nitinol implants against regular materials in many studies. One study focused on patients with Weber type B distal fibular fractures. The results showed nitinol staple-only fixation used smaller cuts and took less time. Patients with nitinol implants felt less pain and needed fewer removals. Both groups’ bones healed, but nitinol was less invasive.

Performance Metric | Nitinol Staple-Only Fixation | Antiglide Plate Fixation |

|---|---|---|

Mean Skin Incision Length | 3.8 ± 0.5 cm | 8.7 ± 1.3 cm |

Mean Operative Time | 19.6 ± 3.6 min | 48.8 ± 10.6 min |

Bone Union | Achieved in all patients | Achieved in all patients |

Implant Discomfort Reported | 32.3% | 71.4% |

Implant Removal Requested | 35.5% | 75.0% |

Meta-analyses show nitinol stents in blood vessel surgery work very well. First-pass recanalization rates can reach 100%. Success rates for recanalization are between 74% and 87.2%. These numbers show nitinol implants help blood flow and lower problems. Special coatings on nitinol implants help vessels heal and lower the chance of narrowing again.

Patient Recovery Data

Nitinol implants help people get better faster and with fewer issues. Studies show that deaths within 90 days drop to 8.6% when nitinol stent retrievers work well. Patients with nitinol implants often do better at discharge and later checkups. High success rates for opening vessels, up to 94.8%, are seen with nitinol stent retrievers.

At 90 days, 54.9% to 57.5% of patients can live on their own in big studies.

Nitinol devices help people recover about 20% faster than regular materials.

Nitinol implants usually have fewer problems and are safer.

Superelasticity and shape memory let nitinol implants open and grab clots without hurting vessels.

Better patient results show up soon after surgery and last a long time.

Doctors pick nitinol implants because they are safe, bend easily, and help patients do better. These reasons make nitinol implants a top pick for surgeries with small cuts.

Limitations and Future Trends

Manufacturing and Cost

Flexible Nitinol tubing has many good points, but making it is hard and costs a lot. Nitinol is tough to cut and shape because of how it changes when worked on. This makes making the tubing more tricky and expensive. Factories need special tools and smart workers to handle Nitinol’s special features. They also must do extra steps like electropolishing and passivation to make the tubing safe for people, which adds more cost.

The table below lists some main problems in making flexible Nitinol tubing:

Limitation | Description | Impact on Manufacturing and Cost |

|---|---|---|

Machining difficulty | Nitinol’s unique properties make it hard to cut and shape | Raises production costs and complexity |

Lack of comparative data | Not enough data on best micromachining methods | Makes it hard to choose the most efficient process |

Continuous drawing issues | Drawing methods can cause uneven tube properties | Lowers yield and quality |

Mandrel hardness trade-offs | Softer mandrels save money but hurt surface finish; harder ones cost more | Balances cost and quality |

Finishing processes | Extra steps like electropolishing are needed | Increases cost and time |

Raw material sourcing | Need for strict controls and multiple suppliers | Raises overhead and risk management costs |

Specialized expertise | Skilled workers and advanced tools are required | Limits scalability and increases labor costs |

Getting the right materials and checking the process is also hard for factories. They need to find and test many suppliers so they do not run out. Many companies buy their own tools and work on their own ways to make tubing better, but this takes lots of money and careful planning.

Note: Making designs easy to build and watching the process closely can help save money without making quality worse.

Innovations Ahead

Scientists and engineers are always finding new ways to make flexible Nitinol tubing better. New plasma arc melt furnaces and more vacuum arc remelting help make more tubing and lower the price. Some companies now control every step of making tubing, which makes things faster and better.

New types of tubing, like DFT® flat wire and very thin wires, let makers build more bendy and tricky shapes. These new ideas help make the next generation of Nitinol tubing for medical tools. 3D printing lets factories make special Nitinol shapes with less waste and in less time.

The table below shows some new ideas:

Innovation / Advancement | Description | Impact on Cost and Production |

|---|---|---|

Plasma Arc Melt furnace upgrades | Better melting and higher capacity | More tubing produced at lower cost |

Second VAR furnace | Doubles melting capacity to 1,000,000 pounds per year | Supports larger production and stable pricing |

Vertical integration | Control over raw materials and processing | Improves quality and reduces costs |

New product forms | DFT® flat wire, helical wire, ultra-fine wires | Enables complex, flexible tubing |

Advanced processing and R&D | Supports prototyping and next-generation projects | Drives innovation and smaller, more complex tubing |

In the future, experts think better cutting methods and using AI and robots will help even more. These changes will let doctors use Nitinol tubing in robot surgeries and for devices made just for one person. The need for flexible Nitinol tubing is growing fast, with new uses in health trackers and sensors inside the body. Companies that spend money on new ways to make tubing and research will be the leaders in making Nitinol tubing easier to get and use in more ways.

Flexible Nitinol tubing is special in minimally invasive surgery. It has shape memory, superelasticity, and lasts a long time. Surgeons can do very exact work with it. Patients feel more comfortable and heal faster. The tubing fits well against vessel walls and keeps its shape. This helps patients feel better as they recover. New studies show it works well and is safe:

Feature | Nitinol Open-cell Stents | Hybrid Nitinol Stents |

|---|---|---|

Clinical procedural success | 100% (377 patients) | Yes |

Adverse event rate | 2.92% | N/A |

Stroke and death rate | 1.33% | N/A |

New ideas will help flexible Nitinol tubing do even more in the future.

FAQ

What makes nitinol tubing different from other metals in surgery?

Nitinol tubing can bend and go back to its shape. This is because it has shape memory and superelasticity. Most other metals cannot do this. Nitinol does not rust and lasts longer inside the body.

Is nitinol safe for patients?

Doctors use nitinol because it is safe for the body. The titanium oxide layer keeps nickel from getting out. Studies show nitinol implants stay safe and work well for many years.

Can nitinol tubing be used in all types of minimally invasive surgery?

Surgeons use nitinol tubing for many surgeries. It helps in heart, blood vessel, and bone operations. Its strength and flexibility help with hard cases. Some surgeries need other materials, but nitinol works for most.

How does nitinol tubing help patients recover faster?

Nitinol tubing lets doctors make smaller cuts. This means less damage to tissue. Patients feel less pain and heal more quickly. Hospitals see shorter stays and fewer problems after surgery with nitinol implants.

What are the main challenges in making nitinol tubing?

Factories need special tools and trained workers to shape nitinol. Extra steps like polishing make it cost more. Getting good raw materials also makes it harder and more expensive to produce.

See Also

Top Suppliers Offering Cost Savings On 2mm Nitinol Tubing

Ways Nickel Titanium Tubing Improves Catheter And Implant Function

NiTi Tubes Transforming The Future Of Medical Device Technology

Reasons NiTi Tubes Lead The Medical Manufacturing Industry Today

How NiTi Tubes Are Changing Medical And Aerospace Applications