What Makes Flexible Nitinol Tubing Essential in Modern Medicine

Flexible nitinol tubing uses a nickel-titanium alloy that gives it superelasticity and shape memory. You see its essential role in medical device design because it lets devices bend, flex, and recover their shape. The market for flexible nitinol tubing continues to grow, as shown below:

Metric | Value | Time Period |

|---|---|---|

Market Size | USD 1.2B | 2024 |

Projected Size | USD 2.5B | 2033 |

CAGR (2026-2033) | 9.5% | |

CAGR (2024-2030) | 6.5% |

You benefit from nitinol tubing in medical devices because it offers:

Flexible stents that fit complex vessels

High fatigue resistance for long-term safety

MRI compatibility for safe imaging

Reduced allergy risks through surface treatments

Nitinol stands out for its ability to perform reliably inside the body, making it vital for modern medicine.

Key Takeaways

Flexible nitinol tubing bends and returns to its original shape, making medical devices safer and more comfortable inside the body.

Nitinol’s superelasticity and shape memory help devices like stents and catheters adapt to complex anatomy and reduce complications.

Surface treatments improve nitinol’s biocompatibility, lowering allergy risks and supporting long-term implant safety.

Nitinol tubing is highly durable and resists corrosion, ensuring medical devices last longer and perform reliably.

The growing use of nitinol in medical devices leads to better patient outcomes and drives innovation in minimally invasive treatments.

Flexible Nitinol Tubing

What Is Nitinol?

You may wonder what makes flexible nitinol tubing so special in medicine. Nitinol is a unique metal alloy made from nearly equal parts nickel and titanium. Scientists call it a shape memory alloy because it can "remember" its original shape. When you bend or twist nitinol, it can return to its original form after you remove the force. This happens because of a reversible phase transformation inside the metal. The alloy was first discovered in 1959 at the Naval Ordnance Laboratory, which is why it is called Nitinol (Nickel Titanium Naval Ordnance Laboratory).

Researchers have studied nitinol for decades. They found that medical-grade nitinol has two main features: superelasticity and the shape memory effect. Superelasticity means you can bend the metal a lot, and it will snap back without breaking. The shape memory effect lets nitinol change shape at one temperature and return to its original shape at another. Scientists use special melting and heat treatment methods to make sure nitinol keeps these properties. Medical-grade nitinol is also safe for your body. Studies show it does not harm human cells and resists corrosion, which means it will not break down easily inside you.

Key Properties

Flexible nitinol tubing stands out because of its remarkable properties. These features make it perfect for medical devices that need to move and adapt inside your body. Here are some of the most important properties:

Shape Memory Properties: Nitinol can "remember" its shape. If you deform it, it will return to its original form when heated or when the stress is removed. This shape memory effect is crucial for devices like stents that need to expand once inside your blood vessels.

Superelasticity: You can bend flexible nitinol tubing much more than other metals. It will not kink or break. This superelastic behavior helps doctors guide devices through winding blood vessels without causing damage.

Flexibility and Durability: Nitinol tubing combines flexibility with strength. It can handle repeated bending and stretching. Thin walls, about 0.08 mm thick, give it the right balance of elasticity and stability.

Biocompatibility: Medical-grade nitinol is safe for long-term use in your body. Surface treatments like electropolishing and titanium nitride coatings make it even safer by reducing nickel release and helping tissue grow around the device.

Corrosion Resistance: Nitinol forms a protective oxide layer. This layer keeps the metal from rusting or releasing harmful ions, even in body fluids.

Customizable Mechanical Properties: Manufacturers can adjust nitinol’s stiffness and flexibility by changing the alloy mix or using different heat treatments. This lets them design tubing for many types of medical devices.

Tip: The superelasticity of flexible nitinol tubing prevents kinking during catheter insertion. This improves patient comfort and reduces complications by 25% compared to stainless steel tubing.

You can see how flexible nitinol tubing compares to stainless steel in the table below:

Metric | Nitinol Tubing Characteristics | Stainless Steel Tubing Characteristics |

|---|---|---|

Flexibility | High flexibility enables smooth navigation through complex anatomy | Limited flexibility restricts use in dynamic environments |

Shape Memory | Exhibits superelasticity and shape memory effect, returning to original shape after deformation | Lacks shape memory properties, remains rigid |

Durability | Durable with high fatigue resistance and corrosion resistance in simulated body fluids | Durable with corrosion resistance but less flexible |

Patient Comfort | Enhances comfort by reducing procedural complications by 25% compared to stainless steel | May cause discomfort due to rigidity |

Maneuverability | Excellent maneuverability, kink resistance, and adaptability in minimally invasive procedures | Limited maneuverability, better suited for static load-bearing applications |

Flexible nitinol tubing’s shape memory properties and superelasticity allow it to adapt to your body’s needs. Clinical studies show that nitinol stents have a primary patency rate of 83.2% at 12 months, much higher than balloon-expandable stents. Nitinol guidewires also reduce complications during procedures. These advantages explain why 75–80% of medical devices now use nitinol tubing, with over 1.5 million cardiovascular stents implanted each year.

Nitinol shape memory alloys have changed the way doctors treat patients. You benefit from safer, more comfortable, and more effective medical devices because of the unique properties of flexible nitinol tubing.

Applications in Medical Devices

Flexible nitinol tubing and wire have changed how you experience modern healthcare. You see these materials in many medical applications, especially where flexibility, durability, and safety matter most. Let’s explore how nitinol and medical grade nitinol wire improve the performance of stents, catheters, guidewires, filters, and orthopedic tools.

Stents and Catheters

You find nitinol tubing and wire at the heart of advanced stents and catheters. These devices must move through your body’s winding blood vessels and then expand or flex without losing their shape. Nitinol’s superelasticity and shape memory make this possible. Medical grade nitinol wire allows stents to open up inside arteries and stay in place, even when vessels twist or compress.

Laser-cut nitinol tubing helps thrombectomy devices like WATCHMAN FLX™ and Solitaire AB/FR reach high recanalization rates—up to 90% in clinical trials. These devices keep their structure and flexibility during minimally invasive stroke treatments, which means less trauma and shorter procedure times for you.

Newer self-expanding nitinol stents for femoropopliteal arterial disease show better flexibility and lower fracture rates than older designs. These stents use spiral orientations and optimized strut connections to resist breaking while keeping strong support.

Catheters made with medical nitinol wire can bend and return to their original shape. This lets doctors guide them through complex anatomy without kinking or buckling.

Note: Quality control in manufacturing ensures that nitinol stents and catheters remain biocompatible and corrosion-resistant, which keeps you safer and reduces device recalls.

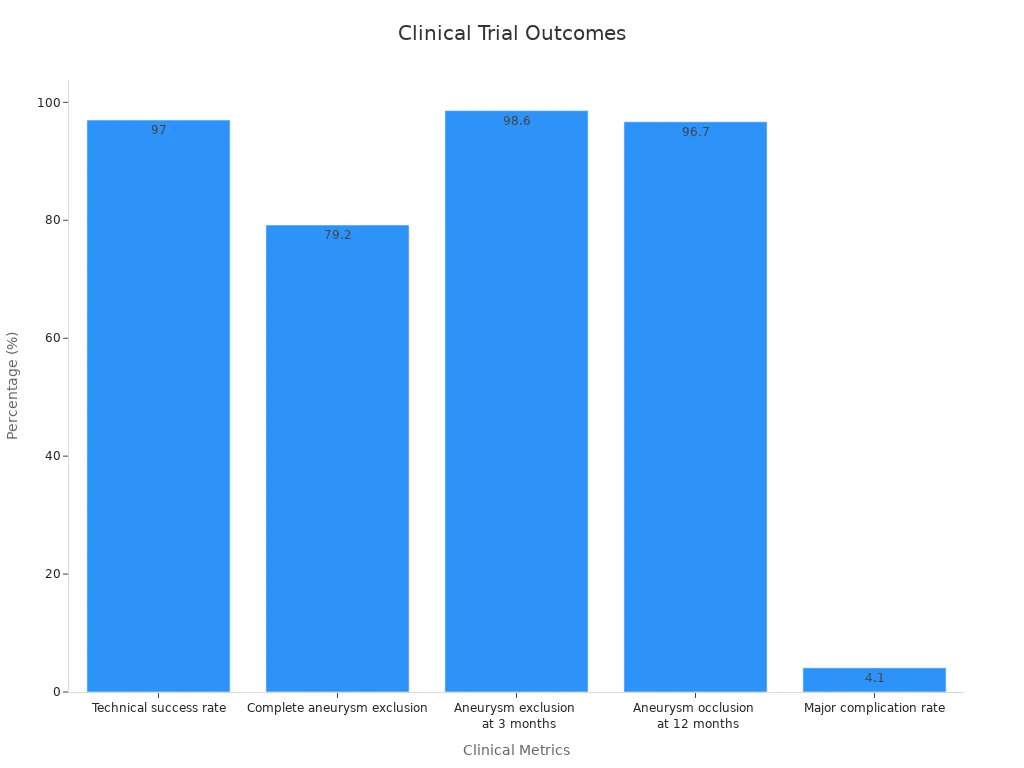

You can see how these devices perform in clinical trials:

Clinical Metric | Outcome |

|---|---|

Technical success rate | 97% (70 of 72 patients) |

Complete aneurysm exclusion | 79.2% (57 of 72 patients) |

Aneurysm exclusion at 3 months | 98.6% (70 of 71 patients) |

Aneurysm occlusion at 12 months | 96.7% (29 of 30 patients) |

Major complication rate | 4.1% (3 patients) |

These results show that nitinol-based stents and catheters help doctors treat vascular conditions with high success and low complication rates. The superelasticity and shape memory of medical grade nitinol wire allow for minimally invasive procedures, which means smaller incisions and faster recovery for you.

Guidewires and Filters

Guidewires and filters use medical nitinol wire to help doctors reach hard-to-access areas in your body. The superelasticity of nitinol lets these devices bend and twist through narrow or curved vessels without breaking. You benefit from safer and more precise procedures.

Ablative Solutions’ renal denervation device uses nitinol’s flexibility for accurate catheter delivery and controlled deployment of micro-needles.

Topera’s heart mapping catheters use nitinol tubing to move through coronary vessels and deploy a basket electrode array. This helps doctors map your heart’s rhythm with precision.

In general, nitinol guidewires and catheters resist kinking and buckling. This means doctors can safely navigate complex vascular pathways, reducing the risk of complications.

Nitinol’s unique properties support many cardiovascular and neurovascular treatments. You see nitinol-based guidewires and filters in procedures like transcatheter aortic valve replacement (TAVR) and carotid artery stenting. These applications and benefits include better vessel conformity, improved trackability, and fewer complications.

Orthopedic and Minimally Invasive Tools

Orthopedic and minimally invasive tools rely on nitinol tubing and wire for strength, flexibility, and reliability. You find these tools in joint repair, bone fixation, and spinal surgery. Medical grade nitinol wire gives these instruments the ability to bend and recover, which is important for minimally invasive procedures.

Metric/Device Type | Reliability/Durability Evidence |

|---|---|

Silverway guidewire | 98% success rate in vessel crossing, indicating high reliability |

Catheters | 92% success rate in delivery, demonstrating durability |

Nitinol implants | 30% lower rejection rate compared to traditional metals |

Superelastic strain capacity | Up to 7%, allowing significant deformation without failure |

Shape recovery strain | 4.16%, showing effective shape memory behavior |

Dimensional tolerances | ±0.0005 inches, ensuring precision and consistent device performance |

You benefit from nitinol implants because they adapt to your body and last longer than traditional metal implants. The superelasticity and fatigue resistance of nitinol mean that flexible medical devices can withstand repeated use without breaking. These applications and benefits lead to fewer surgeries, faster healing, and better long-term outcomes.

Nitinol’s role in orthopedic and minimally invasive medical applications continues to grow. You see it in catheter-delivered implants, bone anchors, and surgical tools. Manufacturing processes like cold working and heat treatment optimize the superelasticity and durability of medical grade nitinol wire, making these devices safer and more effective.

Tip: The use of nitinol in minimally invasive tools helps reduce tissue damage and speeds up your recovery. Devices made from nitinol tubing and wire can conform to your anatomy, improving comfort and clinical results.

Advantages of Nitinol Tubing and Wire

Superelasticity and Shape Memory

You benefit from nitinol tubing and wire because of their superelasticity and shape memory effect. When you bend or twist these materials, they return to their original shape. This happens because nitinol is a shape memory alloy. The unique phase transformation inside the metal lets it recover from stress without permanent damage. Experimental tests show that nitinol shape memory alloys can handle strains up to 6.3% and still return to their original form. This property allows doctors to use devices that fit your body perfectly and adapt during procedures. The shape memory properties also mean that stents and catheters can expand or contract as needed, making treatments less invasive and more effective.

Flexibility and Biocompatibility

Nitinol tubing and wire offer flexibility that you do not get with traditional metals. Devices made from nitinol can move through your body’s complex pathways without kinking or breaking. This flexibility reduces the risk of tissue damage and improves patient comfort. The biocompatibility of nitinol is another key benefit. Studies show that nitinol releases very little nickel into the body, especially when treated with special coatings. The biocompatibility of nitinol means you can have implants that last longer and cause fewer reactions. Surface treatments like electropolishing make nitinol even safer for long-term use.

Tip: The biocompatibility of nitinol helps lower the risk of allergic reactions and supports healing around implants.

Fatigue Resistance and Durability

You want medical devices that last. Nitinol tubing and wire deliver this through outstanding fatigue resistance and durability. Mechanical tests show that nitinol can endure up to 10 million bending cycles. This means your stents, guidewires, and implants stay strong even after years of use. Compared to stainless steel or titanium alloys, nitinol resists corrosion better and keeps its strength with thin walls. The benefits include fewer device failures, less need for replacements, and safer outcomes for you.

Property | Nitinol | Stainless Steel (AISI 316L) | Ti–6Al–4V |

|---|---|---|---|

Shape Memory Effect | Present (unique) | Absent | Absent |

Superelasticity | Present | Absent | Absent |

Fatigue Resistance | Superior | Lower | Lower |

Corrosion Resistance | High (improved with surface treatments) | Moderate | Moderate |

Biocompatibility | Comparable or better than steel | Standard medical grade | Standard medical grade |

The benefits of nitinol tubing and wire make them essential for safer, longer-lasting, and less invasive medical devices. You get better results, fewer complications, and improved quality of care.

Future of Medical Nitinol Wire

Innovations in Treatment

You will see medical grade nitinol wire drive new breakthroughs in medical applications. Researchers continue to develop advanced stents, guidewires, and implants that use nitinol’s unique properties. Recent clinical trials show that devices like the Stentrode, a self-expanding nitinol stent, help patients with severe paralysis control computers using their thoughts. This technology improves quality of life and opens new paths for neuroprosthetic treatments. You also benefit from nitinol stents that keep arteries open longer and reduce the need for repeat procedures. Surface treatments, such as electropolishing and plasma coating, make medical grade nitinol wire even safer by lowering nickel release and helping your body accept implants.

Ongoing studies test nitinol guidewires in cardiology, endovascular surgery, and neurology. These wires move smoothly through complex blood vessels, making procedures safer and more precise. Companies now use advanced manufacturing to create nitinol wires with better performance. You can expect more reliable and effective devices in the future.

Expanding Applications

You will notice medical grade nitinol wire expanding into new medical applications every year. The market for nitinol devices grows quickly, with projections showing a value of USD 35.77 billion by 2033. North America leads this growth because of high demand for surgery and an aging population. Cardiovascular devices hold the largest share, but you also see nitinol used in orthopedics, dentistry, and urology.

Aspect | Supporting Evidence |

|---|---|

Market Growth Projections | CAGR estimates between 6.13% and 9.1% from 2025 to 2033; market size forecasted to reach USD 35.77 billion by 2033 |

Key Market Drivers | Aging global population and rising chronic illnesses increasing demand for implantable devices; growing preference for minimally invasive surgeries benefiting from nitinol's superelasticity and shape memory |

Product Segmentation | Dominance of stents (~68.9% market share in 2024), guidewires, catheters, filters, and others; stents widely used in vascular and non-vascular interventions due to flexibility and shape memory |

Application Segmentation | Cardiovascular applications leading with 58.8% market share in 2024; expanding use in orthopedics, dentistry, neurovascular, and urology |

You will see over 150 new nitinol-based products launched in just one year. Hospitals around the world now use smart nitinol catheters with sensors and ultra-thin implants for brain treatments. Advances in manufacturing, such as additive manufacturing and nano-machining, allow nitinol to be used in more complex and precise medical applications. These improvements help you get safer, more effective treatments and support the future of medical technology.

You see flexible Nitinol tubing as a game-changer in modern medicine.

Its superelasticity and shape memory let devices adapt inside your body, improving comfort and safety.

Surface treatments boost biocompatibility, making implants safer for long-term use.

Clinical trials show better patient recovery and fewer complications.

Strict manufacturing standards ensure each tube meets medical needs.

You can expect Nitinol tubing to drive new advances, helping doctors treat you with safer, more effective tools.

FAQ

What makes Nitinol tubing different from other metals in medical devices?

You see Nitinol tubing bend and return to its shape. Other metals stay bent or break. Nitinol’s superelasticity and shape memory help doctors use it in devices that move inside your body.

Is Nitinol safe for long-term use in your body?

You can trust Nitinol for implants. Medical-grade Nitinol resists corrosion and releases very little nickel. Surface treatments make it even safer. Doctors choose Nitinol because it works well with your body.

Where do you find flexible Nitinol tubing in medicine?

You find Nitinol tubing in stents, catheters, guidewires, and orthopedic implants. These devices need to bend, flex, and fit your body’s shape. Nitinol helps them work better and last longer.

How does Nitinol improve patient recovery?

Nitinol’s flexibility allows for smaller incisions and less tissue damage. You heal faster and feel less pain. Doctors see fewer complications and better results with Nitinol-based devices.

Can Nitinol tubing be customized for different medical needs?

Yes, you can get Nitinol tubing with different thicknesses, stiffness, and coatings.

Manufacturers adjust these features to match each device’s purpose.

Custom Nitinol tubing helps doctors treat many conditions more effectively.

See Also

The Importance Of Nitinol Tubing In Modern Medicine

How Nitinol Tubing Drives Progress In Medical Tech

Nitinol Tubing Transforming The Future Of Medical Devices