Comparing FEP Heat Shrink Tubing and Polyolefins for Electrosurgical Tools

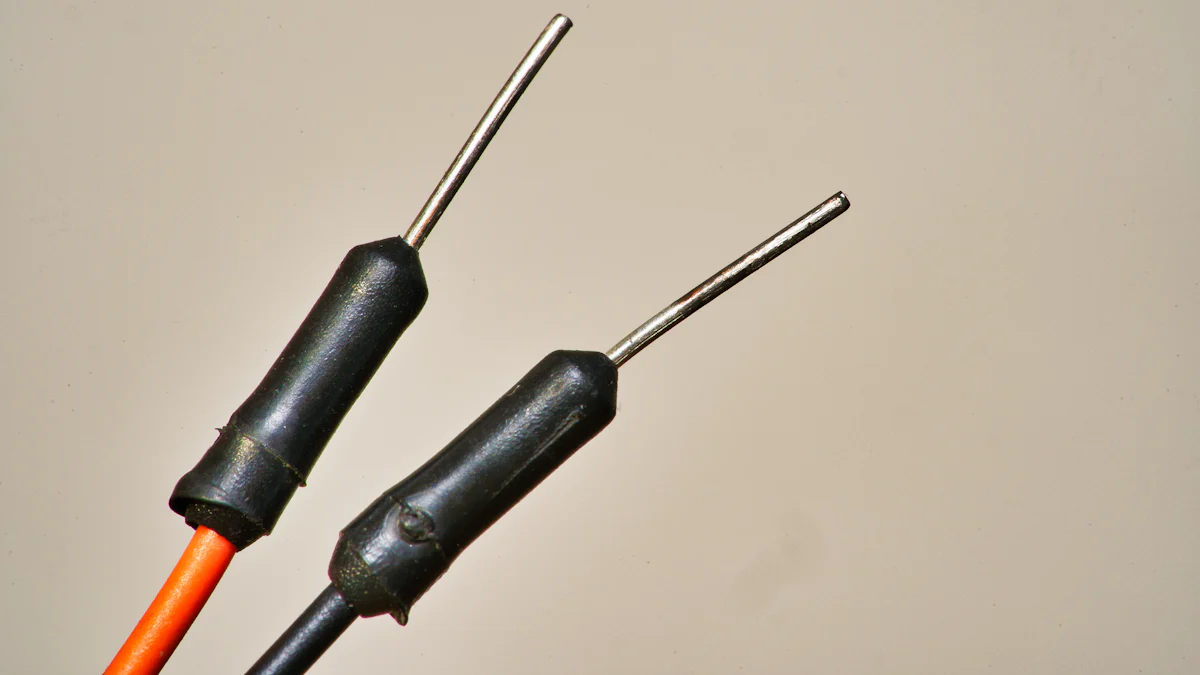

Electrosurgical tools demand precision and reliability, making the choice of insulating materials critical for ensuring safety and performance. Among the available options, FEP Heat Shrink Tubing for Electrosurgery stands out due to its unique properties. Known for its chemical resistance, thermal stability, and dielectric strength, it offers exceptional insulation. Polyolefins, another popular choice, provide versatility and cost-effectiveness. Selecting the right material directly impacts the durability and functionality of these tools, highlighting the importance of understanding their distinct characteristics.

Material Overview of Insulating Materials

FEP Heat Shrink Tubing for Electrosurgery

FEP heat shrink tubing for electrosurgery stands out as a high-performance option among insulating materials. Derived from the copolymerization of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP), this material exhibits exceptional properties that make it ideal for medical applications. Its chemical resistance ensures durability when exposed to harsh sterilization processes or reactive substances. The material’s thermal stability allows it to operate effectively across a broad temperature range, from -200°C to 200°C, making it suitable for tools that encounter extreme conditions.

The non-stick surface of FEP heat shrink tubing prevents adhesion, which is critical in maintaining the precision of electrosurgical instruments. Its dielectric strength provides reliable electrical insulation, ensuring safety during procedures. Additionally, its transparency offers visual clarity, which can be advantageous in certain medical applications. These features collectively position FEP as a versatile and efficient choice for insulating electrosurgical tools.

Polyolefins as Insulating Materials

Polyolefin heat shrink tubing is another widely used material for insulation, offering a balance of performance and cost-effectiveness. Known for its high shrink ratios and low recovery temperatures, polyolefins provide a snug fit around components, ensuring secure insulation. The material’s flexibility and thin walls make it ideal for applications requiring precision and adaptability, such as electrodes and transition tubing.

Polyolefins also exhibit good surface lubricity, which simplifies the manufacturing process by reducing friction during application. While not as chemically resistant as FEP, polyolefins still perform well in environments with moderate exposure to chemicals. Their ability to shrink at lower temperatures minimizes the risk of heat damage to sensitive components, making them a practical choice for many electrosurgical tools.

Both FEP heat shrink tubing for electrosurgery and polyolefin heat shrink tubing offer unique advantages. FEP excels in extreme conditions and provides superior chemical resistance, while polyolefins deliver flexibility and cost efficiency. Understanding these differences helps manufacturers select the most suitable material for their specific needs.

Key Properties Comparison of Heat Shrink Tubing

Thermal Properties

The thermal properties of heat shrink tubing play a crucial role in determining its suitability for electrosurgical devices. FEP heat shrink tubing demonstrates remarkable thermal stability, withstanding temperatures ranging from -200°C to 200°C. This broad temperature range ensures reliable performance in extreme conditions, such as high-heat sterilization processes or cold storage environments. Its ability to maintain structural integrity under such conditions makes it a preferred choice for electrical components in electrosurgical instruments.

In contrast, polyolefin heat shrink tubing operates effectively within a narrower temperature range. While it offers sufficient thermal resistance for many applications, it cannot match the high-temperature tolerance of FEP. However, its lower shrink temperature simplifies the manufacturing process, reducing the risk of heat damage to sensitive components. This characteristic makes polyolefins a practical option for applications where extreme thermal resistance is not a primary requirement.

Electrical Properties

The performance of heat shrink tubing in electrical insulation is critical for ensuring safety in electrosurgical procedures. FEP tubing excels in this area, offering excellent electrical insulation properties. Its high dielectric strength and low dielectric constant provide reliable protection against electrical interference, making it ideal for electrosurgical devices that demand precision and reliability. Additionally, FEP's minimal moisture absorption enhances its insulating capabilities, even in humid or wet environments.

Polyolefins also deliver strong electrical insulation, though they fall slightly short of FEP's superior performance. They provide adequate protection for most electrical components, making them a cost-effective alternative for less demanding applications. However, in scenarios requiring maximum electrical reliability, FEP remains the better choice due to its advanced insulating properties.

Mechanical Properties

Mechanical strength is another critical factor when comparing insulating materials for heat shrink tubing. FEP tubing exhibits high tensile strength, ensuring durability and resistance to mechanical stress. Its toughness and flexibility allow it to withstand repeated use and handling without compromising its structural integrity. These attributes make FEP particularly suitable for electrosurgical instruments, where precision and durability are paramount.

Polyolefins, while less robust than FEP, still offer sufficient mechanical strength for many applications. Their flexibility and adaptability make them easy to work with during manufacturing, especially for intricate designs. However, they may not provide the same level of long-term durability as FEP, particularly in high-stress environments.

Chemical Properties

The chemical properties of insulating materials significantly influence their performance in electrosurgical applications. FEP heat shrink tubing demonstrates exceptional chemical resistance, making it a reliable choice for environments exposed to harsh sterilization processes or reactive substances. Its ability to withstand exposure to acids, bases, and solvents ensures durability and long-term functionality. This resistance also prevents contamination, which is critical in medical settings where maintaining sterility is paramount.

FEP's non-stick surface further enhances its chemical performance. This property minimizes the risk of material adhesion during procedures, preserving the precision and cleanliness of electrosurgical tools. Additionally, FEP exhibits excellent biocompatibility, making it suitable for use in medical devices that come into contact with biological tissues or fluids. Its transparency allows for visual inspection, which can be advantageous in certain applications requiring monitoring or precision placement.

Polyolefins, while offering moderate chemical resistance, do not match the robustness of FEP in highly reactive environments. They perform well in applications with limited exposure to aggressive chemicals but may degrade over time when subjected to harsher conditions. Despite this limitation, polyolefins remain a practical option for less demanding scenarios due to their cost-effectiveness and ease of use.

Performance in Electrosurgical Applications

Sterilization Compatibility

Sterilization processes play a vital role in maintaining the integrity and hygiene of electrosurgical devices. FEP heat shrink tubing demonstrates exceptional compatibility with various sterilization methods, including autoclaving, ethylene oxide (EtO), and gamma radiation. Its ability to withstand high-temperature sterilization without compromising structural integrity ensures consistent performance in demanding medical environments. The chemical resistance of FEP further enhances its durability, allowing it to endure repeated exposure to harsh sterilizing agents.

Polyolefin heat shrink tubing also supports sterilization but within certain limitations. While it performs well under moderate sterilization conditions, it may degrade when exposed to extreme temperatures or aggressive chemicals. This makes polyolefins suitable for applications where sterilization requirements are less stringent. However, for electrosurgical instruments that demand frequent and rigorous sterilization, FEP remains the superior choice due to its resilience and reliability.

Precision and Safety

Precision and safety are paramount in the design of electrosurgical devices. FEP heat shrink tubing offers excellent electrical insulation, ensuring reliable protection against electrical interference during procedures. Its non-stick surface prevents material adhesion, which helps maintain the precision of surgical tools. The transparency of FEP allows for visual inspection, aiding in the accurate placement and monitoring of components.

Polyolefin heat shrink tubing provides adequate insulation and flexibility, making it a practical option for less demanding applications. Its snug fit around components enhances safety by reducing the risk of electrical faults. However, it lacks the advanced insulating properties and precision-enhancing features of FEP. For critical electrosurgical applications where safety and accuracy are non-negotiable, FEP proves to be the more dependable material.

Longevity in Medical Use

The longevity of insulating materials directly impacts the durability and cost-effectiveness of electrosurgical units. FEP heat shrink tubing excels in this regard, offering high temperature resistance and exceptional mechanical strength. Its ability to endure repeated use, sterilization, and exposure to harsh conditions ensures long-term functionality. These attributes make FEP a preferred choice for medical-grade heat shrink tubing in electrosurgical applications.

Polyolefin heat shrink tubing, while cost-effective, may not provide the same level of durability as FEP. Its moderate chemical and thermal resistance limits its lifespan in challenging environments. Despite this, polyolefins remain a viable option for applications with less demanding performance requirements. Manufacturers must weigh the trade-offs between cost and longevity when selecting insulating materials for electrosurgical devices.

Practical Considerations for Insulating Materials

Cost and Availability

Cost plays a significant role in selecting the appropriate heat shrink tubing for medical applications. FEP heat shrink tubing, known for its advanced properties, often comes with a higher price tag compared to other options like polyolefin heat shrink tubing. The superior chemical resistance, thermal stability, and dielectric strength of FEP justify its cost for applications requiring high performance and durability. However, for less demanding uses, polyolefins provide a more budget-friendly alternative without compromising basic functionality.

Availability also influences material selection. FEP tubing, while widely used in specialized industries, may not be as readily available as polyolefins in certain regions. Polyolefins, being more common and versatile, are easier to source in bulk, making them a practical choice for manufacturers prioritizing cost efficiency and supply chain reliability. Balancing cost and availability ensures that manufacturers can meet production demands without sacrificing quality.

Ease of Use in Manufacturing

The manufacturing process benefits significantly from the properties of the chosen heat shrink tubing. FEP tubing, with its lower melting temperature compared to PTFE, simplifies the application process. Its flexibility and transparency further enhance usability, allowing precise placement and visual inspection during assembly. These features reduce the likelihood of errors, ensuring consistent performance in electrosurgical devices.

Polyolefins, on the other hand, excel in ease of use due to their high shrink ratios and low recovery temperatures. These characteristics enable a snug fit around components, streamlining the insulation process. The material’s flexibility and thin walls make it suitable for intricate designs, such as those found in electrosurgical instruments. While both materials offer advantages, the choice depends on the complexity of the manufacturing process and the specific requirements of the application.

Regulatory and Compliance Factors

Compliance with regulatory standards is critical when selecting insulating materials for medical devices. FEP heat shrink tubing meets stringent requirements due to its biocompatibility, chemical resistance, and non-stick surface. These attributes ensure that FEP adheres to medical-grade standards, making it a reliable choice for electrosurgical applications. Its ability to withstand sterilization processes without degradation further supports its compliance with industry regulations.

Polyolefins also meet many regulatory standards but may face limitations in highly demanding environments. Their moderate chemical resistance and thermal stability make them suitable for applications with less rigorous compliance needs. Manufacturers must evaluate the regulatory landscape and ensure that the chosen material aligns with both safety and performance criteria. Adhering to these standards guarantees the reliability and effectiveness of the final product.

FEP heat shrink tubing and polyolefins each offer distinct advantages as insulating materials for electrosurgical devices. FEP stands out with its superior thermal stability, chemical resistance, and electrical insulation, making it ideal for high-performance applications. Polyolefins, on the other hand, provide cost efficiency and ease of use, catering to less demanding scenarios. For tools requiring precision, durability, and high-temperature resistance, FEP remains the preferred choice. Manufacturers must balance cost and performance to select the most suitable material, ensuring the reliability and safety of electrosurgical instruments.

FAQ

What is FEP?

FEP, or fluorinated ethylene propylene, is a melt-processable polymer created through the copolymerization of hexafluoropropylene and tetrafluoroethylene. It shares similarities with PTFE (polytetrafluoroethylene) and PFA (perfluoroalkoxy alkane) in terms of chemical composition. FEP stands out for its excellent thermal stability, chemical resistance, and electrical insulation properties, making it a preferred material in medical and industrial applications.

How does FEP heat shrink tubing differ from polyolefin tubing?

FEP heat shrink tubing offers superior thermal stability, operating effectively across a temperature range of -200°C to 200°C. It also provides exceptional chemical resistance and dielectric strength. Polyolefin tubing, while cost-effective and flexible, operates within a narrower temperature range and offers moderate chemical resistance. FEP is ideal for high-performance applications, whereas polyolefins suit less demanding scenarios.

Why is FEP heat shrink tubing suitable for electrosurgical tools?

FEP heat shrink tubing excels in electrosurgical applications due to its non-stick surface, high dielectric strength, and ability to withstand extreme temperatures. Its chemical resistance ensures durability during sterilization processes, while its transparency allows for visual inspection. These features enhance the precision, safety, and longevity of electrosurgical instruments.

Can polyolefin tubing handle sterilization processes?

Polyolefin tubing supports sterilization methods like ethylene oxide (EtO) and gamma radiation but may degrade under high-temperature conditions such as autoclaving. While it performs well in moderate sterilization environments, it lacks the resilience of FEP tubing in rigorous medical settings requiring frequent and intense sterilization.

What are the cost differences between FEP and polyolefin tubing?

FEP tubing typically costs more due to its advanced properties, including superior thermal stability, chemical resistance, and electrical insulation. Polyolefin tubing, on the other hand, offers a more budget-friendly option for applications where extreme performance is not required. Manufacturers must weigh these cost differences against the specific needs of their applications.

Is FEP tubing biocompatible?

Yes, FEP tubing is biocompatible, making it suitable for medical devices that come into contact with biological tissues or fluids. Its non-stick surface minimizes contamination risks, and its chemical resistance ensures sterility even after repeated exposure to harsh sterilization agents.

How does the transparency of FEP tubing benefit medical applications?

The transparency of FEP tubing allows for visual inspection during assembly and use. This feature proves valuable in medical applications where precision placement and monitoring of components are critical. It enhances the reliability and accuracy of electrosurgical tools.

What are the mechanical advantages of FEP tubing?

FEP tubing offers high tensile strength and flexibility, ensuring durability under mechanical stress. Its toughness allows it to withstand repeated use and handling without compromising structural integrity. These attributes make it a reliable choice for electrosurgical instruments requiring long-term performance.

Are there regulatory considerations when choosing between FEP and polyolefin tubing?

FEP tubing meets stringent medical-grade standards due to its biocompatibility, chemical resistance, and ability to endure sterilization processes. Polyolefin tubing also complies with many regulatory requirements but may face limitations in highly demanding environments. Manufacturers should evaluate the specific compliance needs of their applications before making a selection.

Which material is better for high-precision electrosurgical tools?

FEP tubing is the superior choice for high-precision electrosurgical tools. Its non-stick surface, high dielectric strength, and ability to maintain structural integrity under extreme conditions ensure precision and safety. While polyolefin tubing offers flexibility and cost efficiency, it lacks the advanced performance characteristics required for critical medical applications.

See Also

The Importance of Ultra-Thin PET Tubing in Healthcare

A Global Comparison of Etched PTFE Liner Producers

New Developments in PTFE Liners for Medical Applications