Understanding FEP Tubing with 1.3:1 Shrink Ratio

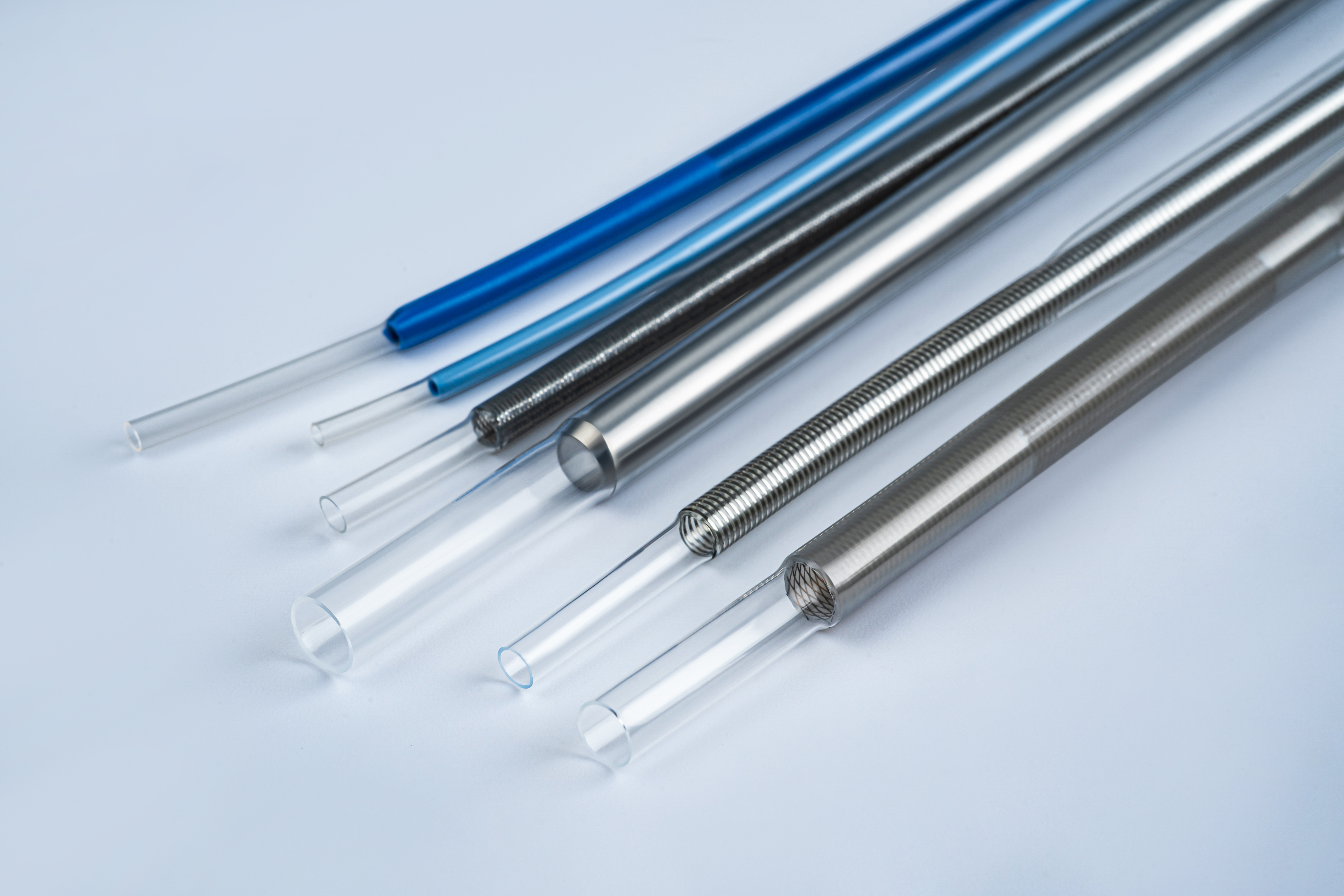

FEP Tubing with 1.3:1 Shrink Ratio is essential in modern medical applications. This advanced tubing provides outstanding chemical resistance, flexibility, and biocompatibility, making it an excellent option for medical devices. Its precise 1.3:1 shrink ratio allows it to conform securely to components, ensuring a tight fit, while its transparency enables easy inspection of underlying parts. Furthermore, FEP Tubing with 1.3:1 Shrink Ratio can endure extreme temperatures, making it ideal for sterilization processes. As global demand for medical-grade FEP continues to grow at over 6% annually, this material remains a cornerstone in the evolution of medical technologies.

For premium FEP Tubing with 1.3:1 Shrink Ratio, explore AccuPath's solutions, tailored to meet the exacting standards of medical professionals.

Key Takeaways

FEP tubing resists chemicals, so it is safe for medical tools.

The 1.3:1 shrink ratio makes it fit tightly on parts.

This tight fit stops contamination and keeps devices working well.

FEP tubing handles high heat, so it works for sterilization.

It can be cleaned with autoclaving or gamma radiation.

Its clear design helps check fluids and parts easily.

This improves safety and makes monitoring in medicine easier.

Picking FEP tubing with FDA and USP Class VI approval is smart.

What Is FEP Tubing with a 1.3:1 Shrink Ratio?

Overview of FEP Tubing

What is FEP and its role in medical applications?

FEP, or fluorinated ethylene-propylene, is a type of fluoropolymer known for its exceptional chemical resistance and thermal stability. It is created by copolymerizing tetrafluoroethylene (TFE) with hexafluoropropylene (HFP). This unique composition gives FEP its non-toxic and biocompatible properties, making it a trusted material in medical applications.

You’ll find FEP tubing used in a variety of medical devices, including catheters, surgical tools, and implantable devices. Its smooth surface minimizes friction, ensuring easy navigation through the body. Additionally, its ability to withstand high temperatures makes it suitable for sterilization processes, ensuring safety and hygiene in medical environments.

Key characteristics of FEP tubing

FEP tubing stands out due to its remarkable properties:

Chemical resistance: It remains unaffected by most medical chemicals, ensuring device integrity.

Thermal stability: It can endure extreme temperatures, making it ideal for sterilization.

Transparency: Its clear structure allows for visual inspection of fluids or components.

Flexibility: It adapts to complex anatomical pathways without compromising performance.

These characteristics make FEP tubing a reliable choice for critical medical procedures.

Understanding the 1.3:1 Shrink Ratio

How the shrink ratio works and its benefits

The 1.3:1 shrink ratio means that FEP heat shrink tubing can reduce its diameter by up to 30% when exposed to heat. This property allows the tubing to conform tightly to components, providing a secure fit. For example, it can encapsulate sensors or protect delicate electronics in medical devices.

This shrink ratio also ensures precision, which is crucial in medical applications. It minimizes gaps and prevents contamination, maintaining the sterility and functionality of the device.

Why the 1.3:1 ratio is ideal for medical applications

The 1.3:1 shrink ratio strikes a balance between flexibility and functionality. It provides enough shrinkage to secure components without compromising the tubing’s structural integrity. This makes it perfect for applications like catheter insulation, surgical tools, and fluid management systems.

If you’re looking for high-quality FEP heat shrink tubing, consider AccuPath’s solutions. Their products meet the stringent demands of medical professionals, ensuring reliability and performance in every application.

Key Properties of FEP Tubing

Chemical Resistance

Compatibility with medical chemicals and substances

FEP tubing offers exceptional chemical resistance, making it a reliable choice for medical environments. It withstands exposure to harsh chemicals like acids, bases, and solvents commonly used in medical procedures. This resistance ensures that the tubing remains intact and does not degrade when in contact with these substances. You can trust FEP tubing to maintain its structure and functionality, even in challenging conditions.

FEP tubing is non-toxic, making it safe for use in applications involving human contact.

It prevents contamination, which is critical in medical and biopharmaceutical settings.

Its chemical composition eliminates the risk of harmful substances leaching into sensitive environments.

Importance in maintaining device integrity

FEP tubing plays a vital role in preserving the integrity of medical devices. Its non-reactive surface prevents chemical reactions with drugs, bodily fluids, or other substances. This property ensures that devices remain reliable and safe during use.

FEP tubing resists oils, gases, and moisture, enhancing the durability of medical devices.

Its low gas permeability ensures airtight seals, reducing the risk of leaks or contamination.

The tubing’s ability to endure extreme temperatures further supports its use in harsh environments.

Transparency and Flexibility

Benefits for visual inspection and maneuverability

FEP tubing stands out for its transparency and flexibility. Its clear structure allows you to visually inspect fluids or components inside the tubing. This feature is especially useful in medical applications where precision and monitoring are essential.

FEP tubing is more transparent than materials like PTFE, providing better visibility.

Its flexibility makes it easier to handle and adapt to complex designs.

Applications in catheter manufacturing and surgical tools

The flexibility of FEP tubing makes it indispensable in the production of catheters and surgical tools. It bends without kinking, ensuring smooth operation in intricate designs. This adaptability is crucial for modern medical devices.

FEP tubing adapts to intricate catheter designs without cracking or breaking.

Its flexibility ensures precision during assembly, making it ideal for heat shrink medical tubing.

Sterilization Compatibility

Withstanding autoclaving and gamma sterilization

FEP tubing is compatible with various sterilization methods, including autoclaving and gamma irradiation. It can endure temperatures up to 200°C, making it suitable for repeated exposure to heat. This durability ensures that the tubing remains effective in medical and pharmaceutical settings.

FEP tubing maintains its structural integrity after multiple sterilization cycles.

It is also compatible with ethylene oxide gas sterilization, offering versatility in medical applications.

Ensuring sterility in medical environments

Sterility is critical in medical environments, and FEP tubing excels in this area. Its ability to withstand rigorous sterilization processes ensures that it remains safe and hygienic for use. You can rely on FEP tubing to meet the highest standards of cleanliness and performance.

For premium FEP heat shrink tubing that meets the stringent demands of medical professionals, consider AccuPath’s solutions. Their products combine chemical resistance, flexibility, and sterilization compatibility to deliver unmatched reliability in medical applications.

Benefits of FEP Tubing in Medical Applications

Biocompatibility

Safe for use in contact with human tissue

FEP tubing with 1.3:1 shrink ratio offers unmatched biocompatibility, making it a trusted choice for medical applications. Its non-toxic and non-reactive nature ensures safety when in contact with human tissue. This makes it ideal for critical uses such as catheters and implantable devices.

FEP tubing meets stringent standards, including FDA and USP Class VI certifications, which confirm its safety and absence of harmful substances.

Standard | Description |

|---|---|

FDA | Ensures safety for medical applications |

USP Class VI | Confirms biocompatibility and absence of harmful substances |

By choosing FEP tubing, you ensure the highest level of biocompatibility and hygiene in your medical devices.

Non-reactive and non-toxic properties

The chemical inertness of FEP tubing ensures it remains unaffected by aggressive substances, maintaining system integrity. Its non-toxic properties prevent hazardous chemicals from leaching into sensitive environments. This makes it a high-performance material for medical devices, where contamination could compromise procedural efficacy.

FEP tubing prevents contamination during critical procedures.

Its biocompatible nature ensures safety for both patients and healthcare professionals.

The tubing’s durability supports long-term use without degradation.

Enhanced Performance

High lubricity for smoother device insertion

FEP heat shrink tubing features a smooth, non-stick surface that minimizes friction. This property allows catheters and guidewires to navigate through the body with ease, reducing the risk of tissue damage. The high lubricity also enhances patient safety during procedures.

The non-stick surface simplifies the assembly process, ensuring a clean and precise fit.

Reduced friction improves the usability of medical devices, such as catheters and surgical tools.

By using FEP tubing, you enhance the quality and efficacy of your medical devices, ensuring smoother operations and better patient outcomes.

Precision fit with the 1.3:1 shrink ratio

The 1.3:1 shrink ratio of FEP heat shrink tubing ensures a precise fit for medical components. This ratio allows the tubing to shrink uniformly, creating a seamless and reliable surface. Such precision is essential for applications like insulating electrical components or encapsulating sensitive medical devices.

AccuPath’s FEP heat shrink tubing delivers consistent performance and reliability, making it the preferred choice for high-quality materials in medical applications.

Selecting and Using FEP Tubing with a 1.3:1 Shrink Ratio

Factors to Consider When Choosing FEP Tubing

Application-specific requirements

When selecting FEP tubing, you must evaluate the specific needs of your application. Consider chemical compatibility to prevent contamination and ensure the tubing can withstand exposure to medical chemicals. Temperature stability is another critical factor, as FEP tubing performs reliably across a wide range of conditions, including sterilization processes. Flexibility and mechanical strength are essential for intricate designs, such as catheters or other medical device components.

Regulatory compliance is equally important. Always choose tubing that meets FDA and USP Class VI standards to guarantee safety and biocompatibility. Additionally, ensure the tubing is autoclavable, as this allows it to endure sterilization without degradation. Cost considerations and supplier reliability also play a role in ensuring consistent quality and availability. For tailored solutions, look for customization options that meet the unique demands of your medical devices.

Compatibility with medical devices and procedures

FEP tubing must integrate seamlessly with medical device components. Verify its compatibility with the chemicals and sterilization methods used in your procedures. Its flexibility makes it ideal for routing through complex setups, while its autoclavable nature ensures it remains effective after repeated sterilization cycles. High-performance tubing, like AccuPath’s autoclavable heat shrink tubing, offers the durability and precision required for demanding medical applications.

Best Practices for Using FEP Tubing

Proper installation and handling techniques

To achieve optimal performance, follow these steps when installing FEP tubing:

Cut the tubing: Measure and cut it to the desired length using sharp scissors.

Position the tubing: Slide it over the component, ensuring complete coverage.

Apply heat evenly: Use a heat gun in a sweeping motion to shrink the tubing uniformly. Avoid uneven heating to prevent damage.

Monitor the process: Stop heating once the tubing has fully shrunk and fits tightly.

Always select tubing with an expanded diameter slightly larger than the component it will cover. This ensures a snug fit after shrinking. Avoid overheating by maintaining a safe distance between the heat gun and the tubing.

Maintenance for long-term performance

Proper maintenance extends the lifespan of FEP tubing. Begin by cleaning the surface of the component to remove dirt or grease before installation. Use a controlled heat source, such as a heat gun, to shrink the tubing without causing damage. Regularly inspect the tubing for signs of wear, such as cracks or discoloration, and replace it promptly if needed.

AccuPath’s autoclavable heat shrink tubing offers exceptional durability, making it a reliable choice for medical device manufacturers. Its ability to withstand repeated sterilization cycles ensures long-term performance, even in demanding environments.

FEP tubing with a 1.3:1 shrink ratio offers unmatched advantages for medical applications. Its unique properties include high chemical resistance, excellent thermal stability, and compatibility with various sterilization processes. You can rely on its biocompatibility and durability to ensure safety and long-term performance in critical medical devices.

When selecting FEP tubing, consider its transparency for fluid monitoring and its non-stick surface, which enhances usability. These features make it ideal for applications like catheters and surgical tools. AccuPath’s FEP heat shrink tubing provides the precision and reliability you need to meet the highest medical standards. Explore their solutions to elevate the performance of your medical devices.

FAQ

What makes FEP tubing unique for medical applications?

FEP tubing offers exceptional chemical resistance, flexibility, and biocompatibility. Its transparency allows easy inspection, while its ability to withstand sterilization ensures safety. These features make it ideal for critical medical devices like catheters and surgical tools.

How does the 1.3:1 shrink ratio benefit medical devices?

The 1.3:1 shrink ratio ensures a precise fit by reducing the tubing’s diameter by 30% when heated. This tight fit protects components, prevents contamination, and enhances the durability of medical devices.

Can FEP tubing handle sterilization processes?

Yes, FEP tubing withstands sterilization methods like autoclaving and gamma irradiation. Its thermal stability ensures it remains effective after repeated sterilization cycles, making it reliable for medical environments.

Why should you choose AccuPath’s FEP Heat Shrink Tubing?

AccuPath provides high-quality FEP heat shrink tubing designed to meet stringent medical standards. Their products offer unmatched reliability, precision, and durability, ensuring optimal performance for your medical devices.

Is FEP tubing safe for human contact?

FEP tubing is biocompatible and non-toxic, making it safe for use in contact with human tissue. It meets FDA and USP Class VI standards, ensuring it is free from harmful substances.

See Also

Key Considerations for Selecting FEP Shrink Tubing

Selecting Optimal FEP Shrink Tubing for Class III Devices

A Simple Guide to FEP Autoclavable Heat Shrink Tubing